Braided Aluminum Wire made from 5154 Al-Mg alloy delivers significant weight and cost reductions versus copper braid while providing reliable EMI shielding and corrosion resistance. It is ideal for automotive, new-energy/EV, and marine applications where lightweight design and budget control are critical.

- 67% lighter · 60% cost saving · Coverage ≥90% (tubular)

- −60 dB attenuation @ 1 MHz (per IEC 62153-4-3)

- Chalco one-stop manufacturing · ISO 9001 / IATF 16949 · 5–7-day lead time

Quick Jump: Flat Braid | Tubular Braid

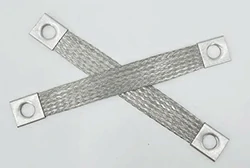

Flat Braided Aluminum Wire

Flat Braided Aluminum Wire is made from woven aluminum filaments rolled flat, offering light weight, flexibility, and corrosion resistance. It is ideal for battery modules, ground straps, lightning protection, and marine systems where moderate conductivity is acceptable.

Contact us now

Spec Overview

Material: 5154 / 5154A Al-Mg alloy

Construction: Multi-filament braid, rolled flat; 24–48 carriers

Single Wire Diameter: Ø0.12–0.20 mm (typical 36–33 AWG)

Nominal Width: 1/32″–3″ (≈ 0.8–76 mm)

Cross-Sectional Area: 10–50 mm² (common range; larger on request)

Approx. Weight: 1–260 lbs/1000 ft (varies with width & construction)

Standards: IEC 60228, ISO 19642

Product Categories

Aluminium Braided Flexible Strip

Master raw strip (roll or cut length) for further processing into ground straps, connectors, or busbars; lightweight and corrosion-resistant.

Aluminum Braided Flexible Busbar

Wide, thick flexible busbar for high-current paths in battery modules, energy storage, and rail; 60–70% lighter than copper busbar.

Braided Aluminium Flexible Connectors

Braid with crimped lugs at both ends for flexible electrical links between busbars, motors, and switchgear; absorbs vibration/misalignment.

Flexible Flat Aluminum Ground Strap

Narrow braid with punched lugs for equipment chassis grounding and equipotential bonding in cabinets, vehicles, and vessels.

Aluminum Braided Shunts

High-flex shunts for welding machines, transformers, and traction equipment; handle high current while damping vibration; compatible with Al/Cu lugs.

Technical Specifications

| Electrical | Conductivity | ≥ 32% -35%IACS |

| Resistivity, 20 °C | ≤ 0.054 Ω·mm²/m | |

| Mechanical | UTS, Annealed | 210 - 330MPa |

| Elongation, Annealed | 8 - 12% | |

| Salt-spray | > 1000 h |

Size Table of Flat Braided Aluminum Wire

-

Construction = carriers–ends–single-wire AWG (e.g., "24-5-36").

Single-wire AWG is the filament gauge; Total Cross-Section is the overall metallic area.

Total Cross-Section is the overall metallic area. Weight per 1000 ft; other lengths on request.

| Width | Construction | Single Wire Size | Total Cross-Section (mm²) | Weight(lbs/1000ft) |

| 1/32″ | 16-1-36 | 36AWG ≈ 0.127 mm | 0.2 | 1.3 |

| 3/64″ | 24-1-36 | 36AWG ≈ 0.127 mm | 0.3 | 1.7 |

| 3/32″ | 24-2-36 | 36AWG ≈ 0.127 mm | 0.6 | 2.3 |

| 3/32″ | 16-3-36 | 36AWG ≈ 0.127 mm | 0.6 | 2.3 |

| 7/64″ | 16-4-36 | 36AWG ≈ 0.127 mm | 0.9 | 2.7 |

| 1/8″ | 24-3-36 | 36AWG ≈ 0.127 mm | 0.9 | 3.0 |

| 5/32″ | 24-4-36 | 36AWG ≈ 0.127 mm | 1.2 | 3.7 |

| 3/16″ | 24-5-36 | 36AWG ≈ 0.127 mm | 1.5 | 4.3 |

| 1/4″ | 24-7-36 | 36AWG ≈ 0.127 mm | 2.1 | 5.7 |

| 1/4″ | 24-10-36 | 36AWG ≈ 0.127 mm | 3.0 | 8.0 |

| 9/32″ | 24-13-36 | 36AWG ≈ 0.127 mm | 4.0 | 10.3 |

| 3/8″ | 48-6-36 | 36AWG ≈ 0.127 mm | 3.6 | 9.3 |

| 3/8″ | 24-5-30 | 30AWG ≈ 0.255 mm | 6.1 | 15.6 |

| 1/2″ | 48-8-36 | 36AWG ≈ 0.127 mm | 4.9 | 13.0 |

| 1/2″ | 24-10-30 | 30AWG ≈ 0.255 mm | 12.2 | 28.3 |

| 5/8″ | 48-8-36 | 36AWG ≈ 0.127 mm | 4.9 | 13.3 |

| 5/8″ | 48-11-36 | 36AWG ≈ 0.127 mm | 6.7 | 17.6 |

| 3/4″ | 48-18-36 | 36AWG ≈ 0.127 mm | 10.5 | 26.3 |

| 3/4″ | 24-67-36 | 36AWG ≈ 0.127 mm | 20.3 | 46.6 |

| 3/4″ | 24-20-30 | 30AWG ≈ 0.255 mm | 24.3 | 56.6 |

| 3/4″ | 48-5-30 | 30AWG ≈ 0.255 mm | 12.2 | 29.3 |

| 13/16″ | 48-19-36 | 36AWG ≈ 0.127 mm | 11.6 | 26.6 |

| 7/8″ | 48-22-36 | 36AWG ≈ 0.127 mm | 13.4 | 31.6 |

| 7/8″ | 24-24-30 | 30AWG ≈ 0.255 mm | 29.2 | 64.3 |

| 7/8″ | 48-12-30 | 30AWG ≈ 0.255 mm | 29.2 | 66.6 |

| 15/16″ | 24-26-30 | 30AWG ≈ 0.255 mm | 32.6 | 69.9 |

| 15/16″ | 24-27-30 | 30AWG ≈ 0.255 mm | 33.8 | 74.9 |

| 1″ | 48-18-36 | 36AWG ≈ 0.127 mm | 10.5 | 25.0 |

| 1″ | 24-32-30 | 30AWG ≈ 0.255 mm | 38.9 | 89.9 |

| 1″ | 48-8-30 | 30AWG ≈ 0.255 mm | 19.5 | 45.6 |

| 1-1/4″ | 48-10-30 | 30AWG ≈ 0.255 mm | 24.3 | 55.9 |

| 1-3/8″ | 48-7-30 | 30AWG ≈ 0.255 mm | 17.1 | 41.0 |

| 1-3/8″ | 48-14-30 | 30AWG ≈ 0.255 mm | 34.1 | 76.6 |

| 1-3/8″ | 48-22-30 | 30AWG ≈ 0.255 mm | 53.5 | 120.5 |

| 1-1/2″ | 48-11-30 | 30AWG ≈ 0.255 mm | 26.9 | 61.6 |

| 1-1/2″ | 48-16-30 | 30AWG ≈ 0.255 mm | 38.9 | 88.2 |

| 1-5/8″ | 48-84-36 | 36AWG ≈ 0.127 mm | 51.1 | 119.5 |

| 1-5/8″ | 48-18-30 | 30AWG ≈ 0.255 mm | 43.8 | 94.2 |

| 1-3/4″ | 48-26-30 | 30AWG ≈ 0.255 mm | 63.2 | 143.0 |

| 2″ | 48-28-30 | 30AWG ≈ 0.255 mm | 68.1 | 154.5 |

| 2″ | 48-32-30 | 30AWG ≈ 0.255 mm | 77.8 | 176.5 |

| 2″ | 48-35-30 | 30AWG ≈ 0.255 mm | 85.1 | 189.8 |

| 2-3/8″ | 48-44-30 | 30AWG ≈ 0.255 mm | 107.0 | 243.1 |

| 2-1/2″ | 48-52-30 | 30AWG ≈ 0.255 mm | 126.5 | 300.0 |

| 3″ | 48-47-30 | 30AWG ≈ 0.255 mm | 114.3 | 259.7 |

By Size, Recommended Uses

- Small Width (≤1/4″) — Grounding for electronics, sensors, and light harnesses.

- Medium Width (3/8″–1/2″) — Flexible connectors & ground straps in automotive and industrial control systems.

- Large Width (≥5/8″) — Busbar/pack connections and power equipment jumpers; a lightweight, corrosion-resistant alternative to copper braid.

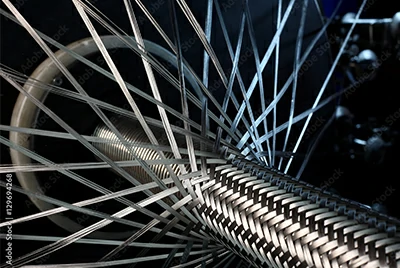

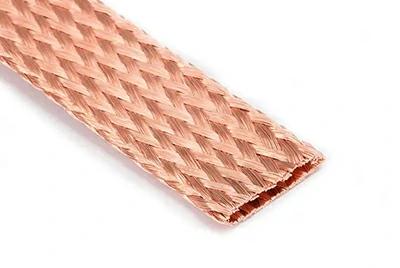

Tubular Braided Aluminum Wire

Tubular Braided Aluminum Wire is a hollow, flexible EMI shielding sleeve that slides over cables or busbars. Compared with aluminum foil shielding, it offers higher coverage, better flex life, and durability under repeated bending, making it ideal for automotive, marine, and industrial cable assemblies.

Contact us now

Spec Overview

Material: 5154 / 5154A Al-Mg Alloy

Shielding Coverage: ≥90% for regular sizes; ≥70% for ultra-small sizes (≤ 0.078″)

Shielding Performance: −60 dB attenuation @ 1 MHz

Nominal Sizes: 1/8″–2″ (≈ 3–50 mm)

Construction: 24–48 carriers, 5–16 ends per carrier

Single Wire Diameter: Ø0.10–0.30 mm (typical 36 / 34 / 30 AWG)

Weight Range: 4.3–76.6 lbs/1000 ft (increases with diameter)

Standards: IEC 60228, ISO 19642; RoHS compliant

Technical Specifications

| Electrical | Conductivity | ≥ 32% -35%IACS |

| Resistivity, 20 °C | ≤ 0.054 Ω·mm²/m | |

| Mechanical | UTS (Annealed) | 210 - 330MPa |

| Elongation (Annealed) | 8 - 12% | |

| Salt-Spray (Neutral) | > 1000 h |

Size Table of Tubular Braided Aluminum Wire

-

Single Wire is the filament size;

Approx. AWG Equiv. is the overall braid's electrical equivalence.

Construction = carriers–ends–single-wire AWG (e.g., "24-5-36"). Coverage can be customized per project.

| Nominal I.D. | Construction | Single Wire | Approx. AWG Equiv. | Weight (lbs/1000 ft) |

| 1/8″ | 24-5-36 | 36 AWG ≈ Ø0.127 mm | 15 AWG | 4.3 |

| 3/16″ | 24-6-34 | 34 AWG ≈ Ø0.160 mm | 13 AWG | 7.3 |

| 1/4″ | 24-16-36 | 36 AWG ≈ Ø0.127 mm | 10 AWG | 12.7 |

| 3/8″ | 48-8-36 | 36 AWG ≈ Ø0.127 mm | 10 AWG | 13.3 |

| 1/2″ | 48-11-36 | 36 AWG ≈ Ø0.127 mm | 9 AWG | 17.6 |

| 5/8″ | 48-8-34 | 34 AWG ≈ Ø0.160 mm | 8 AWG | 18.7 |

| 7/8″ | 48-7-30 | 30 AWG ≈ Ø0.255 mm | 5 AWG | 41.0 |

| 1″ | 48-8-30 | 30 AWG ≈ Ø0.255 mm | 4 AWG | 46.6 |

| 2″ | 48-14-30 | 30 AWG ≈ Ø0.255 mm | 2 AWG | 76.6 |

By Size, Recommended Uses

- Small I.D. (1/8″–1/4″) — Sensor and signal cables; automotive/ECU harness branches requiring lightweight, high-flex shielding.

- Medium I.D. (3/8″–1/2″) — Industrial control cables and vehicle main bundles needing high coverage and stable EMI performance.

- Large I.D. (5/8″–2″) — Power/energy cables, marine cables, and busbar over-sleeving where large-diameter protection, weight reduction, and corrosion resistance are critical.

Chalco supplies a full range of braided aluminum wire solutions for both shielding and flexible connections, with standard and custom builds and a 5–7-day lead time. Get A Quote for rapid sizing guidance and pricing.

Typical Applications & Case Examples of Braided Aluminum Wire

Automotive Industry

Vehicle cables and grounding systems demand aggressive lightweighting. Compared with copper, braided aluminum wire delivers 67% weight reduction with qualified EMI shielding, and is widely used in whole-vehicle harnesses and ground straps.

- Flat Braided Aluminum Wire — used for ground jumpers and flexible connections.

- Tubular Braided Aluminum Wire — used for shielding of main automotive harnesses.

EV Battery & Energy Storage

Battery modules and ESS require high-current flexible connections and vibration tolerance. Flexible braided busbars accommodate thermal expansion/contraction to ensure long-term conductivity.

- Flexible Braided Aluminum Busbar — for flexible interconnects between battery modules/packs.

- Flat Braided Aluminum Wire — for pack grounding and auxiliary circuits.

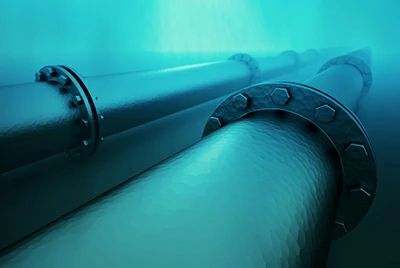

Marine & Offshore

In harsh marine environments, shielding must combine salt-spray resistance with long-term reliability. 5154 Al-Mg braided wire offers natural corrosion resistance and is suitable for marine/shipboard cable shielding solutions (used in systems built to MIL-DTL-24643 requirements).

- Tubular Braided Aluminum Wire — for shielding of shipboard power and control cables.

- Braided Aluminum Sleeve — for overall harness protection.

Rail Transit & Power Distribution

Rail and switchgear applications need numerous flexible ground jumpers with low cost, high flexibility, and easy installation. Aluminum flat braid provides a stable, lightweight grounding solution.

- Flat Braided Aluminum Wire — for ground straps and flexible links in panels.

- Flexible Braided Busbar — as a high-current busbar alternative.

Data Center & Telecom

In high-density cabling, EMI can impact network stability. High-coverage braided aluminum sleeves provide overall shielding for cable bundles.

- Braided Aluminum Sleeve — for cabinet/bundle-level shielding.

- Tubular Braided Aluminum Wire — for EMI suppression on communication cables.

Different scenarios impose different requirements on braided aluminum wire. Chalco supplies a complete portfolio—flat braid, tubular braid, braided sleeves, and flexible busbars—to deliver the best solution for automotive, new energy, marine, rail transit, and data-com/telecom projects.

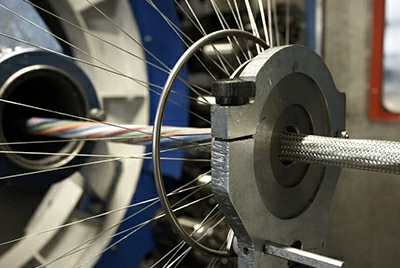

Chalco Braided Aluminum Wire—Integrated Manufacturing & Quality Assurance

From a single aluminum ingot to a qualified braided aluminum wire, Chalco controls every step in-house with full traceability:

Aluminum Melting → Continuous Casting & Rolling → Wire Drawing & Annealing → Single-Wire Spooling → Multi-Filament Braiding → Value-Added Processing → Testing → Packaging & Shipping.

End-to-end production avoids outsourcing risks and ensures consistent quality and stable lead times.

Integrated Manufacturing · Stable Delivery

Multiple 48-carrier automatic braiders produce flat braid, tubular braid, braided sleeves, and flexible busbars. Daily output exceeds 2 tons; standard orders ship in 5–7 days, and expedited small lots in as fast as 72 hours—keeping your project schedule on track.

Value-Added Processing · Flexible Customization

Beyond standard sizes, we offer comprehensive secondary operations to shorten installation time and fit diverse build scenarios:

- Crimped Lugs / Punching — plug-and-play assemblies to reduce on-site work

- Cut-to-Length & Reel Supply — 50–500 m flexible configuration

- Copper–Aluminum Hybrid Solutions — balance cost and interface compatibility

- Surface Finishes — tin or silver plating available for special requirements

Rigorous QC · International Certifications

Each batch is verified by electrical, mechanical, and environmental tests: conductivity ≥ 32% IACS, shielding attenuation −60 dB @ 1 MHz, salt-spray > 1000 h.

Process control aligns with IEC 60228 and ISO 19642; the plant is certified to ISO 9001 and IATF 16949, ensuring dependable global supply.

*Salt-spray per ASTM B117 (NSS), project/customer requirement basis.

Packaging & Logistics · Safe & Efficient

All products use moisture-sealed wraps + eco reels + pallet reinforcement to prevent transit damage. Outer labels record alloy, spec, batch/lot, and QR for test data to streamline warehousing and traceability. With a mature global logistics network, delivery is fast, safe, and reliable.

Copper Braided Wire vs Aluminum Braided Wire (5154)

| Comparison Parameters | Copper Braid | Aluminum Braid (5154) |

| Weight | Heavy; heavier for the same cross-section | Lightweight; ≈67% weight reduction for the same coverage/cross-section |

| Material Cost | High, with significant price fluctuations | Low; ≈60% overall bundle material cost reduction |

| Conductivity | ≈100% IACS (minimum resistance) | ≈32–35% IACS (higher electrical resistivity than copper) |

| Shielding Performance | Lower transfer impedance at the same coverage ratio → Greater shielding margin | Coverage can reach ≥90%, suitable for lightweight shielding |

| Flexibility/Fatigue | Flexible and better resistance to bending fatigue | Slightly inferior; a reasonable structure also allows for assembly and bending |

| Corrosion Resistance | Bare copper easily oxidizes and often requires tin/nickel/silver plating | Self-passivating oxide film; Salt spray resistance >1000 h (properly alloyed/treated) |

| Termination | Proven soldering/brazing and crimping capabilities; A wide range of universal terminals | Mainly crimped; connections to copper components require bimetallic terminals/isolation to prevent galvanic corrosion. |

| Assembly Compatibility | Fully compatible with existing copper busbars/terminals | Pay attention to galvanic corrosion isolation and terminal/torque specifications. |

| Applicable Industries | Used for welding machines, power switchgear, rail transit, and general grounding/shunt applications | Lightweight applications such as new energy vehicles, energy storage, ships, and aviation |

Selection Guidance

If you prioritize lowest voltage drop, maximum shielding margin, and full compatibility with existing copper lugs, choose copper braided wire.

If your goal is significant weight reduction (≈67%) and cost saving (≈60%), and current/voltage drop is not the system bottleneck, choose aluminum braided wire (5154).

If you must use aluminum but need higher conductivity, evaluate 1350 aluminum. Be sure to verify mechanical strength, termination method, and galvanic-corrosion isolation.

FAQ

What forms does aluminum braided wire come in, and what are they used for?

Two common forms—tubular braid for cable over-braiding and EMI/RFI shielding; flat braid for grounding, flexible connections, shunts, and flexible busbars.

How do I choose between copper braided wire and aluminum braided wire?

Decide by objective—choose copper for lowest voltage drop, maximum shielding headroom, and plug-and-play compatibility with copper terminals. Choose aluminum (5154, ≈32–35% IACS) when lightweight and cost reduction matter more and current/drop aren't limiting.

Aluminum braided wire vs. aluminum stranded wire—what's the difference?

Aluminum braided wire: tubular for EMI/RFI shielding; flat for grounding/flexible links with superior multi-axis flexibility—use it when shielding or high flexibility is required.

Aluminum stranded wire: the primary current-carrying conductor with lower DC resistance and broader terminal ecosystem—use it when the priority is lower voltage drop for the main conductor.

How do I select tubular braid size?

Match the nominal I.D. to the cable O.D. with installation clearance. Typical coverage ≥90% (ultra-small sizes ≤0.078″: ≥70%). Typical shielding: −60 dB @ 1 MHz.

How do I select flat braid size?

Use width and total cross-section (mm²) as the primary inputs, then check against target current and allowable temperature rise. Share current, environment, and space limits—we'll propose structure and size.

What should I note when connecting to copper parts?

Prefer crimp terminations for aluminum braid. When mating to copper busbars/lugs, use bi-metal lugs or isolating washers and apply galvanic-corrosion protection; tighten to the specified torque.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote