Chalco Aluminum is a trusted supplier of high-quality aluminum wire mesh products, offering woven, welded, expanded and perforated mesh structures for a wide range of applications. With lightweight structure, excellent corrosion resistance, and flexible processing capability, our aluminum wire mesh is widely used in protection, screening, decoration, ventilation, EMI/RFI shielding and general industrial support. Whether you need fine woven mesh rolls, durable welded panels, or decorative expanded mesh, Chalco delivers consistent quality, customizable solutions, and reliable global supply.

Types of Chalco Aluminum Wire Mesh Products

-

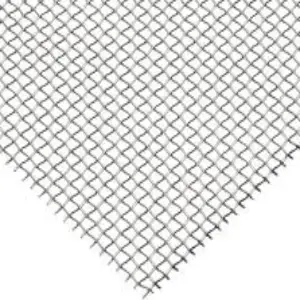

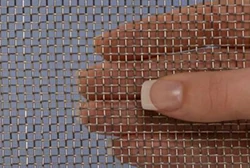

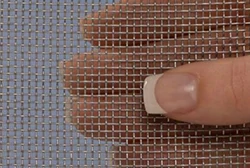

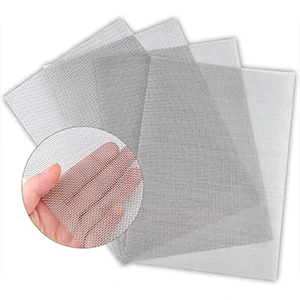

Woven Aluminum Wire Mesh

Woven Aluminum Wire Mesh

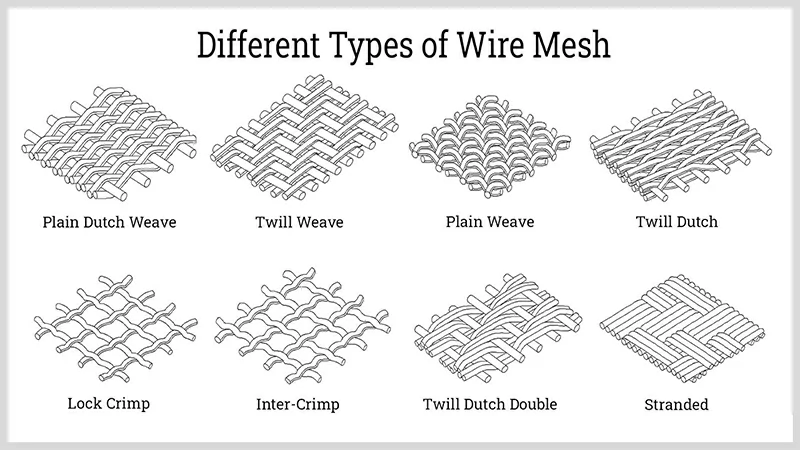

Woven aluminum wire mesh is manufactured in plain, twill, or Dutch weave, providing a flexible structure, uniform openings, and stable dimensional performance. Lightweight and corrosion-resistant, it serves as a general-purpose solution for screening, insect control, fencing, and industrial separation across a wide range of applications.

-

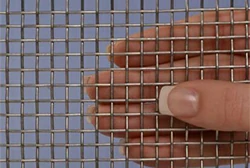

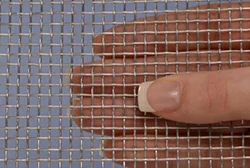

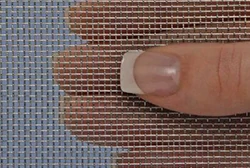

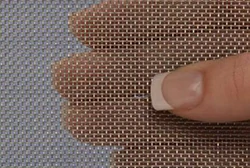

Square Aluminum Wire Mesh

Square Aluminum Wire Mesh

Square aluminum wire mesh features uniform square openings that provide balanced strength and airflow. It is the most common woven configuration, typically selected where consistent aperture size is required. Finer square mesh is used for garden and poultry protection, while hexagonal woven mesh is available for aluminum chicken wire applications.

-

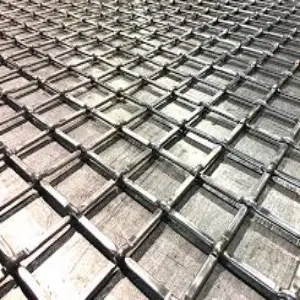

Welded Aluminum Wire Mesh

Welded Aluminum Wire Mesh

Formed by resistance welding at each wire intersection, welded aluminum wire mesh provides high rigidity, structural stability, and impact resistance. It is widely used for fencing systems, machine guards, protective partitions, and industrial safety applications.

-

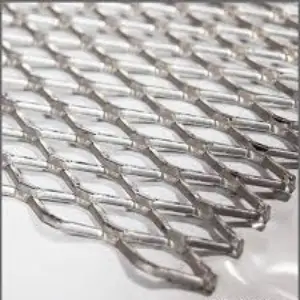

Expanded Aluminum Mesh

Expanded Aluminum Mesh

Produced by slitting and stretching aluminum sheets into diamond-shaped openings, expanded aluminum mesh combines a lightweight structure with high strength and excellent ventilation performance. Typical applications include architectural facades, anti-slip walkways, ventilation covers, and decorative panels.

-

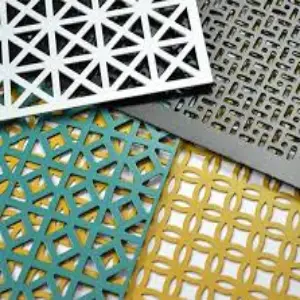

Decorative & Perforated Aluminum Mesh

Decorative & Perforated Aluminum Mesh

Decorative and perforated aluminum mesh combines functional performance with visual design. Available in various hole patterns, surface finishes, and panel formats, it is suitable for curtain walls, interior partitions, exhibition displays, and architectural decoration projects.

Aluminum Wire Mesh Specifications

Chalco supplies aluminum wire mesh with flexible customization across mesh size, wire diameter, opening geometry, and supply forms. The specifications below define our standard manufacturing range; tighter tolerances and special configurations are available upon request.

- Mesh Range: 2 – 200 mesh (available ranges vary by structure: woven, square, welded, or expanded)

- Wire Diameter: 0.08 – 3.0 mm

- Opening Size: approx. 0.07 – 11 mm (dependent on mesh count and wire diameter)

- Open Area (reference): calculated from mesh count and wire diameter; e.g. 10 mesh with 0.5 mm wire ≈ 51% open area

- Dimensional Tolerance: typically ±3% in accordance with ASTM E2016; tighter control available on request

- Supply Forms: rolls (coils), sheets (panels), cut-to-size parts

- Standard Coil Widths: 0.5 m / 1.0 m / 1.2 m / 1.5 m

- Standard Coil Lengths: 10 m, 30 m, 50 m (custom lengths supported)

- Standard Sheet Sizes: 1 m × 2 m; 4′ × 8′ (1220 × 2440 mm)

- Processing Options: cutting, edging, framing, punching; optional anodizing or surface coating

- Packaging: film-wrapped coils with core support; reinforced sheets packed on pallets or in plywood cases

Aluminum Wire Mesh Size & Structure Selection Guide

Aluminum wire mesh selection is primarily determined by mesh size, opening geometry, and structural form. Different combinations of mesh count and manufacturing structure result in distinct airflow, strength, and functional characteristics. The guide below outlines typical selection ranges based on common application requirements.

Coarse Mesh (2–10 Mesh)

Coarse aluminum wire mesh features large openings and high open area, offering excellent airflow and mechanical strength. This range is commonly used for fencing, partitions, ventilation guards, and structural protection.

2 Mesh Aluminum .063" Wire Dia

4 Mesh Aluminum .047" Wire Dia

6 Mesh Aluminum .035" Wire Dia

8 Mesh Aluminum .028" Wire Dia

10 Mesh Aluminum .025" Wire Dia

Selection note: Coarse mesh is typically selected when airflow, visibility, and mechanical strength are prioritized over fine screening accuracy.

Medium Mesh (12–40 Mesh)

Medium mesh aluminum wire mesh provides a balance between airflow, visibility, and screening capability. It is widely applied in insect screens, general screening panels, protective covers, and architectural partitions.

12 Mesh Aluminum .023" Wire Dia

14 Mesh Aluminum .020" Wire Dia

16 Mesh Aluminum .018" Wire Dia

20 Mesh Aluminum .016" Wire Dia

40 Mesh Aluminum .010" Wire Dia

Selection note: Medium mesh is commonly chosen for general-purpose screening where both airflow and insect protection are required.

Fine Mesh (50–200 Mesh)

Fine aluminum wire mesh features small, uniform openings designed for controlled screening and separation. This range is typically supplied as fine woven mesh, where dimensional accuracy and opening consistency are critical.

50 Mesh Aluminum .009" Wire Dia

120 Mesh Al .004" Wire Dia

200 Mesh Al .0021" Wire Dia

Selection note: Fine mesh is selected when controlled opening size and screening precision are more critical than airflow.

Applications of Chalco Aluminum Wire Mesh Products

Chalco aluminum wire mesh is applied across a wide range of industrial, architectural, and general-purpose scenarios. Based on mesh size, opening structure, and mechanical performance, different aluminum wire mesh configurations are selected to meet specific functional requirements in filtration, protection, decoration, and industrial support.

Supported by integrated aluminum wire production and finished mesh manufacturing, Chalco provides consistent material quality and flexible configuration options for diverse application needs.

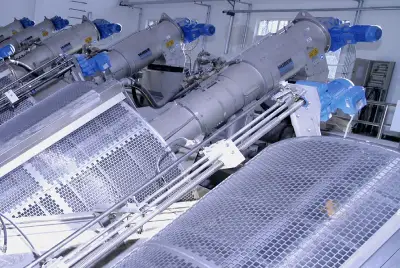

Filtration and Screening

Typical requirements: controlled opening size, uniform mesh geometry, stable dimensional accuracy

Common mesh range: medium to fine mesh (typically 12–200 mesh)

Applications: air handling components, water treatment systems, industrial screening and separation

Protection and Safety

Typical requirements: mechanical strength, impact resistance, airflow and visibility

Common mesh range: coarse to medium mesh (typically 2–40 mesh)

Applications: fencing systems, machine guards, safety partitions, insect protection

Decoration and Architecture

Typical requirements: visual consistency, ventilation performance, structural stability

Common structures: expanded mesh, square woven mesh, perforated mesh

Applications: curtain walls, interior partitions, facades, exhibition and display systems

DIY and Gardening

Typical requirements: easy handling, corrosion resistance, flexible cutting and forming

Common mesh range: coarse to medium mesh

Applications: garden protection, enclosures, plant supports, general-purpose DIY projects

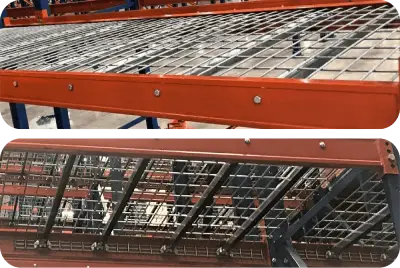

Industrial Support

Typical requirements: load-bearing capacity, slip resistance, structural durability

Common structures: coarse woven mesh, welded mesh, expanded mesh

Applications: flooring panels, walkways, equipment covers, industrial platforms

By aligning mesh size, structure, and processing options with application requirements, Chalco delivers aluminum wire mesh solutions that balance performance, durability, and cost efficiency. Standard sizes and customized configurations are available to support both project-based and bulk supply needs.

Features & Advantages of Aluminum Wire Mesh

- Lightweight with Structural Strength: Aluminum wire mesh offers a high strength-to-weight ratio, reducing handling and installation load while maintaining sufficient mechanical performance for fencing, screening, and structural applications.

- Natural Corrosion Resistance: Aluminum forms a stable oxide layer that resists corrosion without additional coating, enabling long-term use in outdoor, marine, and humid environments.

- Flexible Forming and Processing: Aluminum wire can be woven, welded, expanded, or perforated, and is easy to cut, bend, and shape, supporting both standard mesh production and customized configurations.

- Open Structure for Ventilation and Shielding: The open mesh structure allows airflow, light transmission, and heat dissipation, while selected aluminum wire mesh configurations also support EMI/RFI shielding applications.

- Cost-Efficient Alternative to Stainless Steel: Compared with stainless steel wire mesh, aluminum mesh is lighter and easier to process, often reducing material, fabrication, and installation costs in large-scale projects.

- Wide Specification Coverage: Aluminum wire mesh is available in mesh sizes from 2 to 200 mesh, with wire diameter, opening size, alloy, and surface treatment customizable to meet project-specific requirements.

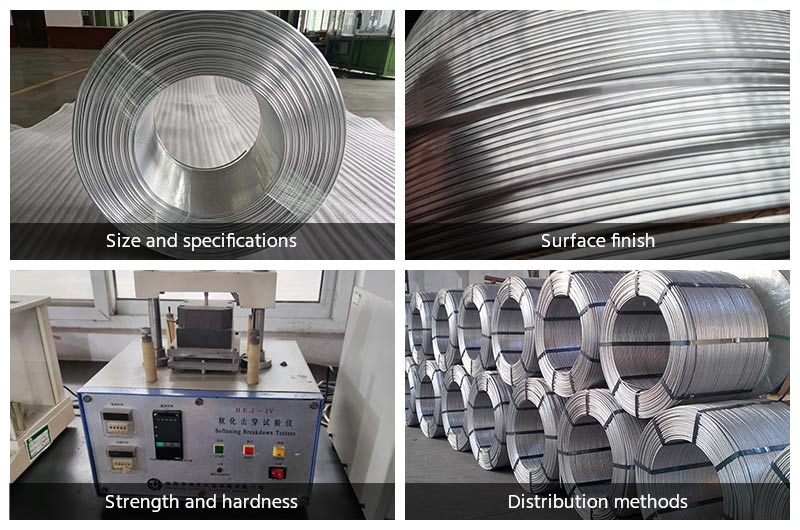

Aluminum Wire Raw Materials for Mesh Weaving

Chalco is a manufacturer of aluminum wire engineered specifically for wire mesh production, supplying both raw aluminum wire and finished aluminum wire mesh. Our integrated production system covers melting, extrusion, wire drawing, heat treatment, and surface finishing, ensuring stable quality, corrosion resistance, ductility, and structural consistency.

Aluminum wire is available in multiple diameters, tempers, and alloy systems to support woven, welded, expanded, and decorative aluminum wire mesh structures. By controlling wire composition and processing parameters at the source, Chalco ensures reliable mesh forming performance and dimensional stability across different mesh types and applications.

Supply Temper: O / H14 / H18 (annealed on request)

Surface Treatment: bare wire, anodized wire, coated wire, conductive film treatment

Supply Form: whole rolls, cut-to-length wire, paralleling, and coating services

Diameter Range: 0.08 mm – 3.0 mm

- ≤0.25 mm: ultra-fine aluminum wire for precision woven mesh and EMI shielding structures

- 0.3–1.0 mm: general-purpose aluminum wire for woven mesh, protective mesh, and decorative mesh

- ≥1.2 mm: heavy-gauge aluminum wire for welded wire mesh panels and load-bearing mesh structures

-

5154 Aluminum Wire

High strength with excellent corrosion resistance, suitable for coarse aluminum wire mesh used in fencing, aquaculture nets, and marine protection applications (typically 2–10 mesh, welded or woven).

-

5052 Aluminum Wire

Good formability and salt spray resistance, commonly used for decorative mesh, ventilation mesh, and agricultural protection mesh (typically 10–60 mesh, woven or expanded).

-

6061 Aluminum Wire

Heat-treatable aluminum alloy with high strength, suitable for structural mesh, support mesh, and functional mesh applications where higher mechanical performance is required (approximately 5–50 mesh).

-

1350 Aluminum Wire

Ultra-high conductivity and excellent flexibility, ideal for fine woven aluminum wire mesh used in high-density screening, filtration support, and EMI shielding structures (typically 50–200 mesh).

-

1100 Aluminum Wire

Very soft aluminum with outstanding ductility, commonly applied in ultra-fine woven mesh for filtration, precision processing, and low-stress screening applications (approximately 80–200 mesh).

-

3003 Aluminum Wire

Economical aluminum alloy with good formability, suitable for decorative mesh, model mesh, and indoor woven aluminum wire mesh applications (typically 10–50 mesh).

Chalco Aluminum Wire Mesh Manufacturing Capabilities Overview

Chalco provides integrated aluminum wire mesh manufacturing capabilities, covering aluminum bar casting, wire drawing, mesh forming, surface finishing, precision cutting, and packaging. This end-to-end production capability ensures stable batch consistency for large-scale supply while supporting project-based customization of mesh structure, size, alloy selection, and surface performance for construction, industrial, electronic, and decorative applications.

Aluminum Wire Production Capacity

- Alloy support: 1100, 1350, 5052, 5154, 6061 and other aluminum alloy systems

- Wire diameter range: 0.08 mm – 3.0 mm with full customization capability

- Available tempers: O / H14 / H18, with annealing option on request

- Process traceability and controlled consistency across production batches

- Surface pretreatment options including degreasing, polishing, and anodized wire preparation

Wire Mesh Forming Capabilities

- Woven aluminum wire mesh: plain weave, twill weave, and Dutch weave structures

- Aluminum welded wire mesh with automated welding and controlled spacing accuracy

- Expanded and perforated aluminum mesh for structural and architectural support

- Mesh size coverage from 2 to 200 mesh, supplied in rolls or sheet formats

- Secondary processing including custom cutting, punching, and shaped mesh fabrication

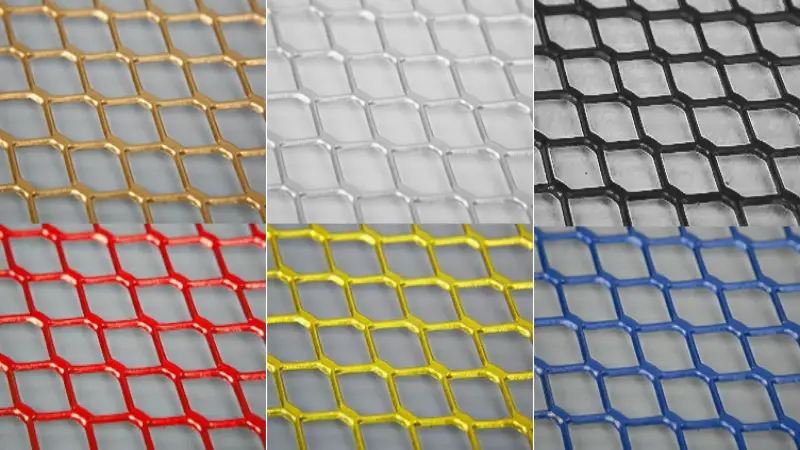

Surface Finishing Options

- Anodizing treatments to enhance corrosion and oxidation resistance

- Powder coating or electrophoretic coating in black, gray, silver, and bronze finishes

- Decorative surface treatments for architectural aluminum wire mesh

- Conductive film treatments for EMI shielding and functional mesh applications

- Combined finishing solutions balancing functional performance and visual appearance

Edge Processing & Finished Shaping

- Edge curling, sealing, punching, and framing services available

- Compatibility with aluminum frames, steel reinforcement bars, and plastic edging systems

- Final leveling and inspection to ensure dimensional accuracy and long-term stability

FAQs About Aluminum Wire Mesh

What is aluminum wire mesh?

Aluminum wire mesh is a lightweight, corrosion-resistant mesh material manufactured from aluminum wire through weaving, welding, or expanding processes.

What is the difference between woven and welded aluminum wire mesh?

Woven aluminum wire mesh is produced by interlacing wires over and under each other, suitable for fine mesh and filtration. Welded aluminum wire mesh uses welding at the cross points, ideal for structural protection, fencing, and flooring applications.

Is aluminum wire mesh rust-proof?

Yes. Unlike steel mesh, aluminum wire mesh naturally resists oxidation and corrosion, making it suitable for outdoor, marine, and humid environments.

What are common aluminum wire mesh sizes?

Mesh counts range from 2 to 200, wire diameter from 0.08 mm to 3.0 mm, and opening size from 0.07 mm to 11 mm. Supply forms include aluminum wire mesh roll, panels, sheets, and custom shapes.

Aluminum vs stainless steel wire mesh – which to choose?

Aluminum wire mesh is lighter, easier to cut and form, and usually more economical. Stainless steel mesh offers higher strength and temperature resistance, but is heavier and more costly. For lightweight construction, insect screens, or EMI shielding, aluminum mesh is often preferred.

Can Chalco provide both raw wire and finished mesh?

Yes. Chalco supplies aluminum wire in multiple alloys (1100, 1350, 5052, 5154, 6061, 3003) and delivers finished aluminum woven mesh, welded mesh, expanded mesh, and decorative mesh in rolls or panels.

What is "Mesh"? How to understand the mesh number?

Mesh refers to the number of openings per inch (25.4 mm). For example, 10 mesh means 10 openings per inch. The larger the mesh number, the denser the openings and the smaller the aperture size.

How is the opening size calculated?

The formula is: Opening size = (25.4 ÷ mesh count) – wire diameter. For example, a 10 mesh aluminum wire mesh with 0.6 mm wire results in an opening of approximately 2.94 mm.

Do you support custom aluminum wire mesh sizes?

Yes. Chalco can customize mesh count, wire diameter, roll width, sheet size, and surface treatment to meet specific project requirements.

How is aluminum wire mesh packaged for export?

- Aluminum wire: coil winding + anti-rust film + label + wrapping film

- Aluminum wire mesh roll: Kraft paper + wrapping film + plastic shaft core

- Aluminum wire mesh panels: corner reinforcement + cushioning + pallet or plywood box

Can I buy both aluminum wire raw materials and mesh products together?

Yes. Chalco provides one-stop supply of aluminum wire and aluminum wire mesh, ensuring stable quality, fast delivery, and convenient procurement.

What are typical aluminum wire mesh products and application forms?

Yes. In addition to common uses, Chalco also provides specialized aluminum wire mesh products for construction, decoration, and industrial projects. Some examples include:

-

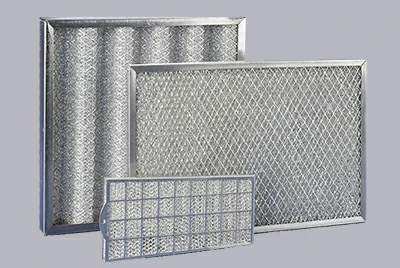

Aluminum filter roll

High mesh count with micro wire diameter, flexible and permeable; widely used in air filtration, water treatment, and ventilation systems.

-

Door and window insect screen roll

Medium to high mesh count (18–40 mesh), lightweight and corrosion resistant; ideal for insect screens, outdoor doors, and vent sealing.

-

Welded structural protection mesh

Thick wire welding, stable and rigid; suitable for fences, equipment protection covers, and safety partitions in industrial facilities.

-

Building decorative mesh

Available in woven, punched, or expanded structures; strong 3D appearance, easy to coat; perfect for curtain wall facades, partitions, and exhibition panels.

Why Choose Chalco Aluminum Wire Mesh?

- Wide alloy & mesh options – From 1100, 1350, 5052, 5154, 6061 to decorative 3003, covering woven, welded, expanded, and perforated aluminum wire mesh.

- Integrated supply – Chalco manufactures both raw aluminum wire and finished aluminum wire mesh, ensuring consistent quality and competitive aluminium wire mesh price.

- Custom services – Mesh cutting, punching, anodizing, color coating, and framing support diverse application requirements.

- Global delivery – Export-ready packaging and fast shipment, serving aluminium wire mesh manufacturers, distributors, and end users worldwide.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote