Aluminum pipe fittings refer to various parts used to connect, control, guide or terminate aluminum pipe systems. They are used in combination with aluminum or other metal pipes to form a complete fluid, gas or structural system.

Chalco is a professional aluminum supplier and manufacturer. We offer a full range of aluminum pipe fittings including aluminum elbows, tees, reducers, couplings, flanges, caps, threaded parts, weldments, and structural fittings.

Our aluminum pipe fittings are widely used in compressed air systems, fluid transportation, agricultural irrigation, fuel lines, structural supports, railings and other industries. Chalco can also provide customized sizes, special connection methods and surface treatment services according to customer drawings to meet diverse system integration needs.

Instant QuoteAluminum square tube fittings

Aluminum square tube fittings are connection fittings specially designed for square aluminum tubes (such as 20×20mm, 40×40mm, etc.), and are used to achieve structural functions such as splicing, cornering, closing or fixing between aluminum square tubes.

Contact us now

Aluminum square tube fittings are usually connected to square tubes by insertion, sliding sleeve, screw locking or riveting, which is convenient for installation and removal. Typical products include the following:

L-type connector

L-type connector L-shaped connectors are used to connect two aluminum square tubes at a 90-degree angle. They are often used in structural corners, box corners, etc. to ensure the stability of the frame corners. They are easy to install and are mostly made of die-cast aluminum. They are suitable for all kinds of display racks, guardrails, and equipment brackets.

T-type connector

T-type connector T-type connectors can connect three square tubes into a "T" structure, suitable for horizontal extension of branches on the main frame, commonly used in display racks, shelves and industrial assembly systems. The structure is stable and easy to modularize.

Cross connector

Cross connector The cross connector can connect four square tubes into a cross shape in the same plane, which is used to build symmetrical structures such as grid frames and information board brackets, with good force balance and structural integrity.

Adjustable angle connector

Adjustable angle connector Adjustable angle connectors support multi-angle connection between two aluminum tubes and are often used in adjustable structures such as diagonal braces and folding brackets. The built-in locking structure can flexibly adjust the angle and ensure stable positioning.

Chalco can provide aluminum square tube connectors of various sizes and specifications to meet the construction requirements of different structural systems. Whether it is the common 1 inch square aluminum tubing connectors, 2 inch square aluminum tubing connectors, or smaller sizes such as 3/4 inch square aluminum tubing connectors, we can provide corresponding L-shaped, T-shaped, cross connectors and end caps and other matching accessories.

Chalco's aluminum square tube connectors are made of high-quality aluminum alloy materials, are easy to install, and are widely used in multiple scenarios such as display rack structures, industrial frames, guardrail systems, etc., helping customers quickly build stable and beautiful aluminum tube structure systems.

Aluminum pipe elbow

Aluminum tube elbow is a kind of pipe fitting used to change the flow direction of aluminum tube pipeline. It realizes the turning of pipeline in space through bending structure. It is widely used in fluid, gas or particle conveying system and is one of the indispensable connecting parts in aluminum tube system.

Here are some of Chalco's customers' favorite elbows:

Aluminum 90 degree elbow

Aluminum 45 degree elbow

Aluminum 180 degree elbow

Chalco offers a wide range of aluminum alloy elbow materials to meet the strength, corrosion resistance and processing performance requirements of different industries. The alloy grades we regularly supply include 6061-T6, 6063-T5 2 /T6, 5083-H112, 5052-H32 and 3003-H14.

Chalco supports customization of different angles (such as 45°, 90°), interface forms (welding, thread, flange) and surface treatment (anodizing, sandblasting and polishing), helping customers to achieve diversified piping system solutions.

Instant QuoteFor more information on elbow types and sizes, please click to view aluminum pipe elbows to help you make the right choice.

Aluminum pipe tee fitting

Aluminum tee is a kind of connecting pipe fitting used to realize pipeline diversion or confluence. It is often used to divide an aluminum pipeline into two directions, or merge two fluids into a main pipeline. It plays a key role in the system of conveying gas, liquid or particulate matter. It is particularly suitable for T-shaped fluid distribution, pipeline extension and direction adjustment, and is an important accessory in aluminum pipe system.

The following are the types of tees that Chalco customers often purchase:

Aluminum equal tee

Aluminum reducing tee

Aluminum threaded tee

Chalco provides a variety of aluminum alloy tees to meet the needs of different pressure levels, corrosion resistance environments and connection methods. The main alloys include 6061, 6063 , 5083 , and 5086 , which have both strength, formability and welding performance, and are suitable for industrial equipment, building systems, automated fluid control and other applications.

We support customization of different specifications (such as 1/2" ~ 4"), branch sizes (equal diameter or reducing diameter) and interface types (butt welding, threaded, socket), and can perform surface treatments such as anodizing, sandblasting or polishing to ensure the product's dual stability in functionality and appearance.

To learn more about the types, structural differences and application recommendations of aluminum tees, please click to view the detailed description of aluminum pipe tee fitting to help you make professional selection decisions.

Aluminum pipe connections

Aluminum pipe connectors are key components for connecting two sections of aluminum pipes or pipe fittings. They are suitable for a variety of connection requirements such as straight extension, turning transition, and size conversion. By properly selecting connectors, the sealing, stability, and installation efficiency of the pipeline system can be effectively improved. They are widely used in compressed air systems, industrial pipe networks, structural frames, exhaust, and fluid control scenarios.

Aluminum pipe coupling

Aluminum pipe joints are basic pipe fittings used to connect two sections of aluminum pipes in a straight line, commonly found in industrial and civil systems. They are usually of equal diameter structure, but can also be made into different diameter forms , suitable for connecting aluminum pipes of the same or different diameters.

Contact us now

The aluminum pipe joint has a simple structure and is easy to install. It can be provided in threaded, welded or quick-install designs, suitable for a variety of system connection methods. When both ends of the joint are internally threaded, it can be directly connected to the externally threaded aluminum pipe with good sealing performance.

Aluminum pipe joints are widely used in water heating systems, air compression systems, structural frame splicing, equipment pipeline extension and other occasions that require straight-through connection.

Aluminum union

Aluminum union is a detachable connector, consisting of two ports and a middle threaded ring, designed for quick disassembly and maintenance of pipelines.

Contact us now

of the aluminum union can be separated without rotating the entire pipe section. It has strong reusability, good sealing performance, and supports threaded or welded connections.

Aluminum unions are suitable for systems that require frequent maintenance, cleaning or replacement of components, such as experimental equipment, compressed gas transmission, water treatment systems and fluid control devices that require high connection flexibility.

Aluminum compression fitting

Aluminum compression joints are mechanical connectors that can achieve sealed connections without welding. They clamp the aluminum tube through a compression ring and a nut to achieve a reliable seal.

Contact us now

Aluminum compression joints are quick to install, do not require special tools, provide strong protection for thin-walled aluminum tubes, provide firm connections, and are suitable for light load vibration situations. They can be repeatedly disassembled and assembled without affecting the sealing performance.

Aluminum compression fittings are widely used in small-diameter pneumatic systems, liquid control lines, instrumentation equipment, and micro-pipe networks that require high sealing performance.

Aluminum slip-on connector

Aluminum slip-on connectors are used for structural aluminum tube assembly. They are slid into the tube and fixed with screws or locks to achieve a stable connection without welding. They are mainly used for bracket and frame construction.

Contact us now

Aluminum sleeve connectors do not require welding and can be quickly positioned and assembled. They are suitable for square or round tubes. Some models have angle adjustment function, flexible disassembly and assembly, and suitable for repeated use.

Aluminum Slip-On Connectors are commonly used in display racks, industrial platforms, guardrail systems, assembly frames and DIY structural projects. They are a very cost -effective solution for non-pressure-bearing connections.

Aluminum pipe flange

Aluminum pipe flange is a round or square flat connector used to connect aluminum pipes to valves, equipment or other pipeline components. Through bolt fixing and gasket sealing, flanges can achieve a high-strength connection method that can be detached and repeatedly installed. It is an important interface component in the aluminum pipe system.

Contact us now

The following are common types of aluminum pipe flanges:

Aluminum flanges are lightweight and corrosion resistant, making them suitable for lightweight structural systems where stainless steel or carbon steel cannot be used. They have excellent thermal conductivity and are highly machinable, and can be anodized or sandblasted to improve weather resistance. Compared with traditional steel flanges, aluminum flanges are easier to install and reduce equipment loads, making them particularly suitable for weight-sensitive applications or those that require frequent assembly and disassembly.

Aluminum flanges are widely used in lightweight piping systems such as aerospace, shipbuilding, food processing, compressed air, vacuum systems, seawater transportation, irrigation projects, and electronic cooling. They are particularly suitable for applications with strong corrosiveness or high space requirements, such as mobile equipment, instrument equipment interfaces, and clean energy pipelines.

Instant QuoteAluminum pipe cap

Aluminum pipe cap is a closed type pipe fitting installed at the end of aluminum pipe to terminate the pipe, stop the flow of fluid or protect the interior from dust, impurities and corrosion.

Aluminum pipe cap is one of the commonly used sealing components in aluminum pipe system, which can be used for temporary sealing as well as long-term sealing. Aluminum pipe cap is usually connected to the pipe by welding, thread connection or ferrule fixing.

Aluminum pipe caps have the advantages of light weight, corrosion resistance, easy installation, good sealing, etc. They are suitable for systems that require light weight, non-magnetic or oxidation resistance. Common materials include alloys such as 6061, 5083 and 5052. Usually there are the following types:

Welded aluminum pipe cap

Welded aluminum pipe cap The welded aluminum pipe cap has a smooth end surface and is connected to the aluminum pipe by butt welding or socket welding. It is suitable for systems with high pressure and strict sealing requirements. It is often used in industrial fluids, pressure vessels or closed liquid storage systems.

Aluminum threaded caps

Aluminum threaded caps The threaded pipe cap has an NPT or BSP thread structure inside, which can be quickly screwed and connected to the external threaded pipe , making it easy to disassemble and maintain. It is suitable for temporary closure of low-pressure gas, water treatment or maintenance pipelines.

Flange type aluminum pipe cover

Flange type aluminum pipe cover Flange type aluminum pipe cover , also known as blind plate, is used for the end sealing of flange connected pipes and is suitable for systems that need to be removable and opened regularly. Used with gaskets and bolts, it has reliable sealing performance and is often used to seal equipment inlets and outlets or inspection ports.

Elastic aluminum pipe plug

Elastic aluminum pipe plug by press-fit fastening or outer ring locking ring. It has a compact structure and is suitable for quick closure in non-high-pressure systems, such as display racks, hollow frames, and end closure of structural pipe fittings

Common sizes of aluminum pipe caps:

| Product | Size |

| 1/8" aluminum pipe cap | 1/8" |

| 1/4" aluminum pipe cap | 1/4" |

| 3/8" aluminum pipe cap | 3/8" |

| 1/2" aluminum pipe cap | 1/2" |

| 3/4" aluminum pipe cap | 3/4" |

| 1" aluminum pipe cap | 1" |

| 1 1/4" aluminum pipe cap | 1 1/4" |

| 1 1/2" aluminum pipe cap | 1 1/2" |

| 2" aluminum pipe cap | 2" |

| 2 1/2" aluminum pipe cap | 2 1/2" |

| 3" aluminum pipe cap | 3" |

| 4" aluminum pipe cap | 4" |

| 6" aluminum pipe cap | 6" |

Don't see the size you're looking for? Contact us to order a custom size.

Instant QuoteAluminum reducer

Reducer aluminum pipe fittings are a type of transition fittings used to connect aluminum pipes of different diameters. Their main function is to achieve smooth conversion of sizes from large to small or from small to large in the piping system.

Contact us now

Chalco can provide different types of reducer aluminum pipe fittings, the main ones are as follows:

Concentric reducer

Concentric reducer Concentric reducers have the same axis, which keeps the connected pipes on the same center line, which is conducive to the uniform flow of the medium and reduces eddy currents and pressure fluctuations. They are often used in vertical or straight pipelines and are suitable for systems with high requirements for fluid power or air pressure control.

Aluminum eccentric reducer

Aluminum eccentric reducer Eccentric reducers are not in the same straight line. It is suitable for preventing liquid accumulation or pipeline systems with high exhaust requirements. It is often used in horizontal pipelines, especially in systems for drainage, exhaust or conveying impurities.

Aluminum reducer coupling

Aluminum reducer coupling A reducer is a connector with different diameters at both ends, used to directly connect two aluminum tubes of different diameters. It can be divided into threaded type, welding type, quick-install type, etc., suitable for a variety of assembly methods, easy to install and maintain.

Reducing elbow

Reducing elbow The reducer elbow not only realizes the change of direction (such as 90° or 45°), but also realizes the transition of diameter. It is suitable for systems with limited space structure but need to turn and change diameter at the same time. It is often used in compact scenes such as automobile intake pipes, air conditioning ventilation pipes, etc.

Reducing flange

Reducing flange Flange reducers directly reduce the diameter at the flange interface, making it easy to connect to flange ports of different standards. They are widely used in pressure pipes and pump and valve connection systems. They are convenient for disassembly and assembly, and enhance sealing and mechanical stability.

Chalco not only provides reducer pipe fittings, but also can customize integrated reducer aluminum pipes that do not require docking, simplifying the system structure, improving sealing and strength, and is widely used in fluid transmission and efficient system docking scenarios.

Aluminum pipe fittings for different application scenarios

Aluminum irrigation pipe fittings

Aluminum irrigation pipe fittings are connecting parts specially used for aluminum alloy pipes in agricultural irrigation systems. They have the advantages of light weight, corrosion resistance, quick installation and low maintenance cost. They are widely used in field drip irrigation, sprinkler irrigation, water supply mains and temporary water supply systems.

Blue aluminum air pipe fittings

Blue aluminum air pipe fittings are aluminum alloy fittings specially used in compressed air systems, usually used with blue aluminum pipes. They are made of high-strength aluminum and anodized to present a blue appearance, which not only has excellent corrosion resistance but also facilitates system identification and management.

Aluminum pipe railing fittings

Aluminum pipe railing fittings are special fittings used to connect and fix the various parts of the aluminum alloy railing system. They are widely used in balconies, stairs, corridors, platforms, industrial walkways and outdoor guardrails, taking into account structural strength, safety and aesthetics .

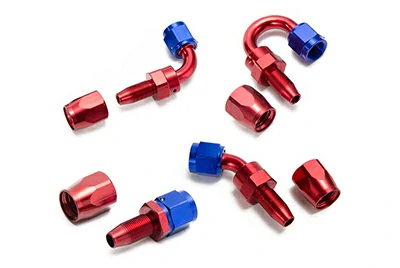

Aluminum fuel line fittings

High-performance fittings specially used for connecting aluminum pipes or hoses in fuel delivery systems of automobiles, motorcycles, racing vehicles, ships, etc. Their main function is to achieve stable connection, direction turning, interface transition and pressure sealing between fuel lines to ensure efficient and safe operation of the fuel system.

Aluminum pipe fittings vs stainless steel pipe fittings

In the fields of industrial fluid systems, structural frames and pneumatic transportation, aluminum pipe fittings and stainless steel pipe fittings are the two most common material choices. They each have unique performance advantages and are suitable for different working conditions.

| Comparison Dimensions | Aluminum Fittings | Stainless Steel Fittings |

| weight | Lighter, density is about 1/3 of stainless steel | Heavier, not suitable for weight-sensitive structures |

| Corrosion resistance | Excellent, especially 6061/6063 has better performance after anodizing | Very high, 316/316L is suitable for extreme environments such as seawater and chemical corrosion |

| cost | Relatively lower, material and processing costs are more economical | Higher, especially in high nickel alloy grades |

| Strength and hardness | Medium strength, suitable for medium and low pressure systems | Higher strength, suitable for high pressure and high temperature systems |

| Machinability | Easier to process, cut and weld; rich anodized surface treatment | Slightly lower processability, high processing cost; beautiful polishing |

| Thermal conductivity | Good thermal conductivity, suitable for heat exchange and heat dissipation occasions | Relatively poor thermal conductivity |

| Typical Applications | Pneumatic systems, frame structures, assembly lines, agriculture, light piping | Food, chemical, pharmaceutical, high temperature/high pressure industrial pipe network |

| Appearance selection | Can be anodized into blue, black and other colors, beautiful and modern | Usually silver in color, but can also be mirror polished |

Selection suggestion:

If the project is sensitive to weight, appearance or budget, such as for pneumatic systems, automation frames, irrigation or lightweight structures, aluminum pipe fittings are a better choice due to their lightness, ease of processing, low cost and the ability to be anodized for a more beautiful appearance .

In the face of high pressure, high temperature or highly corrosive environments, such as chemical, food or marine systems, stainless steel pipe fittings provide higher strength and durability, and are particularly suitable for long-term use under harsh working conditions. Chalco can provide professional selection advice and sample support. Get Sample

Why choose Chalco as your aluminum pipe fittings functional supplier?

Free samples

Chalco understands the importance of engineering selection, so we provide free sample service to interested customers. You can get physical samples for quality evaluation and assembly testing before placing an official order to ensure that the product performance is perfectly matched with the system, helping you make a more informed purchasing decision.

Discounted Price

Chalco values every cooperation with customers. For large-volume orders and long-term cooperative customers, we provide more competitive exclusive discount prices to help you effectively control costs and increase profit margins.

A full range of products to meet diverse connection needs

Chalco offers a complete range of aluminum pipe fittings, including elbows, tees, reducers , joints, flanges, caps, railing accessories, pneumatic system fittings, fuel pipe fittings, etc., covering various applications from structural connections to fluid systems, suitable for multiple fields such as industry, agriculture, construction, automobile, aerospace, etc.

High-quality materials and precision manufacturing ensure performance

We use high-strength, corrosion-resistant aluminum alloys (such as 6061, 6063, 5052, 5083, 3003, etc.), and use CNC processing, hot extrusion, welding, anodizing and other processes to ensure that the product size is accurate, the appearance is consistent, and the product is durable and stable, meeting the standards of the mid-to-high-end market.

Support customization and fast delivery

Chalco has a strong inventory and flexible production capacity. Regular aluminum pipe fittings can be delivered within seven days of spot orders, greatly shortening your project cycle. At the same time, we support the customization of non-standard aluminum pipe fittings according to customer drawings or usage scenarios, including size, angle, connection method and surface treatment. Whether you are a small batch of samples or large-scale production, we can respond efficiently to ensure stable and timely supply.