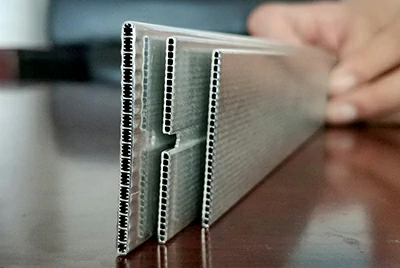

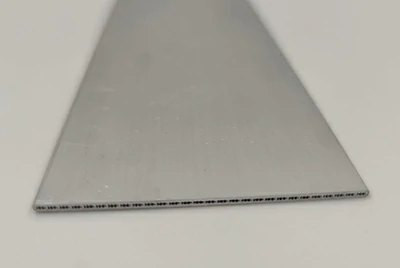

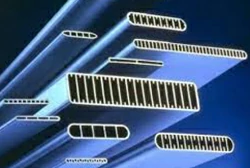

Aluminum microchannel tube, commonly referred to as multi port extrusion or multiport extruded aluminium tubes (MPE tube), is a high-precision, flat rectangular aluminum alloy extruded tube. Its structural feature is that it contains multiple evenly distributed channels inside the flat tube, which significantly increases the surface area per unit volume and enhances the heat transfer efficiency.

Chalco aluminum microchannel tube information

Alloy: 1050, 1060, 1070, 1100, 1197, 3102, 3103, 3003, 9153A, 3C01, 3F01A, 3026A, CR101A, MR306A, MR162A, 3102A, LF21, 3102M, 6063. Click to view detail ↓.

Temper: H111, H112, F, T5

Width: 8–60 mm

Height: 1–5 mm

Cavity wall thickness: 0.15–0.6 mm

Number of holes: 3–40 holes

Channel corners: rounded corners to reduce fluid resistance

Weight per meter: 0.1–2.5 kg/m depending on size and alloy

Length: 3 meters, 6 meters, support customized cutting and roll delivery

Zinc spraying thickness: 5–15 g/m²

Flux coating thickness: 8–25 g/m²

Surface treatment: galvanizing, spray flux, anodizing (optional)

Air tightness test pressure: ≥2.5 MPa (no leakage)

Burst pressure: ≥6.0 MPa (depending on size and alloy)

Thermal conductivity: ≥180 W/m·K (taking 3003 as an example)

Supply form: straight strip, curled edge

Applicable connection methods: furnace brazing, mechanical expansion, laser welding

Production process: hot extrusion, continuous extrusion

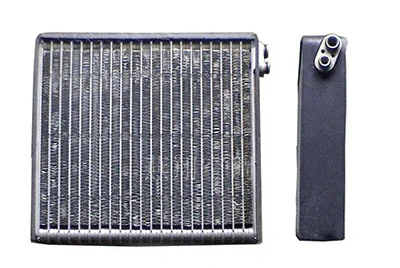

Common Applications: Automotive condensers, evaporators, heat exchangers, battery cooling plates, industrial HVAC systems

Types of aluminum microchannel tubing Chalco can provide

Aluminum micro-channel tube

The basic microchannel aluminum tube is a flat extruded tube with multiple slender inner cavities arranged in parallel, which is used to enhance the heat conduction efficiency.

Contact us now

Common alloys: 1100, 3003, 6063

Features: high thermal conductivity, light weight, compact structure, suitable for welding.

Applications: Automotive air conditioning condensers, evaporators, battery coolers, home/commercial air conditioning heat exchangers.

Size range: width 8–60 mm, height 1–5 mm, cavity wall thickness 0.15–0.6 mm

Other parameters: number of holes 3–40, length can be customized (3 m/6 m/roll)

Aluminium multi-port tube

Also known as MPE tube, another standard name for microchannel tube, it is widely used in various heat exchange systems.

Contact us now

Common alloys: 3003, 3102, 6063

Features: Multiple internal channels are arranged in parallel to provide a larger specific surface area and improve heat exchange efficiency.

Applications: Automotive radiators, heat pumps, industrial HVAC systems, refrigeration units.

Size range: Width 8–120 mm, holes up to 50 holes

Optional treatments: galvanizing, fluxing, anodizing

Parallel flow aluminum flat tube

High-performance flat multi-channel tubes for parallel flow of fluids for uniform heat exchange.

Contact us now

Common alloys: 3003, 6063

Features: Uniform flow channel, stable heat exchange, suitable for high-efficiency condensation and evaporation applications.

Application: Commercial condensers, industrial dehumidifiers, household appliance heat exchange equipment

Structural parameters: height 1–4 mm, channel width 1–2.5 mm, support for customized reinforcement ribs.

Zinc-coated aluminum tube

Galvanizing the surface of aluminum microchannel tubes enhances corrosion resistance and is suitable for high humidity and salt spray environments.

Contact us now

Introduction: Galvanizing on the surface of aluminum microchannel tubes enhances corrosion resistance and is suitable for high humidity and salt spray environments.

Common alloys: 3003, 1100

Features: Greatly improved corrosion resistance, extended service life, and easier surface welding.

Applications: Air conditioning systems in coastal areas, electric vehicle cooling plates, high salt fog application scenarios

Galvanizing thickness: 5–15 g/m²

Coating uniformity: ±0.5 g/m², in line with GB/T33230 standard

Pre-flux coated aluminous tube

The surface of the aluminum tube has been pre-coated with uniform brazing flux (usually potassium-fluorine-aluminum salts) and can be brazed directly.

Contact us now

Common alloys: 3003, 3102

Features: No need to spray additional flux, saving process and improving welding consistency.

Application: The first choice for brazed air conditioners and heat exchanger assembly manufacturers

Flux coating thickness: 8–25 g/m², temperature resistance ≥ 600°C

Si flux coated aluminum tube

Use silicon-based brazing flux, suitable for aluminum/aluminum brazing system, to enhance brazing wettability.

Contact us now

Common alloy: 3003

Features: Improve brazing strength and joint reliability, suitable for a wider range of brazing equipment

Application: New energy vehicle thermal management, HVAC system

Advantages: Strong coating adhesion, suitable for automated welding lines

Large multi-channel tube

Large flat microchannel tubes up to 200 mm wide for high heat transfer capacity systems

Contact us now

Introduction: Large flat microchannel tubes up to 200 mm wide for high heat transfer capacity systems.

Common alloys: 6063, 3003

Features: large number of channels, large unit heat exchange capacity, stable structure

Applications: Large industrial heat exchangers, commercial air conditioning units, bus condensers, energy storage cooling panels

Size range: width 50-200 mm, height 4-10 mm, number of holes up to 60 holes or more

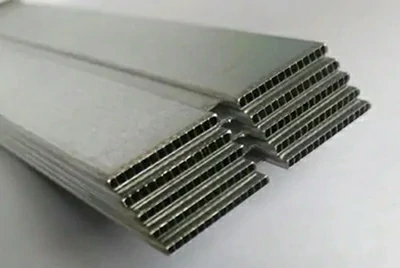

Double row joint multi-channel flat tube

The two-layer channel structure improves the heat exchange efficiency per unit volume through precise connection design.

Contact us now

Common alloys: 3003, 6063

Features: Dual-channel design, enhanced flow rate and condensation effect, higher pressure resistance

Applications: New energy vehicle heat pump systems, modular heat exchangers, energy storage battery cooling systems

Technical parameters: Support T-type and Π-type structures, internal pressure can reach ≥6MPa, support CNC cutting and composite brazing

Microchannel folded tube

(Folded Tube) is an aluminum microchannel tube manufactured using precision roll forming technology and is widely used in condensers and evaporators in automobiles and HVAC systems.

Contact us now

Product type and structure

- Two-piece folded tube: The outer tube and inner fins are formed separately and then assembled, suitable for high-performance heat exchangers.

- Folded tube: Made of a single aluminum strip, it has a compact structure and is suitable for applications with limited space.

Core advantages:

Weight reduction and cost reduction: The heat exchanger with two-piece folded tubes can reduce weight by about 15% and reduce overall costs by 5% to 20%.

Excellent thermal performance: The tube wall thickness is reduced by up to 20% compared to traditional extruded tubes, which increases the free flow area of the refrigerant, reduces pressure loss, and improves heat exchange efficiency.

Superior corrosion resistance: Chalco's multi-layer material provides built-in protection against corrosion, eliminating the need for additional zinc coating. In SWAAT testing (ASTM G85-A3), a folded tube heat exchanger equipped with the MULTICLAD® system was leak-free for 100 days.

Chalco aluminum microchannel tubing popular alloys

-

1050 Aluminum Microchannel Tube

1050 is a 1000-series high-purity aluminum commonly used for microchannel/multiport flat tubing when thermal conductivity and easy forming are key. It's often applied in heat-exchanger tube structures that prioritize efficient heat transfer.

-

1060 Multi-hole Extruded Tube

1060 is a high-purity 1000-series aluminum suited to multi-hole extrusions, offering good formability and stable extrusion behavior for thin-wall profiles. It's typically used in multi-channel flat tube designs where consistent geometry matters.

-

1070 Aluminum Microchannel Tube

1070 is a 1000-series aluminum grade used for microchannel/multiport tubing where high conductivity and good workability are desired. It is commonly considered for heat exchanger tube applications requiring clean material and reliable forming.

-

1197 Aluminum Multi-Port Flat Tube

1197 is a specialized aluminum grade commonly offered for multi-port/parallel-flow flat tubing used in heat exchanger cores. It's typically selected when consistent extrusion quality and stable performance are required for multi-channel tube designs.

-

3003 Multi-hole Extruded Aluminum Tube

3003 is a widely used Al–Mn alloy for multi-hole extruded flat tubing, valued for corrosion resistance and manufacturability in heat exchanger cores. It's often chosen for condenser/evaporator tube designs needing a durable, cost-effective material balance.

-

3102 Aluminum Microchannel Tube

3102 is one of the most common alloys for microchannel/multiport flat tubes, combining strong corrosion performance with excellent extrudability for thin-wall multiport profiles. It is widely used in parallel-flow heat exchanger systems such as condensers and evaporators.

-

3103 Aluminum Multi-Channel Tube

3103 is an Al–Mn alloy widely used for multi-channel/multi-port flat tubing, offering a practical balance of formability and corrosion resistance for heat exchanger applications. It is often chosen for stable extrusion and reliable service in condenser and evaporator tube designs.

-

6063 Aluminum Microchannel Tube

6063 is an Al–Mg–Si alloy frequently used for extruded multiport/multi-channel tube profiles when good extrudability and dimensional stability are important. It can be selected for heat exchanger tube applications depending on required strength, joining method, and corrosion strategy.

-

9153 microchannel tube

9153 is a high-quality alloy developed for more demanding service conditions, often chosen for microchannel/multiport flat tubes where long-term corrosion resistance is critical. In neutral salt spray testing, common alloys typically reach around 500 hours, while 9153 can achieve 1500 hours, indicating stronger durability for high-spec heat exchanger applications.

Characteristics of aluminum microchannel tubes

- High heat exchange efficiency: The multi-channel parallel design significantly increases the surface area per unit volume, improves the heat exchange rate, and is suitable for high-efficiency cooling systems.

- Lightweight and high strength: Aluminum alloy materials are light in weight and high in strength, and are particularly suitable for applications with high requirements for weight reduction, such as new energy vehicles, aviation, and portable devices.

- Precision Dimensions: Extrusion molding has stable dimensions and can achieve a cavity wall thickness as thin as 0.15 mm, meeting the needs of miniaturization and high-density layout.

- Excellent weldability: Can be matched with flux coating or galvanized layer, suitable for furnace brazing, laser welding, mechanical connection and other processes, with good welding effect.

- Strong corrosion resistance: 3003, 3102, 1100 and other corrosion-resistant alloys are selected, combined with surface galvanizing or anodizing to adapt to harsh environments.

- Strong customizability: Supports customization of multiple channel numbers ( 3-40 holes), widths (8-200mm), coating thickness and length (fixed length or roll material) to meet various industrial needs.

- One-piece molding: hot extrusion or continuous extrusion process, no need for splicing, good channel consistency, reduced leakage risk, and improved overall stability.

Application of micro aluminum tubing

Aluminum micro channel tube for automotive

For condensers, evaporators, radiators, battery cooling modules

Contact us now

Home appliances

Heat exchangers for household air conditioners, dehumidifiers, heat pump dryers, etc.

Contact us nowHVAC System

High-efficiency heat exchange components for central air conditioning and heat pump systems

Contact us now

Rail transit and military industry

Cooling and heat dissipation structure for high-demand equipment

Contact us nowChalco aluminum microchannel tube gallery

Aluminum microchannel tube coating standards and corrosion resistance

| Corrosion resistance (common alloy) | Salt spray test: ≥750 hours |

| Zn Coating Standard | 8±2g/㎡, 10±2g/㎡, 13±2g/㎡ |

| Flux Coating Standard | 10-15±2g/㎡ |

Hot selling sizes of aluminum microchannel flat tubes

| Product Name | Size (Width × Height, mm) |

| Aluminum micro-channel tube | 4.0 × 0.5 |

| Aluminum micro-channel tube | 6.0 × 1.0 |

| Aluminum micro-channel tube | 7.0 × 1.0 |

| Aluminum micro-channel tube | 7.94 × 1.0 |

| Aluminum micro-channel tube | 8.0 × 1.0 |

| Aluminum micro-channel tube | 9.05 × 1.5 |

| Aluminum micro-channel tube | 9.52 × 1.0 |

| Aluminum micro-channel tube | 10.0 × 1.0 |

| Aluminum micro-channel tube | 12.7 × 1.2 |

| Aluminum micro-channel tube | 15.88 × 1.2 |

| Aluminum micro-channel tube | 16.0 × 1.0 |

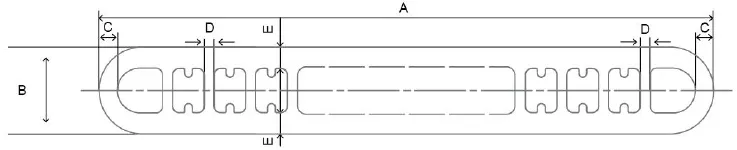

Microchannel tube dimensional tolerances

At Chalco, we control microchannel (multiport) tube dimensions with consistent extrusion and inspection practices to support stable brazing, uniform flow distribution, and reliable heat exchanger performance. The tolerance limits below are typical references used for multiport flat tube production and quality checks.

| No. | Dimension (mm) | Allowed Tolerance (mm) |

| A | 8–150 | ±0.05 MAX |

| B | 0.8–10 | ±0.03 MAX |

| C | ≥0.20 | ±0.08 MAX |

| D | ≥0.12 | ±0.05 MAX |

| E | ≥0.15 | ±0.05 MAX |

Tolerance targets can also be customized to match your drawing and application requirements. If you share the critical dimensions, measuring method, and acceptance criteria, Chalco can confirm feasibility and provide a production-ready tolerance proposal.

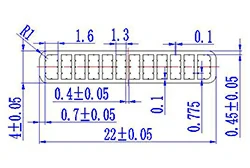

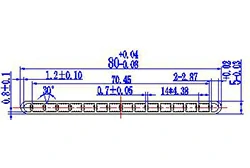

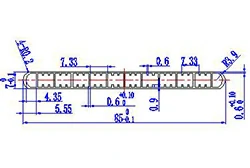

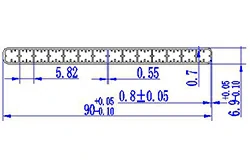

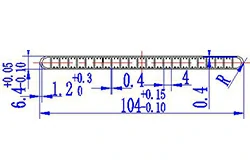

Common cross-sectional dimensions of aluminum microchannel tubes

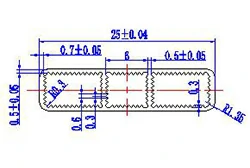

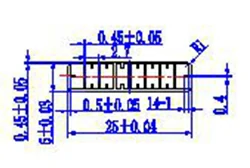

22mm*4mm-12 Hole

25mm*6mm-3 Hole

25mm*6mm-8 Hole

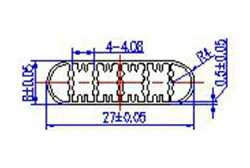

27mm*8mm-6 Hole

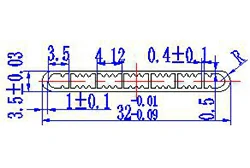

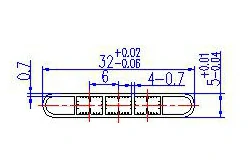

32mm*3.5mm-7 Hole

32mm*5mm-5 Hole

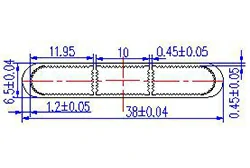

38mm*6.5mm-3 Hole

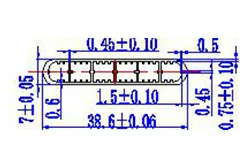

38.6mm*7mm-6 Hole

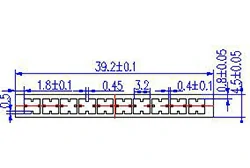

39.2mm*4.5mm-10 Hole

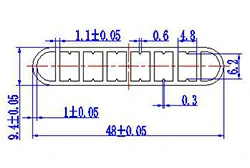

48mm*9.4mm-8 Hole

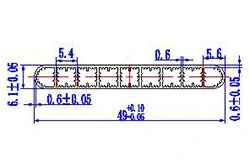

49mm*6.1mm-9 Hole

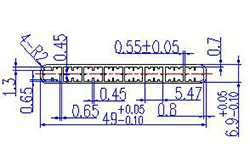

49mm*6.9mm-8 Hole

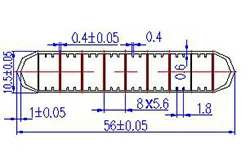

56mm*10.5mm-10 Hole

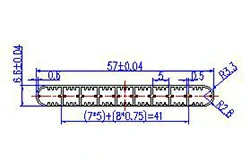

57mm*6.6mm-9 Hole

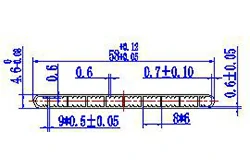

58mm*4.6mm-10 Hole

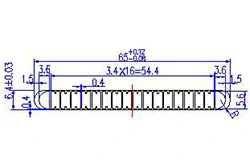

65mm*4mm-10 Hole

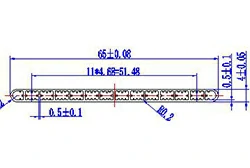

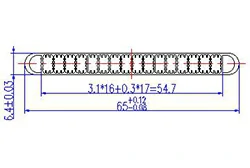

65mm*6.4mm-18 Hole

65mm*6.4mm-18 Hole

70mm*10mm-6 Hole

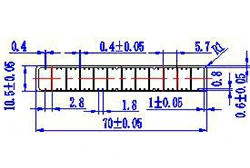

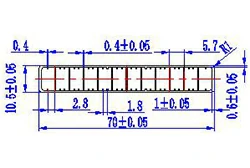

70mm*10.5mm-12 Hole

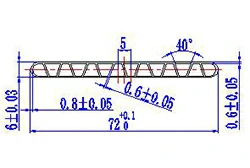

72mm*6mm-16 Hole

80mm*6mm-11 Hole

85mm*7mm-12 Hole

90mm*6.9mm-14 Hole

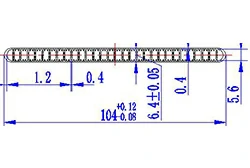

104mm*6.4mm-23 Hole

104mm*6.4mm-30 Hole

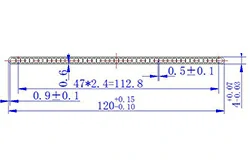

120mm*4mm-47 Hole

Production process of aluminum microchannel tube

- Raw material collection: Collect aluminum bars that meet specifications and are ready to enter the production process.

- Surface cleaning: Remove oil, oxide layer and impurities on the surface of the aluminum rod to ensure cleanliness.

- Ultrasonic Cleaning: Uses high-frequency vibrations to further clean aluminum and improve surface quality.

- Aluminum rod heating: Preheat the aluminum rod to make it ductile and suitable for extrusion molding.

- Die Heating: Heat the die to the working temperature to avoid cracking of the material during extrusion.

- Extrusion molding: The heated aluminum rod is extruded through a die with a microchannel structure to form the aluminum rod.

- Arc zinc spraying (optional): Spray a zinc layer on the surface of the aluminum tube to enhance the anti-corrosion performance.

- Wiring and routing: Arrange and wind the extruded aluminum in preparation for subsequent processing.

- Semi-finished product processing: The pipe is in the original long material state and is ready to be cut into the required size.

- Straightening and cutting: Straighten the pipes and cut them to size.

- Finished product inspection: Check product size, appearance, number of channels and surface quality.

- Packaging and shipment: Pack qualified products and prepare them for transportation, supporting export packaging requirements.

Chalco aluminum microchannel tube commonly used pipeline technologies

Dimple tube technology

- A micro-pit structure is formed on the inner wall of the pipe, destroying the fluid boundary layer, increasing turbulence and improving heat exchange efficiency.

- Suitable for air conditioners, condensers and other scenarios that require high heat transfer performance.

Multi-chamber tube technology

- The tube body contains multiple independent chambers, which reduces the overall thickness and adapts to the narrow space inside the equipment.

- It provides good structural strength and high pressure resistance, and is suitable for high load environments such as automobiles and heat pumps.

End-free Tube Technology

- Flat ends of the tubes facilitate efficient brazing with the headers and reduce the risk of welding defects.

- Provides higher brazing sealing, reduces leakage rate and improves overall system stability.

FAQs about aluminum microchannel tubing

What geometries are available for aluminum microchannel tubing?

Common geometries include triangular ports, square ports, H-ports, and circular ports, and different designs can be selected based on application requirements to optimize airflow and heat transfer performance.

What components does a microchannel tube consist of?

Typical components include: multi-port tubes, air side fins, manifolds, dividers, end caps, shrink tabs, mounting brackets, connection plugs, stiffeners, side mounts, spacer washers, etc.

What types of fins are there for microchannel tubes?

- Louvered fins: high heat transfer efficiency, suitable for high-performance equipment such as air conditioners;

- Flat fins: Suitable for frosting or lower pressure drop environments, such as industrial condensers.

Factors affecting fin performance include fin height, louver angle, number, spacing, etc.

What is a manifold in microchannel tubing?

Manifolds are used to distribute fluids evenly to each channel. They are usually made of AA4045 covered with AA3003/3005 material, which has good brazing and corrosion resistance. Optional diameter: 16–50mm, wall thickness: 1.2–2.3mm. The outlet manifold can be equipped with a baffle to isolate the liquid storage from the gas.

How to design the flow channel inside the microchannel tube?

The pipes are divided into multiple groups of channels, each group is separated by a manifold. The number of channels can be reduced in stages to match the change in refrigerant density, thereby maintaining efficient heat exchange under full/part heat load.

How to choose the connection method of microchannel tubes?

Optional materials include aluminum, copper, and stainless steel. Connection forms include aluminum flange connection, copper sweat connection, stainless steel threaded connection, etc. Accessories also include Schrader valves, brazing end caps, rubber plugs, and plastic caps. The connection direction can be straight, curved, or multi-angle layout.

Why should microchannel tubing be surface coated?

The coating can prevent corrosion failure in coastal, industrial and traffic pollution environments. Electrophoretic coating (e-coating) or trivalent chromium passivation treatment (TCP) is recommended to enhance corrosion resistance and service life.

What is electrophoretic coating?

Electrophoresis is a process that uses an electric current to deposit the coating evenly on the aluminum surface. The process includes: pretreatment, coating application, cleaning and thermal curing, which can achieve uniform film thickness and excellent corrosion protection performance.

Can aluminum microchannel tubing be bent?

Yes. Depending on the application requirements, microchannel tubes can be appropriately bent to fit complex spatial layouts.

Can microchannel tubes be equipped with a casing?

Yes. Some applications may have an optional sealed housing for direct mounting or increased structural strength.

What aluminum alloys are commonly used to manufacture aluminum microchannel tubes?

Common alloys include:

- 1000 Series (1050, 1060, 1100): High thermal conductivity

- 3000 Series (3003, 3102): Excellent corrosion resistance

- 6000 Series (6061, 6063): High strength and weldability

Suitable materials can be selected according to the specific use environment.

Why choose Chalco as your microchannel aluminum tube supplier?

- Free samples: Free samples are provided to help you quickly verify product performance and adaptability. Get free samples

- Price concessions: Exclusive discounts for old customers and large-volume orders, with higher cost-performance.

- Customization supported: Alloy, size, coating type and channel structure can be customized according to requirements.

- Rich mold resources: We have a variety of standard molds, and regular sizes do not require additional molds, saving development costs.

- Complete size: Provide a variety of widths, heights, hole numbers and wall thickness combinations to meet diverse application needs.

- No minimum order quantity limit: All spot products support retail and are flexibly adapted to trial production and small batch projects.

- Timely price updates: Daily quotations based on aluminum ingot market conditions ensure that customers obtain the most accurate and transparent purchasing prices.