Aluminum Expanded Metal is a type of metal mesh formed by cutting and stretching a single aluminum sheet. Unlike traditional welded or woven meshes, aluminum expanded metal is made from a solid piece of aluminum, without seams or welds, making it more robust and stronger.

It offers an excellent lightweight-to-strength ratio, superior corrosion resistance, and good ventilation and light transmission properties. Whether used in architectural facades, machinery guards, industrial walkways, ventilation covers, safety barriers, or decorative panels, aluminum expanded metal provides an economical, durable, and customizable solution.

Instant QuoteTo meet varying application environments and customer needs, Chalco offers a wide range of aluminum expanded metal products, including standard diamond mesh, decorative expanded mesh, thickened industrial mesh, flattened (flattened) and raised (raised) structures, with surface treatment options like anodizing, electrophoretic coating, powder coating, and brushing.

Aluminum Expanded Metal Specifications

| Alloy | 1050, 1060, 1100, 3003, 5005, 5052, 6061 |

| Grid pattern | Diamond, hexagon, fan, fish scale, special patterns can be customized |

| Short pitch (SWD) | 0.5" – 1.5" (12.7mm – 38.1mm) |

| Long pitch (LWD) | 1.0" – 3.0" (25.4mm – 76.2mm) |

| Strand thickness | 0.5mm – 6.0mm |

| Mesh area | 34%-70% |

| Edge treatment | Original edge, trimmed edge |

| Supply type | Sheet, coil, finished mesh |

| Standard size | 12" × 12",12" × 24",12" × 36",12" × 48",24" × 24",24" × 36",24" × 48"(610 × 1220mm),36" × 36",36" × 48"(914mm x 1219mm) |

| Hot selling size | 4'x 8' expanded aluminum sheet(1219mm x 2438mm) 24"×48" expandable aluminum sheet in black 36"x48" black expandable aluminum sheet |

| Coil width | 1000mm,1220mm,1500mm |

| Surface treatment | Mill Finished, Anodized, Powder Coated, Fluorocarbon Sprayed |

| Aluminum substrate standard | ASTM B209, EN 485 |

| Expanded mesh standard | ASTM F1267, ASTM F2548, ASTM F2780 |

| Packaging | Packed with plastic film, shipped by pallet or as per customer's requirements |

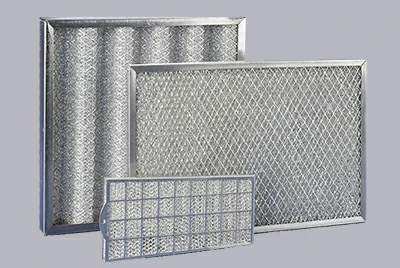

Types of Aluminum Expanded Metal Mesh

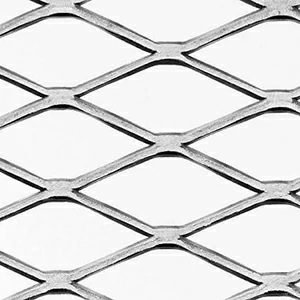

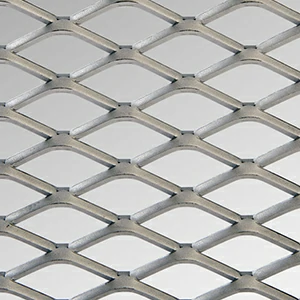

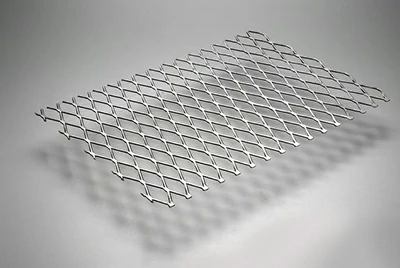

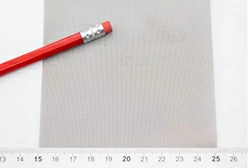

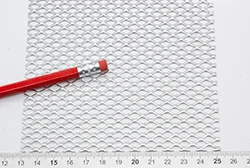

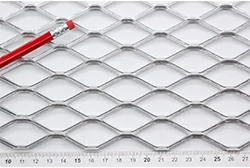

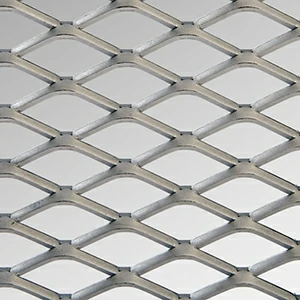

Standard Expanded Metal

Also known as raised expanded metal, this is typically made with uniform diamond-shaped holes and a moderate opening ratio. It is commonly used in industrial and construction fields, with features of high strength and durability. It is often found in ventilators, fences, platforms, etc.Click to view size chart

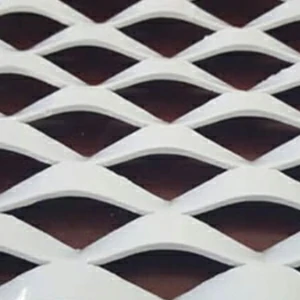

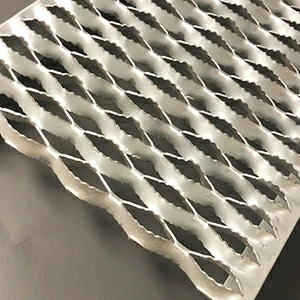

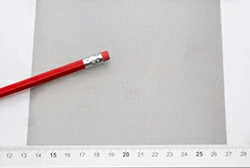

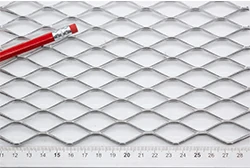

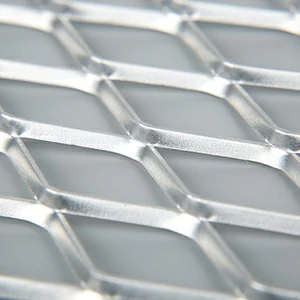

Flattened Expanded Metal

This type is created by further cold rolling the standard raised mesh to flatten it, offering a smoother surface while retaining the strength of the standard expanded metal. It is widely used in decoration, walls, fences, and protective mesh for windows and doors.Click to view size chart

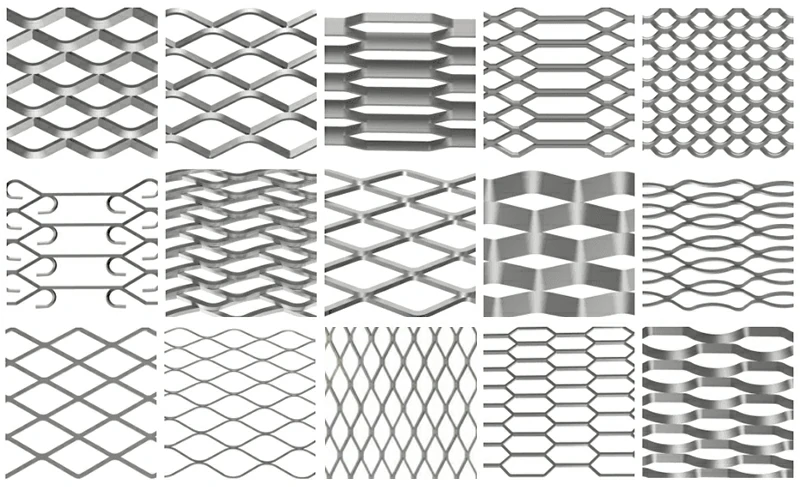

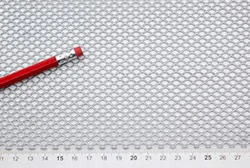

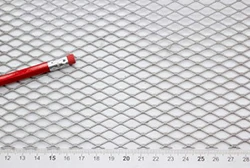

Types of Mesh Holes

- Diamond Holes

The most common shape, offering high opening rates and excellent ventilation and drainage properties, often used in building facades, platform decking, and fencing.

- Square Holes

A variation of diamond patterns, with equal diagonal lengths and strong symmetry. Ideal for decorative uses requiring visual unity, often used in interior decoration and commercial partitions.

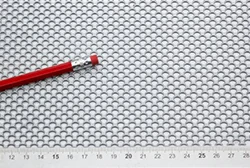

- Hexagonal Holes

With a modern feel, strong structure, and good light transmission, commonly used in building shading systems and ceiling panels.

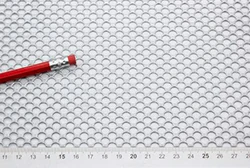

- Scales

Offers unique layering and reflective effects, often used for exterior facade decoration and design projects.

More Mesh Holes type options

Types of Aluminum Expanded Metal Products

Aluminum Diamond Mesh

Aluminum Diamond Mesh Alloys: 1100, 3003, 5052

Thickness: 0.3 - 6mm

Mesh Size: 2x3 - 36x100mm

Features: A common type of expanded metal mesh with even diamond holes and high opening rates, providing good ventilation, drainage, and lighting. Used in architectural facades, ventilators, fences, and platforms. Aluminum Expanded Metal Grating

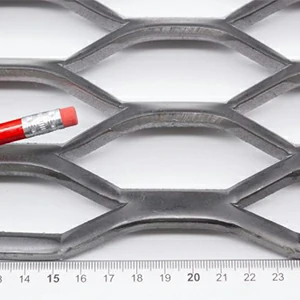

Aluminum Expanded Metal Grating Alloys: 3003, 6061

Mesh Size: 1" - 2"

Thickness: 2.5 - 6.0mm

Features: Often made with thicker aluminum base material and larger mesh designs, providing excellent load-bearing capacity while maintaining ventilation and drainage. Suitable for heavy-duty areas like industrial platforms, stairs, and corridors. Decorative Expanded Metal Mesh

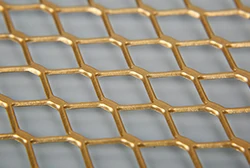

Decorative Expanded Metal Mesh Alloys: 1100, 3003

Mesh Size: 0.3" - 1.5"

Thickness: 0.8 - 2.0mm

Features: Available in various patterns (such as floral, wave, and custom geometric designs), combining aesthetics and ventilation, ideal for commercial spaces and high-end projects like building facades, ceilings, railings, and furniture panels. Heavy Duty Expanded Metal Mesh

Heavy Duty Expanded Metal Mesh Alloys: 5052-H32, 6061-T6

Mesh Size: SWD 10-75 mm, LWD 25-150 mm

Thickness: 3-6mm

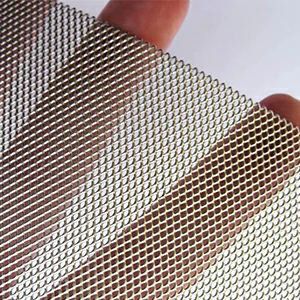

Features: Made from thicker materials and narrower ribs for greater strength and rigidity. Designed for load-bearing and anti-slip applications, commonly used in heavy-duty industrial platforms, pedestrian walkways, and dock walkways. Micro Expanded Metal

Micro Expanded Metal Alloys: 1050, 1060, 1100, 3003

Mesh Size: 0.8 X1, 1 X1.5, 1X2, 1.5X2, 2X3, 2X4, 2.6X5, 3X4.5mm

Thickness: 0.04 - 0.3mm

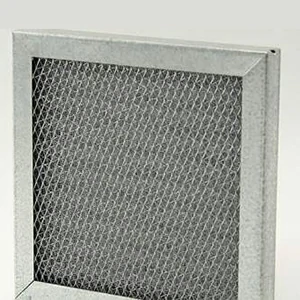

Features: With ultra-small hole sizes (0.1 - 2mm), it is widely used in precision filtration, shielding, dust prevention, and vent protection for electronic components. Its tight structure, high strength, and light weight make it suitable for high-precision and functional scenarios. Aluminum Expanded Metal Screen

Aluminum Expanded Metal Screen Alloys: 1050, 1060, 1100, 3003

Mesh Size: 0.5 - 5mm

Thickness: 0.6 - 2.0mm

Features: Typically used in ventilation systems, air filters, chimney caps, and vent covers. Combines insect-proof ventilation and light protection. It offers good corrosion resistance and plasticity, suitable for residential and commercial building environments. Expanded Metal Lath

Expanded Metal Lath Alloys: 1050, 1060, 1100, 3003

Mesh Size: SWD 0.3" - 0.75", LWD 0.55" - 0.75"

Thickness: 0.4 - 1.0mm

Features: A lightweight, high-strength building substrate often used for plaster, gypsum, and fireproof coatings. Its uniform diamond hole structure offers good adhesion and ventilation, suitable for interior and exterior walls, ceilings, and column covers.

Supply Types for Aluminum Expanded Metal

Aluminum Expanded Metal Sheet

Thickness: 0.5 - 6mm

Dimensions: 4′×8′, 3′×6′

Features: Supplied in standard sheet sizes, easy for cutting, bending, and installation.

Applications: Interior partitions, decorative panels, machinery guards, ventilators, platform decking.

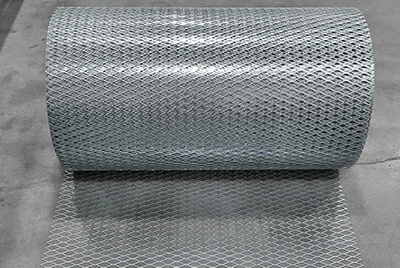

Aluminum Expanded Metal Coil

Thickness: 0.5 - 3mm

Width: 500 - 1500mm

Features: Supplied in coil form, with continuous lengths up to dozens of meters, suitable for large-area, continuous construction.

Applications: Large curtain wall systems, warehouse enclosures, ductwork ventilation covers, grease filters, industrial conveyor belt protection layers.

Aluminum Expanded Metal Panels

Dimensions: 600×1200mm, 800×2000mm

Mesh Alloys: 1100, 3003

Frame Materials: Aluminum, steel

Features:Aluminum expanded mesh panels cut and embedded in aluminum or steel frames for direct installation or clip-on mounting.

Applications:Exterior panels, curtain wall fasteners, partitions...

Hot-Selling Sizes of Aluminum Expanded Metal

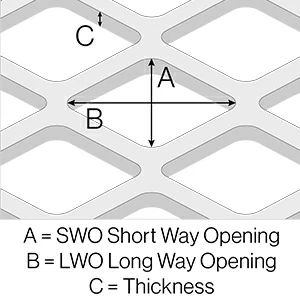

Expanded Metal Dimensions Format

The dimensions below follow the standardized format: SWO × LWO × T × SW

For example: 3.20×5.00×1.50×0.70

Instant Quote

Explanation of abbreviations:

• SWO = Short Way of Opening

• LWO = Long Way of Opening

• T = Thickness

• SW = Strand Width

Hot selling size

0.67×1.00×0.15×0.20

0.92×1.50×0.22×0.15

4.59×6.50×1.40×0.70

3.2×5×1.5×0.7

3.2×5×1.2×0.7

5.4×10.38×1.21×0.64

3.56×6.86×1.27×0.89

4.83×13.97×1.8×0.89

16.93×38.1×1.31×1.5

17.78×40.64×4.04×3.0

22.58×50.8×3.12×3.0

25.4×60.96×1.58×4.7

Common Applications of Aluminum Expanded Metal

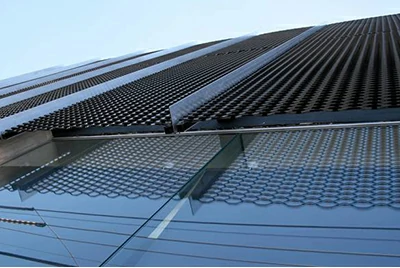

Architecture & Decoration

Aluminum Expanded Metal is widely used in architectural and decorative applications, offering both structural function and aesthetic appeal. It is ideal for modern building façades, interior partitions, ceilings, and sunshades.

Instant QuoteRecommended Products

- Decorative Expanded Mesh

- Flattened Expanded Al

- Standard Diamond Mesh

Typical Applications

- Building façades and curtain wall systems

- Ceiling panels, indoor partitions, stair panel decoration

- Storefronts, exhibition racks, fences, and enclosures

Industrial & Mechanical

In mechanical engineering and heavy industry, Aluminum Expanded Metal is used for its strength and durability in walkways, equipment enclosures, and ventilation panels.

Recommended Products

- Heavy-duty Expanded Mesh

- Aluminum Expanded Grating

- Raised Type Expanded Mesh

Typical Applications

- Equipment guards, server room ventilation covers

- Industrial platforms, walkways, anti-slip stair treads

- Electrical cabinets, cooling system covers

Security & Fencing

In areas requiring physical isolation and protection, aluminum expanded metal is widely used in safety and security installations thanks to its one-piece structure, corrosion resistance, and ease of fabrication.

Recommended Products

- Standard Expanded Metal

- Aluminum Diamond Mesh

- Raised Type Mesh

Typical Applications

- Factory fences, perimeter security fencing, window and door guards

- Air conditioning covers, anti-theft grilles, warehouse security partitions

Ventilation & Filtration

Aluminum expanded metal offers high open area and excellent airflow in ventilation systems, and can also serve as a pre-filter for air, water, and dust, meeting essential filtration needs.

Recommended Products

- Al Expanded Metal Screen

- Micro Expanded Metal Mesh

Typical Applications

- HVAC louver vents, filter covers, chimney caps

- Ventilation and EMI shielding for precision electronics

- Insect screens, vent hole covers, kitchen grease filters

Transport & Infrastructure

In transportation projects and infrastructure requiring high load-bearing capacity and weather resistance, aluminum expanded metal provides a lightweight yet durable solution.

Recommended Products

- Heavy-duty Expanded Mesh

- Expanded Grating Mesh

- Raised Type Mesh

Typical Applications

- Bridge walkways, pedestrian steps, airport maintenance platforms

- Dock catwalks, construction scaffolding, anti-slip ramps

- Subway vent covers, highway safety fences

Advantages of Aluminum Expanded Metal

Aluminum expanded mesh offers a range of outstanding properties, making it suitable for architectural, industrial, and decorative applications:

1.Continuous Structure: Formed from a single sheet with no welding or joints, ensuring consistent strength.

2.Zero Waste: No scrap material is generated during stretching, enabling nearly 100% material utilization and reduced production costs.

3.Lightweight & High Strength: Lighter than solid sheets of the same size while maintaining or enhancing strength—offering superior strength-to-weight ratio.

4.Anti-slip Surface: Raised ridges provide natural traction, ideal for stairs, walkways, and safety-critical areas.

5.Excellent Filtration & Light Transmission: Uniform mesh openings allow free passage of air, light, and liquids while blocking larger particles—ideal for efficient ventilation and filtration.

6.High Rigidity: The integral mesh structure offers strong bending and compression resistance, ensuring superior load stability.

7.Good Conductivity: Continuous metal pathways offer effective electrical conductivity—suitable for shielding and heat dissipation in electrical applications.

8.Decorative Appeal: Available in various mesh patterns and surface finishes (e.g., anodizing, powder coating) for aesthetic and functional use.

9.Corrosion Resistance: Natural aluminum or coated surfaces provide excellent oxidation and corrosion resistance for outdoor and harsh environments.

10.Eco-Friendly & Recyclable: 100% recyclable with low-carbon manufacturing, supporting sustainable development goals.

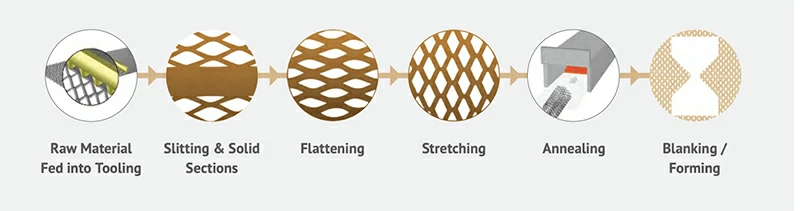

Chalco Aluminum Expanded Metal Manufacturing Process

Aluminum Expanded Metal is manufactured through an integrated "slitting and stretching” process that transforms a single sheet or coil of aluminum into a mesh structure without welding or cracking. This method offers extremely high material utilization with virtually zero waste. The detailed process includes:

Raw Material Preparation

Select aluminum sheets or coils compliant with ASTM B209 / EN 485 standards (commonly used alloys: 1000 and 3000 series), ensuring chemical composition and mechanical properties meet expansion requirements.

Slitting

The aluminum coil is fed into a slitting machine, where blades cut it into specified widths. Uniform slit gaps are created, setting the stage for the expansion process.

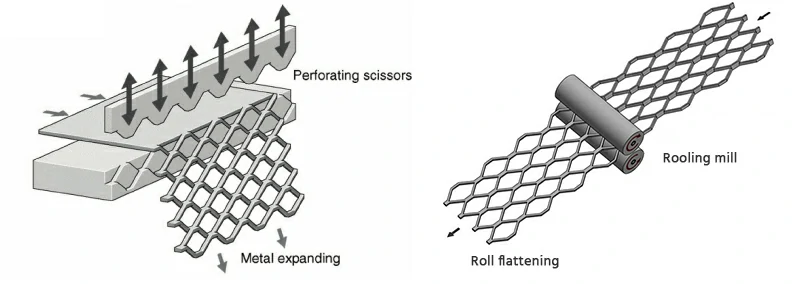

Stretching & Expanding

The slit aluminum strips enter the expander. Upper and lower blades alternately cut and stretch the material, forming diamond or other shaped mesh openings in one step. The result is a seamless mesh with excellent strength and continuity—no welding or joints required.

Instant QuoteFlattening

For applications requiring a smooth surface, a cold-rolling mill is used to flatten raised ridges, producing flattened expanded metal mesh with an even, flat finish.

Finishing

Depending on project needs, surface finishing options like Anodizing, Powder Coating, or PVDF coating are applied to enhance corrosion resistance, weatherability, and decorative appearance.

Inspection & Packaging

Each mesh sheet is inspected for dimensions, open area, and thickness. After quality checks, products are trimmed, packaged (as sheets or coils), and shipped with an inspection report.

This efficient and eco-friendly process ensures stable structure, excellent airflow, strong load-bearing capacity, and flexibility in mesh pattern design.

Surface Finishing & Fabrication Capabilities

To meet various environmental and aesthetic requirements, Chalco offers multiple surface finishes and processing services for Aluminum Expanded Metal, combining performance with visual appeal across industrial, architectural, and decorative sectors.

Instant QuoteSurface Finishing Options

Mill Finish

Mill Finish Natural metallic sheen without surface treatment; suitable for industrial use where appearance is not a priority.

Anodized

Anodized Enhances surface hardness and corrosion resistance of Aluminum Expanded Metal. Widely used for exterior walls, facades, and outdoor facilities. Available in silver, black, gold, and more.

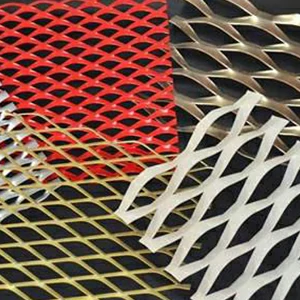

Powder Coated

Powder Coated Provides uniform color and excellent weather resistance. Ideal for decorative facades, commercial interiors, and furniture. Common colors include black, white, and gray.

Available colors of expandable aluminum mesh

Gold expandable aluminum mesh

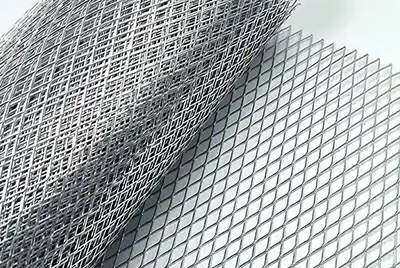

Silver expandable aluminum mesh

Black expandable aluminum mesh

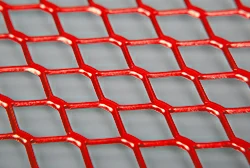

Red expandable aluminum mesh

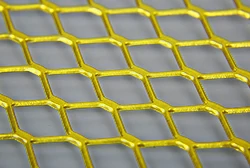

Yellow expandable aluminum mesh

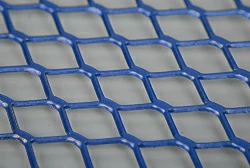

Blue expandable aluminum mesh

Surface finishing not only improves corrosion and weather resistance but also enhances decorative appearance or anti-slip performance—perfect for different application demands.

Fabrication Services

Chalco provides comprehensive custom processing services to help clients save time and reduce costs:

- Shearing: Cut to required dimensions

- Edging: Strengthen edges and enhance safety

- Bending: Adapt mesh to fit installation or design requirements

- Welding: Frame, edge, or join structures as needed

- Punching & Stamping: Meet complex shape or functional demands

We support OEM/ODM custom services, offering tailored solutions based on your drawings or project specifications.

Instant Quote

Why Choose Chalco as Your Aluminum Expanded Metal Supplier?

As a leading aluminum solution provider in China, Chalco offers a fully integrated production chain for aluminum expanded metal—from alloy raw materials and aluminum coil/plate rolling to mesh expansion and deep processing.Our Key Advantages:

Robust Equipment and Advanced Processes

- Multiple automatic expanded mesh machines support custom production with various mesh types and specifications.

- Compatible with both coil and sheet formats, covering a wide thickness range from 0.3mm to 6mm.

- Capable of continuous production to meet large-scale project demands.

Comprehensive Processing Capabilities

- Roll forming, high-force stamping, and precision shearing services.

- Plasma and wire cutting for accurate dimensions and clean edges.

- CNC bending, spot welding, and drilling for complex structures.

- CAD/CAM mold development for customized patterns and special designs.

Expert Team & Engineering Support

- A team of experienced mold engineers enables fast prototyping.

- Full-cycle technical consultation and on-site guidance.

- Industry-specific recommendations help customers optimize selection and reduce cost.

Detailed Specification Chart for Aluminum Expanded Metal

Standard Expanded Metal Size Chart

| Style | Lbs. Per | Design Sizes | Opening Size | Approx. Strand Size | Overall Thickness | Approx. No. | Open Area | ||||

| 100 sq. ft. | (Inches) | (Inches) | (Inches) | (Inches) | Diamonds Per Ft. | % | |||||

| SWD | LWD | SWO | LWO | Thickness | Width | SWD | LWD | ||||

| 1/2" x .051F | 27 | 0.5 | 1.2 | 0.375 | 0.937 | 0.051 | 0.093 | 0.158 | 24 | 10 | 65 |

| 1/2" x .081 | 44 | 0.5 | 1.2 | 0.375 | 0.937 | 0.081 | 0.096 | 0.186 | 24 | 10 | 60 |

| 3/4" x .051 | 17 | 0.923 | 2 | 0.812 | 1.75 | 0.051 | 0.109 | 0.2 | 13 | 6 | 78 |

| 3/4" x .081L | 32 | 0.923 | 2 | 0.75 | 1.68 | 0.081 | 0.129 | 0.22 | 13 | 6 | 76 |

| 3/4" x .081H | 41 | 0.923 | 2 | 0.75 | 1.68 | 0.081 | 0.165 | 0.3 | 13 | 6 | 69 |

| 3/4" x .125 | 65 | 0.923 | 2 | 0.687 | 1.68 | 0.125 | 0.169 | 0.305 | 13 | 6 | 68 |

| 1-1/2" x .081 | 22 | 1.33 | 3 | 1.187 | 2.5 | 0.081 | 0.128 | 0.24 | 9 | 4 | 85 |

| 1-1/2" x .125 | 43 | 1.33 | 3 | 1.187 | 2.5 | 0.125 | 0.162 | 0.3 | 9 | 4 | 79 |

Flattened Expanded Metal Size Chart

| Style | Lbs. Per | Design Sizes | Opening Size | Approx. Strand Size | Overall Thickness | Approx. No. | Open Area | ||||

| 100 sq. ft. | (Inches) | (Inches) | (Inches) | (Inches) | Diamonds Per Ft. | % | |||||

| SWD | LWD | SWO | LWO | Thickness | Width | SWD | LWD | ||||

| 1/2" x .051F | 26 | 50 | 1.27 | 0.312 | 1 | 0.04 | 0.104 | 0.04 | 24 | 9.5 | 61 |

| 1/2" x .081F | 42 | 0.5 | 1.27 | 0.312 | 1 | 0.06 | 0.105 | 0.06 | 24 | 9.5 | 58 |

| 3/4" x .051F | 16 | 0.92 | 2.125 | 0.75 | 1.812 | 0.04 | 0.122 | 0.04 | 13 | 6 | 72 |

| 3/4" x .081LF | 30 | 0.92 | 2.125 | 0.687 | 1.75 | 0.07 | 0.143 | 0.07 | 13 | 6 | 70 |

| 3/4" x .081HF | 39 | 0.92 | 2.125 | 0.687 | 1.75 | 0.07 | 0.181 | 0.07 | 13 | 6 | 63 |

| 3/4" x .125F | 62 | 0.92 | 2.125 | 0.625 | 1.75 | 0.095 | 0.187 | 0.095 | 13 | 6 | 62 |

| 1-1/2" x .081F | 21 | 1.33 | 3.15 | 1.06 | 2.75 | 0.06 | 0.143 | 0.06 | 9 | 4 | 77 |

| 1-1/2" x .125F | 41 | 1.33 | 3.15 | 1 | 2.75 | 0.08 | 0.181 | 0.08 | 9 | 4 | 70 |

Frequently Asked Questions (FAQ)

How effective is aluminum expanded metal in filtration and ventilation?

With an open area up to 80%, it balances airflow and filtration needs. Micro-mesh with 0.1–2.0 mm apertures can serve as a primary filter, effectively capturing particles larger than 5 µm.

Chalco also offers complete filter mesh assemblies featuring a five-layer composite structure:

- Outer Layer (1 layer of rigid mesh): Protects the inner micro-mesh and resists impact for enhanced durability.

- Middle Layer (3 layers of micro-mesh): Apertures down to 0.3 mm for tiered filtration of various particle sizes, suitable for both air and liquid.

- Inner Layer (1 layer of rigid mesh): Provides secondary protection, prolongs service life, and allows easy cleaning and maintenance.

This five-layer design not only improves filtration and ventilation efficiency but also enhances impact resistance and product lifespan, ideal for HVAC systems, commercial vents, chimneys, insect/dust covers, and kitchen range hoods requiring long-term performance.

Why is aluminum expanded metal stronger than perforated sheets or wire mesh?

Aluminum expanded metal is made through a cut-and-stretch process that retains the metal’s continuity without welding, giving it superior tensile and compressive strength compared to perforated or woven metal of similar weight.

How does the expanding process save material and reduce cost?

Cutting and stretching are performed simultaneously, producing little to no scrap. After expansion, the output area can be over three times larger than the original sheet, significantly improving material utilization and cost-efficiency.

Can hole shapes and sizes be customized for projects?

Yes. Chalco supports custom mesh shapes (diamond, square, hexagonal, fish scale, etc.) and sizes (SWO × LWO × T × SW) to meet a variety of needs, from decorative applications to industrial load-bearing uses.

What is the MOQ and lead time?

For standard specifications, the minimum order quantity is as low as 100 sqm. Lead times are typically 2–3 weeks, while custom projects may take 4–6 weeks. Scheduling is flexible based on project needs.

How is corrosion resistance ensured in outdoor environments?

Aluminum inherently offers strong oxidation resistance. Combined with surface finishes like anodizing, powder coating, or PVDF coating, it performs reliably even in coastal or industrial environments.

Is it difficult to install and process aluminum expanded metal?

No. It can be processed using standard metal tools such as shears, benders, and welders. Installation is easy, using either welding or bolt framing, which simplifies on-site operations and shortens the construction timeline.

How much load can aluminum expanded metal bear?

Load capacity depends on thickness (T) and strand width (SW). For example, a heavy-duty 3.0mm thick mesh can support over 500kg of static load per square meter. Engineering verification is recommended for specific uses.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote