Aluminum bent tubes (bents), including standard elbows and complex curved tubes, are key components in piping systems. Widely used in construction, chemical, automotive, and HVAC industries, they feature lightweight, high strength, and excellent corrosion resistance. As a professional manufacturer, we provide high-quality aluminum bent solutions to meet diverse fluid transport and structural needs, ensuring efficient and reliable applications.

Chalco aluminum pipe elbow product parameters

- Alloy: 6061, 6063, 6082, 5083, 1050, 1060

- Specification: ASTM B361, ASME S361, ANSI B16.9, ASME B16.28

- Surface treatment: anodizing, polishing, coating, galvanizing, barrel finishing

- Collaborative Industry: Construction engineering, drainage system, HVAC system, oil and gas pipeline, chemical industry, electric power, automobile industry, nuclear power system, etc. Click to view [Selection Guide] for aluminum elbows in each field

- Size range

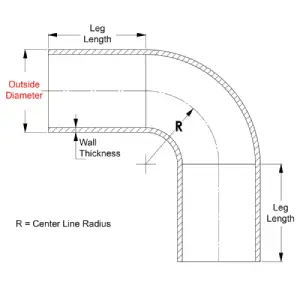

| Nominal diameter (DN): | DN10 (10mm) to DN100 (100mm) or larger (DN150, DN200) |

| Centerline radius (R) | 1D, 1.5D, 2D, 3D (D=nominal diameter) |

| Wall thickness(t) | Typically 1mm to 5mm, depending on the pressure rating and material type of the pipe |

| Elbow Angle | 45 degrees, 90 degrees, 180 degrees etc. |

| Length (L) | Usually between 50mm and 300mm, the specific length can be determined according to project requirements. |

Click to view [Detailed size table]

Chalco aluminum pipe elbow hot products

Aluminum elbows are standardized fittings used to redirect flow in piping systems, widely applied in petrochemical, power, HVAC, and nuclear industries. Chalco offers elbows in common angles such as 45°, 90°, and 180°, with custom angles and end types available upon request.

With a mature production system covering forging, welding, machining, and surface treatment, Chalco ensures excellent dimensional accuracy, pressure resistance, and corrosion protection. Our elbows are ideal for high-demand systems and support stable, large-scale supply.

Explore Chalco's Aluminum Elbow Manufacturing Capabilities

- Aluminum Buttweld Elbow

Both ends are welded flat, with prominent welds, strong pressure bearing capacity, and suitable for high-strength applications. Widely used in high-pressure pipeline systems such as oil, natural gas, chemical and other industries.

- Aluminum Flush-Weld Elbow

The weld is flush with the pipe surface, with a neat appearance and reduced fluid resistance. Suitable for applications with high requirements on appearance, such as construction, food and pharmaceutical industries.

- Aluminum Cast Elbow

Produced by casting process, usually lower cost than welded or seamless elbows. Suitable for low pressure and general industrial applications such as water pipes, cooling systems.

- Aluminum Seamless Elbow

No welds, high strength, good corrosion resistance, smooth fluid flow. Used in applications requiring high strength and corrosion resistance, such as chemical and aviation fields.

- Aluminum Large Diameter Pipe Elbow

Designed for large diameter pipes with adjustable wall thickness and structural strength. Suitable for large industrial piping systems such as oil, gas and water treatment.

- Aluminum Segmented Elbow

Assembled from multiple sections, suitable for installations with limited space. Often used in complex piping systems, especially in space-constrained environments.

- Aluminum Long Radius Elbow

The centerline radius is usually 1.5 or 2 times the nominal diameter, with low fluid resistance. Widely used in applications that require reduced flow resistance, such as HVAC systems and pipeline transportation.

- Aluminum Short Radius Elbow

The centerline radius is usually 1 times the nominal diameter, with sharp turns, suitable for occasions with limited space. It is used in compact piping systems, especially for fluid transportation in narrow spaces.

- Aluminum Street Elbow

One end is of nominal diameter and the other end is of external thread, which is convenient for direct connection to pipes and suitable for changes in fluid direction in narrow spaces. It is widely used in construction and gardening.

- Aluminum Hollaender Elbow

Specially designed for aluminum piping systems, reliable connection, mainly used for scaffolding and supports, with strong load-bearing capacity, widely used in industry and construction projects.

- Aluminum Elbow Flange

The elbow has a flange on one side, which is convenient for connecting other pipes or equipment. It is often used in piping systems that require quick disassembly and maintenance, such as fire protection, water supply and drainage systems.

To meet different pressure, corrosion, and forming requirements, Chalco offers aluminum elbows in a range of commonly used alloys, including 6061 aluminum elbow, 5083 aluminum elbow, 5052 aluminum elbow, and 6063 aluminum elbow. These alloy elbows are widely applied in industries such as oil & gas, marine, construction, and water systems, offering a reliable combination of strength, corrosion resistance, and weldability.

Instant QuoteChalco other hot selling aluminum elbow fittings

- Socket type threadless elbow pipe fittings

Socket connection, suitable for quick assembly and disassembly. No threads, reducing the risk of leakage. Widely used in water pipes and low-pressure gas systems.

- Threaded elbow fittings

There are internal threads at both ends, which are convenient for connecting with other threaded pipe fittings. Easy to install and maintain. Used in many applications such as water pipes, gas pipes, etc.

- Pressure-bearing aluminum threaded pipe fittings

Designed for medium to high-pressure applications, these high-strength aluminum fittings ensure secure connections in chemical and oil & gas piping systems.

- Flared aluminum elbow fittings

One end is flared to facilitate connection with other pipes and provide better sealing. Commonly used in HVAC systems and liquid delivery pipelines.

- Sch40 aluminum elbow pipe fittings

Meets Schedule 40 standards, with moderate wall thickness for general use. Widely used in building and industrial piping systems.

- Sch80 aluminum elbow pipe fittings

Schedule 80 compliant with a thicker wall for high-pressure applications, ideal for industrial and oil pipelines requiring strength and pressure resistance.

- Aluminum side outlet elbows fittings

The side outlet design allows branch connection in the piping system, saving space. It is suitable for piping systems that need to branch from the main pipeline.

- Aluminum tee elbow pipe fittings

The three ports connect a main pipeline to two branches, enabling fluid distribution, collection, and flow management in transportation systems.

- Aluminum reducing elbow pipe fittings

With different end diameters, it connects pipes of varying sizes for smooth flow and reduced resistance, ideal for chemical, construction, and water treatment industries.

Chalco aluminum elbow mandrel bent

Aluminum bent tubes are used in automotive exhaust systems, machinery frames, sports equipment, and structural supports—especially where space is limited or routing is complex. Chalco provides precision-formed bent tubes tailored to diverse design requirements and structural layouts.

With advanced CNC mandrel bending equipment, Chalco ensures smooth, accurate bends with consistent wall thickness and minimal deformation. We support customized diameters, wall thicknesses, and profiles, and offer fast turnaround from design to volume production.

- Hot selling product diameter: 1.5" 38mm, 1.75" 45mm, 2" 51mm, 2.5" 63.5mm, 3" 76mm, 3.5" 89mm and 4" 102mm

- Elbow angle: 30°, 45°, 60°, 90°, 120°, 180° etc.

- Explore Chalco's Aluminum Elbow Manufacturing Capabilities

30 ° elbow mandrel bent

45° elbow mandrel bent

60° elbow mandrel bent

90 ° elbow mandrel bent

180 ° elbow mandrel bent

90 ° /120 ° ultra-tight radius elbow bend

Chalco provides mandrel bent aluminum tubes in high-performance alloys such as 6061 mandrel bent tube, 5052 aluminum bend, 7075 aluminum bend, and 6063 aluminum bend. These materials ensure excellent formability, surface quality, and durability, making them ideal for precision applications in automotive exhaust systems, aerospace structures, racing components, and fluid transport assemblies.

Instant QuoteChalco aluminum alloy elbow size reference table

| 45 degree elbow angle | 90 degree elbow angle | 180 degree elbow angle | ||||

| Outside Diameter | Wall Thickness | Center Line Radius | Wall Thickness | Center Line Radius | Wall Thickness | Center Line Radius |

| 3/4” (19mm) | 1.65mm | 1-1/2” | 1.65 mm | 2” | 1.65 mm | 1-1/2” |

| 3/4” (19mm) | 1.65mm | 2” | - | - | 1.65 mm | 1-1/2” |

| 1” (25mm) | 1.65mm | 1-1/2” | 1.65 mm | 1-1/2” | - | - |

| 1” (25mm) | - | - | 1.65 mm | 2” | - | - |

| 1” (25mm) | - | - | 1.65 mm | 3” | - | - |

| 1” (25mm) | - | - | 1.65 mm | 4” | - | - |

| 1-1/8” (28mm) | 1.65mm | 2” | 1.65 mm | 2” | - | - |

| 1-1/4” (32mm) | 1.65mm | 2” | 1.65 mm | 2” | 1.65 mm | 2” |

| 1-3/8” (35mm) | 1.65mm | 1-3/4” | 1.65 mm | 1-3/4” | 1.65 mm | 1-3/4” |

| 1-3/8” (35mm) | 1.65mm | 2-1/2” | 1.65 mm | 2-1/2” | 1.65 mm | 2-1/2” |

| 1-1/2” (38mm) | 1.65mm | 2” | 1.65 mm | 2” | 1.65 mm | 1-3/4” |

| 1-1/2” (38mm) | - | - | 1.65 mm | 3” | 1.65 mm | 2-1/2” |

| 1-5/8” (41mm) | 1.65mm | 2” | 1.65 mm | 2” | ||

| 1-3/4” (45mm) | 1.65mm | 2” | 1.65 mm | 2” | 1.65 mm | 2” |

| 1-3/4” (45mm) | - | - | - | - | 1.65 mm | 2-1/2” |

| 1-7/8” (48mm) | 1.65mm | 2-1/4” | 1.65 mm | 2-1/4” | 1.65 mm | 3” |

| 2” (51mm) | 1.65mm | 2” | 1.65 mm | 2” | - | - |

| 2” (51mm) | 1.65mm | 3-1/8” | 1.65 mm | 3-1/8” | - | - |

| 2-1/4” (57mm) | 1.65mm | 2-1/4” | 1.65 mm | 2-1/4” | 1.65 mm | 3” |

| 2-1/4” (57mm) | 1.65mm | 3” | 1.65 mm | 3” | 1.65 mm | 3-1/2” |

| 2-3/8” (60mm) | 1.65mm | 3-1/8” | 1.65 mm | 3-1/8” | 1.65 mm | 3-1/2” |

| 2-1/2” (63mm) | 1.65mm | 2-1/2” | 1.65 mm | 2-1/2” | 1.65 mm | 3” |

| 2-1/2” (63mm) | 1.65mm | 4” | 1.65 mm | 4” | 1.65 mm | 3-1/4” |

| 2-3/4” (70mm) | 1.65mm | 2-3/4” | 1.65 mm | 2-3/4” | 1.65 mm | 2-3/4” |

| 2-3/4” (70mm) | 1.65mm | 4-5/16” | 1.65 mm | 4-5/16” | 1.65 mm | 3-1/2” |

| 3” (76mm) | 1.65mm | 3” | 1.65 mm | 3” | 1.65 mm | 4” |

| 3” (76mm) | 1.65mm | 4-3/4” | 1.65 mm | 4-3/4” | - | - |

| 3-1/8” (80mm) | 1.65mm | 5” | - | - | 1.65 mm | 5” |

| 3-1/4” (83mm) | 1.65mm | 3-1/2” | 1.65 mm | 3-1/2” | 1.65 mm | 4-1/2” |

| 3-1/2” (89mm) | 1.65mm | 3-1/2” | 2 mm | 3-1/2” | 1.65 mm | 4-1/2” |

| 3-1/2” (89mm) | 1.65mm | 5-5/8” | 2 mm | 5-5/8” | - | - |

| 4” (102mm) | 1.65mm | 4” | 2 mm | 4” | 1.65 mm | 5-1/2” |

| 4” (102mm) | 1.65mm | 5-1/2” | 2 mm | 5-1/2” | - | - |

| 4-1/2” (114mm) | 2mm | 6” | 2 mm | 6” | - | - |

| 5” (127mm) | 2.5mm | 7-1/2” | 2.5 mm | 7-1/2” | - | - |

Strength for Customing Aluminum Elbows & Bents

Define Your Requirements

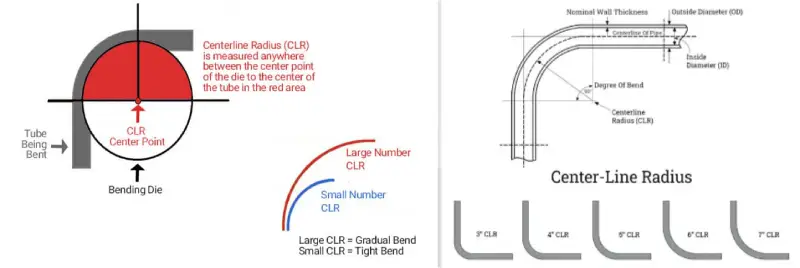

Define Your Requirements Specify the required bend angle (45°, 90°, 180°, or custom), outer/inner diameter, wall thickness, centerline radius (CLR), and total length. Also define end types—flange, threaded, expanded, reducer, or quick-connect. Consider the operating environment: pressure, temperature, vibration, and corrosive conditions.

What is Centerline Radius (CLR) and why does it matter? See FAQ

Material Selection

Material Selection Choose the most suitable aluminum alloy (e.g., 6061-T6 for strength and weldability, 5083 for marine corrosion resistance, 7075 for aerospace-grade toughness). Ensure compatibility with media (e.g., fluid, gas, chemicals), and match wall thickness to pressure rating (e.g., SCH40 or SCH80).

CAD Modeling & Design

CAD Modeling & Design Our engineers use 3D CAD to build precise models, ensuring all angles, paths, interfaces, and tolerances are met. Design optimization focuses on smooth flow paths, reliable sealing, minimal turbulence, and structural stress balance—especially for multi-bend or compact systems.

Manufacturability Review

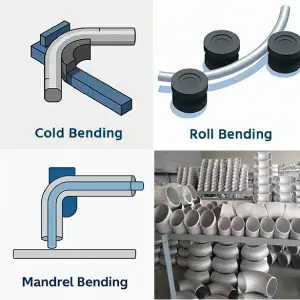

Manufacturability Review We evaluate the design for feasibility and process compatibility. For elbows, hot or cold forging with precise trimming ensures strength and shape retention. For bent tubes, we offer CNC mandrel bending, hot/cold roll forming, and segment welding—selected based on bend complexity, wall thickness, and radius.

Prototyping

Prototyping Chalco offers rapid prototyping for validation before full-scale production. Each sample undergoes checks on bend radius, wall thinning, surface integrity, and interface accuracy. This step is essential for confirming custom specs and eliminating risk in final delivery.

Testing & Validation

Testing & Validation All elbows and bent tubes can be tested per customer specs. Options include pressure testing, air-tightness checks, CRL and ovality measurement (±0.1mm), and full non-destructive testing (NDT) like ultrasonic or X-ray inspection. We also provide Material Test Reports (MTRs), heat treatment records, and certification to ASTM, ASME, or DNV standards.

Selection guide for aluminum elbows in each field selection guide

Aluminum elbows and bent tubes for construction & drainage systems

Selection Guide: Use corrosion-resistant, code-compliant materials; optimize elbow size and flow path to reduce resistance and meet layout needs.

Commonly used products: socket elbow, threaded elbow, flange elbow, reducing elbow.

Aluminum elbows and bent tubes for HVAC systems

Selection Guide: Ensure good thermal conductivity, tight sealing, and flexible radius options to withstand temperature cycles.

Commonly used products: long radius elbow, short radius elbow, flush-weld elbow, short-radius bent tube.

Aluminum elbows and bent tubes for oil, gas & chemical industry

Selection Guide: Use high-pressure, corrosion-resistant materials; ensure sealing performance under extreme conditions.

Commonly used products: buttweld elbow, seamless elbow, flared elbow, large-diameter elbow.

Aluminum elbows and bent tubes for the automotive industry

Selection Guide: Use lightweight, heat-resistant materials for efficient routing in engine, cooling, and exhaust systems.

Commonly used products: mandrel bent tube, cast elbow, short radius elbow, multi-segment bent tube.

Aluminum elbows and bent tubes for power & nuclear energy

Selection Guide: Ensure high strength and durability under high temperature, high pressure, and radiation environments.

Commonly used products: buttweld elbow, pressure-bearing threaded fitting, large-radius elbow, seamless elbow.

Aluminum elbows and bent tubes for machinery & structural frameworks

Selection Guide: Prioritize precision bending, custom shapes, and structural strength in load-bearing and spatial layout applications.

Commonly used products: multi-radius bent tube, oval-section tube, structural elbow.

Technical FAQs when purchasing aluminum elbows & bents

What is Centerline Radius (CLR) and why is it important?

Centerline Radius (CLR) refers to the distance from the centerline of the bend to the centerline of the tube. It is a critical parameter that affects flow efficiency, structural integrity, and fit-up in piping systems. Choosing the right CRL ensures proper routing, minimizes pressure loss, and avoids space interference—especially in compact or multi-bend layouts.

Can you support complex bending and multi-radius tube systems?

Yes. For bent tube applications, Chalco offers CNC mandrel bending, hot and cold forming, and multi-radius segment fabrication. These methods support precise control over CRL, wall thinning, and deformation, making them ideal for automotive exhausts, structural frames, and tight-space installations.

To help customers make the right selection and understand Chalco's capabilities, we address the most frequently asked technical concerns:

Is the elbow seamless or welded?

Seamless elbows are preferred for high-pressure, high-temperature, and cyclic load environments such as aerospace, chemical, and energy systems. Chalco offers seamless forged elbows and seamless mandrel-bent tubes for critical applications that demand superior pressure resistance and fatigue performance.

What is the accuracy of the inner wall and roundness?

The smoothness and roundness of the internal flow path directly affect fluid dynamics and long-term reliability. Chalco performs CNC finishing and internal polishing, achieving tolerance levels up to ±0.1 mm, ensuring optimal flow and surface quality.

Can I customize angle, wall thickness, or end connections?

While 45°, 90°, and 180° are standard, Chalco supports custom angles such as 30°, 60°, or 120°, as well as tailored wall thicknesses to match SCH40, SCH80 pipe systems. We also support flared ends, threaded ends, flanges, reducers, and quick connectors to meet diverse installation needs.

What about heat treatment and mechanical properties?

We provide elbows in T6, T651, O and other heat-treated tempers with matching yield and tensile strength across the pipeline system. Mechanical test reports (MTRs) and heat treatment certificates are available upon request.

How is corrosion resistance and surface finish ensured?

Our products are suitable for marine, acidic, and coolant environments. We offer anodizing, polishing, and clean surface treatments to meet the hygiene standards of pharmaceutical and food industries.

Are testing and certifications provided?

Chalco supports non-destructive testing (X-ray, ultrasonic), pressure testing, dimensional checks, and visual inspection reports. Our products comply with ASTM B361, ASME B16.9, GB/T 26052, and international certifications such as RoHS, REACH, and DNV where required.

Contact Chalco for your pipe fitting project

At Chalco, we don't just manufacture elbows and bent tubes—we help you build the entire piping system. From material selection and engineering support to a full range of aluminum fittings, we provide one-stop solutions for demanding projects in construction, energy, chemical, and automotive industries. Whether you need standard parts or custom-designed components, Chalco ensures every piece works together for optimal performance and reliability.

Explore our full range of Aluminum tees, reducers, flange, threaded fittings, and other aluminum pipe fittings—all available in various alloys and dimensions to build your ideal solution.

- Full-System Compatibility: Matching elbows, bents, tees, reducers, flanges, and threaded fittings for unified piping integration.

- Engineering Precision: ASME/ASTM-compliant fittings with tight tolerances for secure, leak-free connections.

- Advanced Manufacturing: Forging, CNC bending, anodizing, and testing ensure high-quality performance.

- Fast, Flexible Delivery: Short lead times for both bulk and custom orders with dependable logistics.

- Technical Support Included: Expert alloy selection, CAD support, and full documentation provided.

Get in touch now for a tailored aluminum piping solution built for performance, precision, and speed.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote