In the manufacturing of racing components, every gram of weight and every increment of strength can decide the outcome on the track. We understand that top-tier racing parts—such as brake calipers, differential housings, master cylinders, and suspension brackets—not only require excellent CNC machining, but also rely on high-quality aluminum blocks as the foundation.

Chalco's aluminum block (/product/aluminum-block/) are designed specifically for CNC machining and are widely used in the production of precision racing components, including rear axle and drivetrain housings, bearing supports, main bearing caps, brake caliper bodies, structural brackets and mounts, adapters, and functional blocks. For complex parts with thin walls and deep cavities, dense hole patterns, multiple assembly surfaces, and high sealing requirements, machining from aluminum blocks makes it easier to establish stable machining datums, ensuring dimensional consistency and assembly reliability in mass production.

Why are our billet aluminum block the preferred choice for racing components?

- Our aluminum blocks offer excellent machinability, with easy chip control, and can withstand high-speed precision machining.

- We use advanced melting and precision stretching processes to eliminate internal porosity and shrinkage defects. Unlike ordinary castings, our precision-finished aluminum blocks feature a uniform, defect-free internal structure, ensuring no leakage or fracture under high-load, high-pressure conditions (such as high-pressure braking systems).

- With professional pre-stretching treatment, residual stress within the material is greatly reduced. This means that during complex 5-axis machining, the material will not warp or deform due to stress release, ensuring the part's geometric tolerances fully meet design requirements.

Types of racing components machinable from Chalco aluminum blocks

Billet aluminum case

Alloy: 7075-T73

For high-load drivetrain housings, 7075-T73 provides high strength and stress resistance. Solution heat treatment plus vibration stress relief improves consistency and reduces post-machining drift, and anodizing boosts corrosion resistance.

Aluminum differential body

Alloy: 6061, 7075, 6082

6061 for stable machining and corrosion resistance; 7075 for higher strength and stiffness under high loads; 6082 for a stronger-tougher balance, suited to forged lightweight, impact-resistant designs.

One-piece brake rotor

Alloy: 6061, 6082, 7075

A forged aluminum hat offers a high strength-to-weight ratio, reducing unsprung and rotating mass. By keeping critical load sections and drilling lightening holes in non-critical areas (instead of thinning the entire part), it balances weight reduction and stability, and can be anodized for corrosion resistance.

Four piston evolution 4 billet caliper

Alloy: 6061-T6511

A fully machined 6061-T6511 aluminum block body improves caliper stiffness and smoother piston retraction, and can be protected with Type II black anodizing.

Dragster steering rack

Alloy: 6061-T6511

A 6061-T6511 aluminum block housing is lightweight yet strong, and black anodizing improves corrosion resistance.

Tapered bearing pinion support

Alloy: 6061-T6511

A 6061-T6511 aluminum block body enables precise machining of bearing seats and snap-ring grooves, with clear anodizing for improved corrosion resistance.

Ford 8.8 billet aluminum main caps

Alloy: 2024-T351

2024-T351 offers higher strength and stiffness for high-clamping-force retainers, is easy to machine, and can be clear anodized.

Door car steering rack

Alloy: 6061-T6511 (body/clamps); 6061-T6500 (clevis ends)

6061-T6511 is used for the body/clamps for strength and consistency, while the clevis ends are also machined from aluminum block and black anodized for easier assembly and better corrosion resistance.

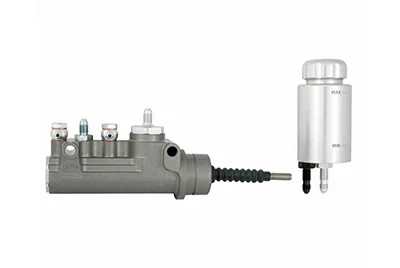

Dual in-line fast fill master cylinder

Alloy: 6061-T6511

A 6061-T6511 aluminum block body with hard anodizing + PTFE coating is better suited for wear and corrosion resistance in brake fluid passages.

Steering box 14"

Alloy: 6061-T6511

A 6061-T6511 aluminum block body is lightweight yet strong, with black anodizing for racing steering components.

Pro Mod aluminum housing kit – four link spacer plates / bottom brace

Alloy: 6061-T6511

Machined 6061-T6511 aluminum blocks with weight-reduction pockets and O-ring sealing, finished with black anodizing for both lightweight design and reliability.

Aluminum spacer washer

Alloy: 6061-T6511

6061-T6511 balances strength and low weight, reduces deformation under high clamping loads, and can be clear anodized for corrosion protection.

Popular Chalco aluminum block alloys

To meet the combined needs of high load capacity, high reliability, and lightweight design for racing components, Chalco supplies multiple high-quality aluminum block grades for motorsport and high-performance vehicles. The following alloys are among the most popular choices thanks to proven performance and extensive racing application experience.

-

7075 aluminum block

With exceptionally high strength and stiffness, 7075 aluminum block is widely used in motorsport for critical load-bearing structures. For parts that must remain stable under hard acceleration, braking, and drivetrain shock, 7075 provides a higher safety margin.

-

6061 aluminum block

6061 aluminum block is widely used in motorsport, offering a strong balance of strength, low weight, and reliability. It is commonly used for brake components, steering housings, brackets, and mounts, making it one of the most proven and versatile racing alloys.

-

2024 aluminum block

2024 aluminum block offers high strength and stiffness, making it suitable for racing parts under high clamping force or sustained loads. It is often used for main bearing caps and load-retaining components, providing stable performance in high-performance racing engines and drivetrains.

Material advantages of aluminum blocks in high-sealing racing components

Track conditions are extreme: loads, temperature, and pressure change constantly. In racing, safety margins come from consistent, predictable internal quality, which is why billet-based parts are often preferred.

Dynamic loads and impacts

Acceleration, hard braking, cornering, curbs, and shift shock create changing loads and short peak impacts. Billet material is denser and more uniform, with fewer weak points, reducing the risk of cracking or instability under impact.

Vibration and fatigue

Racing parts typically fail from long-term cyclic loading. More uniform billet structure makes fatigue cracks less likely to initiate early and harder to propagate, supporting season-level reliability.

Heat and thermal cycling

Brake components see rapid heating and cooling, while powertrain parts face sustained heat and repeated cycles. Uniform billet response helps reduce local stress concentration and improves dimensional stability.

High-pressure sealing

Hydraulic components face pressure pulsation and peaks. Billet material reduces internal uncertainty that can develop into leakage paths, making sealing reliability more controllable.

Billet vs. casting in racing components

In racing parts manufacturing, the choice between billet and casting is not about which is more premium, but which route better controls risk under impact, vibration, thermal cycling, and pressure pulsation. Racing programs care most about stability, predictability, and keeping rework and failure rates low.

Internal quality and consistency

Casting is efficient for near-net shaping, but internal quality can vary, with risks such as local porosity, micro-voids, or inclusions. If these fall in critical load or sealing areas, they can become failure starters.

Billet parts emphasize a more uniform, consistent material structure, reducing performance variation between parts and helping keep project risk predictable.

Stability under impact and peak loads

Curbs, launches, hard braking, and shift shock create short, high-amplitude impacts. The real risk is not average strength, but internal weak points being amplified into sudden cracking or local instability.

Castings depend more on whether hidden weak zones exist, while billet reduces these uncertainties, making parts more stable at the limit.

Fatigue durability

Most racing failures come from cyclic loading, not one-time overload. Fatigue cracks tend to initiate earlier around defects or discontinuities and grow under repeated loads.

With a more uniform structure, billet is less prone to early crack initiation and rapid crack growth, which matters for season-level reliability and long test cycles.

Hydraulic sealing risk

Calipers, master cylinders, and hydraulic housings face pressure pulsation and peaks. Over time, small internal uncertainties can develop into leakage paths.

Billet is often preferred because it reduces leakage risk at the material level, making sealing reliability more controllable.

When to choose which

For high-volume production, complex near-net shapes, and milder operating limits, castings can be more cost-effective.

For high-load structures, high-sealing hydraulic parts, and critical components that demand maximum consistency, billet is commonly chosen to reduce variability and lower failure probability.

Quality control for Chalco racing aluminum blocks

Internal quality focus

We control microstructure uniformity to minimize porosity and inclusions, reducing crack and leak risk under impact, fatigue, and pressure pulsation.

NDT screening

For critical applications, we perform internal inspections before shipment to catch defects early and cut rework and trial costs.

Full traceability

Each batch is clearly identified and recorded to support fast iteration and consistent repeat orders.

FAQ

Which parts are better made from billet rather than castings?

Billet is better for high-sealing, high-load, thin-wall/deep-cavity parts, or components under long-term vibration/thermal cycling; castings are more cost-effective for very complex shapes with mild service conditions.

How to choose 6061 / 7075 / 2024?

6061 is the most stable and versatile; 7075 prioritizes strength and stiffness; 2024 suits locations demanding very high structural stability.

Why are T6511 / T73 / T351 commonly used?

These tempers provide better stress relief, reducing machining distortion and improving sealing and assembly consistency.

How to reduce deformation in thin-wall 5-axis machining?

Use staged, symmetric material removal, machine critical surfaces last, and choose well stress-relieved tempers.

How does material affect leakage in high-pressure brake parts?

More uniform material with fewer internal defects lowers leakage risk under long-term pressure pulsation.

Is 7075 always the best choice?

No. Many parts perform better with 6061 for corrosion resistance, stability, and mass-production consistency.

What should be considered for anodizing billet parts?

The coating affects dimensions, so allow machining compensation for critical holes and sealing surfaces.

What blank forms can you supply?

We can supply sawn blanks or near-net blanks to reduce roughing and deformation risk.

Why does machining performance vary between batches?

Differences in residual stress and microstructure consistency directly affect distortion and assembly stability.

What services can Chalco provide for you?

- Chalco can supply CNC-friendly aluminum block blanks, including envelope-size sawn cuts and fixture-ready preforms, to reduce cutting/roughing time and improve batch consistency.

- We can recommend alloy/temper and blank strategy based on your load, pressure, thermal cycling, and assembly needs, and advise on machining allowance and cutting direction to reduce trial-and-error.

- For anodizing or hard anodizing, we align the process to your critical surfaces and manage coating dimensional effects upfront to cut rework.

- We provide full traceability (certs and batch ID) and can link material lots to part lots for repeat orders.

- We support prototype-to-production scaling by locking key specs in the trial stage and duplicating the same conditions for follow-on supply.

Backed by Chalco's in-house capacity and technical know-how, we can tailor the alloy/temper and blank solution to your part's service conditions, design, and machining route.

If you have any selection or sourcing needs, feel free to contact us for professional support.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote