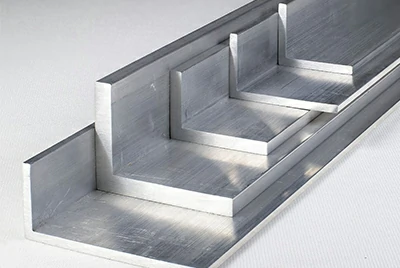

Due to their stable structure and convenient installation, aluminum angles are widely used in building curtain walls, equipment frames, machinery supports, industrial assembly, and custom structural components.

Chalco has established a complete aluminum angle mold system, covering equal sides, unequal sides, rounded corners, flanges, reinforcing ribs, and various irregular structures. It can directly extrude and produce according to requirements, reducing mold opening costs and procurement risks , and supports custom services for special sizes or non-90° angles.

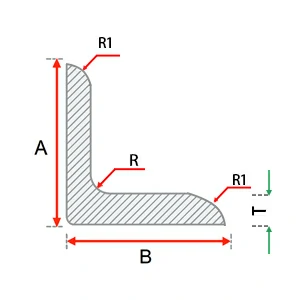

- Standard structures: Equal angle aluminum, Unequal angle aluminum, Rounded & Special-Shaped angles (R-Corner).

- Special structures: Flanged, reinforced/stepped/channel angle aluminum, non-90°/irregular angle aluminum

- Optional alloys: 6061 / 6063 / 6082 / 6005 / 7075 and other industrial aluminum alloys

- Condition and mechanical properties: T5, T6, T66, etc. Mechanical property reports can be provided upon request.

- Surface treatment: Anodizing, sandblasting, electrophoresis, wire drawing, powder coating, and other industrial or decorative processes.

- Size range capability: Side length 5–400 mm, wall thickness 0.8–30 mm; non-standard structures can be developed according to drawings.

Below are the aluminum angle specifications that we can directly extrude using our existing molds (no mold opening fee required). You can also click to view the product details page for "aluminum angle ," or jump to view our production and processing capabilities.

Chalco Equal Aluminum Angle Extrusion Dies

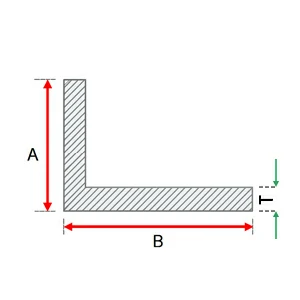

Chalco offers a comprehensive range of equilateral angle aluminum molds, including lightweight angles such as 5×5mm and 10×10mm, as well as heavy-duty structural angles such as 50×50mm, 100×100mm, and even 200×200mm. These molds produce standard 90° right-angle equilateral aluminum profiles, which can be directly extruded without additional mold costs.

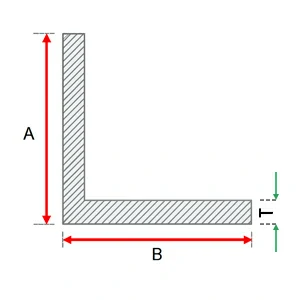

Equal-angle aluminum mold (≤30mm)

-

Used to produce equilateral aluminum with a side length not exceeding 30 mm, featuring a symmetrical structure and precise right angles, suitable for applications such as lightweight frames, decorative edging, and small connectors.

| Specification | A = B (mm) | Thickness T (mm) |

| 5×5×0.6 | 5 | 0.6 |

| 5×5×1.0 | 5 | 1.0 |

| 6×6×1.0 | 6 | 1.0 |

| 8×8×1.0 | 8 | 1.0 |

| 9×9×1.0 | 9 | 1.0 |

| 10×10×1.0 | 10 | 1.0 |

| 10×10×1.5 | 10 | 1.5 |

| 12×12×1.0 | 12 | 1.0 |

| 12×12×1.2 | 12 | 1.2 |

| 12×12×1.5 | 12 | 1.5 |

| 15×15×1.2 | 15 | 1.2 |

| 15×15×1.5 | 15 | 1.5 |

| 16×16×1.2 | 16 | 1.2 |

| 16×16×1.4 | 16 | 1.4 |

| 18×18×1.5 | 18 | 1.5 |

| 19×19×1.5 | 19 | 1.5 |

| 20×20×1.5 | 20 | 1.5 |

| 20×20×2.0 | 20 | 2.0 |

| 22×22×2.0 | 20 | 2.0 |

| 25×25×1.5 | 25 | 1.5 |

| 25×25×2.0 | 25 | 2.0 |

| 25×25×3.0 | 25 | 3.0 |

| 28×28×2.5 | 28 | 2.5 |

| 30×30×2.0 | 30 | 2.0 |

| 30×30×2.5 | 30 | 2.5 |

| 30×30×3.0 | 30 | 3.0 |

| 30×30×4.0 | 30 | 4.0 |

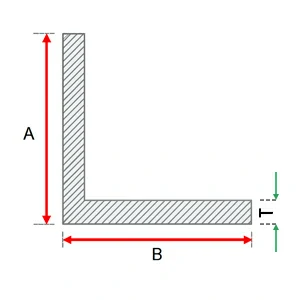

Equal-angle aluminum mold (30–60 mm)

-

Suitable for batch extrusion of medium-sized equilateral aluminum, with stable side length and higher strength, it is often used in mechanical structures, equipment frames, door and window profiles and load-bearing components.

| Specification | A = B (mm) | Thickness T (mm) |

| 32×32×3.0 | 32 | 3.0 |

| 35×35×3.0 | 35 | 3.0 |

| 36×36×3.0 | 36 | 3.0 |

| 38×38×3.0 | 38 | 3.0 |

| 38×38×4.0 | 38 | 4.0 |

| 40×40×3.0 | 40 | 3.0 |

| 40×40×4.0 | 40 | 4.0 |

| 40×40×5.0 | 40 | 5.0 |

| 45×45×3.0 | 45 | 3.0 |

| 45×45×4.0 | 45 | 4.0 |

| 50×50×3.0 | 50 | 3.0 |

| 50×50×4.0 | 50 | 4.0 |

| 50×50×5.0 | 50 | 5.0 |

| 50×50×6.0 | 50 | 6.0 |

| 55×55×5.0 | 55 | 5.0 |

| 56×56×4.0 | 56 | 4.0 |

| 60×60×4.0 | 60 | 4.0 |

| 60×60×5.0 | 60 | 5.0 |

| 60×60×6.0 | 60 | 6.0 |

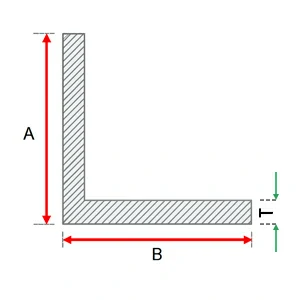

Equal-angle aluminum mold (60–200 mm)

-

Used for extruding large-size equilateral aluminum profiles, with wide cross sections and excellent stress performance, suitable for high-strength applications such as heavy structural supports, industrial frames, transportation equipment, and building components.

| Specification | A = B (mm) | Thickness T (mm) |

| 63×63×4.0 | 63 | 4.0 |

| 63×63×5.0 | 63 | 5.0 |

| 63×63×6.0 | 63 | 6.0 |

| 65×65×6.0 | 65 | 6.0 |

| 70×70×5.0 | 70 | 5.0 |

| 70×70×6.0 | 70 | 6.0 |

| 70×70×7.0 | 70 | 7.0 |

| 75×75×6.0 | 75 | 6.0 |

| 75×75×8.0 | 75 | 8.0 |

| 80×80×6.0 | 80 | 6.0 |

| 80×80×8.0 | 80 | 8.0 |

| 90×90×6.0 | 90 | 6.0 |

| 90×90×7.0 | 90 | 7.0 |

| 90×90×8.0 | 90 | 8.0 |

| 100×100×8.0 | 100 | 8.0 |

| 100×100×10.0 | 100 | 10.0 |

| 110×110×10.0 | 110 | 10.0 |

| 120×120×10.0 | 120 | 10.0 |

| 120×120×12.0 | 120 | 12.0 |

| 130×130×10.0 | 130 | 10.0 |

| 150×150×10.0 | 150 | 10.0 |

| 150×150×12.0 | 150 | 12.0 |

| 150×150×15.0 | 150 | 15.0 |

| 160×160×12.0 | 160 | 12.0 |

| 180×180×15.0 | 180 | 15.0 |

| 200×200×16.0 | 200 | 16.0 |

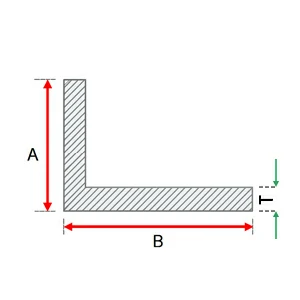

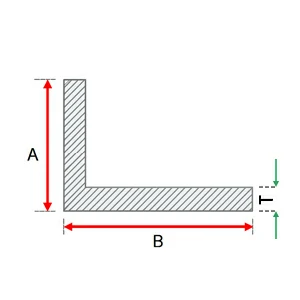

Chalco Unequal Aluminum Angle Extrusion Dies

Unlike equilateral angle aluminum, unequal angle aluminum has different dimensions in the two side length directions (A≠B), making it more suitable for applications requiring eccentric load-bearing, structural reinforcement, or asymmetrical mounting surfaces. Chalco has a complete library of unequal angle aluminum extrusion dies, capable of producing sizes from small 15×20mm to large 100×150mm and above directly without additional die-making costs.

Unequal Aluminum Angle Dies (≤ 40mm)

-

Used to produce lightweight unequal-sided aluminum angles with small differences in side width. The design with one long and one short side improves installation flexibility and is suitable for applications such as door and window frames, heat dissipation supports, and decorative corners.

| Specifications (mm) | Side A (mm) | Side B (mm) | Thickness T (mm) |

| 15×20×1.2 | 15 | 20 | 1.2 |

| 20×25×1.5 | 20 | 25 | 1.5 |

| 20×30×2.0 | 20 | 30 | 2.0 |

| 20×38×2.0 | 20 | 38 | 2.0 |

| 25×30×2.0 | 25 | 30 | 2.0 |

| 25×30×3.0 | 25 | 30 | 3.0 |

| 25×38×2.0 | 25 | 38 | 2.0 |

| 30×40×2.0 | 30 | 40 | 2.0 |

| 30×40×3.0 | 30 | 40 | 3.0 |

| 30×45×3.0 | 30 | 45 | 3.0 |

| 32×40×3.0 | 32 | 40 | 3.0 |

| 35×40×3.0 | 35 | 40 | 3.0 |

| 35×45×3.0 | 35 | 45 | 3.0 |

Unequal Aluminum Angle Dies (40–80 mm)

-

Suitable for medium-sized unequal-angle aluminum extrusion, with a more pronounced ratio of long to short sides, combining structural load-bearing capacity and installation adaptability, it is commonly used in equipment frames, support skeletons, tracks, and connecting components.

| Specifications (mm) | Side A (mm) | Side B (mm) | Thickness T (mm) |

| 40×50×3.0 | 40 | 50 | 3.0 |

| 40×50×4.0 | 40 | 50 | 4.0 |

| 40×60×3.0 | 40 | 60 | 3.0 |

| 40×60×4.0 | 40 | 60 | 4.0 |

| 45×60×4.0 | 45 | 60 | 4.0 |

| 45×70×4.0 | 45 | 70 | 4.0 |

| 50×65×4.0 | 50 | 65 | 4.0 |

| 50×75×5.0 | 50 | 75 | 5.0 |

| 55×65×5.0 | 55 | 65 | 5.0 |

| 56×70×5.0 | 56 | 70 | 5.0 |

| 60×80×4.0 | 60 | 80 | 4.0 |

| 60×80×5.0 | 60 | 80 | 5.0 |

| 60×80×6.0 | 60 | 80 | 6.0 |

| 65×75×6.0 | 65 | 75 | 6.0 |

| 70×90×6.0 | 70 | 90 | 6.0 |

| 75×100×8.0 | 75 | 100 | 8.0 |

Unequal Aluminum Angle Dies (side width ≥80 mm)

-

Used for extruding large-size aluminum profiles with unequal angles, the longer sides provide higher load-bearing capacity and structural stability, suitable for applications such as industrial platforms, heavy equipment frames, building beam and column connections, and transportation structural components.

| Specifications (mm) | Side A (mm) | Side B (mm) | Thickness T (mm) |

| 80×100×8.0 | 80 | 100 | 8.0 |

| 90×110×8.0 | 90 | 110 | 8.0 |

| 100×120×8.0 | 100 | 120 | 8.0 |

| 100×150×10.0 | 100 | 150 | 10.0 |

| 120×150×10.0 | 120 | 150 | 10.0 |

| 120×160×12.0 | 120 | 160 | 12.0 |

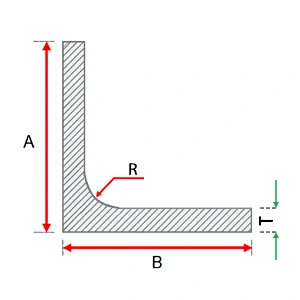

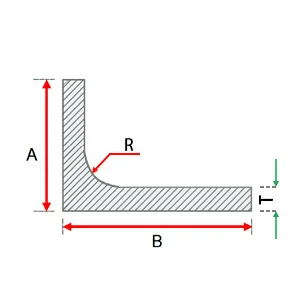

Round Corner & Special Angles

In addition to standard equilateral and unequal-sided 90° angle aluminum profiles, Chalco also offers a wide range of angle aluminum extrusion dies with special structures to meet the needs of applications such as architectural decoration, structural reinforcement, equipment edging, door and window sealing, and special mechanical parts. These profiles can be produced without molds, have short delivery cycles, and come in a variety of cross-sections, making them a common choice for high-end projects and custom structures.

Dimensions of equal side aluminum angle with rounded corners

-

This product is used to manufacture L-shaped aluminum profiles with uniform side lengths and rounded inner and outer corners. The rounded corner design reduces stress concentration, improves aesthetics and assembly fit, and is commonly used in furniture, decorative corner protectors, small structural components, and applications where sharp corners need to be avoided.

| Model | A (mm) | T (mm) | R (mm) | Weight (kg/m) |

| J50x50R-1.6 | 50 | 1.6 | 1 | 0.427 |

| J50.8x50.8R-3.18-A | 50.8 | 3.18 | 3.18 | 0.854 |

| J63.5x63.5R-9.53 | 63.5 | 9.53 | 9.53 | 3.087 |

| J75x75R-1.8 | 75 | 1.8 | 0.5 | 0.724 |

| J76.2x76.2R-6.35 | 76.2 | 6.35 | 6.35 | 2.56 |

| J76.2x76.2R-9.53 | 76.2 | 9.53 | 6.53 | 3.793 |

Dimensions of unequal side aluminum angle with rounded corners

-

This product is used to manufacture unequal-sided aluminum profiles with different side lengths and rounded inner and outer corners. The rounded corner design improves the profile's impact resistance, reduces welding stress, and provides a smoother fit in connections or edging structures. It is suitable for applications requiring both strength and aesthetics, such as heat sink frames, equipment supports, edging decorations, and machine corner protectors.

| Model | A (mm) | B (mm) | T (mm) | R (mm) | Weight (kg/m) |

| J16x12R-1.54 | 16 | 12 | 1.54 | 1 | 0.111 |

| J20x12R-1.54 | 20 | 12 | 1.54 | 1 | 0.128 |

| J20x16R-1.54 | 20 | 16 | 1.54 | 1 | 0.144 |

| J25x20R-1.54 | 25 | 20 | 1.54 | 1 | 0.182 |

| J32x16R-1.54 | 32 | 16 | 1.54 | 1 | 0.195 |

| J32x20R-1.54 | 32 | 20 | 1.54 | 1 | 0.211 |

| J32x25R-1.54 | 32 | 25 | 1.54 | 1 | 0.232 |

| J40x20R-1.54 | 40 | 20 | 1.54 | 1 | 0.245 |

| J40x25R-1.54 | 40 | 25 | 1.54 | 1 | 0.266 |

| J40x32R-1.54 | 40 | 32 | 1.54 | 1 | 0.295 |

| J42.93x20.65R-1.27 | 42.93 | 20.65 | 1.27 | 3.18 | 0.22 |

| J50x20R-1.6 | 50 | 20 | 1.6 | 1 | 0.297 |

| J50x25R-1.54 | 50 | 25 | 1.54 | 1 | 0.307 |

| J50x38.1R-6.35 | 50.8 | 38.1 | 6.35 | 6.35 | 1.444 |

| CN-FT0118 | 50 | 14 | 2.5 | 1 | 0.416 |

| J50x40R-1.6 | 50 | 40 | 1.6 | 1 | 0.384 |

| CN-FT0102 | 60 | 38 | 3 | 1.5 | 0.769 |

| J50.8x38.1R-6.35 | 50.8 | 38.1 | 6.35 | 6.35 | 1.444 |

| J75x20R-1.6 | 75 | 20 | 1.6 | 1 | 0.406 |

| J75x50R-4 | 75 | 50 | 4 | 0.7 | 1.311 |

| J76.2x50.8R-6.35 | 76.2 | 50.8 | 6.35 | 6.35 | 2.1 |

| J90x20R-1.8 | 90 | 20 | 1.8 | 1 | 0.528 |

| J100x20R-1.8 | 100 | 20 | 1.8 | 1 | 0.577 |

| J100x50R-4 | 100 | 50 | 4 | 0.7 | 1.583 |

| J101.6x76.2R-6.35 | 101.6 | 76.2 | 6.35 | 6.35 | 2.974 |

| CEN0014 | 120 | 100 | 10 | 5 | 5.708 |

| J125x50R-6 | 125 | 50 | 6 | 0.7 | 2.748 |

| CEN0006 | 130 | 100 | 10 | 5 | 5.977 |

| J150x50R-8 | 150 | 50 | 8 | 1.4 | 4.162 |

| J203.2x101.6R-12.7 | 203.2 | 101.6 | 12.7 | 12.7 | 10.147 |

| HK-UN0003 | 300 | 152 | 13 | 10 | 15.524 |

| J304.8x76.2R-9.53 | 304.8 | 76.2 | 9.53 | 12.7 | 9.687 |

Irregular angle aluminum mold dimensions

-

We not only have standard aluminum corner molds, but also a large stock of irregular-shaped aluminum corner molds such as rounded corners, flanges, and reinforcing ribs, which can be directly produced and shipped without the need for new mold making.

| Model | A (mm) | B (mm) | T (mm) | R / R1 (mm) | Classification type |

| HM26893 | 28 | 28 | 3 | R5/R2 | Rounded |

| CN-FT0103 | 60 | 41 | 3 | R1 | Rounded |

| J60×60-10E | 60 | 60 | 10 | R5 | Rounded |

| J76.2×76.2R-6.35-I | 76.2 | 76.2 | 6.35 | R12.7/R6.35 | Rounded |

| YXL5×25×25×R2 | 25 | 25 | 5 | R2 | Rounded |

| YXL12×70×100×R5 | 70 | 100 | 12 | R5 | Rounded |

| YXL 3×21.8×44.5 | 21.8 | 44.5 | 3 | - | Rounded |

| YXL30×70×8 | 30 | 70 | 8 | - | Rounded |

| YXL15×76×115 | 76 | 115 | 15 | - | Rounded |

| YXL 50.8×38.1×3.2 | 50.8 | 38.1 | 3.2 | R | Rounded |

| YXL4×5.2×19.5×38.79 | - | - | - | - | Flanged/Lip |

| YXL 6.6×32×60 | - | 32 | - | - | Flanged/Lip |

| YXL 6.6×7.6×37×41.1 | - | - | - | - | Flanged/Lip |

| YXL10×30×40×R5 | 30 | 40 | 10 | R5 | Flanged/Lip |

| YXL7×14×51×34.9 | 7 | 14 | - | - | Flanged/Lip |

| YXL10×32×64 | 10 | 32 | - | - | Flanged/Lip |

| YXL25×151×160 | 25 | 151 | - | - | Flanged/Lip |

| YXL 27×56×148 | 27 | 56 | - | - | Flanged/Lip |

| YXL12×70×100×R5 | 70 | 100 | 12 | R5 | Flanged/Lip |

| YXL5×20×20×R2 | 5 | 20 | 20 | R2 | Flanged/Lip |

| YXL 32.6×54.6×17.6 | 32.6 | 54.6 | 17.6 | - | Flanged/Lip |

| YXL3×22.5×24 | 3 | 22.5 | twenty four | - | Reinforced/Stepped/Grooved |

| YXL4×25×40 | 4 | 25 | 40 | - | Reinforced/Stepped/Grooved |

| YXL6×46×11×16 | 6 | 46 | 11 | - | Reinforced |

| YXL7×17.7×104 | 7 | 17.7 | - | - | Reinforced |

| YXL9×26×36×8 | 9 | 26 | 36 | - | Reinforced |

| YXL10×50×8×68 | 10 | 50 | 8 | - | Stepped |

| YXL11×40×81 | 40 | 81 | - | - | Reinforced |

| YXL12×38×90 | 38 | 90 | - | - | Reinforced |

| YXL 13×45.5×67.5 | 45.5 | 67.5 | - | - | Stepped |

| YXL15×90×90 | 90 | 90 | - | - | Reinforced |

| YXL20×150×205 | 150 | 205 | - | - | Reinforced |

| YXL30×80×12 | 30 | 80 | 12 | - | Grooved |

| YXL 34×154×142 | 154 | 142 | - | - | Stepped |

Custom & Non-Standard Angles

In addition to standard equilateral, unequal-sided, and irregularly shaped angle aluminum profiles with existing molds, we also undertake custom mold making for various special structural angle aluminum profiles. Many manufacturers only provide standard L-shaped angle aluminum profiles, while we not only have a large number of ready-made molds, but can also produce non-standard sizes, non-90° angles, angle aluminum profiles with ribs, angle aluminum profiles with flanges, or multi-stage combination structures according to customer drawings.

Customizable angle aluminum types include:

- Non-90° angle aluminum (such as 60°, 120°, 135°, etc.)

- Special size (A ≠ B, and not a standard size)

- Flanged/clasp-edge aluminum angle (for slots, connections, or reinforcement)

- Reinforcing ribs/support ribs (used to improve load-bearing capacity)

- Stepped, recessed, and multi-layered angle aluminum

- Aluminum angles with holes, mounting grooves, and sliding grooves

- Extra-wide, extra-thick, and extra-long large angle aluminum structural components (extruded up to 6 meters)

Customization methods we support:

| Customer provided | We completed |

| CAD drawings / PDF dimension drawings | Mold Design and Extrudability Assessment |

| Sample or physical object | Reverse modeling, copying the mold |

| Basic Dimensions Sketch | Assist in optimizing the ratio of structure to wall thickness |

| Surface treatment requirements | Anodizing, sandblasting, electrophoresis, spraying and other processing |

If you don't have existing molds but still wish to produce special angle aluminum profiles, simply provide the dimensions or drawings, and we can design molds and extrude them for you. We offer rapid response from single-piece samples to mass production.

Why Choose Chalco Aluminum Angles

Chalco offers more than just standard angle aluminum. With a complete mold system, mature extrusion technology, and stable quality control, we can quickly deliver standard and irregular angle aluminum to meet the strength, precision, and appearance requirements of industrial applications.

1. Complete mold supply, saving on mold making costs.

- We have a large number of aluminum molds with equal sides, unequal sides, rounded corners, flanges, and reinforcing ribs.

- Most specifications can be manufactured directly without requiring customers to bear mold costs.

- Supports mainstream industrial aluminum alloys such as 6061, 6063, 6082, and 7075.

2. Supports customized non-standard angle aluminum

- If no existing mold is available, production can be carried out by making a mold according to the drawings.

- Customizable non-90° angle, thick edge, stepped, groove, and multi-segment structural aluminum angles are available.

- The mold production cycle is approximately 7–15 days, and the sampling process can be completed in 10–20 days.

3. Mature technology and controllable dimensional accuracy.

- Capable of extrusion, stretching, straightening, CNC precision machining, punching, and cutting.

- Surface treatment options include: anodizing, sandblasting, electrophoresis, and powder coating.

- The straightness, angular deviation, and wall thickness accuracy of the profiles all conform to ASTM/EN standards.

4. Full-process quality inspection

- Size & Surface Inspection

- Chemical composition analysis

- Tensile strength, yield strength, and elongation tests

- Anode film thickness, hardness, and 3.1 material certification

Contact Chalco today to check available dies, optimize your aluminum angle design, and receive a fast quotation for your project.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote