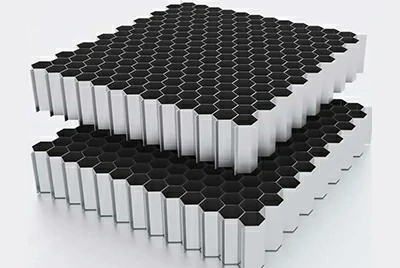

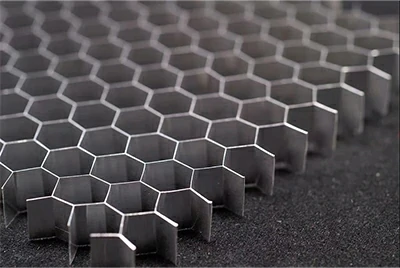

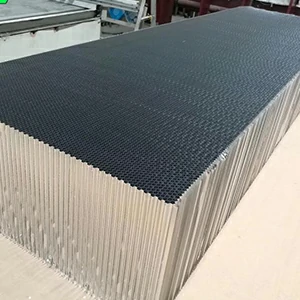

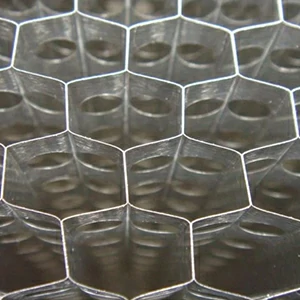

5052 aluminum honeycomb core material is a lightweight structural core material made of high-strength 5052-H18 aluminum alloy foil through precision rolling, bonding and expansion processes. Its interior is arranged in a hexagonal honeycomb shape, with high specific strength, dimensional stability and excellent corrosion resistance, and is particularly suitable for the aerospace field that has extremely high requirements for lightweight and structural reliability.

Chalco can provide 5052 aluminum honeycomb core materials with various structural parameters, support delivery in unexpanded/expanded states, anodizing treatment recommendations, structural parts lamination customization, and supporting professional technical services to meet the structural sandwich application needs of high-end manufacturing customers such as aviation, rail transit and industrial equipment.

Chalco 5052 aluminum honeycomb core parameters overview

In order to meet the requirements of different structural designs and composite sandwiches, Chalco provides 5052 aluminum honeycomb core materials in a variety of specifications and combinations, which can be delivered in both unexpanded and expanded states. Core parameters such as side length, core thickness, flute thickness and density can be customized according to customer needs, and surface treatment and material consistency testing supporting services are provided.

Instant Quote| Standard | Maximum | Tolerance | ||||

| inches | mm | inches | mm | inches | mm | |

| Ribbon (L) | 48 | 1219 | 100 | 2540 | +2.0 / -0.0 | +50.8 / -0.0 |

| Transverse (W) | 96 | 2438 | 144 | 3658 | +4.0 / -0.0 | +101.6 / -0.0 |

| Thickness (T) | - | - | 35 | 889 | ||

| up to 4 inches (102mm) T | ±0.005 | ±0.127 | ||||

| over 4 inches (102mm) T | ±0.062 | ±1.575 | ||||

| Density | Check [mechanical characteristics chart] | ±10% | ||||

| Cell Size | Check [mechanical characteristics chart] | ±10% | ||||

- Standard size: 48" x 96"; 48" x 120"; 48" x 144"; 24" x 96"; 36" x 96"; 60" × 120"; 1220 x 2440; 1220 x 3050; 1220 x 3660; 610 x 2440; 915 x 2440; 1524 x 3050

- Standard state: 5052-H18 high-strength hard foil, high structural density, good performance consistency

- Delivery form: Unexpanded/expanded/pre-cut blocks can be delivered in fixed length and width according to the drawing, which is convenient for bonding and assembly of composite panels.

- Surface: Bare foil/XR1 anti-corrosion coating/Perforated/anodized coating (anodization is recommended for aviation interlayer to improve corrosion resistance and bonding strength)

- Support CAD drawing/sample analysis: provide structural strength and connection method evaluation

- Provide consistency test data: side length error, thickness tolerance, batch density, mechanical properties, etc.; jump to view [Technical Parameters Detailed Explanation];

- Perfect quality system and aviation material compliance capabilities: ISO 9001, AS9100, RoHS / REACH, GB/T 19001, GJB 9001, Nadcap (NDT / Heat Treating / Welding / Materials Testing) …

Chalco 5052 honeycomb core patented product type

In order to meet the needs of complex sandwich structures, nonlinear surfaces and special functionalities, Chalco has developed a variety of special structural types based on 5052 aluminum alloy honeycomb core materials, which are widely used in aerospace precision structural parts, aircraft auxiliary system sandwiches, cabin buffer modules and high-performance composite structures.

-

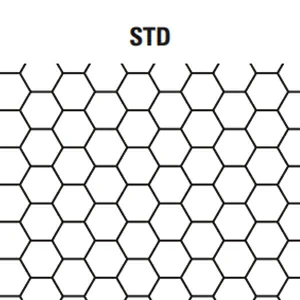

5052 STD Standard Configuration Honeycomb Core

The most common unit form, hexagonal equilateral arrangement, has uniform compressive and shear strength in all directions and is suitable for most structural laminates and energy absorbing elements.

-

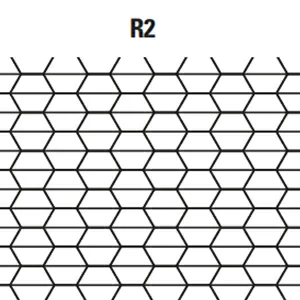

5052 (cut hexagonal honeycomb structure R2) honeycomb core

The standard hexagon is cut horizontally to enhance the mechanical properties in a specific direction. It is often used in structural parts that require uniaxial force optimization.

-

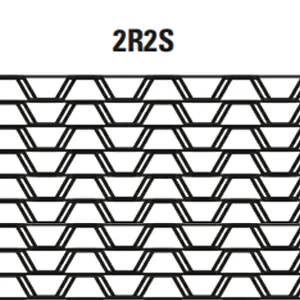

5052 reinforced staggered cut structure 2R2S honeycomb core

Based on the R2 structure, a staggered stacking arrangement is adopted to further enhance its compression and impact resistance, making it suitable for scenarios with high energy absorption or concentrated force.

-

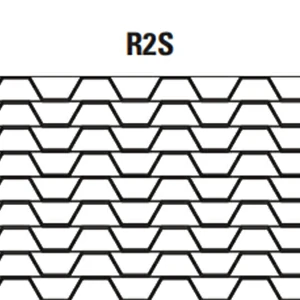

5052 multi-axis staggered honeycomb structure R2S honeycomb core

The unit axial design with alternating arrangement significantly enhances the multi-directional shear performance and is suitable for use in complex loading environments or for supporting blocky structural parts.

-

Microcell honeycomb core

Microcell honeycomb core

Honeycomb side length is less than 1.6mm, high density, strong rigidity, excellent energy absorption performance

Advantages: Improve the vibration resistance and stability of complex structural parts, suitable for high-load sandwich parts in narrow spaces

-

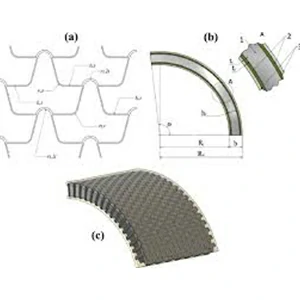

Curved/Pre-formed core

Curved/Pre-formed core

The mold can be pre-bent to fit the three-dimensional curved substrate

Advantages: Reduce installation stress, improve assembly efficiency, suitable for hot pressing composite and curved surface structural parts

-

Block form core

Block form core

Honeycomb thickness ≥ 150mm, supports layered composite or integral one-piece molding

Advantages: Provides good energy absorption and middle support capabilities, suitable for pressure and collision resistance conditions

-

Perforated honeycomb core

Perforated honeycomb core

The surface of the corrugated sheet is perforated to form a ventilation and pressure-permeable structure

Advantages: Optimize thermal management and acoustic environment, suitable for internal layers of aerospace and electronic structures

In order to meet the requirements of different structural spaces, mechanical properties and process forming, 5052 honeycomb core materials can provide a variety of product forms and a variety of unit structure types of honeycomb cores to adapt to a variety of complex application environments and performance requirements.

To view the characteristics and selection recommendations of various honeycomb structures, please jump to [Honeycomb Core Structure Selection Guide]

Instant QuoteAnalysis of the performance advantages of 5052 honeycomb core materials

As the preferred core material for high-reliability structures, 5052 aluminum honeycomb core material performs well in multiple key dimensions such as strength, corrosion resistance, and dimensional stability . It is significantly better than conventional alloys such as 3003 and 5056, and is widely used in aviation, rail transit, drones, and composite structure interlayers.

High specific strength, optimal choice for structural weight reduction: Made of H18 hard foil, it has higher compression and shear strengths, and is suitable for repeated load conditions such as cockpit floors and avionics compartments, taking into account both lightness and strength.

Excellent corrosion resistance, adaptable to harsh environments: Aluminum-magnesium alloys have strong oxidation resistance and are resistant to marine and industrial atmospheric corrosion. They are better than 3003 series and are suitable for humid, high-salt, and hot and cold cycle scenarios.

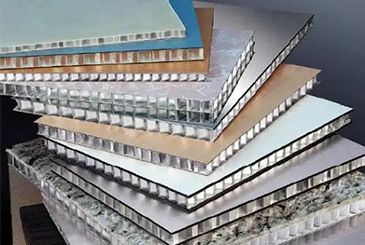

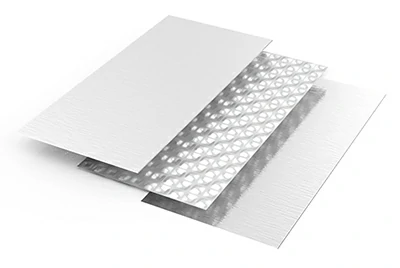

Strong processing adaptability and compatible with a variety of panels: The honeycomb structure is stable and can be well matched with aluminum panels, CFRP/GFRP and other composite panels, and supports hot pressing, anodizing and gluing.

Stable dimensions, suitable for high-precision structures: small warpage, high expansion consistency, suitable for slide rails, equipment housings, symmetrical structural plates, etc. with high assembly precision requirements.

Good batch consistency, suitable for large-scale applications: Chalco's own aluminum foil system ensures batch control and supports large-scale aviation sandwich parts production and standardized component integration.

Chalco 5052 honeycomb core material processing and supply capabilities

In order to meet the high requirements of aerospace and high-end equipment fields for honeycomb core material structure accuracy, consistency and adaptability, Chalco has established a complete set of 5052 aluminum honeycomb core material processing and supply system, covering the whole process from aluminum foil raw materials → honeycomb forming → post-processing → precision delivery, which can realize customized structural design, stable batch production and rapid delivery worldwide.

Processing service capabilities

Expansion: Supports standard expansion, over-expansion and directional expansion control to ensure the core is flat, uniform and warp-free

Precision cutting: Cutting to a fixed length and width according to the drawing size, suitable for large-area paneling and molding

Preforming: Coordinate with the mold to perform curved surface bending and local deformation processing, suitable for complex cabin sections or curved surface structure composite parts

Hole opening/punching: Processing special structures such as honeycomb vents and diversion holes to support thermal management and air pressure regulation structure design

Core thickness laminated composite: multiple layers are laminated into a thick core, suitable for buffer/pressure-bearing structures

Surface treatment package

Anodizing: Enhances corrosion resistance, improves adhesion with adhesives, and meets aviation process requirements

Chemical cleaning and sealing treatment: Adapt to the bonding system, improve the stability of interface adhesion, and enhance the structural integrity of the composite board

Coating support: Surface coating pretreatment can be performed as needed, suitable for non-aviation directions such as architecture/transportation/interior

Supply capacity and support

Delivery status:

- Unexpanded state → convenient for customers to expand by themselves and reduce transportation volume

- Expanded state → ready-to-install delivery, suitable for batch composite sandwich lamination

- Module cutting state → Suitable for hot pressing and laminating with panel

Packaging: Industrial strong protective corrugated box + positioning foam partition + anti-oxidation vacuum film, support export wooden box reinforcement

Delivery control: conventional specifications can be delivered within 7-10 working days at the earliest, and the delivery time of complex structures can be evaluated and confirmed

Certification and documentation: density test, side length/thickness test report, anodizing record, batch traceability information can be attached

Chalco offers integrated honeycomb core services from raw material to molding and assembly, aligned with the production rhythm of complex aerospace structures. We also provide related products to support one-stop sandwich structure solutions. Submit your drawings or requirements for technical support and quotations.

Instant QuoteChalco 5052 honeycomb core material application cooperation areas

5052 aluminum honeycomb core material has become an irreplaceable core material for sandwich structures in a variety of aerospace equipment due to its high specific strength, corrosion resistance and excellent dimensional stability. Its typical applications include multiple modules such as aircraft main/secondary structures, avionics cabins, internal system support structures and ground support equipment, helping to reduce the weight of the entire aircraft, improve reliability and enhance structural design flexibility.

Aircraft cockpit and cabin interior

Application areas: floor interlayers, ceiling modules, side wall decorative panels, luggage compartment linings, etc.

Functional value: Reduce weight and noise, stable structural strength; hot-pressed with aluminum plate/GFRP surface material to form honeycomb sandwich panels, easy to assemble in batches

Avionics equipment bay and system support module

Application areas: instrument back panel, control module base, ventilation and heat conduction sandwich panel

Functional value: good dimensional stability and bonding performance, adapting to the multiple structural requirements of heat conduction/air conduction/seismic resistance, ensuring the reliable operation of the avionics system

Satellite structures and spacecraft internal supports

Application areas: load platform core, instrument support wall panels, buffer filling interlayer

Functional value: It can be designed as a thick core structure to improve the buffering energy absorption capacity and the mechanical support of the middle section module, suitable for long-term service under high and low temperature alternation and weightlessness conditions

Engine cover and streamlined skin structure

Application areas: air intake fairing, engine thermal insulation lining, nose streamline structure interlayer

Functional value: Supports pre-bent honeycomb core materials to fit complex curved surfaces, maintains a smooth structural appearance, is resistant to high-frequency thermal expansion and contraction environments, and is suitable for a variety of composite surface materials

UAV/General aviation lightweight structural parts

Application areas: Wing sub-beam sandwich, main shell internal buffer, tail connecting plate

Functional value: Lightweight and high rigidity, convenient for the development of special-shaped composite structures, supporting rapid prototyping and sample iteration

Rail transit and high-end industrial equipment

Application: Train floor interlayer, sound insulation board, industrial equipment bulkhead structural core material

Functional value: Provides excellent corrosion resistance and composite structural stability, suitable for high-performance interior panel systems that require structural weight reduction and fire insulation.

Detailed explanation of technical parameters of Chalco 5052 new honeycomb material

| Mechanical Characteristics (Typical Values – US units) | |||||||||

| Stabilized Compressive | Crush | Shear | Shear | ||||||

| Strength | Strength | Strength | Modulus | ||||||

| lbs/ft3 – inches – inches | psi | psi | psi | ksi | |||||

| L | W | L | W | ||||||

| 75° F | 350° F | 75° F | 75° F | 350° F | 75° F | 350° F | 75° F | ||

| 3.1 – 1/8 – .0007 | 305 | 200 | 145 | 215 | 145 | 132 | 90 | 32 | 16 |

| 4.5 – 1/8 – .0010 | 580 | 380 | 270 | 345 | 240 | 225 | 150 | 51 | 25 |

| 6.1 – 1/8 – .0015 | 1030 | 660 | 450 | 565 | 400 | 345 | 220 | 77 | 37 |

| 8.1 – 1/8 – .0020 | 1575 | 1075 | 760 | 810 | 575 | 540 | 310 | 112 | 50 |

| 10.0 – 1/8 – .0025 | 1875 | 1300 | 1070 | 1075 | 810 | 610 | 415 | 140 | 60 |

| 12.0 – 1/8 – .0030 | 2920 | 1550 | 1400 | 1955* | 1300* | 950* | 440 | 160 | 75 |

| 2.6 – 5/32 – .0007 | 245 | 150 | 105 | 170 | 110 | 102 | 80 | 24 | 12 |

| 3.8 – 5/32 – .0010 | 415 | 280 | 210 | 275 | 200 | 168 | 140 | 41 | 20 |

| 2.0 – 3/16 – .0007 | 180 | 100 | 70 | 122 | 80 | 71 | 65 | 17 | 9 |

| 3.1 – 3/16 – .0010 | 340 | 200 | 145 | 215 | 145 | 128 | 90 | 32 | 16 |

| 4.4 – 3/16 – .0015 | 555 | 375 | 270 | 335 | 235 | 220 | 145 | 50 | 24 |

| 5.7 – 3/16 – .0020 | 870 | 600 | 410 | 465 | 380 | 305 | 200 | 70 | 34 |

| 6.9 – 3/16 – .0025 | 1185 | 780 | 570 | 600 | 500 | 380 | 275 | 91 | 42 |

| 8.1 – 3/16 – .0030 | 1735 | 1075 | 760 | 735 | 575 | 490 | 310 | 112 | 50 |

| 2.3 – 1/4 – .0010 | 215 | 125 | 85 | 145 | 90 | 88 | 70 | 21 | 11 |

| 3.4 – 1/4 – .0015 | 375 | 235 | 160 | 235 | 160 | 145 | 100 | 35 | 18 |

| 4.3 – 1/4 – .0020 | 545 | 365 | 250 | 325 | 235 | 205 | 140 | 48 | 24 |

| 5.2 – 1/4 – .0025 | 770 | 500 | 330 | 415 | 330 | 270 | 160 | 62 | 31 |

| 6.0 – 1/4 – .0030 | 1110 | 650 | 430 | 535 | 390 | 350 | 210 | 75 | 36 |

| 7.9 – 1/4 – .0040 | 1505 | 1025 | 720 | 710 | 550 | 450 | 300 | 108 | 49 |

| 1.6 – 3/8 – .0010 | 98 | 70 | 50 | 88 | 60 | 51 | 35 | 13 | 6 |

| 2.3 – 3/8 – .0015 | 205 | 125 | 85 | 145 | 90 | 88 | 70 | 21 | 11 |

| 3.0 – 3/8 – .0020 | 315 | 190 | 135 | 205 | 140 | 128 | 85 | 30 | 15 |

| 3.7 – 3/8 – .0025 | 415 | 265 | 200 | 255 | 190 | 165 | 105 | 40 | 20 |

| 4.2 – 3/8 – .0030 | 565 | 340 | 240 | 315 | 230 | 205 | 130 | 47 | 23 |

| 5.4 – 3/8 – .0040 | 810 | 540 | 360 | 435 | 355 | 285 | 180 | 66 | 32 |

| 6.5 – 3/8 – .0050 | 1015 | 750 | 510 | 555 | 440 | 360 | 265 | 83 | 40 |

| 4.0 – 1/2 – .0040 | 400 | 320 | 220 | 290 | 220 | 170 | 120 | 44 | 22 |

| Mechanical Characteristics (Typical Values – SI/metric units) | |||||||||

| Stabilized Compressive | Crush | Shear | Shear | ||||||

| Strength | Strength | Strength | Modulus | ||||||

| lbs/ft3 – inches – inches | MPa | MPa | MPa | MPa | |||||

| L | W | L | W | ||||||

| 23° C | 177° C | 23° C | 23° C | 177° C | 23° C | 177° C | 23°C | ||

| 3.1 – 1/8 – .0007 | 2.1 | 1.38 | 1 | 1.48 | 1 | 0.91 | 0.62 | 221 | 110 |

| 4.5 – 1/8 – .0010 | 4 | 2.62 | 1.86 | 2.38 | 1.65 | 1.55 | 1.03 | 352 | 172 |

| 6.1 – 1/8 – .0015 | 7.1 | 4.55 | 3.1 | 3.9 | 2.76 | 2.38 | 1.52 | 531 | 255 |

| 8.1 – 1/8 – .0020 | 10.86 | 7.41 | 5.24 | 5.58 | 3.96 | 3.72 | 2.14 | 772 | 345 |

| 10.0 – 1/8 – .0025 | 12.93 | 8.96 | 7.38 | 7.41 | 5.58 | 4.21 | 2.86 | 965 | 414 |

| 12.0 – 1/8 – .0030 | 20.13 | 10.69 | 9.65 | 13.48* | 8.96* | 6.55* | 3.03* | 1103 | 517 |

| 2.6 – 5/32 – .0007 | 1.69 | 1.03 | 0.72 | 1.17 | 0.76 | 0.7 | 0.55 | 165 | 83 |

| 3.8 – 5/32 – .0010 | 2.86 | 1.93 | 1.45 | 1.9 | 1.38 | 1.16 | 0.97 | 283 | 138 |

| 2.0 – 3/16 – .0007 | 1.24 | 0.69 | 0.48 | 0.84 | 0.55 | 0.49 | 0.45 | 117 | 62 |

| 3.1 – 3/16 – .0010 | 2.34 | 1.38 | 1 | 1.48 | 1 | 0.88 | 0.62 | 221 | 110 |

| 4.4 – 3/16 – .0015 | 3.83 | 2.59 | 1.86 | 2.31 | 1.62 | 1.52 | 1 | 345 | 165 |

| 5.7 – 3/16 – .0020 | 6 | 4.14 | 2.83 | 3.21 | 2.62 | 2.1 | 1.38 | 483 | 234 |

| 6.9 – 3/16 – .0025 | 8.17 | 5.38 | 3.93 | 4.14 | 3.45 | 2.62 | 1.9 | 627 | 290 |

| 8.1 – 3/16 – .0030 | 11.96 | 7.41 | 5.24 | 5.07 | 3.96 | 3.38 | 2.14 | 772 | 345 |

| 2.3 – 1/4 – .0010 | 1.48 | 0.86 | 0.59 | 1 | 0.62 | 0.61 | 0.48 | 145 | 76 |

| 3.4 – 1/4 – .0015 | 2.59 | 1.62 | 1.1 | 1.62 | 1.1 | 1 | 0.69 | 241 | 124 |

| 4.3 – 1/4 – .0020 | 3.76 | 2.52 | 1.72 | 2.24 | 1.62 | 1.41 | 0.97 | 331 | 165 |

| 5.2 – 1/4 – .0025 | 5.31 | 3.45 | 2.28 | 2.86 | 2.28 | 1.86 | 1.1 | 427 | 214 |

| 6.0 – 1/4 – .0030 | 7.65 | 4.48 | 2.96 | 3.69 | 2.69 | 2.41 | 1.45 | 517 | 248 |

| 7.9 – 1/4 – .0040 | 10.38 | 7.07 | 4.96 | 4.9 | 3.79 | 3.1 | 2.07 | 745 | 338 |

| 1.6 – 3/8 – .0010 | 0.68 | 0.48 | 0.34 | 0.61 | 0.41 | 0.35 | 0.24 | 90 | 41 |

| 2.3 – 3/8 – .0015 | 1.41 | 0.86 | 0.59 | 1 | 0.62 | 0.61 | 0.48 | 145 | 76 |

| 3.0 – 3/8 – .0020 | 2.17 | 1.31 | 0.93 | 1.41 | 0.97 | 0.88 | 0.59 | 207 | 103 |

| 3.7 – 3/8 – .0025 | 2.86 | 1.83 | 1.38 | 1.76 | 1.31 | 1.14 | 0.72 | 276 | 138 |

| 4.2 – 3/8 – .0030 | 3.9 | 2.34 | 1.65 | 2.17 | 1.59 | 1.41 | 0.9 | 324 | 159 |

| 5.4 – 3/8 – .0040 | 5.58 | 3.72 | 2.48 | 3 | 2.45 | 1.97 | 1.24 | 455 | 221 |

| 6.5 – 3/8 – .0050 | 7 | 5.17 | 3.52 | 3.83 | 3.03 | 2.48 | 1.83 | 572 | 276 |

| 4.0 – 1/2 – .0040 | 2.76 | 2.21 | 1.52 | 2 | 1.52 | 1.17 | 0.83 | 303 | 152 |

5052 honeycomb core structure selection guide and FAQs

In actual engineering projects, the selection of honeycomb core structure needs to be accurately matched according to the force direction, application environment and panel matching method. The following are common structural type recommendations and answers to typical questions to help you quickly determine the applicable solution.

Instant QuoteRecommendations for selecting common 5052 honeycomb core material structure types

| Structure Type | Performance characteristics | Recommended application scenarios |

| STD (Standard Hexagon) | Uniform in all directions, light and high strength | Conventional sandwich structures such as floors, interior panels, equipment housings, etc. |

| R2 (halved hexagon) | Transverse shear enhancement, suitable for plane force | Slide support plate, avionics module, vehicle side wall |

| 2R2S (offset cut structure) | Strong energy absorption, enhanced compression and multi-axis load bearing | Anti-collision structure, battery compartment, cabin buffer zone |

| R2S (multi-axis staggered structure) | High multi-directional shear stiffness | Curved composite parts, structural transition sections, insert bases |

| R2S[DG] (different thickness dislocation structure) | Lightweight and strength synergistic optimization | Optoelectronic carriers, aerospace cabin walls, functional composite laminates |

- If you are looking for strength-to-weight ratio + processability, STD / R2 is preferred

- If you need energy absorption + impact resistance, give priority to 2R2S / R2S

- For complex structures or multi-directional loading, it is recommended to use R2S / R2S[DG]

- All structures can be configured with different core hole sizes, densities and perforation methods according to project requirements

How to order 5052 honeycomb core material? How to understand the ordering parameters of 5052 honeycomb core material?

PAA – 5052 – 3.1 – 3/16 – N – E

PAA – 5052 – Density – Pixel Size – Perforation Status – Dilation Status

The meaning of each parameter is as follows:

| Product code | PAA | Indicates the honeycomb core product line (PAA-CORE®) |

| Alloy type | 5052 | Use 5052-H18 aluminum foil |

| density | 3.1 | The unit is pcf (pounds per cubic foot) |

| Pixel size | 3/16 | Cell aperture, in inches |

| Perforation status | N or P | N = Non-perforated, P = Perforated |

| Expansion state | E or U | E = Expanded, U = Unexpanded |

What are the advantages of 5052 honeycomb core compared with 3003 and 5056?

5052 has higher strength and better corrosion resistance, and is particularly suitable for extreme environments such as humidity, high salt, and hot and cold cycles. It is widely used in aviation and rail transit.

Can I buy in small quantities? Can I customize?

Yes. Chalco can provide a variety of delivery methods such as unexpanded, expanded, pre-cut blocks, pre-formed, etc., and supports small batch proofing and customization according to drawings.

What panel materials can it be used in combination with?

5052 honeycomb core is suitable for aluminum plates, CFRP, GFRP, stainless steel panels, etc. It can be composited by gluing, hot pressing, etc. The surface state can be selected from bare foil/anodized/XR1 coating.

Can you provide test reports and quality certificates?

We can provide COC, COA, batch test data and third-party reports (such as aerospace material research institutes/research institutes) to meet the compliance requirements of aviation and military projects.

Does the honeycomb core support punching?

Yes. We can provide perforated honeycomb core materials in various specifications for functional scenarios such as weight reduction, ventilation, and pressure relief. They are also suitable for the design of energy-absorbing layers of aviation composite panels.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote