Aluminum Alloy Curtain Wall Systems Overview

Aluminum alloy curtain wall systems, consisting of aluminum alloy frames, panels, and connecting fittings, are the most commonly used non-load-bearing facade structures in modern architecture. They can be combined with various facade materials such as glass, aluminum panels, honeycomb panels, and stone to achieve a safe, stable, and modern facade effect. With their lightweight, weather-resistant, and flexible design characteristics, they are widely used in commercial buildings, airports, exhibition halls, and public buildings.

Why Aluminum Curtain Wall Systems?

- Lightweight and highly weather-resistant: Lighter weight and stronger corrosion resistance reduce the load on the main structure, making it suitable for high-rise buildings and complex environments.

- High machinability and design freedom: It can be bent, slotted, shaped and formed into large sheets, supporting a variety of façade designs.

- Advantages in construction efficiency and maintenance costs: Aluminum is easy to process, quick to install, has a stable surface, and low long-term operation and maintenance costs.

- Excellent sustainability: Aluminum has a high recycling rate and is a widely used curtain wall material in green building systems.

Main Types of Aluminum Curtain Wall Systems

Modern aluminum curtain wall systems employ various structural forms depending on installation methods, facade appearance, and project scale. Chalco provides comprehensive material solutions and engineering support for all types of curtain wall systems, achieving excellent collaboration between design, production, and on-site installation to ensure the overall performance and consistency of the facade system.

Stick Curtain Wall

Modular curtain walls are widely used for their flexibility and adaptability in commercial and office buildings. Chalco aluminum frame systems support hybrid façades combining glass with solid aluminum or honeycomb panels.

Unitized Curtain Wall

Unitized curtain walls are widely used in high-rise and large-scale buildings for their high flatness and system integration requirements. Chalco frame systems support large glass panels with honeycomb or solid aluminum cladding in solid zones.

Exposed Frame Curtain Wall

Exposed frame curtain walls feature clear lines and easy maintenance, making them suitable for commercial and office buildings. Chalco systems support glass panels and metal panels for borders, corners, and shading areas.

Concealed Frame Curtain Wall

Frameless curtain walls deliver a clean, unified façade by concealing frames, ideal for modern designs. Chalco precision systems support large glass areas with solid aluminum, honeycomb, or sandwich panels in solid zones.

Semi-Concealed Curtain Wall

Semi-concealed frame curtain walls balance clean façades with subtle frame rhythm, suitable for commercial and segmented façades. Chalco profiles support horizontal or vertical semi-concealed systems with glass or metal panels.

Chalco's Aluminum Alloy Curtain Wall Material Solutions

Curtain wall engineering places stringent requirements on material compatibility, stress stability, and processing precision. Modern building curtain walls typically consist of three core materials:

① Aluminum alloy frame profiles

② Glass/Metal Panels

③ Accessories & Hardware.

Chalco provides stable and reliable material support for various curtain wall systems, including Stick, Unitized, exposed frame, and concealed frame, through a complete aluminum alloy material system, achieving overall consistency in facade structure, appearance, and installation efficiency.

Aluminum Frame Profiles

The frame is the load-bearing core of the curtain wall system, determining the panel installation accuracy and the overall stability of the facade. Chalco can customize 6063-T5/T6 extruded profiles to meet project requirements, including key components such as vertical frames, horizontal beams, pressure plates, and cover plates. Customizable projects include:

- Customized cross-section based on wind load, panel thickness, and installation depth.

- The profile interface can be seamlessly matched with accessories and panel systems.

- Supports various weather-resistant surface treatments such as anodizing, PVDF, and powder coating.

Curtain Wall Structural Accessories and Hardware

The reliability of curtain wall connections depends on the compatibility of fittings with profiles and panels. Chalco provides project-level components to ensure the stability of the facade structure under long-term stress, temperature variations, and wind pressure. Chalco offers standard and custom components to match the profile structure, including:

- Supports, corner brackets

- Hanging ornaments/hooks

- Aluminum/Stainless Steel Connectors

- Fasteners for panel mounting

A unified source can reduce node mismatches, batch differences, and installation deviations, ensuring the integrity and long-term stability of the façade.

Metal Curtain Wall Panels

In aluminum curtain wall systems, transparent areas typically use glass panels, while equipment areas, shielding areas, corner areas, floor zones, and other non-transparent areas often use metal panels as solid surface materials. Chalco's aluminum-based curtain wall panels can be flexibly combined with glass curtain walls to form a unified visual and structural façade system.

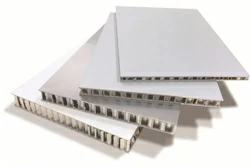

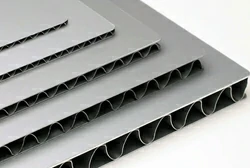

These panels are lightweight, highly flat, and possess excellent weather resistance, meeting the engineering requirements for large-format, irregularly shaped, and solid partitioned projects. Available types include:

- Solid aluminum panel

- Aluminum honeycomb panel

- Sandwich/Insulated Aluminum Panel

- 3D Core / Beaded Core Panels

- Perforated aluminum sheet, shaped aluminum sheet

All aluminum panels can be customized in terms of thickness, specifications, edge folds, reinforcement structures, and surface treatments to ensure high consistency with the frame profiles and facade segmentation.

Aluminum Curtain Wall Fabrication Capabilities and Engineering Support

To ensure higher precision, compatibility, and stability of the curtain wall system during on-site installation, Chalco provides end-to-end support from factory prefabrication to engineering collaboration, bringing complex processes to the factory to significantly reduce on-site risks and improve façade quality.

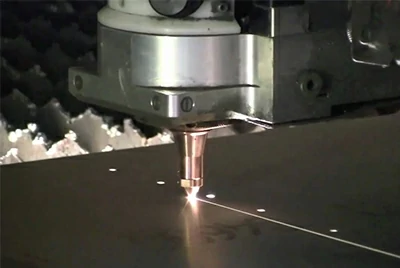

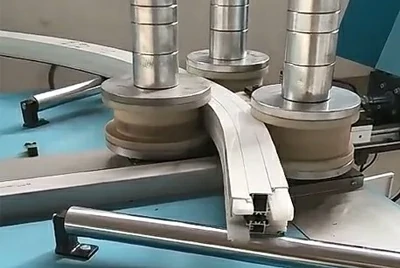

Factory Prefabrication

Chalco offers a full range of deep processing services for aluminum sheets and profiles, including CNC cutting, grooving, bending, edge bending, pre-drilling, reinforcing rib welding, and large-plate flatness control. This significantly reduces on-site cutting and rework, ensuring the accuracy of complex nodes and system stability.

Surface Finishes & Consistency

We can provide CNC cutting, grooving, bending, edge folding, pre-drilling, and reinforcing rib welding, and adopt unified batch management to ensure that large-area curtain walls maintain a high degree of consistency in color difference, gloss and weather resistance.

Engineering Coordination and Technical Support

It provides collaborative support such as node refinement suggestions, panel layout and edge folding scheme optimization, hole planning, and corner and edge finishing node matching, so that frame profiles, metal panels and accessories meet the installation matching standards before leaving the factory, reducing on-site adjustments and improving overall installation efficiency.

Chalco Aluminum Curtain Wall System Collaboration Project Showcase

Chalco provides aluminum alloy frame profiles, metal panels, and prefabrication support for various curtain wall projects worldwide, delivering superior facade performance and more stable construction results through material consistency and engineering capabilities.

Commercial complex and office building projects

Modern commercial facades often use a combination of glass and aluminum panels, requiring strict control over the flatness and color difference of the large panels.

In this project, Chalco's large-format honeycomb panels, solid aluminum panels, and custom frame profiles significantly improved the consistency and visual flatness of the facade, effectively reducing on-site adjustments and rework.

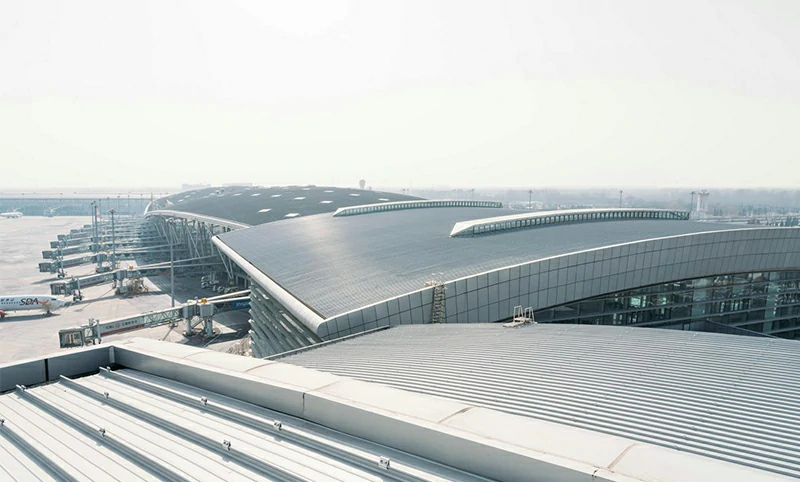

Airport, exhibition hall and transportation hub projects

These types of buildings are large in scale and subject to high wind loads, requiring materials that are both lightweight and structurally reliable.

In this project, Chalco's honeycomb panels, 3D Core panels, and prefabrication techniques such as pre-drilling/bending significantly improved the efficiency of curtain wall installation and maintained stable performance under long-term stress.

Hospitals, schools and public service projects

Public buildings emphasize facade durability, color consistency, and ease of maintenance.

In this project, Chalco's PVDF/anodized aluminum panels and matching profiles effectively reduced long-term maintenance costs and ensured the façade maintained a consistent appearance over many years of operation.

Old building renovation / stone replacement projects

The renovation of old curtain walls emphasizes weight reduction, rapid construction, and aesthetic upgrades.

In this project, Chalco's lightweight aluminum panels (solid/honeycomb) and custom-made original modules enabled the rapid replacement of old stone, significantly reducing structural load and shortening the construction period.

Choose Chalco Curtain Wall Materials – Start Your Next Project

Chalco provides engineering projects with enhanced system stability, installation efficiency, and long-term weather resistance through a complete aluminum alloy curtain wall material system (frame profiles + metal panels + installation accessories) and end-to-end prefabrication. Below are our core advantages in actual projects:

- System-level material synergy: The frame profiles, metal panels and accessories are made from the same material system, reducing mismatches at joints, color differences and compatibility issues, making the overall façade performance more stable.

- Standardized engineering supply: Materials are controlled according to the mechanical, dimensional and weather resistance requirements of curtain wall projects, and long-term consistent batch supply is supported to reduce the quality risks of large projects.

- Stable delivery and project adaptation: Improve the reliability of material delivery through standardized processes and traceable quality management, helping projects reduce coordination costs and shorten the construction period.

- More controllable overall costs: Factory prefabrication reduces on-site labor and rework costs, and integrated supply reduces the procurement chain, making the project's TCO (Total Cost of Ownership) more controllable.

Whether it's a brand-new building facade or a renovation project for an existing curtain wall, we can provide you with stable and reliable solutions for aluminum alloy frame profiles, metal panels, and engineered materials. Contact us for project drawing evaluation, samples, and customization support.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote