4×8 feet (1220×2440 mm) aluminum honeycomb panels are the most common and widely used standard size in building curtain walls, interior decoration, transportation, cleanroom systems, and equipment enclosures. Their ease of processing, transport adaptability, and compatibility with system modules make them the most frequently inquired specification for honeycomb panels worldwide.

Price of 4×8 Aluminum Honeycomb Panels

When purchasing 4×8 aluminum honeycomb panels, price is often the primary concern. However, it is common to see large price differences between suppliers for panels of the same size, which can be confusing—especially for first-time buyers.

The reason is that "4×8” defines only the panel dimensions, not its structure or performance. Differences in face sheet thickness, alloy, honeycomb core design, coating system, fire rating, and processing methods directly affect cost and performance, making dimensional comparison alone insufficient.

Main Factors Affecting the Cost of 4×8 Aluminum Honeycomb Panels

I. Aluminum Panel Thickness and Alloy Type

The thickness of the aluminum sheet is a crucial factor in the performance of honeycomb panels. Greater thickness translates to greater rigidity, wind pressure resistance, and flatness stability, but also results in higher material costs.

Commonly used aluminum alloys include 3003, 5005, and 5052; higher alloy grades offer superior corrosion resistance and mechanical properties, but also correspond to different costs.

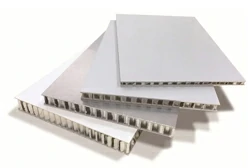

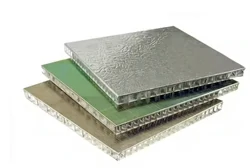

For further information on honeycomb panel structures, please click to view the Honeycomb Panel Product.

II. Honeycomb Core Height, Density, and Pore Size

The honeycomb core structure directly determines the lightweight effect and load-bearing capacity of the honeycomb panel. Differences between different parameters can significantly affect the cost.

Height determines overall thickness and bending stiffness.

Higher density means greater load-bearing capacity, but also higher material costs.

Smaller apertures result in better flatness, but also higher processing costs.

The performance of different alloy honeycomb cores also varies considerably:

III. Surface Coating System and Process Requirements

The coating determines the weather resistance, color stability, and decorative effect of the board.

Powder coating: Suitable for indoor use, lower cost.

PVDF fluorocarbon coating: suitable for curtain wall exterior panels, with strong weather resistance.

Wood grain/stone grain heat transfer printing: used for decorative effects.

Anodizing: produces a high-end look, but requires higher quality substrates and is more expensive.

The cost differences between different coating systems are significant.

IV. Fire Protection Rating Requirements (A2 / B1)

The higher the fire resistance rating, the more stringent the requirements for the material system and manufacturing process. Traditional composite honeycomb panels rely on flame-retardant adhesive films, whose fire resistance directly affects the overall rating.

It's worth mentioning that, in addition to traditional composite honeycomb panels, an upgraded structure more suitable for high-temperature and high-fire-resistance requirements has emerged in the industry—the brazed aluminum honeycomb panel.

These products employ a one-piece metal brazing process without the use of any adhesives. The metal-to-metal connection between the panel and the honeycomb core is achieved through brazing filler metal, making it one of the most technologically advanced structural forms in the honeycomb panel field in recent years.

Chalco has also been continuously investing in research and development in this direction and has achieved stable mass production capabilities for the brazing process of large-size aluminum honeycomb structures, enabling these panels to be applied to more demanding scenarios such as curtain walls, rail transit, and equipment structures.

- High temperature resistance is significantly improved, and metal connections are less prone to decomposition or failure under high temperature conditions.

- It is easier to achieve a high fire resistance rating without relying on flame-retardant adhesive film systems.

- It exhibits superior peel strength and long-term stability, making it suitable for complex environments such as vibration and damp heat.

- The overall structure has stronger continuity and performs more reliably in scenarios with high safety requirements.

V. Complexity of Deep Processing Structure and Technology

In engineering projects, honeycomb panels are typically not shipped as "flat panels," but rather require:

Hemming | Grooving | Back bolt holes | Reinforcing ribs | Tongue and groove, lugs and other structural adaptations.

The more complex the processing, the higher the precision requirements, and the higher the labor and equipment costs.

VI. Application Scenarios Determine Performance Levels

Different applications require different performance, which naturally leads to different cost structures:

| Application scenarios | Typical performance requirements |

| Interior wall panels and ceilings | Aesthetically pleasing, lightweight, and easy to install |

| Building curtain wall | Flatness, wind pressure performance, weather resistance |

| Cleanroom system | Surface cleanliness and sealing |

| Transportation, shipping | Earthquake resistant, fatigue resistant, lightweight |

| Equipment casing | Machining accuracy and structural stability |

| Aircraft honeycomb aluminum structures | Ultra-lightweight, high specific strength, fatigue resistance, fire and temperature resistance |

The higher the engineering level, the higher the requirements for materials and processes.

How to Choose a Suitable Honeycomb Panel Supplier?

Whether 4×8 aluminum honeycomb panels can truly achieve the expected performance ultimately depends on whether the supplier possesses a complete and mature engineering system. A reliable honeycomb panel manufacturer should typically have the following capabilities:

Engineering structural configuration capability

It can make professional configurations in terms of aluminum sheet thickness, honeycomb core density and plate thickness according to requirements such as wind pressure, vibration and cleanliness level.

Stable and reliable composite/brazing process

It has the capabilities of constant temperature pressing, online tension control, and metal brazing to ensure the flatness, peel strength, and long-term stability of the large board.

Complete system adaptation capabilities

It can provide interface structures such as tongue and groove, slot, hanging lug, and back bolt to achieve alignment with curtain wall or equipment system.

Batch consistency and quality traceability system

It can provide traceability data such as color difference control, coating curing, and composite process parameters to meet the stability requirements of large-scale projects.

Supported by multi-industry application experience

Familiar with industry standards such as EN, ASTM, GB, and ISO, and can provide professional selection advice for scenarios such as construction, transportation, shipbuilding, and cleanrooms.

Choose Chalco as Your Supplier for Your Aluminum Honeycomb Panel Project

As a supplier deeply involved in aluminum materials and honeycomb structure manufacturing, Chalco has formed a complete system in aluminum panel rolling, honeycomb core processing, constant temperature composite, metal brazing, deep processing of structural components and engineering-level quality control.

It can provide transparent, verifiable and traceable honeycomb panel solutions for different projects and achieve overall delivery from materials to structure.

If you are evaluating the configuration or selection of 4×8 aluminum honeycomb panels, the Chalco team can provide further technical communication and structural advice based on project requirements to help you obtain a more stable and adaptable engineering solution.

Related Product Gallery

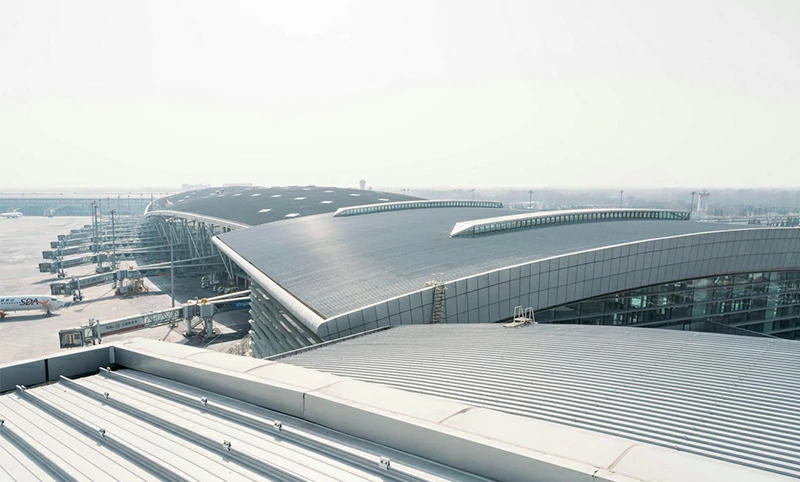

Chalco Honeycomb Aluminum Panel Cooperation Project Showcase

Chalco's honeycomb aluminum panels have been widely adopted in various industries, resulting in numerous project deliveries and covering diverse needs ranging from building facades to industrial equipment. Below are some typical examples of their collaborations:

- Large public building facade systems (airport terminals, convention centers, urban complexes)

- Commercial interior decoration and ceiling systems (shopping mall atriums, brand showrooms, transportation hub interiors)

- Interior structure of rail transit vehicles (body partitions, equipment covers, functional component panels)

- Ships and lightweight transportation equipment (internal bulkheads, compartment panels, lightweight structural components)

- Cleanroom wall panel and modular system (electronics factory, medical facility, food-grade clean space)

- Equipment enclosures and industrial structural components (rack doors, equipment covers, fan/environmental protection equipment housings)

By participating in various projects across these industries, Chalco has accumulated extensive experience in structural design, manufacturing processes, and system integration, enabling it to provide more stable and mature cellular panel solutions tailored to the performance requirements of different engineering scenarios.

If you are comparing 4×8 aluminum honeycomb panel specifications, pricing, or suppliers, contact Chalco with your drawings or requirements for technical evaluation, configuration advice, and a project-based quotation.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote