Chalco is committed to providing customized services for various large-size free forgings and ring-rolled forgings, supporting forging needs of various materials, structures and sizes. We have a complete heavy-duty free forging and CNC ring rolling production line, which can manufacture key forged structural parts weighing more than 80 tons and with a diameter of more than 2.5 meters, which are widely used in energy equipment, engineering machinery, military heavy-duty structures and other fields.

Supported forging material coverage:

- Aluminum alloy: 6061, 7050, 7075, 2219, etc., light weight, high strength, excellent processability

- Titanium alloy: TA2, TC4, Ti-6Al-6V-2Sn, etc., corrosion resistance, high specific strength

- Steel alloy: carbon steel/alloy steel/stainless steel, pressure and heat resistance, stable mechanical properties

Product size range of various large-size forgings (conventional large size, larger size can be customized upon consultation)

| Product Type | Maximum outer diameter/width | Maximum length/height | Maximum unit weight |

| Forged shaft (solid/hollow) | Ø2100 mm | 12 m | ≈30 tons |

| Forged Rings /Rolled Rings | Ø10m | 400 mm Height | ≈5 tons (depending on material) |

| Forging Block / Forging Plate Billet | 1600 × 1600 mm | 1000 mm thick | ≈40 tons |

| Forged disc /flange/round piece | Ø2000 mm | 500 mm thick | ≈10 tons |

| Forged pipe /thick wall forged pipe fittings | Ø1500 mm (outer diameter) | 3000 mm Length | ≈6 tons |

| Forged bars (round bars/special shaped bars) | Ø800 mm (round bar) | 6000 mm Length | ≈4 tons |

| Special shaped parts/special structural parts | Processing according to drawings (free forging) | Support multi-axis machining | Single piece ≤80 tons |

We support multiple delivery modes including blank delivery, rough machining + flaw detection, heat treatment state control, etc. You are welcome to submit drawings for suggestions and quotations.

Instant QuoteChalco customize large size forgings product display

Chalco integrates large-tonnage forging, CNC ring rolling, and multi-axis precision machining technologies to support both free forging and die forging customization based on client drawings, fully meeting the high standards of aerospace, energy equipment, rail transit, and deep-sea engineering industries. With these capabilities, we offer a complete portfolio of large-scale forged products, including forged rings, shafts, blocks, disks, pipes, bars, and custom-shaped structural parts.

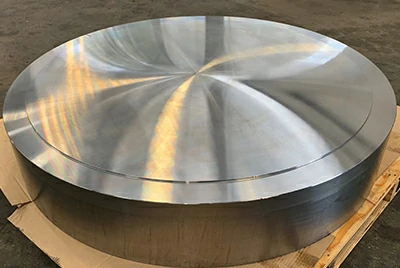

Large diameter forged ring

Integrated free forging and CNC ring rolling for large diameter forged rings with precise grain flow and dimensions. Supports heat treatment and custom sizes.

Max size: OD Ø2500 mm, height 400 mm, weight up to 5 tons (material dependent). Maximum overall size up to 10 meters.

Contact us now

- Bearing forged rings

- Connecting flange

- Turbine base ring

- Reducer housing side ring

- Guide structure ring

- Sealing ring

- Landing gear connection ring

- Tank interface ring

Large size forged shafts - solid/hollow

Chalco supports free forging, die forging and multi-stage coupling forming , has ±0.05mm precision control capability, and is suitable for various structural designs such as straight shafts, stepped shafts, flange shafts, hollow shafts, etc.

Max size: up to 23 meters, unit weight approximately 30 tons.

Contact us now

- Transmission spindle

- Wind turbine main shaft

- Hydraulic cylinder shaft

- Ship propulsion shaft

- Landing gear shaft

- Metallurgical roller shaft

- Steam turbine shaft

- Ship tail shaft

- Reducer spline shaft

- Turbine output shaft

Extra thick forging plate /block

It is suitable for load-bearing components, structural bases and large molds. It can forge regular blocks, non-standard sections and multi-step structures according to drawings, and supports customization of various alloys such as aluminum, titanium, and steel.

Max size: 2000 × 2000 mm, thickness up to 1000 mm, unit weight about 40 tons.

Contact us now

- Large engine mounts

- Mold base

- Box shell

- Track connection block

- Heating support block

- Buffer insulation block

- Clamping positioning body

- Cabin structure block

- Seat bearing block

- Equipment connector

Large size forging discs /flanges/round pieces

It supports free forging, die forging and integral forming processes, and is suitable for high-strength connections, seals and rotating structures. It is often used in system parts such as pressure vessels and high-speed rotors.

Max size: Ø2 600 mm, thickness up to 500 mm, unit weight about 10 tons.

Contact us now

- Gear connecting plate

- Coupling flange

- Turbine cover

- Pump impeller

- Compressor end cover

- Chassis connection plate

- Brake disc substrate

- Hot section insulation plate

- Mould positioning disc

- Cabin interface ring

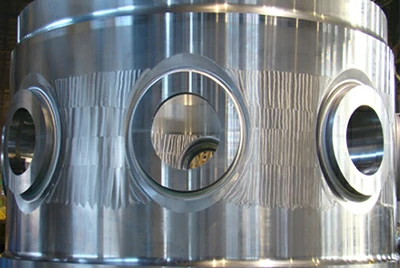

Large diameter forged pipes / thick wall forged pipe fittings

It uses free forging or ring rolling for hollow structures, ideal for high pressure, high temperature, or corrosive environments, with support for aluminum, titanium, alloy steel, and inner hole machining.

Max size: outer diameter Ø1500 mm, length up to 3000 mm, unit weight about 6 tons.

Contact us now

- High pressure pipe joint

- Sealed connection tube

- Propulsion system casing

- Chemical corrosion resistant pipe

- Nuclear reaction interface tube

- Insulated duct

- Turbine casing

- Cabin bearing cylinder

- Guide slide

- Hydraulic system shell

Large diameter forged bar

Supports custom round, hex, rectangular, and special profiles with multi-state heat treatment and precision turning — ideal for high-strength joints, machining, and load-bearing structures.

Max size: Ø800 mm, length up to 6000 mm, unit weight approximately 4 tons.

Contact us now

- Connecting rod

- Spline shaft blank

- Supporting slide column

- Spline shaft blank

- Pin body

- Guide rod

- Electric drive rod

- Forming core

- Rotating bracket axis

- Hydraulic tie rod

Customization of large-size special-shaped structural forgings

Supports forging complex shapes—stepped, polygonal, and hollow composites—for major equipment, military, and special conditions, with customizable designs and integrated solutions.

Max size: single piece weight up to 80 tons, free forging per drawings, with advanced multi-axis machining capabilities.

Contact us now

- Stepped shaft

- Eccentric shaft blank

- Module flange

- Guide shell

- Assembly support seat

- Strengthen the connector

- Special-shaped guide plate

- Sealing ring

- Inner convex platform

- Non-standard flange ring

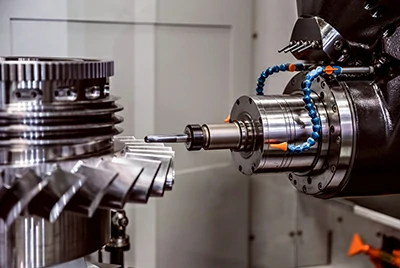

Overview of Chalco's large-size forging manufacturing and processing capabilities

In the manufacture of high-strength, large-diameter, and long-size forgings, the upper limit of equipment, process matching, and processing accuracy determine whether the product can meet actual engineering needs. Chalco focuses on high-demand industries such as aviation, energy, and equipment, and has built a full-process production capability with high-tonnage free forging + CNC ring rolling + multi-axis CNC machining + state heat treatment as the core, with the ability to deliver large-size, large-volume, and multi-category forgings stably.

Core forging capabilities - the basis for forming large forgings

Free Forging Equipment Capacity

- Equipped with 800- ton open forging hammer and 6,000-12,000-ton hydraulic press

- Supports large diameters of Ø2500mm (steel) / Ø3000mm (aluminum)

- Forging length up to 18 meters (shaft type) / 12 meters (block type), can be forged and welded in sections

- The maximum weight of a single piece can reach 50 tons (equipped with a 200- ton manipulator)

CNC diametrical-axial ring rolling capabilities

- Large ring size Ø2500mm × height 800mm (steel) / Ø3500mm × 1200mm (aluminum)

- Roundness control ≤0.08% (Aviation grade ≤0.05%)

- Material utilization rate increased to ≥75%

Die forging and special-shaped parts development

- Multi-station die forging supports flange shafts and stepped shafts (≤5 tons) ±1.5mm tolerance

- Special-shaped blanks: inner cavity and asymmetric cross-section structure can be forged according to the drawing (such as turbine disc blanks, aircraft landing gear prefabricated parts)

Post-forging processing capabilities – the guarantee of performance and precision

- Aluminum alloy: T6 / T651 (solution + aging), furnace uniformity ±3 °C

- Titanium alloys: vacuum heat treatment (≤10⁻³ Pa), β annealing, double annealing

- Steel: quenching & tempering, isothermal normalizing, and other state control

- Heat treatment capacity: max workpiece size Ø3000 mm × length 10 m

- Vertical turning: Ø5000 mm × height 3000 mm, radial runout ≤0.01 mm/m

- Horizontal turning: 15 m length, 80 tons load (with tool rest)

- Five-axis machining: accuracy ±0.015 mm, Ra ≤0.8 μm

- Deep hole drilling: aspect ratio ≤30:1 (e.g., Ø20 mm × 600 mm)

- Assembly surface accuracy: ±0.02 mm (e.g., engine flange)

- Structural surface accuracy: ±0.1 mm (e.g., wind turbine housing)

)

) Testing and delivery guarantee——the whole process is controllable and traceable

- UT ultrasonic flaw detection: can detect Ø0.8mm flat bottom holes (ASTM E2375)

- X-ray digital detection (DR): resolution ≤ 10μm

- High temperature tensile test (1200℃)

- Grain size rating (ASTM E112, titanium alloy β grains can be controlled to ≤3)

- Support third-party certification: SGS / BV / TUV / NADCAP (heat treatment, NDT)

- MES system covers: smelting → forging → heat treatment → processing → testing full process tracking

Chalco avoids the risks of multi-node subcontracting through the integrated management of its own factories, and can efficiently undertake the batch and single-piece customization needs of large structural forging projects such as aviation, military industry, wind power, marine engineering, and chemical industry.

Chalco large size forging industry application and cooperation case

Large-size forgings are critical in high-end manufacturing for load-bearing, sealing, and rotating components. With integrated free forging, ring rolling, and finishing, Chalco delivers high-performance, custom forgings to aerospace, wind power, petrochemical, rail, and defense sectors — supporting various alloys, heat treatments, and third-party certifications.

Aerospace - core application scenarios of high-performance large-size forgings

In aerospace, large-diameter forgings (Ø600–2500 mm) are essential for critical load-bearing parts such as landing gear supports, cabin joints, propulsion system brackets, and engine structures. These components demand not only high strength, fatigue resistance, and lightweight design, but also strict control over grain flow, dimensional precision, and heat treatment consistency.

Chalco has delivered mass-produced aluminum and titanium alloy forging rings and high-strength shafts tailored to aircraft and engine systems. Our products are widely applied by leading OEMs and research institutions, supporting high-end aerospace engineering.

Instant Quote

Wind power and energy equipment - core components of large-size forgings in heavy-duty structures

In wind power and energy systems, large forged rings, shafts, and flanges (Ø1000 mm and above, several tons) are essential for load-bearing, rotating, and transmission components — such as wind turbine main shafts, pitch systems, large flanges, and high-temperature housings, where durability and dimensional accuracy are critical.

Chalco offers large carbon steel, alloy steel, and aluminum alloy forgings with excellent strength, corrosion resistance, and flaw detection compliance. Our products are trusted in onshore/offshore wind farms, gas units, compressors, and hydropower systems worldwide.

Instant Quote

Petrochemical and deep-sea equipment systems - key large-scale applications of corrosion resistance and high-pressure sealing

In petrochemical and deep-sea energy fields, large-size forgings—often exceeding 1000 mm in diameter and weighing several tons—are critical for high-pressure seals, corrosion-resistant joints, and deep-sea load-bearing structures. These components operate under extreme conditions such as high temperature, high pressure, corrosive media, and ultra-deepwater environments, demanding exceptional metallurgical uniformity, structural density, and dimensional stability.

Chalco leverages extensive experience in manufacturing large steel and titanium alloy forgings, complying with ASME, NACE, GB/T, and other industry standards. Our products serve major petrochemical plants, deep-sea pipeline systems, and key equipment manufacturers, reliably supporting their large-scale, high-performance needs.

Instant Quote

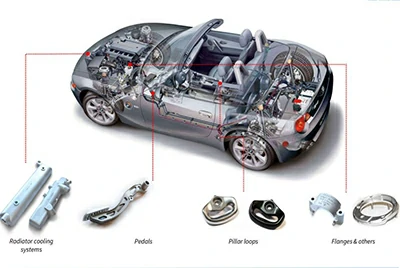

Automobile and high-end structural manufacturing - core components for high-strength support and module connection

In automotive, construction machinery, automation, and mold manufacturing, large-size forgings—such as solid shafts, discs, and rectangular blocks—play a crucial role in powertrains, chassis joints, structural frames, and mold bases. These components ensure heavy load transmission as well as the overall structural accuracy and stability.

Chalco supplies a wide range of large forgings tailored for passenger cars, commercial vehicles, construction equipment, and intelligent machinery. Our products consistently meet demanding requirements in machining performance, heat treatment stability, and timely delivery.

Instant Quote

FAQ on purchasing large size forgings

What forging sizes and weights can Chalco support?

We can produce large forged rings, forged shafts, forged blocks, forged discs and other products with a maximum diameter of Ø2500mm, a length of 18 meters and a single piece weight of ≤50 tons. The specific capacity depends on the material, shape and heat treatment method. Welcome to send drawings for evaluation and suggestions.

Do you support customization according to drawings? Can you assist with design and selection?

Yes, we support full customization according to drawings, and can assist customers in providing technical pre-qualification and engineering advice services in material selection, process path, size optimization, etc., to help you improve efficiency and reduce material waste.

Can you provide third-party testing and certification?

Yes. All products can provide standard quality control records such as material reports, UT flaw detection, metallographic analysis, mechanical properties testing, etc., and can assist in connecting with third-party testing agencies such as SGS, TÜV, BV, NADCAP, etc. to issue compliance certification.

Do you support export? How long is the delivery cycle?

We support global delivery. The regular forging proofing cycle is 7 to 15 days, and the batch delivery cycle varies from 20 to 45 days depending on the material and processing complexity. For large projects, the schedule can be flexibly negotiated.

How to determine whether a part is suitable for manufacturing with large-size forgings?

If your parts have the following characteristics, it is recommended to give priority to forging solutions:

- Large load, complex structure, harsh service environment

- Requires high strength, high fatigue life, high consistency

- The original design used welding or multi-section splicing in the hope of improving structural integrity and performance stability

Please contact us and provide your application and drawings. We will evaluate whether your forging solution is suitable for you.

What are the advantages of large-size forgings compared to extrusions?

Compared with extrusions, forgings have the following advantages:

- Good grain flow line continuity: The metal flow lines of the forging can be arranged along the contour of the part to improve fatigue life

- High size flexibility: not limited by mold size, more suitable for oversized or non-standard parts

- Fewer defects: The internal density is better than that of extruded materials, and it is more suitable for key pressure-bearing, rotating or force-bearing parts. It is suitable for medium and large structural components with high strength requirements and complex environments, such as flanges, bearing seats, wheels, etc.

What are the advantages of large-size forgings compared to castings or welded structural parts?

Compared with castings and welded structural parts, forgings have the following significant advantages:

- Higher structural strength and fatigue life, no grain section, no welding heat affected zone

- Lower internal defect rate, less prone to fatal defects such as pores and shrinkage

- Better consistency and stability, especially suitable for high temperature, high pressure and high speed conditions. Suitable for core components with extremely high requirements for safety, durability and reliability.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote