What is tinned copper braided strap?

Tinned copper braided strap is made of multiple T2 copper wires (≥99.9% Cu), braided into flat or tubular conductors with typical wire diameter of 0.15 mm (customizable 0.05–0.25 mm). Finer wires give higher flexibility, suitable for frequent bending and vibration absorption.

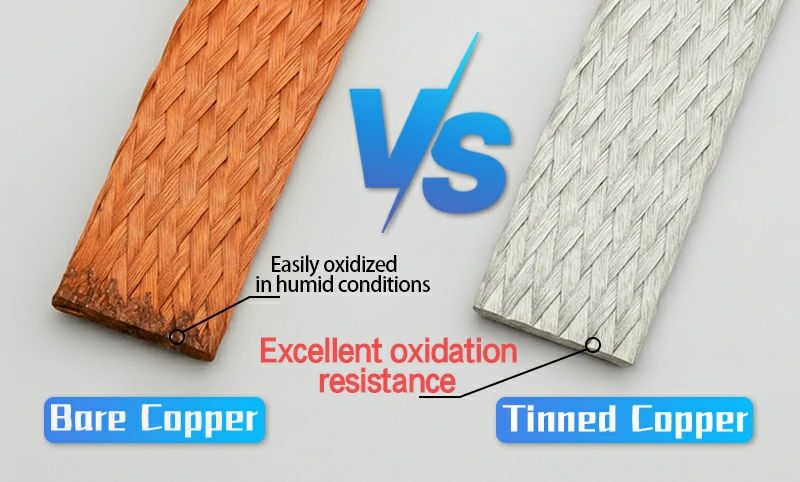

Surface finish can be bare copper or tin-plated. Tinning improves corrosion resistance and solderability, while lowering contact resistance. In humid, salt-spray, or outdoor environments, tinned copper straps offer better long-term reliability.

For easier installation, both ends are crimped with copper lugs (single or double hole) and fixed directly to busbars or frames, forming ready-to-install grounding jumpers. This ensures grounding, equipotential bonding, and added shielding for short cables, reducing potential differences and EMI.

Product specifications and options

Dimensions: Width 6–50 mm; thickness determined by braid density and flattening ratio; length customizable per drawing.

Braid parameters: Carriers × ends × wire diameter (e.g., 48×8×Ø0.20–0.36 mm); higher density results in a larger effective cross-sectional area.

Matching terminals: Default with tinned copper lugs; single-hole is used for general points, while double-hole is recommended for main grounding points or locations subject to high short-circuit forces to improve anti-rotation performance.

Hole size and spacing: Common options M6 / M8 / M10 / M12 / M16 / M20; spacing customizable according to busbar templates.

Surface and accessories: Optional heat shrink tubing, marking sleeves, spring washers/lock washers, and conductive paste.

Common specifications of tinned copper braided straps

| Nominal cross-section (mm²) | Calculated cross-section (mm²) | Braiding structure (layers × strands × wire dia.) | Width ≤ (mm) | Thickness ≤ (mm) | Calculated weight (Kg/Km) |

| 2 | 2.12 | 24×5×0.15 | 5 | 0.8 | 21 |

| 2.5 | 2.54 | 24×6×0.15 | 6 | 0.8 | 25.4 |

| 4 | 4.24 | 24×10×0.15 | 7 | 1.2 | 42.2 |

| 6 | 6.24 | 32×11×0.15 | 10 | 1.2 | 54.5 |

| 8 | 8.45 | 48×10×0.15 | 13 | 1.3 | 88 |

| 10 | 10.18 | 48×12×0.15 | 15 | 1.5 | 102 |

| 12 | 12.72 | 48×15×0.15 | 16 | 1.5 | 128 |

| 16 | 16.96 | 48×20×0.15 | 18 | 1.8 | 170 |

| 25 | 25.45 | 48×25×0.15 | 22 | 2 | 254 |

| 35 | 35.46 | 48×30×0.15 | 25 | 2 | 340 |

| 50 | 50.87 | 48×30×0.15 | 30 | 3.5 | 510 |

| 70 | 70.34 | 80×54×0.15 | 36 | 2 | 765 |

| 95 | 95.67 | 48×28×0.15 | 35 | 6 | 1000 |

| 120 | 127.23 | 48×30×0.15 | 37 | 7 | 1271.8 |

Copper lugs specifications and selection

Copper lugs are used as end connectors for tinned copper braided straps, ensuring reliable connection with busbars, switchgear or equipment. Models are usually selected based on cable cross-section or current rating.

By cable cross-section

| Model | Theoretical weight (kg) | Actual weight (kg) |

| DT-1-10 | 0.02 | 0.023 |

| DT-1-16 | 0.027 | 0.028 |

| DT-1-25 | 0.035 | 0.033 |

| DT-1-35 | 0.046 | 0.041 |

| DT-1-50 | 0.061 | 0.062 |

| DT-1-70 | 0.084 | 0.089 |

| DT-1-95 | 0.118 | 0.11 |

| DT-1-120 | 0.149 | 0.153 |

| DT-1-150 | 0.176 | 0.18 |

| DT-1-185 | 0.24 | 0.243 |

| DT-1-240 | 0.31 | 0.312 |

| DT-1-300 | 0.374 | 0.38 |

| DT-1-400 | 0.54 | 0.562 |

| DT-1-500 | 0.590 / 0.620 | 0.62 |

| DT-1-630 | — | — |

By current rating

| Model (rated current) | Size (mm) | Actual weight (kg) |

| 10A | 81×10.8 | 0.001 |

| 20A | 70×11.0 | 0.002 |

| 30A | 72×11.1 | 0.002 |

| 50A | 84×12.0 | 0.003 |

| 60A | 91×13.3 | 0.004 |

| 80A | 100×14.0 | 0.005 |

| 100A | 115×15.0 | 0.008 |

| 120A | 120×15.5 | 0.009 |

| 150A | 130×17.0 | 0.01 |

| 200A | 150×19.0 | 0.012 |

| 250A | 170×21.0 | 0.016 |

| 300A | 190×24.0 | 0.019 |

| 400A | 210×28.0 | 0.027 |

| 500A | 240×30.0 | 0.032 |

| 600A | 292×27.0 | 0.039 |

Reference table: braid × lug × hole spacing

| Strap nominal size | Braid structure | Approx. cross-section (mm²) | Reference current (A) | Recommended lug model | Hole type / size | Suggested hole spacing (mm) | Typical application |

| 1/2″ flat braid | 48×8×Ø0.36 | — | ≈53 | DT-1-35 / 50 | Single M6/M8 (double for main) | 25 / 30 | Door–cabinet bonding |

| 3/4″ flat braid | 48×18×Ø0.36 | — | ≈88 | DT-1-70 | Double M8/M10 | 30 / 35 / 50 | Busbar–busbar bonding |

| Metric example | 24×12×Ø0.20 | ≈8.3 | ≈90 | DT-1-10 / 16 | Single M6/M8 | 25 / 30 | Compact grounding / shielding |

Applications and Use Cases

Tinned copper braided straps with lugs are mainly used for grounding and equipotential bonding, and can also provide additional shielding for short cables to ensure the safety and stability of electrical systems.

Electrical industry (switchgear and distribution cabinets)

They are commonly used for bonding between cabinet doors, busbars, and enclosures. This ensures reliable grounding even when doors are opened and closed, preventing potential differences that could cause electric shock or interference. They are a fundamental safety design in data centers and industrial distribution cabinets.

Typical selection: 16–50 mm² with double-hole lugs (M6/M8/M10), effectively reducing the risk of loose connections and ensuring long-term cabinet operation.

New energy industry (photovoltaic and energy storage systems)

Widely used for grounding connections in combiner boxes, inverters, and battery clusters. With strong resistance to salt spray and humidity, tinned braids can maintain low-impedance conductivity outdoors for extended periods, reducing the risk of DC fires and system failures.

Common selection: 25–70 mm², recommended with full-tinned braids and waterproof heat shrink protection to ensure PV plants and ESS projects pass grid connection and acceptance inspections smoothly.

Transportation and marine industry (rail transit and ships)

Applied in bonding between car bodies and bogies, as well as decks and cabins. The braids offer high flexibility to absorb vibration and displacement, avoiding fractures common with rigid conductors, ensuring continuous potential equalization in high-vibration, high-humidity environments.

Common specifications: 35–120 mm², with M10/M12 lugs, meeting strict safety and reliability standards in rail and marine industries.

Building protection (construction and lightning protection systems)

Typically installed between curtain walls, metal windows/doors, and rooftop lightning conductors and grounding grids. They help discharge lightning energy quickly, meeting electrical and lightning protection code requirements and ensuring safety of buildings and occupants.

Recommended selection: 16–35 mm², used with protective sleeves and conductive paste to enhance weather resistance and contact reliability.

Standards and Compliance

The production and testing of tinned copper braided straps with lugs comply with international standards.

AA-59569: Braid structure and dimensional reference

ASTM B33: Tinned soft copper wire material

UL 486A-486B / IEC 61238-1-1: Lug crimping and type testing requirements

EN 10204 3.1: Factory material certificates

RoHS / REACH: Environmental compliance for export

Selection and Calculation (Procurement Guidelines)

Selection requires identifying continuous current and pulse current, combined with allowable temperature rise and duty cycle to define requirements.

Cross-sectional area can be estimated with copper resistivity ρ≈0.0175 Ω·mm²/m. Using the formula R≈ρ/A, DC resistance can be approximated and adjusted for conductor length and cooling conditions.

Braid selection should consider effective cross-section, braid density, and wire diameter to match application requirements.

Lug selection should match the equivalent cable cross-section, choosing equal or slightly larger barrel size and length. For critical points, double-hole lugs are preferred to improve short-circuit resistance and prevent rotation.

Final designs must be verified on-site through temperature-rise tests or infrared thermography to ensure proper contact quality and tightening torque.

Installation and Quality Inspection

Hexagonal crimping with proper sequence: Use matched dies to crimp hexagonally, progressing outward from the lug tongue; deburr and apply heat shrink or ID sleeves afterward.

Pull-out and temperature-rise testing: Inspect visually (no cracks, bulges, or loose strands), perform pull-out force and resistance/temperature-rise sampling tests; tighten to specified torque and recheck.

Torque and hole-spacing guidance: Torque recommendations, hole-spacing templates, and assembly notes are supplied; for critical positions, conductive paste, lock washers, and double-hole lugs are advised.

FAQ

Q: Why are double-hole lugs commonly used at main grounding points?

A: Double-hole lugs resist short-circuit electrodynamic forces that cause rotation/loosening, making them more stable and secure long term.

Q: Why do current ratings vary across different sources?

A: Differences in effective cross-section, braid density, installation cooling, and contact resistance affect current ratings; thermal tests are recommended for validation.

Q: Can products be customized according to AA-59569?

A: Yes. Carriers/ends, width, thickness, and equivalent cross-section can be customized. Wires are made of ASTM B33 tinned copper; 3.1 certificates and RoHS/REACH compliance available.

Q: Are they suitable for coastal or salt-spray environments?

A: Yes. Both braids and lugs should be tinned, with clean contact surfaces tightened to specified torque; anti-loosening and conductive paste recommended where necessary.

Q: What is the minimum order quantity (MOQ)?

A: Standard sizes support small-batch orders; MOQ for custom sizes can be confirmed upon request. Samples are available within 48h.

Contact Us

Samples: Ready in 48h

Bulk orders: 7–10 days delivery

Customization: OEM/ODM supported

Email: sale@chalcoaluminum.com

Phone: +86 17344894490