Seamless rolled rings are precision forged rings made from a pierced preform and finished by CNC radial–axial ring rolling. The seamless grain flow delivers high fatigue strength, tight concentricity/roundness, and repeatable quality for demanding rotating and load-bearing structures.

Chalco manufactures seamless rolled rings in aluminum, titanium and steel/stainless for bearings & slewing rings, ring gear blanks, flange rings, couplings and valve bodies. Typical seamless range Ø400–2500 mm with thin-wall options; UT to ASTM B594, documentation per EN 10204 3.1/3.2. Trusted in aerospace & defense, wind & energy, rail & heavy machinery, and chemical/pressure systems.

-

Materials at a glance

Aluminum: 6061 / 6082 / 7050 / 7075 / 2024 / 5083 / 2219 (O, T6, T651, T73/T74/T76)

Titanium: Gr2 (TA2), Ti-6Al-4V (Gr5/TC4), TC11 (anneal / solution & aging)

Steel/Stainless: 42CrMo4/4140, 20MnCr5, 18CrNiMo7-6; 304/316, 17-4PH

-

Typical uses

Bearings: inner/outer races, slewing rings

Powertrain: ring gear blanks, drive rings, couplings

Pressure boundary: flange rings, valve/sealing collars

-

Industries served

Aerospace & defense — structural rings, high-load flanges

Wind & energy — main-shaft interfaces, rotor/coupling rings

Rail/heavy machinery · Chemical/pressure systems

Seamless Rolled Rings — Quick Specs

| Typical OD (seamless) | Ø400–2500 mm | Height | 30–1450 mm |

| Wall thickness | ≥46–1500 mm (geometry dependent) | Concentricity / roundness | ≤0.5–1.0 mm (size dependent) |

| Single-piece weight | up to 80 tons (material & size dependent) | ||

| Materials | Aluminum · Titanium · Steel/Stainless | ||

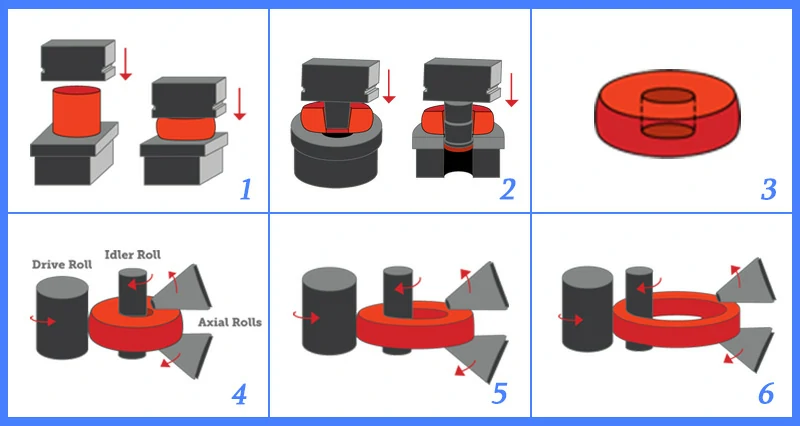

- Process: free-forging preform → CNC radial–axial ring rolling → heat treatment → machining

- Heat treatment: O, T6, T651; anneal, solution, tempering per drawing

- Pre-machining: turning, chamfering, drilling, bolt circle, flange prep on request

- Rough-machining accuracy: ±0.5 mm (special requirements negotiable)

- Standards: ASTM, AMS, ASME, GB, EN

- Testing & docs: dimensional check, UT to ASTM B594 (per PO), metallography, mechanical tests; EN 10204 3.1/3.2; third-party (SGS/BV/TÜV) on request

- Need ultra-large OD up to 10 m? See Large-Diameter Aluminum Forged Rings

Components & Use-Cases for Seamless Rolled Rings

One supplier for your ring families: inner/outer bearing races, ring-gear blanks, flange rings, and custom/stepped/tapered housings. Seamless rolled in Al/Ti/steel, OD Ø400–2500 mm with thin-wall options and stable roundness. Email the drawing—24-hour route selection and quote.

Bearing Ring Forgings (inner/outer races · slewing rings)

Seamless grain flow around the circumference boosts fatigue life and keeps roundness/concentricity tight for smooth rotation and lower noise. Suited to heavy-duty slewing bearings and large gearbox bearings.

Contact us now

- Typical seamless range Ø400–2500 mm; thin-wall options for weight-sensitive designs

- Concentricity / roundness ≤0.5–1.0 mm(size dependent); uniform wall reduces grinding time

- Materials: aluminum, steel/stainless, titanium; heat treatment per drawing

- Use cases: slewing bearings, turntables, large reducer bearings, rotary indexers

Ring Gear Blanks (internal/external gear prep)

Our seamless gear blanks offer excellent strength and precision, ensuring smooth and consistent operation in high-torque applications. Perfect for large gear rings and gear blanks in transmission systems.

Contact us now

- Typical seamless range Ø400–2500 mm; high-torque applications

- Concentricity / roundness ≤0.5–1.0 mm (size dependent); high precision for gear teeth machining

- Materials: aluminum, steel/stainless, titanium; heat treatment per drawing

- Use cases: large gear rings, gear blanks, rotary systems

Flange Rings (pressure boundary · valve/connector collars)

Seamless flange rings provide high strength and tight tolerances, suitable for high-pressure applications and flange connections in critical systems.

Contact us now

- Typical seamless range Ø400–2500 mm; thick-wall options for heavy-duty applications

- Concentricity / roundness ≤0.5–1.0 mm (size dependent); optimized for pressure seal applications

- Materials: aluminum, steel/stainless, titanium; heat treatment per drawing

- Use cases: flanges for high-pressure systems, valve bodies, sealing rings

Custom & Special Rings (stepped · D-shaped · tapered · housings)

Chalco offers fully customizable seamless rings, including special shapes, stepped designs, and housings, catering to unique industry needs with precision and flexibility.

Contact us now

- Typical seamless range Ø400–2500 mm; customized sizes and shapes available

- Concentricity / roundness ≤0.5–1.0 mm (size dependent); perfect for special geometries

- Materials: aluminum, steel/stainless, titanium; heat treatment per drawing

- Use cases: custom rings, special components, non-standard geometries

Seamless Rolled Ring Forgings — Key Industries & Typical Parts

Our seamless rolled rings run in safety-critical rotating and pressure-boundary assemblies worldwide. Below are the most requested fields and parts; materials and heat treatment are matched to service conditions.

Aerospace & Defense

Typical parts: engine interface/combustor rings, landing-gear couplings, fuel/valve collars

Typical sizes: Ø400–2500 mm; tight concentricity/roundness ≤0.5–1.0 mm

Recommended alloys: 7050, 7075, 2219; Ti-6Al-4V/TC4, TC11; stainless/steel as required

Wind & Energy

Typical parts: main-shaft flange rings, slewing bearing races, coupling support rings

Typical sizes: large OD, thin-wall options for weight-sensitive nacelles

Recommended alloys: 6082, 7050 aluminum; stainless/structural steel; titanium for corrosion points

Oil & Gas / Chemical

Typical parts: high-pressure flange rings, valve/sealing collars, heat-exchanger fixing rings

Typical sizes: pressure-boundary rings with UT to ASTM B594, docs EN 10204 3.1/3.2

Recommended alloys: 5083, 6082 aluminum; Ti Gr2/Gr5; stainless & alloy steel for sour service

Rail & Heavy Machinery

Typical parts: slewing rings, reducer drive rings, turntable/brake support rings

Typical sizes: Ø400–2500 mm; uniform wall to minimize grinding time

Recommended alloys: 6061, 6082 aluminum; structural steels; stainless for harsh environments

Nuclear & Power Systems

Typical parts: reactor sealing/support rings, turbine connecting rings, HP boundary components

Typical sizes: tight-tolerance rings with inclusion control and full traceability

Recommended alloys: 2219, 5083 aluminum; Ti Gr2/Gr5; stainless/alloy steels per spec

We also serve marine & offshore, mining, pulp & paper, metallurgy and general equipment projects.

Send your drawing for a 24-hour process recommendation and quote, or see specs on our Aluminum Forged & Seamless Rolled Rings page.

Material Overview for Chalco Seamless Rolled Rings

We produce seamless rolled rings in aluminum, titanium, and steel/stainless to fit different load, weight and environment needs. Below is a quick view of the three core material families—each supports heat treatment, UT to ASTM B594, and documentation per EN 10204 3.1/3.2.

-

Aluminum Seamless Rolled Rings

Aluminum Seamless Rolled RingsLightweight with high specific strength and good corrosion resistance. Ideal for bearings, flanges and gear blanks where weight reduction and tight concentricity are required.

Lightweight Fatigue-resistant Corrosion-resistant -

Titanium Seamless Rolled Rings

Titanium Seamless Rolled RingsHigh specific strength and excellent corrosion resistance with stable performance at temperature. Used in aerospace hot-end parts, marine equipment and chemical sealing structures.

High strength Low density Heat/corrosion resistant -

Steel & Stainless Seamless Rolled Rings

Steel & Stainless Seamless Rolled RingsTough and wear-resistant for heavy loads and harsh environments. Common in powertrain couplings, valve bodies, pressure flanges and large industrial bearings.

High toughness Wear-resistant Wide size range

Sizes & Tolerances for Seamless Rolled Rings

Typical seamless range and control targets for CNC radial–axial ring rolling. Values vary with alloy and drawing; we confirm on review.

- Typical OD: Ø400–2500 mm; thin-wall options for weight-sensitive designs

- Height: 30–1450 mm; wall/height set by tooling and reduction schedule

- Concentricity / roundness: ≤0.5–1.0 mm (size-dependent); uniform wall reduces finish grinding

- Machining allowance: defined per part and route to balance yield vs. finish time

- Inspection: UT to ASTM B594 (grade per PO); dimensional report with EN 10204 3.1/3.2 docs

Need ultra-large diameters or extra-thin walls? See Large-Diameter Aluminum Forged Rings.

Seamless Rolled Ring Advantages

Circumferential grain flow and weld-free structure deliver higher fatigue life and dimensional stability. Typical concentricity/roundness ≤0.5–1.0 mm (size-dependent); thin-wall options reduce machining time while keeping weight down.

- Circumferential grain flow resists fatigue and stress-corrosion cracking

- Weld-free, dense structure avoids heat-affected risks

- Tight concentricity/roundness and uniform wall; smaller finish allowances

- High material yield; suited to lightweight designs

- Strong batch repeatability for paired and series parts

- Supports large ODs and special geometries (stepped, flanged, housing rings)

| Seamless rolled rings vs. common ring-forming methods | ||||

| Aspect | Seamless rolled rings | Cast rings | Plate-cut rings | Welded/rolled rings |

| Structure & grain flow | Continuous, circumferential, dense | Segregation/inclusion risk | Unidirectional; exposed ends | Weld zone inconsistency |

| Fatigue/impact | High | Medium | Medium | Low |

| Concentricity/allowance | Easy to control; low allowance | Average | Large stock removal | High weld distortion |

| Material yield/cost | High yield | Medium | Low (cut-off) | High post-weld finishing |

| Reliability/consistency | High | Medium | Medium | Low |

Want the forming route step-by-step? See our process note: Seamless Rolled Ring Forging – Process Guide.

Production, Machining, Quality Assurance & Why Choose Chalco

Unified route: pre-form (open-die) → CNC radial–axial ring rolling → heat treatment → machining and inspection. All core processes are in-house to ensure structural integrity, dimensional stability and reliable delivery.

- Equipment & process: open-die forging lines + CNC ring rolling; matched heat-treat lines and multi-axis machining

- Machining: turning/boring/drilling/chamfering, flange reservations and location holes; rough-to-finish delivery

- Size envelope: typical seamless range Ø400–2500 mm; thin-wall options; concentricity/roundness target ≤0.5–1.0 mm (by size)

- Docs & traceability: UT to ASTM B594 (class per PO), EN 10204 3.1/3.2, dimensional report; mechanical/metallography as needed; full heat-treat records

- Standards: ASTM, AMS, ASME, GB, EN; execution strictly per drawing and project specs

- Delivery & response: prototype → small batch → volume; pre-machined delivery available to shorten assembly time

- Engineering support: drawing review, alloy/temper advice, reduction-schedule optimization; 24-hour route suggestion and quote

Need ultra-large ODs or thin-wall high concentricity? See Large-Diameter Aluminum Forged Rings, or send your drawing for a 24-hour recommendation and quote.

FAQ

Q1: What size range do you supply for seamless rolled rings?

Typical seamless range Ø400–2500 mm. Larger ODs are evaluated case-by-case; thin-wall options depend on reduction schedule and tooling.

Q2: How tight are concentricity/roundness?

We target ≤0.5–1.0 mm depending on size and drawing tolerance. Uniform wall helps reduce grinding time and improve runout.

Q3: Which materials and certificates can you provide?

Aluminum, titanium and steel/stainless. UT to ASTM B594 with documentation per EN 10204 3.1/3.2; mechanical & metallographic reports on request.

Q4: Can you pre-machine features before shipment?

Yes. Turning, boring, drilling, chamfering, flange allowances and datum prep are available to speed assembly and reduce on-site machining.

Q5: What quality controls and documents are supplied?

- UT per ASTM B594 (level per PO) with full dimensional report

- Material traceability & documentation to EN 10204 3.1/3.2

- Mechanical testing & metallography on request; inclusion/cleanliness control

- Process records: forging/rolling reductions, heat-treatment charts, final inspection

- Optional NDT: PT/MT for critical surfaces; hardness & conductivity as specified

Specs, Selection & Quote

Need specs, alloys and a fast quote? Visit the product page: Aluminum Forged & Seamless Rolled Rings.

Targeting ultra-large OD or thin-wall on big diameters? See Large-Diameter Aluminum Forged Rings (Up to 10 m OD).

Want the forming route in depth? Read our process blog: Seamless Rolled Ring — Process & Selection Guide.

For drawings and pricing, please email our sales manager — we provide a 24-hour process recommendation and quotation.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote