Sandwich wall panels are widely used in modern architectural wall systems, combining face sheets and core structures to achieve structural strength, lightweight performance, and efficient installation. Among various material options, aluminum sandwich wall panels are commonly applied in interior and exterior wall applications due to their durability, corrosion resistance, and stable fire performance.

Chalco offers aluminum sandwich wall panel solutions with different core structures, including aluminum corrugated composite panels, honeycomb panels, and insulated sandwich panels. These products are designed to meet diverse architectural and engineering requirements for façade cladding, modular wall systems, and public building projects, with flexible options in structure, surface finish, and project-based customization.

What Is a Sandwich Wall Panel?

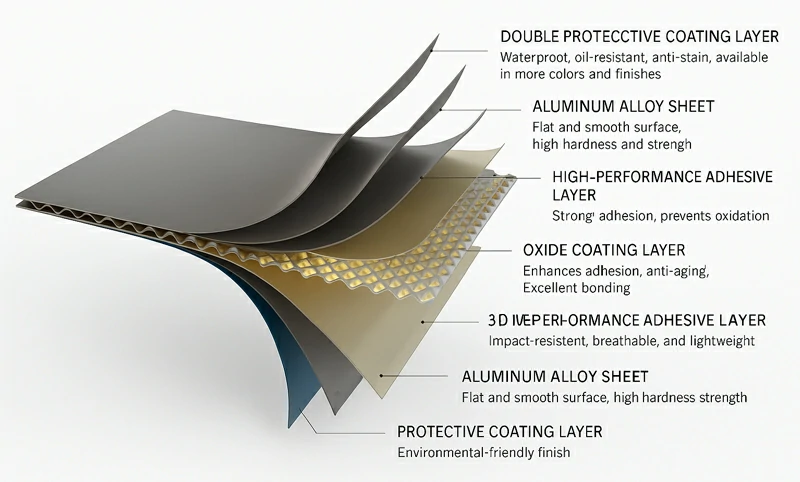

A sandwich wall panel is a type of structural wall panel composed of two face sheets bonded to a core layer, forming an integrated panel structure. This construction concept is widely applied in modern wall systems and building envelope applications, where structural efficiency and system integration are key considerations. Among different material options, aluminum sandwich wall panels are commonly used in architectural projects and can be configured with different core structures to meet a wide range of interior and exterior wall requirements.

- High strength-to-weight performance achieved through integrated face sheet and core structure

- Lightweight panel design supporting efficient installation and reduced structural load

- Flexible configuration through different core structures to match functional requirements

- Suitable for modular, prefabricated, and system-based wall construction

- Compatible with various surface finishes for architectural and aesthetic applications

Based on core structure design, aluminum sandwich wall panels supplied by Chalco are mainly available in the following configurations:

Aluminum Corrugated Composite Panel (3D-Cored Aluminum Sandwich Panel)

Lightweight all-aluminum structure with enhanced strength and system-level performance for prefabricated architectural applications

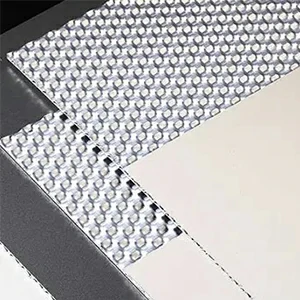

Aluminum corrugated composite panels, also commonly referred to as 3D-cored aluminum sandwich panels, are based on an all-aluminum structure combined with a three-dimensional corrugated core design. Through precision composite technology, this structural configuration achieves an optimized balance between strength, weight, and processing performance. It retains the durability and metallic characteristics of traditional façade sandwich panel systems while meeting modern architectural requirements for lightweight construction, energy efficiency, environmental performance, and rapid installation.

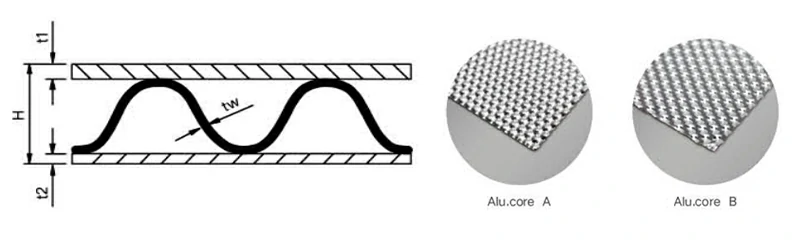

| Item | Parameters/Specification |

| Width | ≤ 1600 mm, length adjustable |

| Panel Thickness | 3 mm, 4 mm, 6 mm, 8 mm |

| Thickness of top sheet (t1) | 0.5 – 0.8 mm |

| Thickness of corrugation (tw) | 0.3 – 0.5 mm |

| Thickness of bottom sheet (t2) | 0.5 – 0.8 mm |

| Overall thickness (H) | 4 – 6 mm |

-

Structural Innovation

Core: 3D cone-shaped aluminum core for stronger, more uniform load performance.

Stability: Highly stable, deformation-resistant, with excellent impact and fire performance.

-

Process Upgrade

Production: Automated lamination ensures consistent bonding and high flatness.

Safety: All-aluminum, plastic-free structure; A2 fire rating and EO environmental standard.

-

Processing Breakthrough

Machining: 3D core resists collapse; supports bending, milling, drilling and arc forming.

Assembly: High-precision and easy to install; compatible with curtain wall and modular systems.

-

System Extension

Finishes: Supports anodized, PVDF, wood grain, stone grain and brushed finishes.

Durability: Scratch-resistant, color-stable, moisture-proof and weather-resistant surface.

In short,

the core competitiveness of aluminum corrugated composite sandwich wall panels lies not only in lightweight construction, structural strength, and fire performance, but in their integrated structural design and manufacturing approach. This system-level optimization enables architectural curtain wall and prefabricated interior wall applications to achieve consistent performance, efficient installation, and reliable long-term stability.

Whether it's high-end curtain wall projects, medical cleanrooms, or prefabricated modular engineering, we can provide customized structural designs and rapid installation solutions (sandwich building panels) to meet your application needs. Please contact us to obtain sample testing or project solution evaluation.

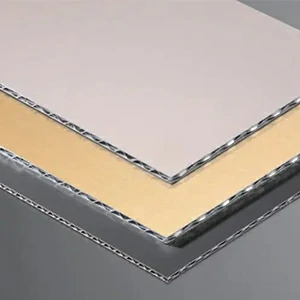

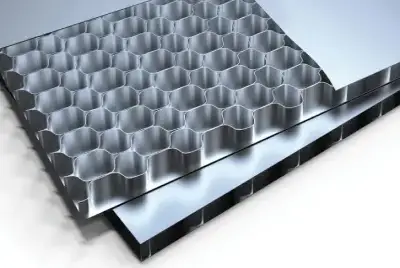

Aluminum Honeycomb Sandwich Panel

Aluminum honeycomb sandwich panels use a hexagonal aluminum honeycomb core bonded between aluminum face sheets. Compared with corrugated composite panels, honeycomb panels typically feature greater overall thickness and are suitable for applications requiring different stiffness-to-weight characteristics. This structure is widely used in architectural and transportation projects where panel thickness and uniform load distribution are primary considerations.

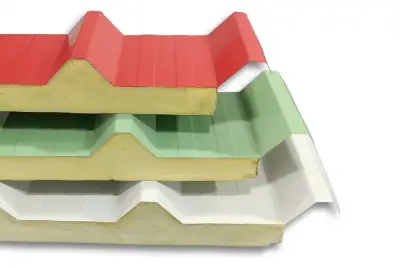

Insulated Sandwich Panel

Insulated sandwich panels represent another major category of sandwich wall panels, typically designed with insulation cores to enhance thermal performance. These panels are commonly applied in temperature-controlled buildings and energy-efficiency–oriented projects. Due to differences in structural composition, insulated sandwich panels differ from all-aluminum sandwich wall panel solutions and are not the primary focus of aluminum corrugated composite panel applications.

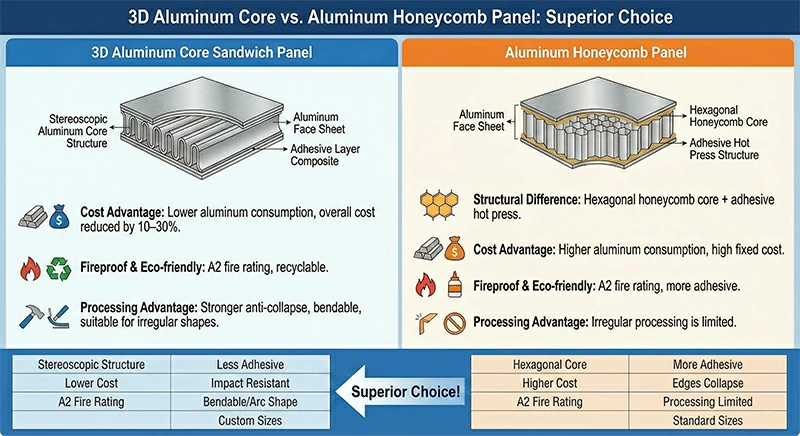

Aluminum ACCP wall panel vs. Aluminum honeycomb panel: Why is it the better choice?

- Structural differences: Aluminum corrugated composite panels (ACCP) use a corrugated aluminum core bonded with face sheets, while honeycomb aluminum panels adopt a hexagonal honeycomb core structure with multi-layer adhesive bonding.

- Cost advantages: ACCP structures typically require lower aluminum consumption and simpler manufacturing processes, without reliance on honeycomb expansion and extensive adhesive layers, allowing overall cost reductions of approximately 10–30%.

- Fire performance and sustainability: All-aluminum corrugated composite panels contain no plastic or foam core materials, supporting A2 fire rating requirements and full recyclability.

- Processing advantages: Corrugated composite cores offer higher resistance to collapse, enabling bending, milling, and arc forming, making ACCP suitable for irregular curtain wall systems and prefabricated sandwich wall panels.

| Aluminum Corrugated Composite Panel (ACCP) | Aluminum Honeycomb Sandwich Panel |

| Corrugated aluminum core structure | Hexagonal honeycomb aluminum core |

| Lower aluminum consumption | Higher aluminum consumption |

| Optimized and controllable cost structure | Relatively higher and fixed production costs |

| A2 fire resistance rating | A2 fire resistance rating |

| Fewer adhesive layers | Multiple adhesive bonding layers |

| Higher impact resistance and edge stability | Edges more susceptible to crushing |

| Supports bending and arc-shaped fabrication | Irregular shape processing is relatively limited |

| Custom sizes and project-based configurations supported | Primarily standard specifications |

If your project requires samples, structural drawings, or system-matched configurations for curtain wall or sandwich wall panel applications, please contact us for technical support and a project quotation.

Chalco Aluminum Sandwich Wall Panel Cooperation Areas

Chalco aluminum sandwich wall panels are widely applied in building curtain walls, interior wall systems, and integrated architectural applications. By combining aluminum face sheets with different core structures, these sandwich wall panel solutions offer a balance of lightweight construction, structural stability, installation efficiency, and surface design flexibility.

Through long-term project cooperation, Chalco sandwich wall panels have been successfully supplied to a wide range of public buildings and commercial developments, supporting both exterior and interior wall systems with reliable performance and adaptable system configurations.

Interior Wall System

Structure: Sandwich wall panel with keel-slot or modular assembly

Applications: High-standard interiors, partitions, and clean spaces

Features: Lightweight, fire-rated, moisture resistant, with sound and thermal performance

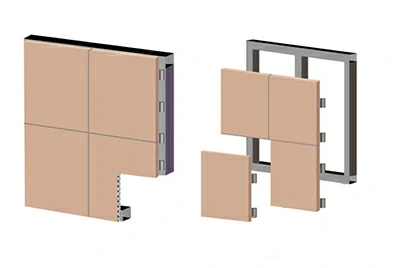

Facade Curtain Wall System

Structure: Aluminum sandwich wall panel façade cladding system

Applications: Exterior walls, large-panel façades, and architectural envelopes

Features: Dry-hanging compatible, high flatness, fast installation, and design flexibility

Metal Ceiling System

Structure: Lightweight sandwich panel ceiling system with keel suspension

Applications: Public spaces, integrated roof–wall systems

Features: Supports curved designs, fire-safe, easy installation and maintenance

Collaboration Case Gallery

The following are typical application scenarios for Chalco aluminum sandwich wall panel solutions:

- Public and landmark buildings: Suitable for large-span and irregular curtain wall systems such as stadiums, conference centers, and exhibition halls, supporting lightweight and curved panel installation.

- Commercial and mixed-use projects: Applied to exterior and interior wall systems of offices, hotels, and shopping centers, combining architectural appearance with long-term durability.

- Medical and research spaces: Fire-rated, easy-to-clean sandwich wall panels meeting cleanliness and safety requirements for hospitals and laboratories.

- Transportation and public hubs: Used in airports, metro stations, and rail terminals where impact resistance, corrosion resistance, and maintenance efficiency are critical.

- Educational and cultural buildings: Applied in campuses, libraries, and museums, supporting flexible design and integrated wall solutions.

- Prefabricated and modular construction: Compatible with factory-prefabricated sandwich wall panel systems, supporting dry installation and shortened construction cycles.

Contact us to obtain drawings and material samples for similar projects.

Chalco Aluminum Sandwich Wall Panel Project Overall Solution – Manufacturing and Processing System

Chalco, a professional aluminum alloy materials manufacturer, provides integrated manufacturing and processing solutions for aluminum sandwich wall panel projects worldwide. Serving curtain wall systems, interior wall applications, and prefabricated construction, Chalco supports sandwich wall panels with different core structures through a complete production system covering raw material preparation, panel composite processing, precision fabrication, and finished product delivery.

By integrating materials supply with pre-installation fabrication, Chalco ensures that sandwich wall panels are delivered in ready-to-install condition, supporting efficient on-site assembly and consistent project quality.

Raw Material & Quality Control

- High-purity aluminum ingots are melted and cast under controlled conditions, with production strictly following international standards such as GB/T 3880 and ASTM B209;

- Aluminum plate production capability supports a wide range of sandwich wall panel requirements, with thickness, width, and length configured according to project needs;

- Sandwich panel cores and face sheets are bonded using environmentally friendly, high-strength adhesive systems, with controlled curing processes to ensure panel flatness and bonding stability;

- Aluminum sandwich wall panels meet fire performance, weather resistance, and corrosion resistance requirements for long-term interior and exterior applications;

- Each production batch undergoes flatness, bonding strength, fire performance, and appearance inspection, with traceable quality records and inspection reports;

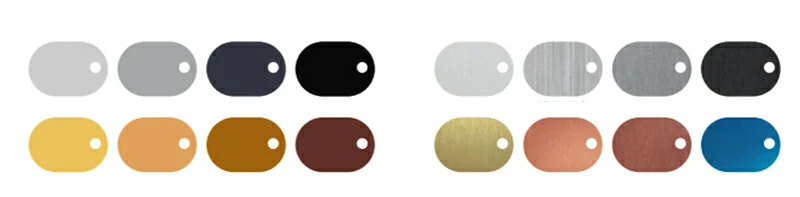

- Surface finish options include anodizing, fluorocarbon coating, polyester coating, wood grain transfer, stone grain, brushed metal, and mirror finishes.

Pre-installation Fabrication Capabilities

Aluminum sandwich wall panels supplied by Chalco can be prefabricated and processed before factory delivery, allowing customers to proceed directly to installation or system assembly upon arrival at site.

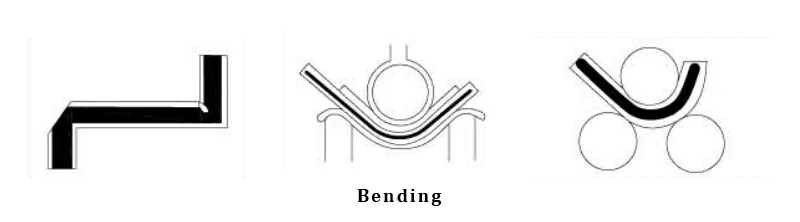

- Bending and folding: edge forming, corner shaping, and panel folding while maintaining structural integrity;

- Curving: roll forming supports large-radius and curved sandwich wall panels with smooth, uniform surfaces;

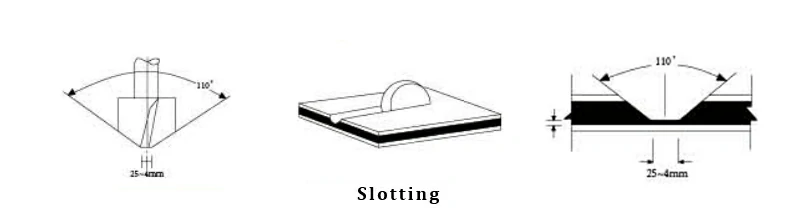

- Slotting: back-side slotting improves bending accuracy and enables controlled angle forming;

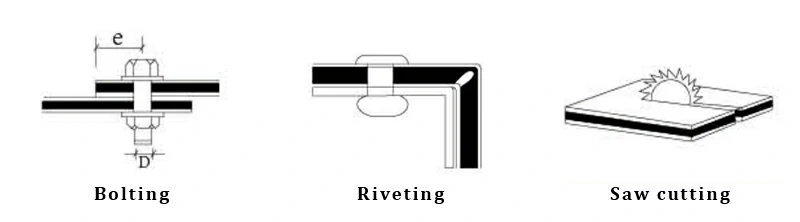

- Drilling and riveting: pre-drilled fixing points and connection positions improve installation efficiency;

- CNC cutting: precision cutting ensures dimensional accuracy and clean panel edges for system integration;

All fabrication processes are completed in-house, supporting ready-to-install sandwich wall panel delivery, reducing on-site workload, minimizing installation risks, and shortening overall construction schedules.Contact Chalco for customized fabrication and integrated sandwich wall panel project solutions.

Project Cooperation and Procurement Guide for Aluminum Sandwich Wall Panels

1. Sandwich Wall Panel Selection and Performance Comparison

To assist project owners and engineering teams in selecting suitable solutions, the following comparison outlines typical aluminum sandwich wall panel structures used in curtain wall and building envelope systems.

| Panel Type | Core Structure | Fire Performance | Weight Level | Cost Control | Processing Flexibility | Environmental Performance |

| Aluminum Corrugated Composite Panel (ACCP) | Corrugated aluminum core, all-aluminum composite | A2 | Light | ★★★★★ | ★★★★★ | Recyclable, plastic-free |

| Aluminum Honeycomb Sandwich Panel | Hexagonal honeycomb aluminum core | A2 | Light | ★★★ | ★★★★ | Recyclable |

| Foamed Aluminum Sandwich Panel | Aluminum alloy with porous foam core | A2 | Medium | ★★★ | ★★ | Recyclable |

| PU / EPS Sandwich Panel | Metal sheets with polymer insulation core | B and below | Heavy | ★★ | ★★★ | Non-recyclable |

| Aluminum Composite Panel (ACP) | Aluminum sheets with polyethylene core | B | Light | ★★★★ | ★★★ | Plastic-based core |

Different aluminum sandwich wall panel structures offer distinct advantages depending on project priorities such as fire performance, structural strength, processing flexibility, cost control, and sustainability. Selection should be based on specific architectural requirements, installation systems, and lifecycle expectations.

2. Can aluminum corrugated composite panels replace honeycomb sandwich panels?

In many curtain wall and prefabricated applications, aluminum corrugated composite panels can serve as an effective alternative to honeycomb panels, offering comparable flatness and weight while providing improved processing flexibility and cost control. Final selection depends on project structure and performance requirements.

3. Can you provide samples or small-batch testing?

We support sample delivery and customized processing, and samples can be produced within 3–7 days.

4. What finishes are available?

We offer anodized, fluorocarbon, polyester, wood grain, stone grain, brushed, and mirror finishes, and support RAL/PANTONE color matching.

5. Does it meet overseas engineering standards?

The product complies with standards such as GB/T 3880, ASTM, and EN13501, and is accompanied by material certification in section 3.1, making it suitable for export to the global market.

6. Can you provide a matching installation system?

Chalco can provide keel clips and mounting system design support to achieve ready-to-install.

Select Chalco

- Full-process manufacturing capability: From primary aluminum melting and casting to composite panel production and surface finishing, Chalco supports complete aluminum sandwich wall panel manufacturing with stable quality control.

- High-standard quality system: Certified under ISO 9001, EN 13501, GB/T 3880, ASTM and related standards, ensuring compliance with international sandwich wall panel project requirements.

- Advanced equipment and processing technology: Equipped with automated composite production lines, constant-temperature curing systems, CNC machining, and electrostatic coating facilities for sandwich wall panel fabrication.

- Professional technical support team: Experienced in curtain wall systems, interior wall assemblies, and prefabricated sandwich wall panel applications, providing structural optimization and detailing support.

- Global project delivery experience: Long-term supply experience for overseas construction projects, familiar with international standards, logistics coordination, and export packaging requirements.

- Rapid customization and response: One-stop support for sample development, small-batch testing, mass production, and long-term international project cooperation.

Project Cooperation Flow:

① Project requirements and drawings →

② Material and structure confirmation →

③ Prototype and sample production →

④ Mass production →

⑤ Inspection, packing, and shipment

Chalco supports aluminum sandwich wall panel projects with integrated materials, manufacturing, and processing solutions, helping architects, engineers, and contractors achieve safe, lightweight, and durable wall systems for global construction applications. Contact us for customized solutions, sample support, and international project cooperation.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote