Chalco, Asia's largest supplier of commercial aircraft engine ring forgings, is a trusted partner for global high-end equipment clients thanks to its robust quality system, certified processes (AS9100D, ISO 9001, NADCAP), and large-scale delivery capability.

Chalco's products serve both military and commercial aircraft engines and are widely used in gas turbines, aerospace, and nuclear power, making it a reliable international supplier of ring forgings and structural components.

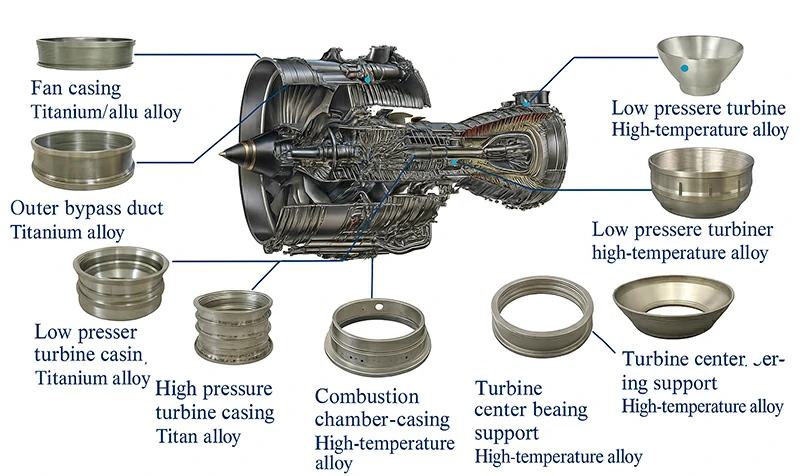

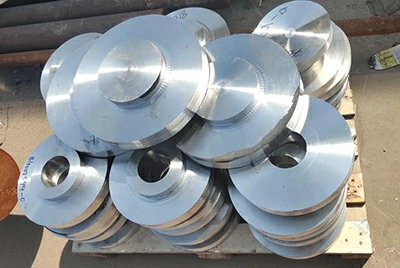

Aircraft Engine Components

Core aircraft engine components must operate reliably under high loads and harsh conditions, with stringent strength and performance requirements. Chalco's aluminum forging components have been used in engines such as the GE9X, LEAP, Trent1000, and China's C919 CJ1000, demonstrating outstanding performance and reliability.

For internationally certified, high-precision aluminum forgings with scalable delivery, contact us for technical support and customized quotes.

Fan Case

The fan case, located at the front of an aircraft engine, is a key structure that encases the fan blades. It serves both as an external protective barrier and as a focus for overall weight reduction.

Chalco Titanium offers fan cases in titanium and aluminum alloys to suit different thrust levels and design approaches.

High-thrust engines or those requiring blade containment typically use Ti-6Al-4V titanium alloy forged fan cases, optionally with composite fiber cladding, for superior impact and heat resistance.

Medium- to low-thrust engines, or those not requiring containment, can use aluminum alloy fan cases such as 2219-T6/T87 or 2618-T851. These provide good thermal strength and dimensional stability at 200–300 °C, with options for welded segmented construction or integral ring rolling.

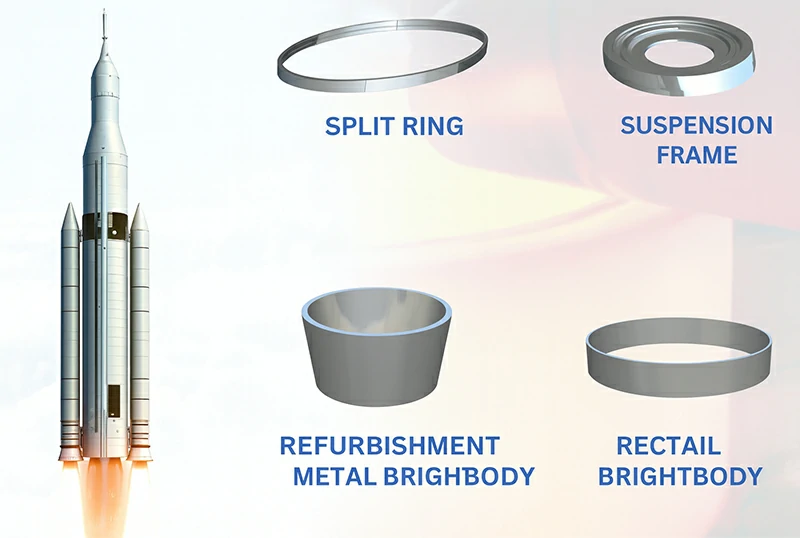

Aerospace Components

Spacecraft impose extreme demands on structural materials, requiring not only lightweight design but also long-term mechanical stability and sealing performance under low temperatures, vacuum, and high-radiation environments.

Chalco Titanium's high-performance aluminum alloy ring forgings, manufactured with precision, have been successfully used in multiple launch vehicles and spacecraft fuselage sections, demonstrating excellent fatigue resistance and thermal cycle adaptability.

For aerospace-qualified, high-reliability forgings, contact us for customized solutions and engineering support.

Y-shaped Ring

The Y-shaped ring is a critical connector in rocket structures, designed to withstand and transmit thrust and vibration loads between upper and lower stages. Forged from 2219-T87 or 7050-T7451 aluminum alloys, it combines lightweight design with high strength and excellent fatigue performance. Its good weldability allows integration with cylinders or fuselage sections, ensuring overall structural integrity.

Hanger Frame

The hanger frame is mainly used for connecting and lifting rocket stages or spacecraft modules, requiring both structural strength and dimensional stability. 6061-T6 aluminum alloy significantly improves machining efficiency and, after anodizing, offers excellent corrosion resistance. For models with higher load requirements, 2219 aluminum alloy can be used to balance weldability and strength.

Service Module Metal Shell

The service module shell is a key pressure-bearing component of rocket propellant tanks or auxiliary modules, needing long-term structural stability during launch and orbital maneuvers. 2219-T87 aluminum alloy is widely used for liquid fuel tanks and module shells due to its high strength at low temperatures and excellent weldability.

Rear Skirt Shell

The rear skirt shell, located at the rocket's tail, bears engine thrust and connects to lower structures. It must withstand significant thrust and vibration loads. 2219-T87 and 2618-T851 aluminum alloys are commonly used; the former is suitable for welded assembly, while the latter offers high thermal fatigue resistance, ideal for integral ring forging to ensure mechanical stability of large shells.

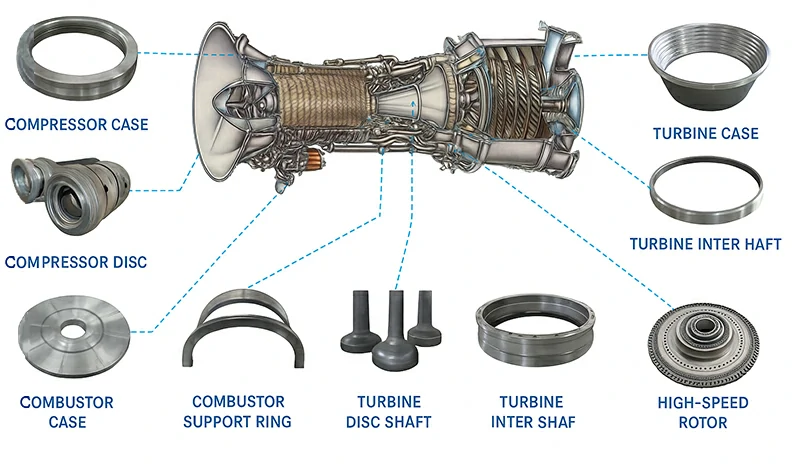

Gas Turbine Components

Gas turbines are widely used in power generation, petrochemical, and energy equipment industries, serving as key devices for modern energy conversion and efficient electricity production. Their core components must remain reliable under high-temperature, high-pressure, and long-duration continuous operation. Leveraging advanced aluminum alloy forging technology, Chalco provides a range of critical rings and structural components for gas turbines.

Compressor Casing

The compressor casing is one of the most important ring-shaped components at the front of a gas turbine, forming the airflow channel and providing structural support for the blades. During long-term operation, it must withstand the pressure and vibrations from high-speed airflow.

Chalco Titanium manufactures compressor casings using Ti-6Al-4V and 2219 aluminum alloys. Through near-net ring rolling and NADCAP heat treatment, wall thickness uniformity and geometric precision are ensured. This component significantly improves airflow compression efficiency and turbine lifespan while reducing maintenance costs.

Inlet Guide Ring

The inlet guide ring (Inlet Case & IGV Support Ring) can be made from 6061-T6 aluminum alloy. Its low operating temperature (<150 °C), excellent machinability, and enhanced corrosion resistance through anodizing make it ideal for accessory installation and guide vane support.

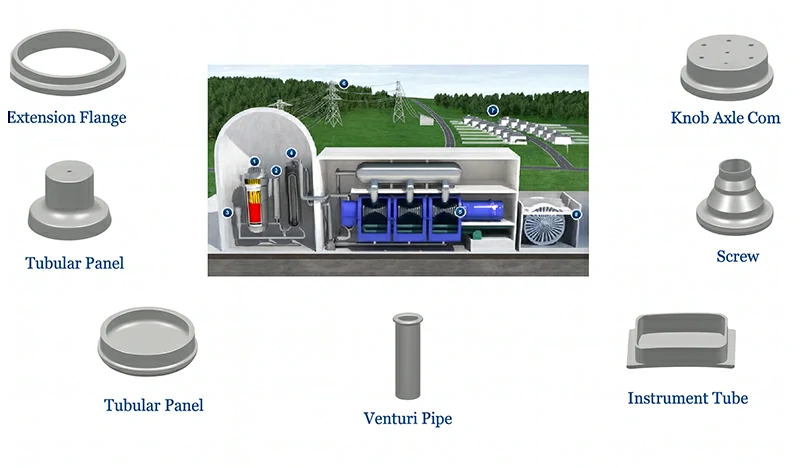

Nuclear Power Components

Tube Sheet

The tube sheet is the core component of a heat exchanger, used to secure thousands of heat transfer tubes and separate the primary loop from the cooling water. For highly corrosive primary loops, titanium alloys are typically used. For less corrosive secondary loop heat exchangers or experimental reactor systems, 2219 or 6061 aluminum alloy tube sheets are a mature choice.

- 2219: Offers excellent high-temperature strength and good weldability, stable at 200–300 °C.

- 6061: Easy to machine, and anodizing improves resistance to pitting and crevice corrosion.

Using aluminum alloy tube sheets significantly reduces weight and manufacturing costs while meeting secondary loop heat exchanger requirements.

Damper Support Pad

Damper support pads in reactor cooling systems provide support, vibration damping, and energy absorption. Under moderate load and corrosion conditions, 6061-T6 aluminum alloy pads offer an economical solution. Anodized or hard-coated aluminum enhances wear and corrosion resistance, making it suitable for secondary loop cooling water environments, reducing weight and production cost.

Instrument Tube

Instrument tubes are critical for nuclear power monitoring and control systems, connecting sensors and control devices, requiring high precision and long-term stability. Non-pressure measurement and control lines can use 6061 or 6063 aluminum alloy tubes. These alloys are lightweight, cold-bendable, weldable, and, when anodized, corrosion-resistant, making them ideal for secondary loop and auxiliary system instrumentation.

Chalco Certifications and Qualifications

In high-end equipment manufacturing, certifications are not only a guarantee of quality but also a gateway to the international supply chain. Chalco Titanium strictly adheres to global standards and has obtained certifications from major aircraft engine manufacturers and nuclear power companies, ensuring its products are fully qualified for aerospace, aviation, energy, and nuclear industries.

Management System Certifications

- Quality management: ISO 9001, AS9100D, GJB 9001C

- Environmental management: ISO 14001

- Laboratory capability: ISO 17025

- Occupational health and safety: ISO 45001

- Energy management: ISO 50001

- Digitalization integration: GB/T 23001

- Intellectual property management: GB/T 29490

- Production safety: Level 2 enterprise for standardized production safety

- International trade compliance: AEO advanced certified enterprise

These certifications provide customers with confidence in traceable, environmentally friendly, and compliant delivery.

Special Process Certifications (NADCAP)

In aerospace, NADCAP certification is essential to enter global OEM supply chains. Chalco Titanium holds the following process certifications:

- NADCAP MMM (forging)

- NADCAP HT (heat treatment)

- NADCAP NDT (non-destructive testing)

This demonstrates that Chalco not only has the capability to manufacture complex ring forgings but also meets the strictest process and testing standards required by global aerospace clients.

One-stop Solution for Precision Forging and Intelligent Manufacturing

High-end equipment clients need more than parts—they require a complete, reliable, controllable, and traceable system solution. Chalco seamlessly integrates material development, complex forging, precision machining, and intelligent delivery, providing a one-stop service platform from design to finished product, helping projects launch faster and remain competitive.

Complex Forming Solutions for High-End Equipment

Leveraging advanced ring rolling and quick forging technologies, along with the lightweight and high-strength advantages of aluminum alloys, Chalco can produce large aluminum alloy ring forgings and complex structures over 2 meters in diameter. Near-net shaping reduces machining allowance while combining light weight, high strength, and high reliability, offering high-performance structural solutions for aerospace, aviation, and energy equipment.

Precision Machining and Surface Treatment

In high-end equipment manufacturing, precision determines performance and process determines lifespan. Chalco applies micron-level machining combined with heat treatment, coatings, and polishing, giving components long-lasting durability, corrosion resistance, and low maintenance. This reduces downtime and maintenance costs while enhancing operational efficiency over the equipment's lifetime.

Intelligent and Automated Manufacturing

By implementing flexible forging production lines and intelligent workshops, Chalco achieves full-process automation from robotic machining and automatic inspection to logistics handling. Every product is fully traceable, ensuring high quality while significantly shortening delivery times.

Why Chalco is a Trusted Partner?

In the aerospace and high-end equipment manufacturing sectors, capability and qualifications determine partnership value. With leading production capacity, stringent international certifications, and long-term global collaborations, Chalco has become a trusted supplier of ring forgings.

Asia's Largest | Global Leader

- The largest supplier of commercial aircraft engine ring forgings in Asia, with leading annual production capacity and equipment level.

- The only Asian ring forging company qualified to supply major global aircraft engine manufacturers, with products integrated into international core supply chains.

Advanced Equipment | Exceptional Technology

- Invested 200 million RMB to build Asia's heaviest ring forging production line at the time, establishing industry leadership.

- Equipped with an 8 MN quick-forging hydraulic press, enabling efficient forming and mass production of large rings.

International Certifications | Military-Grade Assurance

- First to pass military qualification review, becoming China's first enterprise with core qualifications for titanium and high-temperature alloy ring forgings.

- Certified to supply LEAP, GE9X, and other engine ring forgings, with products used in over 70 aircraft engine models.