Perforated aluminum sheet, also known as perforated aluminum panel or punched aluminium sheet, is a high-performance aluminum mesh product widely used in architecture, decoration, ventilation, and filtration systems. It is manufactured by uniformly punching holes into aluminum coils or sheets, offering a variety of hole shapes, sizes, and arrangement patterns.

As one of the most popular metal mesh products, Chalco's perforated aluminum sheet features a lightweight structure, excellent corrosion resistance, and outstanding visual appeal. It is widely chosen for both indoor and outdoor applications where performance and aesthetics are equally important.

Whether you need small or large holes, standard or custom patterns, they can all be achieved with precision molds to meet both functional and decorative requirements. Available in a wide range of thicknesses, it is a versatile and practical metal material ideal for various engineering and architectural uses.

Chalco: your trusted partner for perforated aluminum sheets

Chalco is a professional manufacturer and supplier of perforated aluminum sheets, committed to providing high-quality, high-precision products to global customers, with a strong reputation in architectural, decorative, ventilation, and filtration applications.

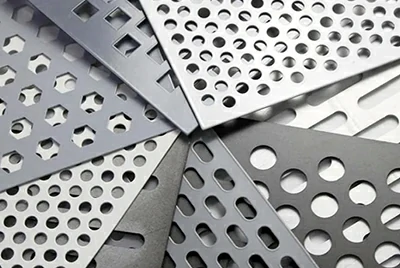

Our perforated aluminum sheets cover round holes, square holes, slotted holes, hexagonal holes, decorative patterns, and custom-shaped perforations, meeting both functional and aesthetic needs. Whether for façade cladding, ceiling sunshades, industrial screening, or acoustic systems, we offer reliable solutions.

Instant Quote

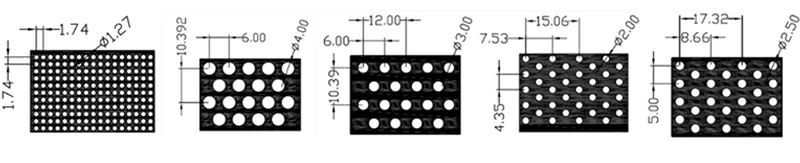

Chalco processes perforated aluminum sheets with thicknesses ranging from 0.4 mm to 6.0 mm and hole diameters from 0.5 mm to 25 mm. Standard sheet sizes such as 1220×2440 mm are available, as well as fully customized dimensions. Precision punching and CNC laser processing are supported to accommodate different shapes and patterns.

We utilize automated punching equipment and a complete quality control system, including visual inspection and flatness monitoring, to eliminate defects like hole distortion, burrs, or edge collapse, ensuring stable and high-quality delivery.

Chalco is certified with ISO 9001, RoHS, REACH, CE, and more. We not only offer competitive pricing, but also aim to be your long-term and trusted partner in the perforated aluminum sheet industry..

Hot-selling sizes of Chalco perforated aluminum sheets

Chalco offers customized aluminum perforated plates in various sheet sizes, thicknesses, hole diameters, pitches, staggered patterns, and open area percentages to meet specific customer needs.

Instant QuoteChalco specializes in custom perforated aluminum sheets, offering a wide range of hole patterns, sheet thicknesses, and surface finishes. We provide perforated aluminium sheets cut to size based on your specific project requirements. Click to view Chalco's aluminum sheet cutting methods.

| Hole diameter | Staggered center | Open area | Thickness | Sheet(W x L) |

| 3/8" | 9/16" | 40% | 0.040" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1/8" | 3/16" | 40% | 0.050" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/16" | 1/4" | 50% | 0.063" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1/4" | 3/8" | 42% | 0.063" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/8" | 9/16" | 51% | 0.063" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/8" | 1/2" | 51% | 0.063" | 4'x8', 4'x4', 4'x10', 6'x10' |

| .020" | .045" | 18% | 0.018" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1/32" | 1/16" | 23% | 0.028" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/64" | 5/64" | 33% | 0.024" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/64" | 3/32" | 23% | 0.028"–0.048" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1/16" | 3/32" | 40% | 0.028"–0.063" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1/16" | 7/64" | 30% | 0.036"–0.063" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1/16" | 1/8" | 23% | 0.018"–0.063" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 5/64" | 1/8" | 35% | 0.028"–0.078" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/32" | 5/32" | 33% | 0.024"–0.078" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/32" | 3/16" | 23% | 0.024" | 4'x8', 4'x4', 4'x10', 6'x10' |

| .117" | 5/32" | 51% | 0.048" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1/8" | 7/32" | 30% | 0.078"–0.105" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1/8" | 1/4" | 23% | 0.078"–0.090" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 9/64" | 3/16" | 51% | 0.048" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 5/32" | 3/16" | 63% | 0.028"–0.063" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 5/32" | 1/4" | 35% | 0.036"–0.134" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/16" | 7/32" | 67% | 0.028"–0.063" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/16" | 1/4" | 51% | 0.024"–0.105" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/16" | 5/16" | 33% | 0.134"–0.188" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/16" | 3/8" | 23% | 0.078"–0.134" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1/4" | 5/16" | 58% | 0.036"–0.063" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1/4" | 3/8" | 40% | 0.018"–0.250" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 17/64" | 5/16" | 66% | 0.036" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 5/16" | 7/16" | 46% | 0.036"–0.250" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/8" | 9/16" | 40% | 0.036"–0.250" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1/2" | 11/16" | 48% | 0.036"–0.250" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1/2" | 3/4" | 40% | 0.063" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 5/8" | 7/8" | 46% | 0.134"–0.250" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3/4" | 1" | 51% | 0.063"–0.250" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1" | 1-3/8" | 48% | 0.134"–0.250" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1-1/4" | 1-5/8" | 54% | 0.250" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 1-1/2" | 2" | 51% | 0.250" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 2" | 2-1/2" | 58% | 0.250" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 2-1/2" | 3" | 63% | 0.188" | 4'x8', 4'x4', 4'x10', 6'x10' |

| 3" | 3-1/2" | 67% | 0.188" | 4'x8', 4'x4', 4'x10', 6'x10' |

Chalco perforated aluminum sheet overview

Alloys: 1060, 1100, 3003, 5005, 5052, 6061, 6063

Hole types: Round, square, slotted, hexagonal, decorative patterns, custom-shaped holes

Common hole diameters: 1/16", 1/8", 1/4"

Hole diameter range: Micro holes (0.5–2.0 mm), standard holes (2.0–10.0 mm), large openings (10.0–25.0 mm)

Sheet sizes: 1000×2000 mm, 1220×2440 mm (4ft×8ft), 1250×2500 mm, customizable sizes available

Applications: Architectural decoration, exterior facades, sunshade ceilings, filtration systems, ventilation panels, acoustic control, safety protection

Surface finishes: Mill finish, brushed, anodized, powder coated, PVDF coated, painted, sandblasted

Standards: ASTM B209, EN 485, EN 573, JIS H4000, AMS QQ-A-250/2

Certifications: ISO 9001:2015, SGS, RoHS, REACH, CE, ASTM compliant

Common colors of Chalco perforated aluminum sheets

Black perforated aluminum sheet

Bronze perforated aluminum sheet

Copper metallic perforated aluminum sheet

Gold perforated aluminum sheet

White matte perforated aluminum sheet

Metallic rose perforated aluminum sheet

Silver metallic perforated aluminum sheet

Dark grey perforated aluminum sheet

Emerald perforated aluminum sheet

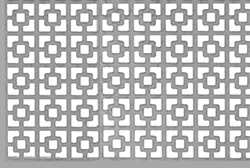

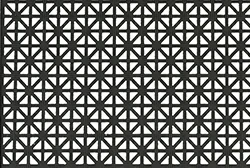

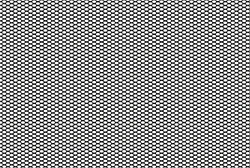

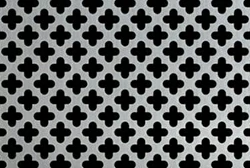

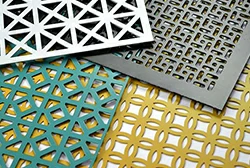

Different patterns of Chalco perforated aluminum sheets

Chalco offers a variety of patterned perforated aluminum sheets in a standard size of 12 x 24 inches and a thickness of 0.020 inches, with customization available upon request. Our products feature excellent corrosion resistance and are easy to cut and install.

Alloy types of Chalco perforated aluminum sheets

1060 perforated aluminum sheet

1060 perforated aluminum sheet With an aluminum content of 99.6%, it is classified as industrial pure aluminum. It offers excellent formability, softness, and cost-effectiveness. Ideal for applications requiring good conductivity and thermal performance rather than high strength, such as decorative panels and ventilation screens.

1100 perforated aluminum sheet

1100 perforated aluminum sheet 1100 perforated aluminum sheet is made of commercially pure aluminum with excellent corrosion resistance and workability. It is suitable for deep drawing and bending, and commonly used in interior decoration, ventilation panels, and other applications where appearance and oxidation resistance are important.

3003 perforated aluminum sheet

3003 perforated aluminum sheet Alloyed with manganese, 3003 perforated aluminum sheet offers higher strength than 1060 and 1100, along with excellent rust resistance. It is widely used for both interior and exterior applications such as building facades, ceilings, and ventilation systems.

5005 perforated aluminum sheet

5005 perforated aluminum sheet Similar to 3003, but with a smoother surface and superior anodizing performance with minimal color variation. It is commonly used for curtain walls, decorative panels, and signage where a high-quality anodized finish is required.

5052 perforated aluminum sheet

5052 perforated aluminum sheet Medium-high strength with excellent corrosion resistance, ideal for marine environments. Commonly used in ship decks, ventilation grilles, engine room panels, and gangway steps.

6061 perforated aluminum sheet

6061 perforated aluminum sheet Medium to high strength and corrosion resistance, suitable for structural and functional uses such as machine guards, equipment platforms, and industrial ventilation panels.

6063 perforated aluminum sheet

6063 perforated aluminum sheet Excellent formability and surface finish, with a high-quality anodized appearance. Commonly used for curtain walls, sunshades, ceilings, and decorative perforated panels.

What are the popular types of perforated aluminum sheets offered by Chalco?

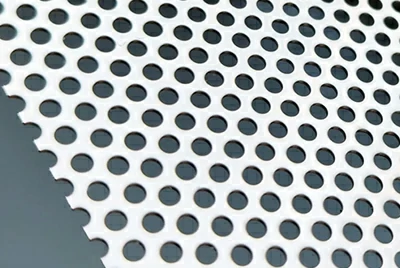

Round hole aluminum perforated sheet

The most common hole type with uniform spacing and a clean appearance, suitable for ventilation, decoration, and screening applications.

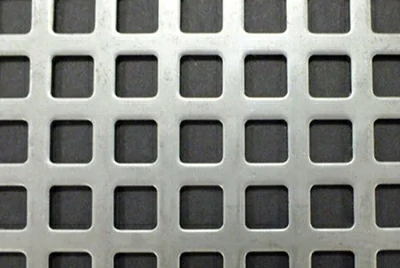

Square perforated aluminum sheet

Clean and simple structure with good light and air permeability, commonly used in railings, partitions, and architectural facades.

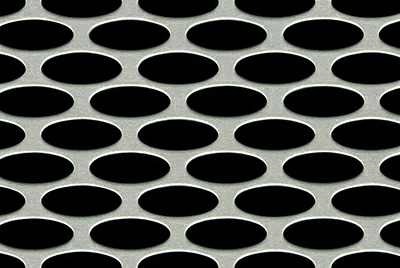

Oval perforated aluminum sheet

Offers a unique visual effect that enhances decorative appeal, ideal for modern architecture and artistic design applications.

Slotted perforated aluminum sheet

Ideal for high-flow applications such as acoustic panels, filtration screens, and machine guards.

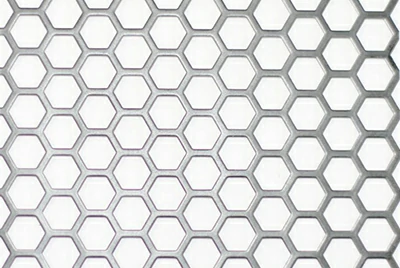

Hexagonal perforated aluminum sheet

Tightly arranged with a high open area, commonly used for efficient ventilation, screening, and lightweight structural components.

Decorative perforated aluminum sheet

Featuring stylish patterns punched into lightweight and durable aluminum, it is an ideal choice for both interior and exterior design. It combines aesthetics with functionality, offering ventilation, privacy, and light filtration.

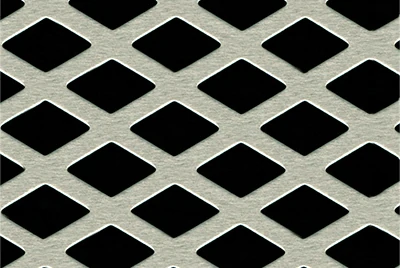

Perforated diamond aluminum mesh sheets

A lightweight and corrosion-resistant panel with diamond-shaped holes that offer both strength and visual appeal. Widely used in industrial and architectural applications such as ventilation panels, safety screens, and decorative facades.

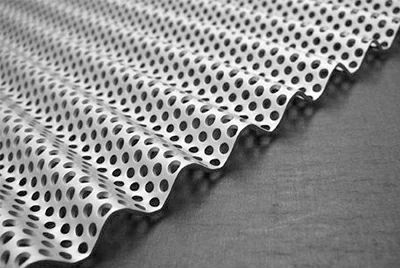

Perforated corrugated aluminum panels

Combines the strength of corrugation with the ventilation of perforation, offering lightweight, high strength, and excellent corrosion resistance. Widely used in building facades, industrial enclosures, sunshade systems, and acoustic barriers.

Anodized perforated aluminum sheet

Processed with anodizing after perforation, it offers enhanced corrosion resistance and superior surface aesthetics. Commonly used in curtain walls, ceilings, and decorative partitions where appearance and durability are critical.

Applications of Chalco perforated aluminum sheets

Perforated aluminium panels façade

Perforated aluminium panels façade Aluminum alloy with manganese as the main alloy element can not be strengthened by heat treatment and has good corrosion resistance. It can also be called rust proof aluminum, with good welding performance and good plasticity.

Aluminum perforated metal screen sheet

Aluminum perforated metal screen sheet Aluminum perforated metal screen sheet is a lightweight, corrosion-resistant material widely used for filtration, screening, and ventilation. With various evenly distributed hole patterns, it is commonly applied in HVAC covers, machinery enclosures, barriers, and architectural decoration.

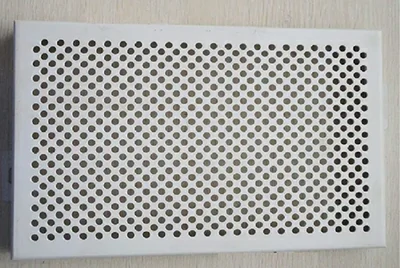

Aluminum perforated for Ceiling panels

Aluminum perforated for Ceiling panels Suitable for ceiling systems, perforated aluminum sheets provide effective ventilation and sound absorption while enhancing interior aesthetics. They are commonly used in office buildings, shopping malls, and public spaces.

Aluminum perforated for Machine guards

Aluminum perforated for Machine guards Perforated aluminum sheets are widely used as equipment guards in industrial settings, providing strength, corrosion resistance, visibility, and heat dissipation.

Aluminum perforated for HVAC grilles and vents

Aluminum perforated for HVAC grilles and vents Used in HVAC systems for outlets, grilles, and vents, perforated aluminum sheets are lightweight, easy to process, and customizable in size and hole pattern, helping improve airflow efficiency.

Aluminum perforated for Ceiling panels

Aluminum perforated for Ceiling panels Suitable for ceiling systems, perforated aluminum sheets provide effective ventilation and sound absorption while enhancing interior aesthetics. They are commonly used in office buildings, shopping malls, and public spaces.

Perforated aluminum panels for transportation industry

Perforated aluminum panels for transportation industry Widely used in components of vehicles, aircraft, and trains, such as front grilles, ventilation covers, and decorative panels. Common hole types include round, diamond, and rounded slotted holes, balancing structural strength with aesthetic design.

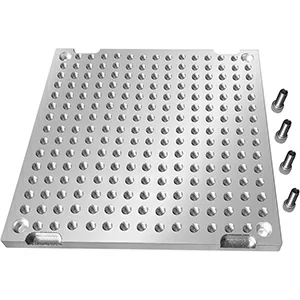

High-strength perforated tooling plates

High-strength perforated tooling plates Perforated tooling plates made from high-strength alloys like 6061 and 7075 are suitable for applications requiring excellent strength, thermal conductivity, and corrosion resistance. Hole shapes can be customized based on tooling needs, including round, square, and hexagonal holes.

Related products of perforated aluminum sheets

Perforated aluminum screen

Perforated aluminum screens offer privacy, ventilation, and decorative appeal. They are lightweight, corrosion-resistant, and ideal for facades, partitions, fences, and sunshades with customizable patterns.

Contact us now

Perforated aluminum strip

Perforated aluminum strip is a narrow aluminum material with evenly punched holes, available in various patterns and widths. It is widely used in cable shielding, ventilation, acoustic systems, and decorative trims.

Contact us now

Perforated aluminium composite panel

Perforated aluminum composite panels combine strength and aesthetics, ideal for facades and decoration. The perforated surface enhances ventilation and visual appeal.

Contact us now

Advantages of Chalco perforated aluminum sheets

- Good ventilation: The perforated design allows air to flow freely, ideal for cooling and ventilation applications.

- Light and privacy balance: Allows natural light through while providing privacy and sun shading.

- Strong decorative appeal: Customizable patterns enhance visual aesthetics for modern designs.

- Acoustic performance: Works with sound-absorbing materials for noise reduction projects.

- Lighter weight: Lighter than solid aluminum sheets, making handling and installation more efficient.

- More functionality: Combines structure and appearance, suitable for a wider range of applications.

Perforated aluminum sheet FAQs

What affects the perforated aluminium sheet price?

The perforated aluminium sheet price depends on several factors including alloy type, sheet thickness, hole pattern, open area percentage, sheet size, and surface treatment. Custom specifications and small order quantities may also impact the final cost. For an accurate quote, please contact Chalco with your detailed requirements.

Instant QuoteWhat are the common hole sizes and patterns available?

Common hole diameters include 1/8 inch (3.18 mm), 3/16 inch (4.76 mm), and 1/4 inch (6.35 mm). Patterns can be round, square, hexagonal, or custom decorative shapes, with straight or staggered arrangements.

In "1/8 perforated aluminum sheet" and "1/4 perforated aluminum sheet", what do 1/8 and 1/4 refer to?

In these terms, 1/8 and 1/4 refer to the diameter of the holes in the aluminum sheet, measured in inches. So a 1/8 perforated aluminum sheet has 1/8-inch (≈3.18 mm) holes, while a 1/4 perforated aluminum sheet has 1/4-inch (≈6.35 mm) holes. This measurement is key to determining the sheet’s airflow, appearance, and suitability for different applications.

How to choose reliable perforated aluminium sheet suppliers?

When selecting perforated aluminium sheet suppliers, consider factors such as material quality, range of available specifications, customization capability, surface treatments, certifications (like ISO, RoHS), and delivery time. A good supplier should offer both standard and custom perforated sheets with consistent hole patterns, precise dimensions, and competitive pricing.

What does the percentage of open area mean?

The open area refers to the portion of the sheet surface occupied by holes, typically expressed as a percentage. A higher open area improves airflow and reduces weight but may lower structural strength.

What surface finishes are available?

We provide mill finish, anodized, powder coated, PVDF coated, brushed, and custom painted finishes to match architectural and functional needs.

How to choose the right perforated aluminium sheet for my project?

Consider factors like hole size, pitch, open area, sheet thickness, material alloy, and surface finish. Contact our sales team for tailored recommendations.

Can perforated aluminum sheets be machined?

Yes, perforated aluminum sheets can be machined by cutting, bending, welding, drilling, and CNC processing. Proper tools are recommended to avoid deformation, and Chalco offers custom fabrication based on customer drawings.

How are perforated aluminum sheets packaged?

Chalco packages perforated aluminum sheets using export-standard methods to ensure safety and protection during transport. Common packaging includes:

- Plastic film or kraft paper wrapping for moisture and scratch resistance

- Reinforced corner protectors to prevent edge deformation

- Fumigation-free wooden pallets or steel straps for easy forklift handling and container loading

- Custom packaging available with printed labels, shock-absorbing materials, or individual sheet protection

Chalco also provides tailored packaging solutions based on different shipping methods such as sea, air, or land freight to ensure safe delivery.

Why choose Chalco?

Free samples for testing before ordering

We provide free samples of standard perforated aluminum sheets for quality inspection, compatibility testing, or engineering validation, helping you make confident decisions before placing an order.

Exclusive discount pricing

Chalco offers special discount policies for long-term partners and bulk purchase orders, helping customers reduce procurement costs and enhance market competitiveness. Click to get your exclusive discounted price.

Instant QuoteCustom specifications available

We offer customization of hole diameter, pitch, open area, pattern layout, thickness, dimensions, and surface finish based on your project needs. Drawings and samples are supported to meet requirements across architectural, ventilation, and acoustic applications.

Extensive mold resources, saving tooling costs

We have a wide selection of ready-made perforation molds—including round, square, hexagonal, and decorative patterns—which allows most custom orders to be produced without additional mold costs or delays. With over 150 molds available, we ensure fast and flexible response to customer needs. Custom mold development is also available for various architectural and decorative metal applications.

Material certificates and compliance documents provided

Each batch of products can be supplied with a mill test certificate (MTC), chemical composition analysis, and dimensional inspection report. Third-party inspection reports (such as SGS) are also available upon request to meet export compliance requirements including RoHS, REACH, and CE.

Fast quotation and quick response

Our professional sales team can provide pricing for standard products within 24 hours, while custom product quotes are typically available within 1–3 working days, helping you move forward with your procurement process efficiently.

Instant Quote