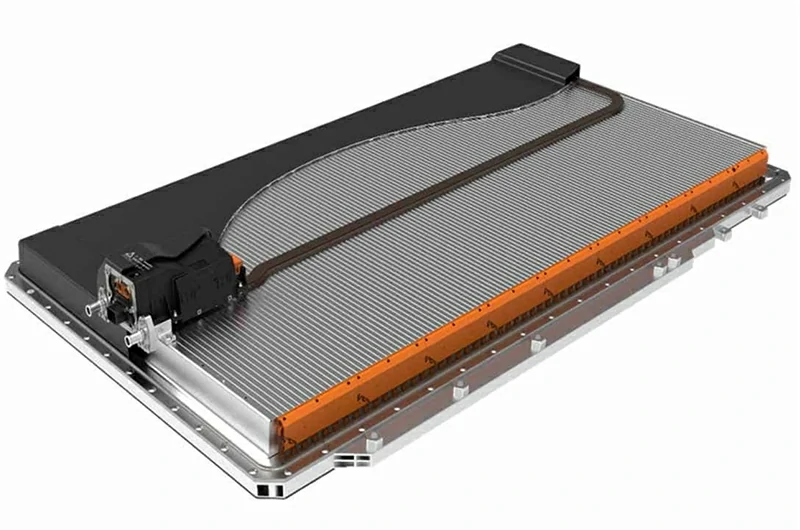

Why integrate microchannel aluminum flat tubes into BESS separators?

BESS separator = structure + cooling + safety

Embedding MPE (Multi Port Extruded) microchannel aluminum flat tubes directly into the separator delivers.

Thermal management

High surface area channels + high thermal conductivity aluminum → ~30% better heat transfer vs traditional cold plates.

TRP (Thermal Runaway Propagation) blocking

Works with flame-retardant/insulation layers to conduct heat and block fire—providing component-level data for UL9540A certification.

Weight reduction & assembly simplification

Eliminates separate cold plates and complex piping; the BESS separator cooling channel becomes part of the structure, speeding up assembly.

Standardization + fast customization

Common 11/13/19-port profiles in stock, cut to drawing/vacuum brazed; CAD/CFD feedback within 24h.

Specifications & Technical Parameters (Standard Profiles)

Dimensions & Structure Parameters

| Model Code | W (mm) | H (mm) | Ports N | Dh (mm) | t (mm) | Zn Coating (g/m²) | Stock Lengths (mm) |

| MPE-20×2.0-11 | 20 | 2 | 11 | 1.1 | 1.2 | 5±2 | 3000 / 6000 |

| MPE-22×1.8-13 | 22 | 1.8 | 13 | 0.95 | 1.1 | 7±2 | 3000 / 6000 |

| MPE-25×2.2-19 | 25 | 2.2 | 19 | 0.85 | 1.4 | 7±2 | 3000 / 6000 |

| MPE-28×2.5-19H | 28 | 2.5 | 19 | 0.9 | 1.6 | 10±2 | 4000 / 6000 |

| MPE-18×1.5-11L | 18 | 1.5 | 11 | 1.2 | 1 | 5±2 | 3000 |

| MPE-32×3.0-19R | 32 | 3 | 19 | 1 | 1.6 | 10±2 | 4000 / 6000 |

| MPE-24×2.0-13A | 24 | 2 | 13 | 1.05 | 1.3 | 7±2 | 3000 / 6000 |

| MPE-30×2.2-19S | 30 | 2.2 | 19 | 0.88 | 1.5 | 10±2 | 4000 / 6000 |

Performance & Processing

| Model Code | Burst Pressure (MPa) | ΔP @ 60 L·min⁻¹ Single Plate (MPa) | Min Bend Radius Rmin (mm) |

| MPE-20×2.0-11 | 4.8 | 0.015 | ≥10 |

| MPE-22×1.8-13 | 5.2 | 0.014 | ≥9 |

| MPE-25×2.2-19 | 5.6 | 0.013 | ≥11 |

| MPE-28×2.5-19H | 6 | 0.012 | ≥13 |

| MPE-18×1.5-11L | 4.5 | 0.017 | ≥8 |

| MPE-32×3.0-19R | 6.2 | 0.011 | ≥15 |

| MPE-24×2.0-13A | 5 | 0.014 | ≥10 |

| MPE-30×2.2-19S | 5.8 | 0.012 | ≥12 |

Special Requirements for Flat Tubes in Energy Storage Baffle Applications

| Requirement Point | Background Reason | Flat Tube Requirements | Our Solution |

| Thermal Runaway Blocking (UL9540A) | Large single-cell capacity with concentrated heat generation | Wall thickness 1.0–1.6 mm; redundant weld design | Rounded weld seams, burst/leak test reports, flame-retardant layer bonding compatibility tests |

| Large-Area Flatness (≤0.3 mm/m) | Large cell contact surface; warping = poor thermal contact | Symmetrical tube layout, aspect ratio w/t ≤ 25 | FEM pre-compensation, anti-deformation fixtures, brazing process control documentation |

| Low ΔP & Low Pump Power | Long-term operational energy efficiency sensitivity | Dh 0.8–1.2 mm, 11/13/19-hole cross section | ΔP–Q test curves, CFD optimization recommendations, pump selection reference table |

| Corrosion/Environmental Resistance | EG water/insulating oil, salt spray conditions | Zinc spray 5±2 / 7±2 / 10±2 g·m⁻² + coating | 1,000 h NSS test report, compatibility charts, surface treatment options |

| Complete Certification Documentation | PED, UL1973/9540A, IEC62619 | Full burst, fatigue, ΔP–Q, corrosion documentation | Master report templates + project-specific variation tests, shipment-ready documentation package |

Selecting Section & Key Parameters

| Parameter | Recommended Range (BESS) | Impact Indicators | Design Notes |

| Number of holes N | 11 / 13 / 19 | ΔP, temperature uniformity | Increasing N → reduces flow velocity → lowers ΔP; excessive holes raise cost and clogging risk. 11/13/19 covers most application needs. |

| Hydraulic diameter Dh | 0.8–1.2 mm | ΔP, Re, heat transfer | Re ≈ 300–1200 (laminar/transitional) for controllable pump power; locally >2000 to enhance heat transfer. |

| Wall thickness t | 1.0–1.6 mm | Burst strength, fatigue, safety factor | Greater t improves safety but slightly reduces thermal conductivity; select based on TRP/pressure requirements. |

| Overall dimensions w×h | 18–32 mm × 1–3 mm | Flatness, stiffness | Keep w/t ≤ 25 to prevent buckling; match thickness to total baffle thickness. |

| Zinc spray weight | 5±2 / 7±2 / 10±2 g·m⁻² | Brazing wetting, corrosion resistance | For coastal/salt spray projects, select 10±2; clean surface after brazing to aid subsequent flame-retardant coating. |

| Surface treatment | Anodizing / Nano-coating / Bare tube | Bonding, corrosion protection | Choose treatment compatible with bonding/flame-retardant processes to avoid peeling or contamination. |

Quick selection: Send ΔT target, allowed ΔP, coolant, and plate size → CFD/ΔP–Q preliminary in 24h.

Six Key Procurement Criteria for BESS Separators

UL9540A support: ≥4× burst margin, >10⁷ fatigue cycles, leak/fire data.

30%+ higher heat transfer & lower ΔP.

2-week shipment for standard profiles, ≤5 free samples by DHL in 3–5 days.

CAD/CFD files within 24h for internal review.

Full documentation: CE, PED, UL, IEC62619, RoHS/REACH/SDS, MTC, PQR/WPS.

Flatness ≤0.3 mm/m & w/t ≤25.: Ensure close contact with the electrode and smooth assembly.

Four Processes for Integrating Flat Tubes into Baffles

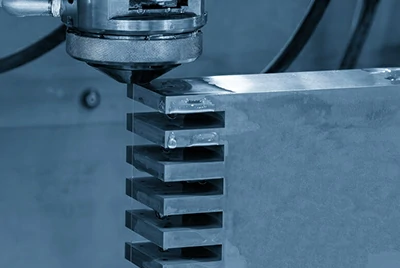

CNC Slotting + Vacuum Brazing (Embedded Type): Slot width allowance of +0.05–0.15 mm; ensure uniform zinc spray; use anti-deformation fixtures. Apply a brazing layer at the slot bottom to prevent cold joints.

Sandwich Structure: Upper and lower plates with intermediate flat tubes/ribs; control the brazing curve to prevent bulging or collapse; match flat tube wall thickness with rib dimensions to increase stiffness.

Extruded Profile + Flat Tube Insert Welding: Extrude ribs into the main profile and locally insert/weld flat tubes; reserve a weld seam buffer zone and perform post-weld heat treatment to avoid fatigue weak points in the heat-affected zone (HAZ).

One-Piece Bending: Minimum bending radius Rmin ≥ 3–5× t; use internal mandrels or segmented bending when necessary. Verify via FEM analysis that the inner wall at the bend does not collapse.

Risk Mitigation Measures

Weld leak prevention: optimized brazing, CT scan, 100% helium test.

Temperature uniformity: CFD-optimized porting, cleaning, filtration.

Flatness control: symmetrical layout, FEM, anti-deformation jigs.

Pitting resistance: Zn + coating, compatibility testing.

We provide: ΔP–Q curves, CFD files, burst/pressure/fatigue reports, corrosion reports, MTC, PQR/WPS, RoHS/REACH/SDS.

Delivery & Cost Control

Lead time: Standard profile + process → 2 weeks; custom (new die) → 4–5 weeks.

Cost strategies: Use standard profiles, unify Zn/coating specs, leverage master test reports, batch brazing.

FAQ

Q: How does it help UL9540A?

A: Component-level test data supports faster certification.

Q: Is Zn coating mandatory?

A: Recommended for large plates in vacuum brazing; alternatives possible.

Q: Can the same section be used for oil cooling?

A: Yes, with coating/seal compatibility validation.

Q: Fastest for small-batch projects?

A: Standard profile + embedded process → 3–5 days DHL samples.

Q: Can you provide CAD/CFD files?

A: Yes, under NDA.

Contact Us

Send CAD sketch, ΔT target, allowed ΔP, coolant, and annual usage to: sale@chalcoaluminum.com

2h: Engineering section suggestion & preliminary results

24h: CAD/CFD model + ΔP–Q estimate + quotation

≤5 free samples: DHL 3–5 days

Global delivery: 2-week standard lead time, DDP to NA/EU available