Co-developed by Chalco and Zhengzhou Light Metal Research Alloy Technology Co., Ltd. , the alloy is produced using advanced vacuum induction melting (VIM) technology. This allows precise control of chemical composition, ensuring that the material maintains excellent structural stability and functional properties even under intense neutron irradiation environments.

Core Technical Parameters

To meet the demanding requirements of nuclear fusion materials, this Pb-17Li ingot is manufactured with strict control over the following indicators:

Chemical Composition

| Parameter | Value |

| Lithium (Li) content | 0.68%–0.80% |

| Total impurities | ≤300 ppm |

| Oxygen content | <50 ppm |

Physical Properties

| Parameter | Value |

| Solidus temperature | 232°C |

| Liquidus temperature | 238°C |

| Density | 11.34 ± 0.15 g/cm³ |

| Microstructure | Directionally solidified, grain size ≥ ASTM No.6 |

Product Forms and Dimensions

| Cast rectangular PbLi ingot | |

| Dimensions (L×W×H) | 60×60×30mm |

| Unit weight | 1.5~3.0kg |

| Cylindrical Pb-17Li cast ingot | |

| Diameter | 90~140mm |

| Height | 150~300mm |

| Unit weight | 15~50kg |

Key Advantages for Fusion Applications

This Pb-17Li cast ingot serves as the core material for liquid metal tritium breeding modules (TBM) and is particularly suitable for advanced nuclear fusion test reactors such as ITER and DEMO. Its key advantages include:

High-efficiency tritium breeding and neutron multiplication

Through precise control of lithium content (especially Li-6 isotopes), the tritium breeding alloy significantly enhances tritium production—an essential step for sustaining fusion fuel cycles.

Excellent radiation shielding performance

The high-density lead matrix effectively absorbs neutrons and secondary gamma rays, reducing radiation load on surrounding components and improving overall reactor safety.

Low melting point for operational ease

With a working melting range of 232–238°C, the alloy simplifies system processes such as melting, flow circulation, and drainage, making operations and maintenance more efficient.

Stable microstructure

Directional solidification results in uniform, refined grains, imparting superior thermal shock resistance and irradiation tolerance, ensuring long-term stability in demanding fusion reactor environments.

Rigorous Quality Control System

Strictly produced in accordance with enterprise standard QY/LQ-238, the entire production process is governed by a comprehensive quality control system:

Raw Material Traceability: High-purity lithium and refined lead ingots with full batch traceability

Process Monitoring: Real-time LIBS (Laser-Induced Breakdown Spectroscopy) analysis during melting to ensure alloy uniformity

Final Inspection Items:

- Ultrasonic testing (internal defects, in line with EN 12680-3)

- Surface roughness Ra ≤ 3.2 μm

- Dimensional and geometric tolerance (e.g., end-face perpendicularity ≤ 0.1 mm / 100 mm)

Professional Packaging and Transport

Given the highly reactive nature of lithium, the product is packaged using a strict dual-layer protection system to ensure absolute safety.

| Layer | Description | Protective Function |

| Inner | Vacuum-sealed aluminum-plastic wrap | Isolates air and moisture (dew point ≤ –40°C) |

| Outer | Foam-wrapped layer | Provides physical cushioning and impact protection |

Recommended storage conditions: 15–25°C, relative humidity <30%, in a dry environment

Comprehensive Technical Support and Services

Beyond product delivery, we offer extensive technical support and customization services for nuclear energy research institutions and system integrators, including:

- Sharing thermal fatigue test records (e.g., 1000 phase-change cycles)

- Providing high-temperature creep rate data (e.g., 400°C / 100 h)

- Adjusting lithium content and product dimensions based on your specific requirements

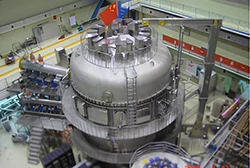

The superior performance of this Pb-Li alloy has already been validated in critical fusion research projects, including China's EAST tokamak reactor.

— Explore our dedicated "Nuclear Materials Solutions" section for whitepapers and expert support.

Instant Quote

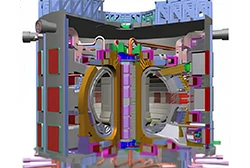

Multifunctional loop

China's EAST nuclear fusion reactor

Reactor core