Lead-Bismuth Eutectic (LBE) is considered one of the most promising nuclear fission coolant materials for Generation IV fast reactors.

Compared with traditional sodium or sodium-potassium alloys, LBE exhibits lower chemical reactivity, lower neutron absorption cross-section, and superior thermal stability, making it safer and more adaptable for long-term reactor operation.

Product Specifications

| Pb-Bi Rectangular Ingot | |

| Dimensions (L×W×H) | 60×60×30mm |

| Unit weight | 1.5~3.0kg |

| Form | Solid cast block |

| Pb-Bi Cylindrical Cast Rod | |

| Diameter | 90~140mm |

| Height | 150~300mm |

| Unit weight | 15~50kg |

Packaging

| Layer | Description | Protective Function |

| Inner | Vacuum-sealed aluminum-plastic wrap | Isolates air and moisture (dew point ≤ –40°C) |

| Outer | Foam-wrapped layer | Provides physical cushioning and impact protection |

Performance Advantages

The Lead-Bismuth Eutectic alloy provides a unique combination of properties for safe and efficient reactor operation:

| Property | Value/Description |

| Melting Point | < 400 K (~127°C) |

| Boiling Point | 1943 K (~1670°C) |

| Neutron Absorption | Very low |

| Chemical Reactivity | Inert compared to alkali metals |

| Impurity Control | ≤ 100 ppm total (O, Cd, Sb, etc.) |

These properties allow LBE to serve not only as an efficient coolant, but also as a neutron moderator and radiation shield, extending the life of core materials and improving reactor safety.

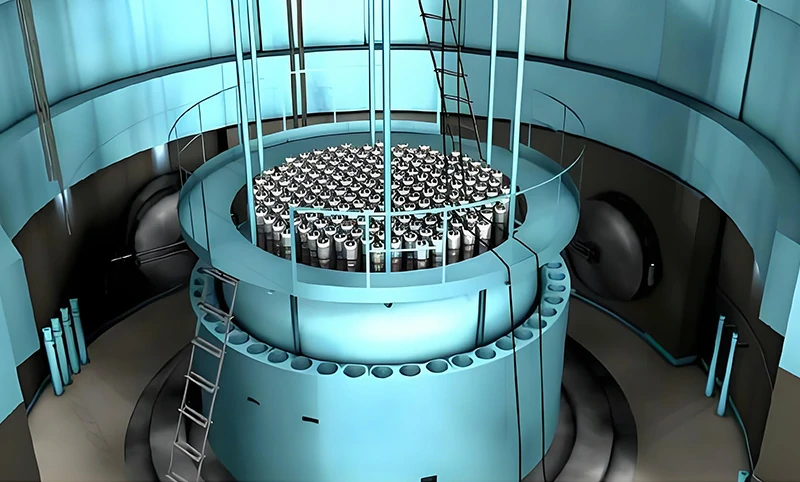

Applications in Nuclear Reactor Systems

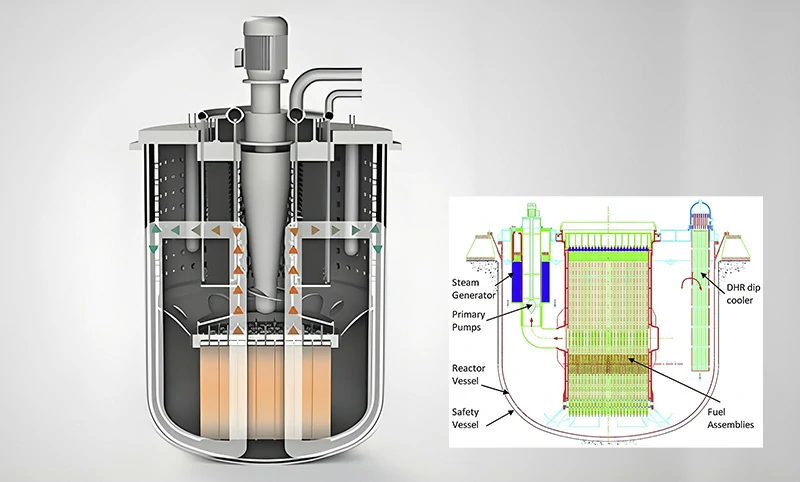

High-purity LBE is widely adopted in research and deployment of lead-cooled fast reactors (LFRs). Prominent programs include:

- SVBR-100 and BREST-OD-300

- SSTAR and LFR-DEMO concepts

- Ongoing material compatibility tests

- Deployed in PHOENIX-I circulation loop as coolant candidate for future fast reactors

Thanks to its thermal, chemical, and neutronic advantages, LBE is positioned to become a core material in next-generation reactor designs focused on safety, efficiency, and reduced long-lived waste.

Quality Control and Traceability

We ensure material quality through full-process management:

Raw Material Traceability: Verified batches of refined lead and bismuth

Smelting Control: Vacuum induction melting (VIM) to ensure alloy homogeneity

Testing Parameters:

- Impurity content: Certified by ICP-MS

- Surface finish: Ra ≤ 3.2 μm

- Dimensional tolerance: ±0.5 mm

- Phase stability verification via thermal cycling

Storage Recommendations

Store in a dry environment at 15–25°C, relative humidity <30%. The sealed packaging protects against moisture, oxidation, and cross-contamination.

Customization and Technical Support

We provide comprehensive solutions for nuclear research institutes, reactor developers, and system integrators:

- Customizable ingot sizes and geometry

- Radiopurity documentation & impurity profiles

- Support for international fusion & fission R&D

- Performance validation under thermal stress and corrosion environments

to discuss your reactor-grade coolant material requirements or request a technical whitepaper.

Instant Quote