In urban expressways, vehicle noise pollution has become an unavoidable issue. Traditional soundproof materials often suffer from moisture absorption, deformation, poor durability, and insufficient fire resistance, leading to high maintenance costs and failing to meet today's stringent noise reduction requirements.

Foam aluminum, with its lightweight yet high strength, Class A fire resistance, 100% recyclability, and excellent sound absorption, is rapidly emerging as the ideal noise barrier material for urban expressways.

Outstanding performance of foam aluminum barriers

| Performance | Index | Comparison |

| Density | 1.0–1.3 g/cm³ | 1/10 of aluminum, 1/4–1/3 of water |

| Size | 2460×500×300mm | |

| Compressive Strength | 3–14.5 MPa | 20 times stronger than polyurethane foam of the same density |

| Stiffness | 0.7–1.6×10⁴ MPa | 50–100 times higher than similar metals |

| Coefficient of Thermal Expansion | (14–20)×10⁻⁶/K | Comparable to concrete |

| Thermal Conductivity | (0.2–0.8) W/(m·K) | 1/51–1/500 of aluminum, 1/3 of water |

| Heat Resistance | No deformation at 780°C | GB 8624 Noncombustible Material, Grade A |

| Energy Absorption | 2–3 J/cm³ | Significantly reduces impact energy harmful to humans |

| Sound Insulation | 20–40 dB | Regular foam plastics only achieve 10–20 dB |

| Electromagnetic Shielding | 60–100 dB | Excellent shielding with no electromagnetic pollution |

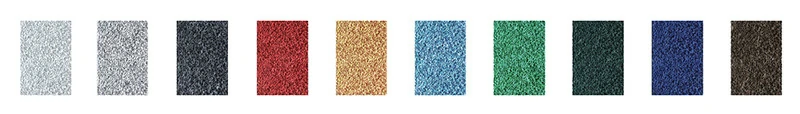

Our foam aluminum panels can be powder-coated in custom colors per customer requirements, with a coating thickness of ≥40 microns.

Highway noise barriers

Highway noise barriers come in various materials, such as glass wool panels, rock wool panels, sprayed polyurethane foam, and acoustic concrete. However, these materials lack the soundproofing efficiency of foam aluminum and are not fire-resistant.

Foam aluminum highway noise barrier advantages

- Superior sound insulation & noise reduction

- Fire resistance, thermal insulation & eco-friendliness

- Energy absorption & shock mitigation

- Durability & safety

- Lightweight yet high strength

- Enhanced lighting & visual aesthetics

Types of noise barriers

Fully enclosed noise barrier

Semi-enclosed noise barrier

All-metal noise barrier

Semi-transparent noise barrier

Vertical noise barrier

Curved noise barrier

Landscape noise barrier

Subway and high-speed rail noise barriers

Foam aluminum, as a new type of soundproofing material, is widely used in subway stations and tunnels due to its lightweight, high strength, excellent sound absorption, corrosion resistance, and Class A1 fire resistance.

The interior walls of subway stations are fitted with foam aluminum noise insulation panels, which effectively absorb train noise, enhance aesthetics, and ensure long-term durability, reducing maintenance costs.

In tunnel walls, a porous foam aluminum structure is used to create a diffuse reflection acoustic layer, significantly reducing echo and improving passenger comfort.

Subway and High-Speed Rail Noise Barrier

Tunnel noise barriers

Tunnels are critical transportation infrastructures that require significant investment and, once built, are difficult to modify on a large scale.

Therefore, the design and materials used in tunnels must be highly durable. Foam aluminum is water-resistant, corrosion-resistant, aging-resistant, and impact-resistant. It does not deform in tunnel environments and has a service life of 30-50 years, while being 100% recyclable with no environmental pollution.

Foam aluminum has a unique porous structure, which, when applied to tunnel walls, forms a diffuse reflective surface that enhances tunnel lighting effects. This smooth transition between the entrance and interior lighting helps prevent glare and visual discomfort.

Foam Aluminum Tunnel Diffuse Reflection Effect

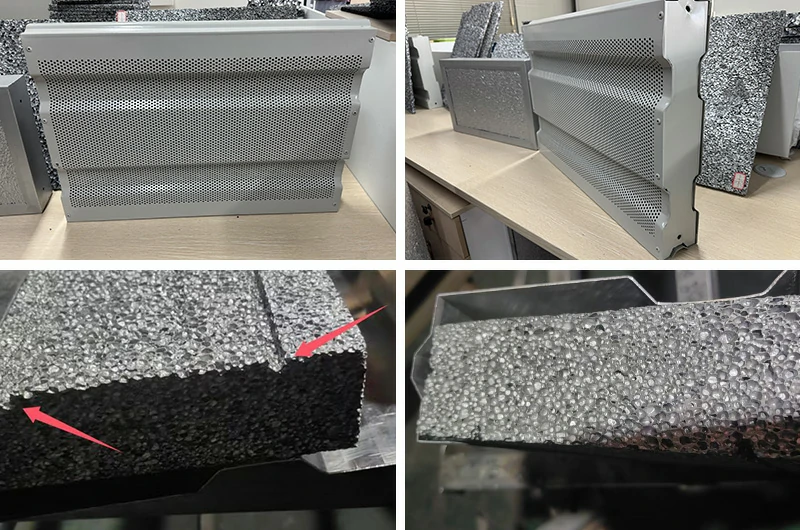

The tunnel walls are installed with 10mm-thick foam aluminum panels, with a 50mm cavity behind. The installation uses light steel keel structures, and the design features a silver-white main color with a green waistline, making the space appear wider while enhancing visual continuity.

Installation of Foam Aluminum Tunnel Noise Barriers

Fires are one of the most severe hazards in tunnel traffic accidents. In the past, tunnels primarily used standard fireproof materials, which tend to absorb moisture, develop mold, discolor, and peel off due to the damp, cool, and poorly ventilated tunnel environment.

Foam aluminum has an extremely low thermal conductivity, only 1/51 to 1/500 that of pure aluminum. As a metal material with thermal insulation properties, foam aluminum is Class A fire-resistant and does not produce toxic or harmful gases at high temperatures, making it an ideal replacement for traditional fire-resistant materials in tunnels.

Underwater tunnel noise barriers

Our company utilizes 10mm perforated foam aluminum acoustic panels for riverbed tunnel soundproof enclosures, with a 60mm cavity behind for enhanced sound absorption.

Due to the high humidity in underwater tunnels, foam aluminum does not absorb moisture, maintaining excellent soundproofing performance. Additionally, its sidewalls absorb impact energy and vibration waves, protecting the tunnel's interior structure.

The surface of the foam aluminum panels is treated with nickel plating and powder coating, ensuring corrosion resistance against seawater.