Performance of foam aluminum

| Property | Value / Range |

| Density | 0.5 ~ 0.8 g/cm³ |

| EMI Shielding | 60 ~ 100 dB |

| Compressive Strength | 15 ~ 35 MPa |

| Energy Absorption | 10 ~ 30 MJ/m³ |

| Stiffness | Elastic Modulus: 0.7 ~ 1.4 GPa |

| Thermal Expansion | (14 ~ 20) × 10⁻⁶ /°C |

| Thermal Conductivity | 0.2 ~ 0.8 W/(m·K) |

| Heat Resistance | No deformation at 780°C; heat resistant up to 1000°C |

| Sound Absorption | Noise Reduction Coefficient (NRC): 0.4 ~ 0.8 |

| Sound Insulation | 20 ~ 40 dB |

Naval compartment walls

Foam aluminum composite panels are used in ship compartments for multi-functional protection. They offer sound insulation, shock absorption, flame retardancy, bullet resistance, and explosion-proof capabilities, making them ideal for military vessel interiors.

Contact us now

Ship deck panels

A composite structure of armor plate + foam aluminum + steel is used on ship decks.

This increases the deck's strength by over 2x and significantly enhances its anti-explosion and ballistic resistance, providing better protection for critical areas.

Engine room noise reduction (surface vessels)

In destroyers and similar vessels, foam aluminum panels are applied in engine rooms and partition walls to reduce vibration and noise.

These panels integrate acoustic dampening, fire safety, and structural reinforcement into a lightweight solution.

Contact us now

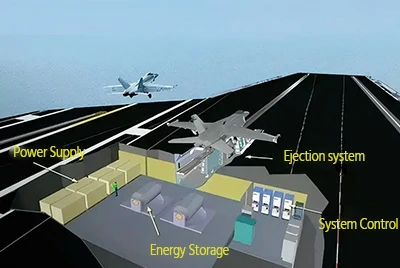

Electromagnetic catapult systems (aircraft carriers)

Foam aluminum can shield high-power electromagnetic radiation in carrier-based EM catapults.

It performs well in pulse fields >2 Tesla, providing effective EMI shielding with low heat generation, which is crucial for high-frequency equipment stability.

Contact us now

Submarine engine room sound boxes

Sound absorption boxes made with foam aluminum panels are installed in submarine engine compartments.

They reduce cabin noise by over 20 dB, facilitating the development of low-noise or silent submarines, improving stealth and crew comfort.

Contact us now