F95 achieves approximately 95% ± 2 total reflectance and 5% ± 2 diffuse reflectance within the visible spectrum. It combines mirror polishing with continuous roll-to-roll PVD processing to ensure batch consistency and surface stability. The coating offers excellent adhesion, as well as strong heat and UV resistance. With a lightweight, recyclable, and easily formable aluminum substrate, F95 delivers superior total cost of ownership (TCO) across material performance, processing yield, lead time, and maintenance.

Why Choose F95?

The "F95” mirror aluminum product features outstanding reflective performance, providing high reflectance across various application scenarios — making it a highly cost-effective solution.

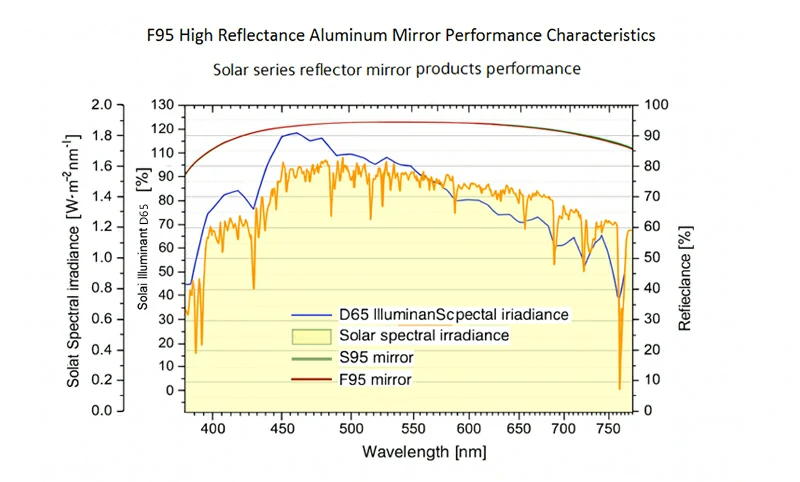

The red line represents the spectral curve of the F95 aluminum mirror; the blue line shows the D65 standard illuminant corresponding to human visual sensitivity; and the orange line indicates the solar spectral irradiance curve.

Dimensional Tolerances

| Item | Specification |

| Thickness tolerance (coil & sheet) | ±8% of nominal thickness |

| Coil width tolerance [mm] | +2.00 / −0.00 |

| Slit coil width tolerance [mm] | +0.06 / −0.00 |

| Coil longitudinal curvature [mm] | ≤1 per 1000 mm length |

| Sheet size [mm] | Width < 1250; Length < 4000 |

| Sheet size tolerance [mm] | +0.50 / −0.00 (<500 mm) • +1.50 / −0.00 (500–2000 mm) • +2.50 / −0.00 (2000–4000 mm) |

| Flatness (%S ≤ 3 mm) | <1% (special leveling available upon request) |

Mechanical Properties

| Property | Specification |

| Tensile strength [N/mm²] | ≥ 140 |

| Yield strength [N/mm²] | ≥ 120 |

| Elongation A50 [%] | ≥ 2 |

| Uniformity across width [%] | ± 2.5 |

| Uniformity along length [%] | ± 5.0 |

| Elongation [%] | ≥ 1 |

| Forming bend radius | ≥ 1.5 × strip thickness |

Physical Properties

| Property | Specification |

| Density [g/cm³] | 2.7 |

| Coefficient of thermal expansion [10⁻⁶ K⁻¹] | 23.1 |

| Specific heat capacity [J/(kg·K)] | 900 |

| Effective thermal conductivity [W/(m·K)] | > 220 |

Optical Properties

| Property | Specification |

| Total reflectance (Y / D65 / 2°) [%] | 95% ± 2 |

| Diffuse reflectance (Y / D65 / 2°) [%] | 5% ± 2 |

| Color (CIELAB D65 10°) | L*: 98 ± 1 • a*: 0–4 • b*: 0–4 |

| Iridescence | No visibly noticeable iridescence |

Applications

Lamp Reflector Cups / Reflector Shades

With a mirror finish and total reflectance of ≈95% ± 2, F95 is ideal for downlight, spotlight, and track light reflector cups and shades. Typical thickness ranges from 0.4–0.6 mm. For small-diameter or deep-cup forming, the minimum bending radius should be R ≥ 1.5×t, and die corner polishing is recommended to prevent surface drag marks. Medium- or heavy-duty protective films with slip layers are preferred. Maintain precise punch clearance and control springback.

Quality control includes visual inspection, cross-cut adhesion, and Y/D65/2° reflectance testing, with optional NSS 24h / 85-85 humidity–temperature resistance evaluation.

Linear Light Guides / Mixing Chambers

To achieve uniform light output and glare control, F95 utilizes a diffuse reflectance of ≈5% ± 2. Typical thickness is 0.3–0.5 mm. For bending or snap-fit designs, maintain R ≥ 1.5×t and compensate for edge warpage and springback. Use light- or medium-duty protective film. After blanking, perform chamfering and deburring to prevent assembly scratches. Quality control should include stripe/bright-spot inspection and cross-section photometric sampling.

Architectural Reflector Panels / Photography Reflectors

Flatness and handling are critical. Thickness 0.6–1.0 mm, with heavy-duty protective film and soft interleaving pads throughout the process. Use point or line mounting to avoid mirror surface pressure marks or "orange peel.” Clean only with neutral solvents. Conduct 100% visual inspection and sampling reflectance tests before shipment, with optional large-panel flatness verification.

Daylight Redirection / Solar Lighting (Indoor / Semi-Outdoor)

Used as reflective plates for skylights and light guides, with thickness 0.5–0.8 mm. Maintain R ≥ 1.5×t for structural bending, and seal joints against dust and condensation. For semi-outdoor use, add transparent edge protectors; for long-term exposure or corrosive environments, upgrade to outdoor-durable coating systems. Perform thermal–humidity cycling, short-term salt spray, and light-aging validation before mass production.

F95 vs L95 vs Anodized Mirror Aluminum

F95: General-purpose high-reflectance material (≈95% ± 2 total / ≈5% ± 2 diffuse). Offers the best cost-performance ratio, ideal for indoor and moderate environment applications.

L95: Optimized for CoB-LED wavelength ranges (450 / 550 / 625 nm) and long-term heat–humidity conditions, providing more stable luminous efficiency retention.

Anodized Mirror Aluminum: Excellent for decorative and scratch-resistant purposes, but with lower initial total reflectance (TR) and less consistent optical and forming performance.

| Dimension | F95 (PVD Mirror Aluminum) | L95 (PVD | LED-Optimized) | Anodized Mirror Aluminum |

| Optical (VIS) | TR ≈95% ±2; DR ≈5% ±2 (Y/D65/2°) | TR ≈ 95% ±2; DR ≈ 5% ±2 — optimized for 450 / 550 / 625 nm LED wavelengths | TR ~90–94% (typical); DR difficult to control |

| Durability | Passed short-cycle tests: 180 °C / 2 h, NSS 24 h, 85/85 (24 h) | Excellent long-cycle stability: 150 °C / 1000 h, 85 °C–85% RH / 1000 h, NSS 72 h with well-controlled ΔY% | Hard oxide layer with good scratch resistance, but limited optical stability under prolonged heat and humidity |

| Formability | R ≥ 1.5 × t; excellent for stamping and bending | R ≥ 1.5 × t; requires stricter cleanliness and protection during processing | Hard and brittle film; prone to cracking or imprinting during deep forming |

| TCO (Material + Processing + Lead Time + Maintenance) | Outstanding overall cost-efficiency; consistent from rapid prototyping to mass production | Slightly higher initial cost, but lower lifecycle cost due to better luminous efficiency retention | Moderate material and processing cost; less cost-effective when high luminous efficiency is required |

| Typical Applications | Downlight / spotlight / track light reflectors, linear light guides, architectural & exhibition reflectors, daylight redirection (indoor / semi-outdoor) | CoB-LED reflector cups, mixing chambers, high-power commercial lighting, fixtures demanding high color consistency and luminous flux stability | Decorative mirror panels and general reflectors where optical performance is not critical |

| Remarks | Eco-friendly PVD process with excellent surface and appearance uniformity | Specially designed for LED spectral response and long-term resistance to heat and humidity | Available in various anodized colors; lower ceiling for optical reflectance compared to PVD-coated mirrors |

If LED cavity efficiency, lifespan, or color stability are the priorities, choose L95.

If general reflectance and cost-performance are more important, choose F95.

If the focus is on decorative appearance or simple mirror finish, anodized mirror aluminum is a suitable option.

Processing Guidelines

Material Preparation & Protection

Use 1085 aluminum (H18/H19 temper) with the coated surface facing outward. Maintain workshop conditions at 15–30 °C and RH < 60%.

Select light-, medium-, or heavy-duty protective films according to process requirements. For long strips or large panels, add soft corner guards and spacers.

For small diameters, deep cups, or ultra-tight radii, conduct prototyping first to verify springback and surface risk.

Incoming materials must pass visual and flatness inspection; when necessary, sample-test total and diffuse reflectance (Y/D65/2°).

Blanking & Edge Treatment (Shearing / Punching / Laser Cutting)

Set single-side clearance at 5–8% × t, ensuring sharp, chip-free die edges.

For laser or turret punching, validate the heat-affected zone and burr height before fixing mass-production parameters.

Immediately deburr and chamfer after blanking to prevent film surface scratches during assembly.

Control burr height ≤ 0.05 mm; ensure no edge drag and maintain dimensional accuracy and coaxiality of holes.

Forming & Bending

Maintain a minimum bend radius of R ≥ 1.5 × t. For tight-radius forming, use medium or heavy protective films with slip layers.

Polish die pressure surfaces and corners to Ra ≤ 0.4 µm, and form along the rolling direction when possible.

Apply a thin coat of neutral, low-volatility lubricant and use moderate forming speeds to minimize wrinkling and springback.

Ensure surfaces remain free from dents and drag marks, with no edge cracking. For lighting components, conduct sectional photometric or UGR sampling as required.

Assembly, Cleaning & Packaging

Before and after assembly, clean with neutral detergent and lint-free cloths. Avoid strong solvents and dry wiping. Remove protective film only after assembly is completed.

Use soft interleaving sheets or foam pads with corner protectors during packing to prevent vibration and scratches.

Sampling inspection should include appearance, cross-cut adhesion ≤ Grade 1, and total/diffuse reflectance (Y/D65/2°).

According to service conditions, perform short-cycle reliability tests such as 180 °C/2 h heat resistance, NSS 24 h salt spray, and 85 °C/85% RH humidity testing.

For large panels, verify flatness ≤ 1 mm per 1000 mm, record process parameters and retain samples before batch release.

Durability Tests

| Test Item | Result |

| Cross-cut adhesion test (coating removal grade) | Grade ≤ 0 |

| High-temperature baking (180 °C / 2 h / coating removal grade) | Grade ≤ 1 |

| High-temperature baking (180 °C / 2 h / total reflectance change) | ΔY% < 0.5% |

| Neutral salt spray (coated sample / 24 h / coating removal grade) | Grade ≤ 1 |

| Neutral salt spray (coated sample / 24 h / total reflectance change) | ΔY% ≤ 1% |

| Artificial climate chamber (85 °C – 85% H / 24 h / coating removal grade) | Grade ≤ 1 |

| Artificial climate chamber (85 °C – 85% RH / 24 h / total reflectance change) | ΔY% ≤ 1% |

| Artificial climate chamber (40 °C – 95% RH / 168 h / coating removal grade) | Grade ≤ 1 |

| Artificial climate chamber (40 °C – 95% RH / 168 h / total reflectance change) | ΔY% ≤ 1% |

Why Choose Chalco?

Chalco offers distinct advantages for F95 mirror aluminum.

1. Aluminum substrate: Excellent ductility and flexibility with low yield strength—easy to bend and form.

2. Recyclable & cost-effective: Aluminum is readily recyclable, delivering superior value for money.

3. PVD coating: Physical vapor deposition ensures an environmentally friendly process and product (no toxic residues).

4. Lightweight: Easier installation, cleaning, repair, and maintenance.

FAQ

Q1: Can F95 be used outdoors long-term?

A: F95 is designed for indoor and moderate environments. For long-term outdoor or highly corrosive conditions, choose an outdoor-durable system.

Q2: Is laser cutting, CNC punching, and bending feasible? What's the minimum bend radius?

A: Yes. We recommend R ≥ 1.5 × t, and using suitable tooling/protective films/pads to minimize indentations and scratches.

Q3: What test reports can you provide?

A: Total/diffuse reflectance (Y/D65/2°), cross-cut adhesion, 180 °C/2 h heat resistance, salt spray (NSS), 85 °C/85% RH, and product specifications.

Q4: What does "effective thermal conductivity >220 W/(m·K)” mean?

A: It's a composite effective value for the coated laminate (substrate + coating). Film thickness can influence the reading.

Q5: What are the common thicknesses and widths?

A: Typical thickness 0.3–1.0 mm; width 1000–1250 mm. Cut-to-size, slit coils, and blanks are available.

Q6: How should I choose thickness for each application?

A: Reflector cups/shades: 0.4–0.6 mm.

Linear light guides/mixing chambers: 0.3–0.5 mm.

Large architectural/photography panels: 0.6–1.0 mm (balance stiffness and handling).

Q7: Why use protective films? How to choose light/medium/heavy?

A: Films reduce scratches during processing and handling. Light for straight feeding/light forming; Medium is general-purpose; Heavy for tight-radius flanging, deep cups, and large-panel handling.

Q8: What about tooling edges and clearances during processing?

A: For punching, set single-side clearance at 5–8% × t; keep cutting edges sharp and chip-free. For bending, polish pressure surfaces and radii to Ra ≤ 0.4 μm.

Q9: What are the recommended cleaning methods and prohibitions?

A: Use only neutral detergents with lint-free cloths. Avoid strong solvents and dry wiping. Peel off the protective film after assembly.

Q10: What are the storage and environmental requirements?

A: Maintain 15–30 °C, RH < 60%, and avoid sunlight and dust. Store coils and sheets with the coated side out, using soft pads and corner guards.