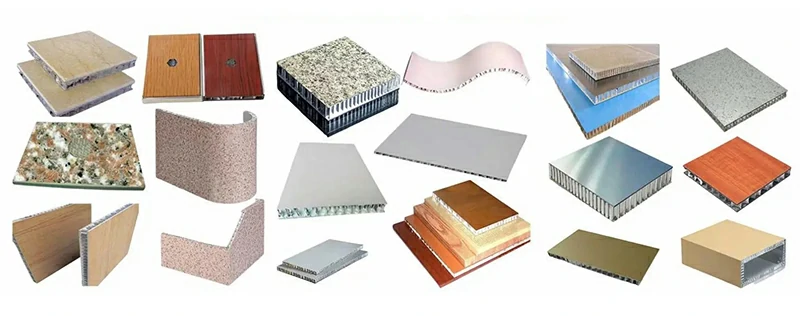

Architectural decorative honeycomb aluminum panels are lightweight, high-strength composite panels for wall, floor, and ceiling systems, consisting of aluminum face sheets, a honeycomb core, and a back panel. They offer high flatness, fire resistance, and long-term dimensional stability, making them suitable for large public buildings, commercial spaces, transportation hubs, and high-end interiors.

Chalco provides project-based engineering guidance on panel materials, core thickness, back panel structures, and surface finishes to ensure reliable structural performance and enhanced decorative results.

Aluminum Honeycomb Walls, Floors & Roof Panel Overview

Architectural decorative honeycomb aluminum panels utilize a composite structure of aluminum face panels, honeycomb cores, and back panels. Lightweight internal honeycomb supports achieve high rigidity, high flatness, and stable fire resistance. Different applications (wall panels, floor panels, ceiling panels) have varying requirements for the load-bearing capacity, flatness, and structural stability of the panels. Chalco can adjust the specifications and combinations of each layer of materials according to actual usage needs.

-

Front Skin Panel

Aluminum panel: 3003 / 5005 / 5052, standard thickness 0.7–1.5 mm

Support for thin stone veneer finishes for high-end wall and floor decoration

Surface finishes: PVDF, FEVE, anodized, wood grain, stone grain, etc.

-

Aluminum honeycomb core

Uses 3003/5052 aluminum honeycomb core

Common core thickness 6–25 mm

Provides overall stiffness, compressive strength and resistance to deformation.

-

Structure and back panel

Mainstream structure: engineering-grade flame-retardant film bonding.

Optional brazed structure for metal-to-metal panel–core bonding.

Back panel configuration based on application: wall panel/floor panel/ceiling panel (including FRP)

Jump to view configuration details →

Chalco's Three Major Application Systems for Architectural Decoration and Honeycomb Aluminum

Chalco integrates its architectural decorative honeycomb aluminum panels into three mature application systems, focusing on core decorative components such as building walls, ceilings, and floors. This addresses different structural forms, processing methods, and decorative needs, providing product solutions that can be directly used in engineering projects.

Chalco Wall Panel Systems

Chalco honeycomb aluminum wall panel system is suitable for building facade and interior wall decoration, taking into account decorative effect, structural stability and installation adaptability.

Product Type

Aluminum honeycomb wall panels (3003 / 5005 / 5052)

Stone-composite honeycomb aluminum panels

Color-coated, fluorocarbon, wood-grain, and stone-grain panels

Common processing and structural forms

Folded-edge, snap-on, and tongue-and-groove structures

Back-bolt machining for dry-hanging systems

Edge sealing and corner reinforcement

Customization of medium to large-sized panels is supported, suitable for both regular panel shapes and irregular facade designs. For more wall decoration solutions, please refer to Chalco's Aluminum Wall Panel product page. Consultations and discussions regarding specific project needs are also welcome.

Chalco Aluminum Honeycomb Ceiling & Roof Systems

Chalco honeycomb aluminum ceiling systems are designed for interior ceilings and building roof decoration, suitable for large-area continuous installations and functional integrated ceiling designs.

Product type

Flat honeycomb aluminum ceiling

Perforated honeycomb ceiling (sound absorption/ventilation)

Grille-style, strip-style and modular honeycomb ceilings

Common processing and functional configuration

Punching and drilling (round, slotted, custom holes)

Prefabricated openings for lighting, vents, sprinklers, and access panels

Folded-edge or concealed-keel installation

Chalco's honeycomb aluminum ceiling system is suitable for large-span and large-size ceiling applications, and panel weight and structural configuration can be customized to project requirements. For more ceiling decoration solutions, please refer to Chalco's Aluminum Ceiling Panel product page. Consultations and discussions regarding specific project needs are also welcome.

Chalco Load-Bearing Aluminum Cellular Floor Panel Systems

Chalco load-bearing honeycomb aluminum floor systems are used in functional and equipment areas inside buildings to meet load-bearing, safety, and structural stability requirements.

Typical Structural Capacity Range (Configured by Project)

- Total thickness: 20 – 200 mm

- Concentrated load: 500 kg – 20 MT

- Single-layer span: 600 – 2000 mm

Product Type

Anti-slip aluminum honeycomb flooring

Modular movable honeycomb floor panels

Load-bearing floors for equipment and maintenance areas

Structural form and processing configuration

Thickened honeycomb cores for different load levels

Reinforced frame and load-bearing design

Integrated machining for mounting and positioning holes

For specific load-bearing capacity, span requirements, and support structures, Chalco can provide structural configuration suggestions and product customization support for load-bearing honeycomb aluminum floors based on the project's usage scenario, assisting the project in achieving a stable and safe ground system solution.

Chalco Honeycomb Architectural Decorative Panels: Common Specifications and Dimensional Capabilities (Typical Sizes & Customization)

Architectural decorative honeycomb aluminum panels are typically delivered on a project-by-project basis, with their specifications and dimensional capabilities primarily determined by panel configuration, honeycomb core structure, and overall assembly method. Mature engineering application areas have been established around typical application scenarios such as wall panels, ceilings, and floors, serving as a reference for scheme design and selection.

Panel and Surface System

In architectural decoration applications, honeycomb aluminum panels typically use aluminum panels as the main decorative layer, with commonly used alloys including 3003, 5005, and 5052. Different surface systems can be selected according to the project's positioning. In high-end decorative scenarios, composite surface layers such as thin stone sheets can be used to enhance the overall decorative effect and control the weight of the panels.

The panel thickness can be configured according to the panel size, usage environment and weather resistance requirements, and can be customized to meet the decoration needs of different parts such as exterior walls, interior walls and ceilings.

Honeycomb Core Structure and Overall Thickness Range

The structural performance of aluminum honeycomb panels is mainly determined by the aluminum honeycomb core. By adjusting the height and density of the honeycomb core, a balance can be achieved between strength, stiffness and weight.

- The overall thickness of wall panels and ceiling systems is mostly concentrated in the range of 10-30 mm, and they are suitable for building facades, interior walls and decorative ceilings.

- The overall thickness of load-bearing ground systems is typically in the range of 20–200 mm, depending on the load-bearing capacity, span requirements, and supporting structure.

Different application systems achieve differentiated matching of performance and thickness through the combination of honeycomb core height and backplane structure.

Backplate, Connection Method and Dimensional Capability

Architectural decorative honeycomb aluminum panels support the processing of medium to large-sized single panels, with common sizes reaching ≤1500 mm × ≤6000 mm. Non-standard and irregular shapes are also supported to adapt to different installation system requirements. Different back panel structures and connection methods can be configured for different application areas.

- Wall panel systems often use aluminum back panels or reinforced back panels to improve overall stability;

- The ceiling system primarily uses lightweight aluminum or FRP back panels, balancing strength and weight control.

- The ground system uses a high-strength backplate and is designed in conjunction with the load-bearing and support structure.

- Conventional building decoration applications employ an adhesive structure using engineering-grade flame-retardant film;

- For projects with high requirements for durability or structural consistency, a brazing structure can be used to achieve a metal connection between the panel and the honeycomb core.

Chalco Architectural Decorative Honeycomb Panel Project Support and Customization Collaboration

Chalco provides project-level collaborative support centered on honeycomb aluminum panels, tailored to the specific needs of architectural decoration projects.

- Supports structural configuration suggestions based on application location.

- Supports drawing communication, structural confirmation, and product customization.

- We can provide samples and technical support to align with project schedules.

Chalco's architectural honeycomb aluminum panel system is suitable for engineering projects of varying sizes and complexities. We welcome project consultations and technical discussions regarding specific application scenarios.