Copper bus bar is a current-carrying conductor primarily made of highly conductive copper, used for current collection, distribution, and connection in power systems. Compared to combinations of wires or cables, copper busbar can carry higher currents in a more compact structure and effectively reduce contact resistance and system losses.

Leveraging its extensive experience in copper processing and power product manufacturing, Chalco offers copper busbar solutions in a variety of structural forms, covering solid, flexible, and laminated busbar types, and supports project-based customization needs for different specifications, sizes, processing methods, and surface treatments.

Copper Busbar - Product Specifications Overview

-

Size and current carrying capacity

Width: 10–240 mm

Thickness: 2–24 mm

Cross-sectional area: approximately 30–3800 mm²

Supports non-standard size customization

-

Materials and Processing

Manufacturing of high conductivity copper materials

Supports cutting, drilling, punching, and bending.

Hole positions and structures can be customized according to drawings.

-

Surface treatment

Bare copper

Tin plating

Nickel plating

Other protective coatings (as needed)

Chalco copper busbar product types

Solid copper busbar

High current carrying capacity:integral copper cross-section, suitable for continuous operation.

Structural stability:Rigid design, not easily deformed after installation.

Mature processing capabilities:supports cutting, drilling, and bending.

Flexible copper busbar

Flexible structure:Multilayer copper foil absorbs stress

Good vibration resistance:reduces load at connection points

Reliable connection:Suitable for interface between cabinet and equipment.

Braided copper busbar

High flexibility:The woven structure adapts to complex spaces

Connection-oriented:Designed with a focus on connection applications

Easy to install:suitable for quick assembly

Laminated copper busbar

Multi-layer structure:copper busbar and insulating layer composite

Low stray inductance:Optimize system performance

High power density:suitable for batteries and energy storage

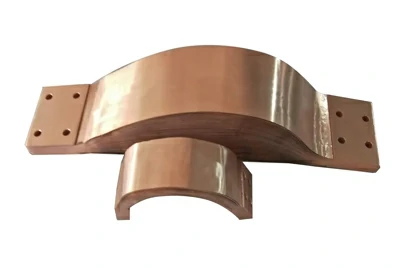

Custom copper busbar

When standard busbar specifications cannot meet project requirements, custom-shaped copper busbars can be manufactured to suit specific applications, supporting complex bends, multi-layer structures, and special surface or protective coatings.

Chalco copper busbar surface treatment options

In addition to bare copper busbars, Chalco offers a variety of surface treatment options to enhance the busbars' oxidation resistance, connection stability, and environmental adaptability, depending on the operating environment and connection requirements. Different surface treatments are suitable for different electrical and installation scenarios and can be selected according to project needs.

Tinned copper busbar

It has good surface oxidation resistance and stable connection, making it suitable for long-term operation in power distribution and grounding systems.

Nickel-plated copper busbar

It has stronger corrosion resistance and higher surface hardness, making it suitable for humid conditions or environments with high requirements for surface durability.

Insulating or protective coatings (as needed)

provide additional protection against electric shock and environmental adaptability, and can be applied locally or entirely depending on project requirements.

Typical application scenarios of Chalco copper busbars

Copper busbars, with their stable current-carrying capacity and mature engineering application foundation, are widely used in various power and energy systems as important conductors for current distribution, connection and safe grounding.

Electrical Panel / Switchgear

In distribution cabinets and switchgear, copper busbars are typically used as main busbars or branch busbars to achieve current distribution and connection between the power supply side and various circuits. They are structurally stable, have strong current-carrying capacity, and are suitable for long-term operation in power distribution systems.

Typical applications: Main busbars inside distribution cabinets | Current-carrying connections in switchgear | Circuit distribution and busbar structure

Grounding and Equipotential Systems / Neutral Busbar

In grounding and equipotential bonding systems, copper busbars are often used as main grounding busbars or neutral busbars to centrally connect various grounding conductors, ensuring system operational safety and potential balance. These applications require high connection reliability and long-term stability.

Typical applications: Main grounding busbar (MGB / TMGB) | Communication and equipment grounding | Equipotential bonding system

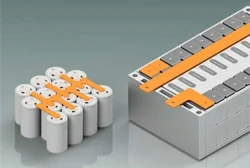

Battery and New Energy Systems Battery Busbar

In battery and new energy systems, copper busbars are used to achieve high-current connections between battery modules and power units, and are suitable for energy storage systems, EVs, and related power equipment. These applications typically have high requirements for structural compactness and current-carrying stability.

Typical applications: Battery module connection | Energy storage system current-carrying bus | New energy power system

Electrical Panel / Switchgear

Ground Busbar

Battery Busbar

Chalco copper busbars commonly use high-grade materials.

The electrical performance and processing stability of copper busbars largely depend on the grade of copper selected. Chalco offers a variety of high-conductivity copper materials for busbar production, tailored to different application requirements, and performs material matching and performance control during the production phase.

You can just put product images in these two options; there's no difference, and either one is fine.

-

Electrolytic tough copper (ETP Copper)

Has ≥99.90% copper content, excellent conductivity and processing consistency, suitable for copper busbars in power distribution equipment and switchgear.

-

Oxygen-Free Copper (OFHC)

has ≥99.95% copper purity, very low oxygen content, excellent conductivity and oxidation resistance, suitable for high-reliability applications.

Chalco Copper Busbar Production Customization and Performance Reference

Chalco copper busbars are made from highly conductive copper. Common raw material forms include round bars and square steel, with sizes typically ranging from approximately 1/8–8 inches in diameter for round bars and 1/4–3 inches in cross-section for square steel. Solid/flat copper busbars are the primary standardized production form, allowing for consistent control over material purity, processing conditions, and critical dimensional tolerances. Depending on project requirements, busbars can also be formed or processed into round, hollow, and custom-shaped structures.

The parameters listed in the table below are based primarily on flat copper busbars, and also consider the achievable range of round, hollow, and custom-shaped busbars for technical communication regarding material properties and manufacturing capabilities. Specific parameters can be adjusted according to the busbar structure, processing technology, and project requirements.

| Reference for busbar dimensions, tolerances and structural forms | ||||

| Description | Flat busbar | Circular busbar | Hollow busbar | Custom-shaped busbars |

| Dimensional tolerances | BS EN 13601 / ASTM B187 | BS EN 13601 / ASTM B187 | BS EN 13601 / ASTM B187 | According to custom design |

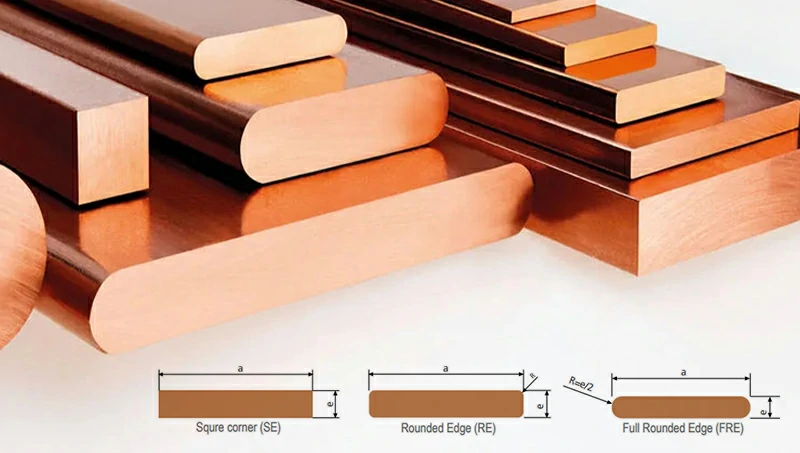

| Edge/corner form | Sharp corners / rounded corners / fully rounded corners | Full rounded corners | Rounded corners | According to custom design |

| Size specifications (for reference) |

1/16″×1/2″ – 1/16″×1-1/2″ 1/8″×1/4″ – 1/8″×2″ 3/16″×1/2″ – 3/16″×3″ 1/4″×1/2″ – 1/4″×6″ 3/8″×1/2″ – 3/8″×4″ 1/2″×1″ – 1/2″×8″ 5/8″×1″ – 5/8″×2″ 3/4″×1″ – 3/4″×8″ 1″×1-1/2″ – 1″×8″ |

1/8″×1/2″ – 1/8″×3″ 3/16″×1″ – 3/16″×3″ 1/4″×3/4″ – 1/4″×8″ 3/8″×1″ – 3/8″×8″ 1/2″×1″ – 1/2″×8″ 3/4″×4″ |

Design confirmation based on pipe diameter and wall thickness | Custom-made according to drawings |

| The dimensions above are for reference only and are within the standard production range. Specific specifications are subject to the project drawings and technical confirmation. | ||||

| Reference for Copper Busbar Materials and Performance Parameters (Performance Table) | ||||

| Description | Flat busbar | Circular busbar | Hollow busbar | Custom-shaped busbars |

| Tensile strength | ≥250 MPa | ≥260 MPa | ≥240 MPa | It depends on the situation. |

| Elongation | ≥12% | ≥13% | ≥11% | It depends on the situation. |

| Electrical conductivity | ≥98.3% IACS | ≥98.5% IACS | ≥98.1% IACS | It depends on the situation. |

Building upon its stable production and material performance control of basic copper busbars, Chalco possesses the capability to manufacture structural busbar products such as laminated busbars, braided busbars, and flexible copper busbars. Through comprehensive control of conductor structure, connection methods, and assembly techniques, it can support multi-layer lamination, flexible connections, and insulation configurations to meet the spatial layout, electrical performance, and installation requirements of various systems.

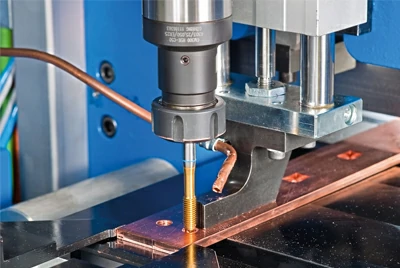

Chalco copper busbar project's processing capabilities

Copper busbars can be customized according to project drawings and installation requirements to adapt to different electrical system structures and assembly methods.

Custom cutting: Supports cutting to different lengths, widths, and thicknesses to meet non-standard needs.

Hole machining: Drilling, punching, and hole spacing layout can be performed according to drawings.

Bending and forming: Supports planar or three-dimensional bending, adaptable to cabinet and equipment installation space.

End processing: Supports chamfering, rounding, and other edge treatments to improve assembly safety.

Surface treatment options: After processing, tin plating, nickel plating, or a protective coating can be applied.

Quality and Supply Assurance

Chalco emphasizes material consistency, processing precision, and project coordination capabilities in the production and delivery of copper busbars to ensure that products meet engineering application requirements.

Material traceability: The source of copper is clear and batches are controllable.

Processing quality control: Inspection of dimensions, hole positions, and structural details during the machining process.

Surface treatment control: Coating and protective treatments meet project requirements.

Supply capacity support: Supports project-based orders and bulk delivery requirements.

Frequently Asked Questions (FAQ)

How to choose between copper busbars and aluminum busbars?

Copper busbars have higher conductivity and better connection stability, making them suitable for high-current power systems with high reliability requirements. The specific selection needs to be made based on a comprehensive judgment of operating conditions and cost requirements.

Does it support small batches or samples?

Depending on the project stage and requirements, it supports sample or small batch production for structural confirmation or testing verification.

Can you customize the hole positions and bends according to the drawings?

We support hole processing, bending and shaping, and structural customization according to customer drawings to match different installation methods.

How should surface treatment be selected?

The surface treatment method is usually determined based on the usage environment, connection method, and protection requirements, and the selection can be confirmed during the project communication stage.

Electrical parameter selection notes and project coordination

The rated current-carrying capacity of a copper busbar needs to be determined comprehensively based on factors such as the busbar cross-sectional area, installation method, heat dissipation conditions, and ambient temperature. For project-based applications, selection calculations are typically performed based on the actual system operating conditions to ensure that the copper busbar has stable current-carrying performance and a safety margin during long-term operation.

Rigid / Flat Copper Busbar – Typical Ampacity (Reference)

Reference conditions: Ambient temperature 35°C, maximum busbar temperature 65°C, conductivity approximately 98% IACS, natural air cooling.

|

Rigid / Flat Copper Busbar – Typical Ampacity (Reference) Reference conditions: Ambient temperature 35°C, maximum busbar temperature 65°C, conductivity approximately 98% IACS, natural air cooling. |

||||

| Busbar dimensions (width × thickness mm) | Single busbar 1 bar (A) | Two bars side by side (A) | Three bars side by side (A) | Four bars side by side (A) |

| 20 × 2 | 123 | 202 | 228 | — |

| 20 × 3 | 189 | 302 | 313 | — |

| 20 × 5 | 319 | 560 | 728 | — |

| 25 × 3 | 287 | 470 | 525 | — |

| 25 × 5 | 384 | 662 | 869 | — |

| 30 × 3 | 337 | 544 | 593 | — |

| 30 × 5 | 447 | 760 | 944 | — |

| 30 × 10 | 676 | 1200 | 1670 | — |

| 40 × 5 | 573 | 952 | 1140 | — |

| 40 × 10 | 850 | 1470 | 2000 | 2580 |

| 50 × 5 | 697 | 1140 | 1330 | 2010 |

| 50 × 10 | 1020 | 1720 | 2320 | 2950 |

| 60 × 5 | 826 | 1330 | 1510 | 2310 |

| 60 × 10 | 1180 | 1960 | 2610 | 3290 |

| 80 × 10 | 1500 | 2410 | 3170 | 3930 |

| 100 × 10 | 1810 | 2850 | 3720 | 4530 |

| 120 × 10 | 2110 | 3280 | 4270 | 5130 |

| 160 × 10 | 2700 | 4130 | 5360 | 6320 |

| 200 × 10 | 3290 | 4970 | 6430 | 7490 |

| The above data are reference values under typical operating conditions, used for engineering selection and specification comparison. The actual current carrying capacity needs to be confirmed in conjunction with busbar spacing, installation method, heat dissipation conditions, and operating environment. | ||||

To confirm copper busbar specifications, current selection, or fabrication feasibility, please submit drawings or application requirements. Chalco can provide technical communication and solution confirmation support in accordance with project schedules.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote