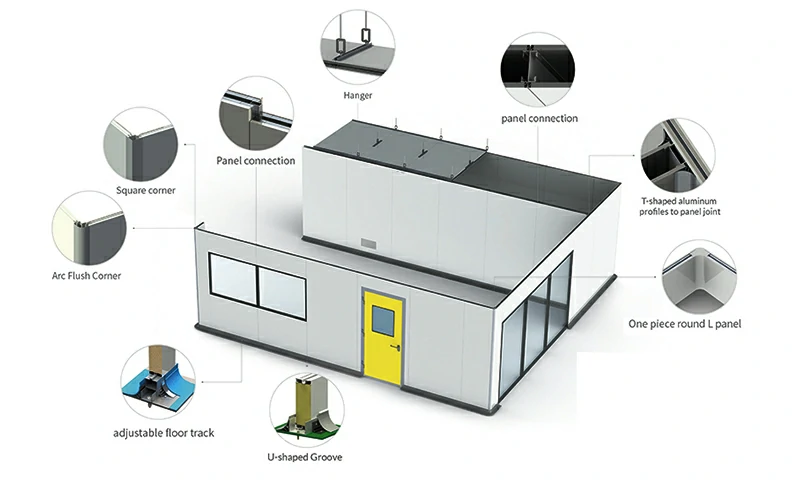

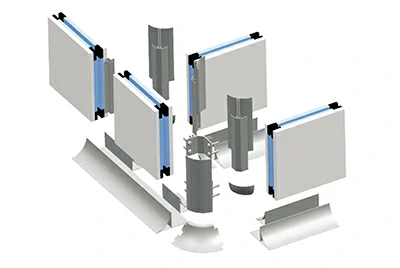

Clean Room Aluminium Profile refers to a system of aluminium extrusions and accessories for cleanroom walls, ceilings, door/window frames, and coving transitions. Key attributes are low-seam, flush, non-porous, and easy-to-clean surfaces, with modular fast installation and convenient maintenance.

- Hygienic Junctions: Coving + flush, low-seam nodes reduce particle traps, making cleaning/disinfection more efficient.

- Fast-Build Delivery: Match Existing Dies + Pre-cut/Pre-drilled to minimize welding and dust, shortening downtime.

- System Compatibility: Panels/gaskets/H-/U-trims/doors & windows work together to form a continuous airtight surface; maintenance-friendly.

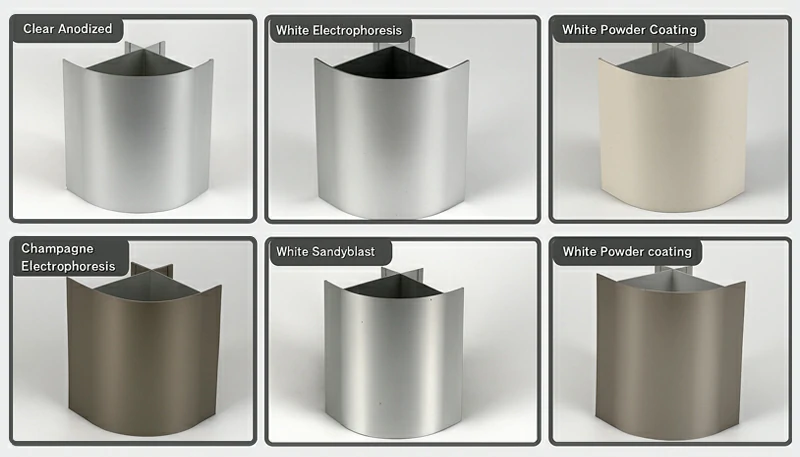

- Finishes & Corrosion Resistance: Anodized / Powder Coated with controlled ΔE color variation; resistant to common cleaners, stable appearance, and lower TCO.

Chalco provides a one-stop aluminium system supply: a ready die library + complete fittings + pre-cut/pre-drilled + rapid sampling, supporting OEM/contract manufacturing and Match Existing Dies. We can provide a catalog PDF and compatibility/slot charts. Design principles align with ISO 14644-4, and documentation aligns with GMP Annex 1 to support compliance and on-time delivery.

Not sure where to start? Choose your industry or system module to jump directly to the relevant solutions and specifications (Clean Room Aluminium Profile).

Why Choose Aluminium for Cleanroom Systems

Still choosing between stainless/plastics and aluminium? Check these four points, then follow the links for details.

- Installation Efficiency: Pre-cut/Pre-drilled, less welding and dust, shorter downtime.

- Hygiene & Appearance: Non-porous surfaces + Anodized/Powder Coated finishes, easy to clean with controlled ΔE (see "Finishes").

- System Compatibility: Works with panels, gaskets, and H/U trims to form a more stable continuous seal (see "System Modules & Components").

- Cost & Supply: Lightweight for lower logistics costs; Match Existing Dies reduces tooling; OEM supported (see "Why Us").

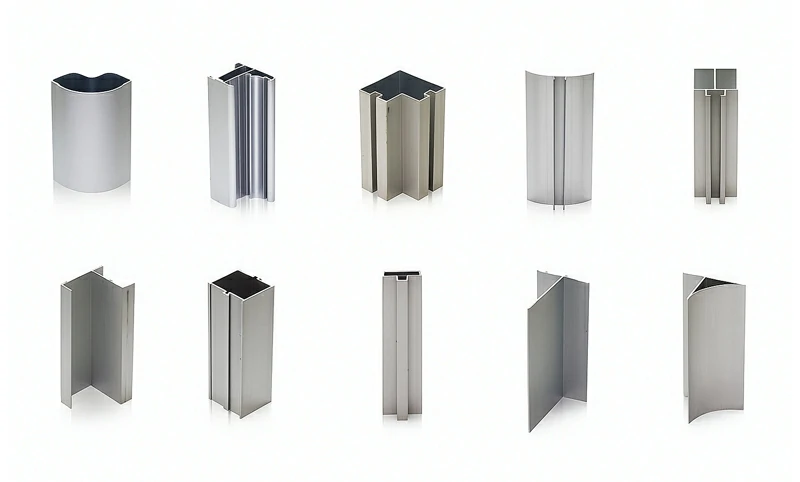

System Modules & Components Overview

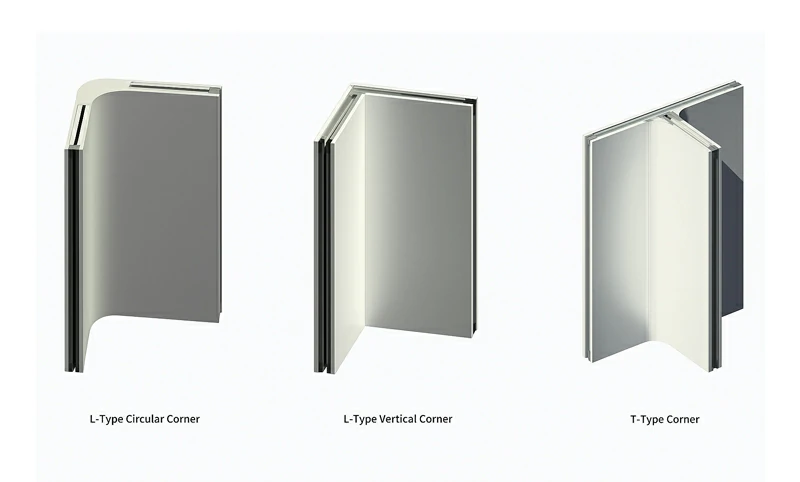

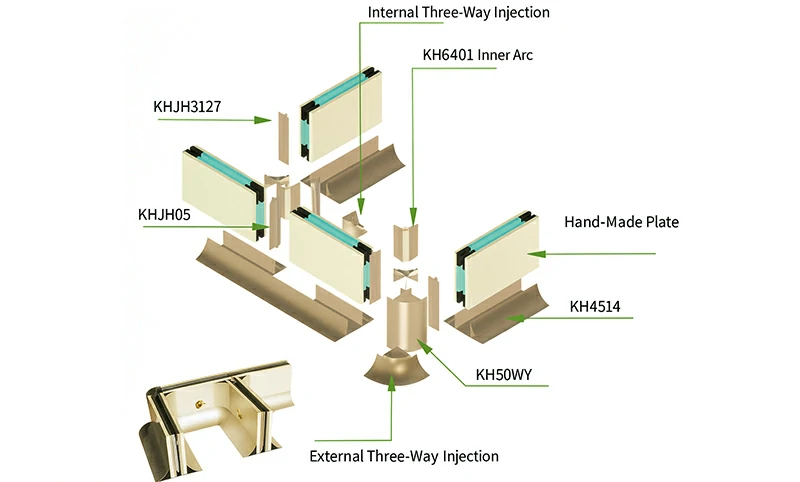

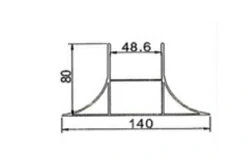

Coving System

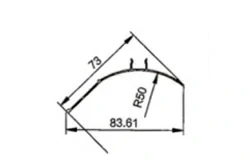

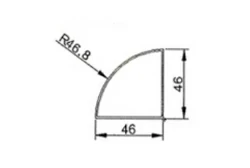

In clean zones, Coving is the default. By combining inner/outer/double radii with bases and positioning connectors, wall-to-wall, wall-to-floor, and door-opening turns become flush, low-seam continuous seals—friendly for mopping and spray-down, audit-ready, and consistent with ISO 14644-4 principles on minimal seams and cleanability.

Contact us now

Components & Functions

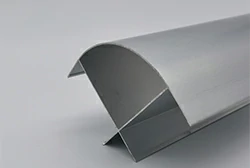

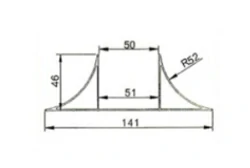

KH50WY Outer Radius (R≈50)

Smooth outer-corner transition; often paired with a base to avoid dirt traps.

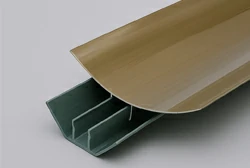

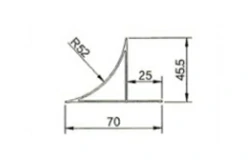

KH6401 Inner Radius

Rounds inner corners; seals in the same direction as the panel groove/gasket.

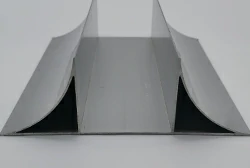

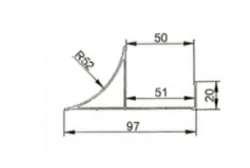

KH4514 Double Radius

Two-way turns for column edges/door jambs, keeping visual and hygienic continuity.

KH36LDZ Base

Plinth at wall-to-floor junction; receives inner/outer radii for easier mopping and drainage.

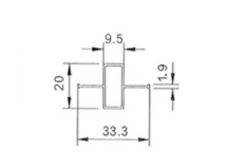

KHJH05 Positioning Piece

Short piece for positioning/fixing coving and base profiles.

KHJH3127 Positioning Connector

Alignment/connection to reinforce node integrity.

If your area is non-critical, space-constrained, or budget-sensitive, we can also provide Square Corner transitions, provided flushness and airtightness are maintained.

Selection & Installation Notes

- Confirm panel thickness / slot width / gasket series first, then match the profile; Pre-cut/Pre-drilled to reduce onsite dust and labor.

- Keep a unified radius (e.g., R50) for trolley passage and consistent appearance.

- Finishes: default Anodized; use Powder Coated for feature areas; evaluate ESD dissipative layer for electronics/semiconductor zones.

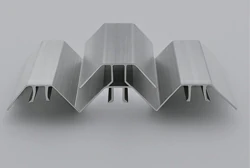

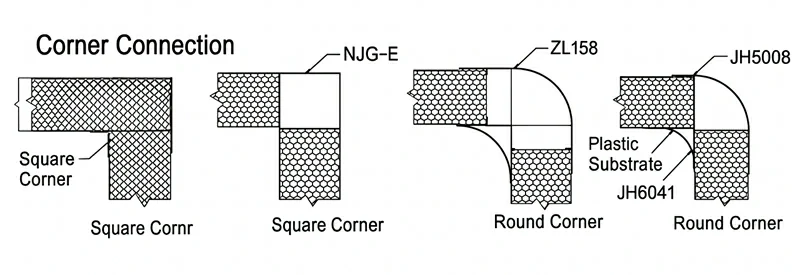

Square-Corner Transitions

With flushness and airtightness ensured, use square-corner profiles, right-angle pressure/snap-in strips, and end caps for a crisp look with smaller space claim. Selection tips: choose profiles by panel thickness/slot width/gasket; unify elevation with doors and the Adjustable Floor Guide; add gaskets where needed to avoid step joints. Recommendation: prefer coving in audit-sensitive zones; square corners are suitable for dry areas or where equipment abuts walls.

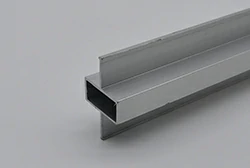

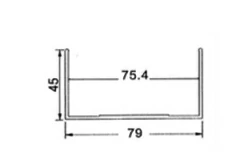

Wall / Partition Frames & Edge Trims

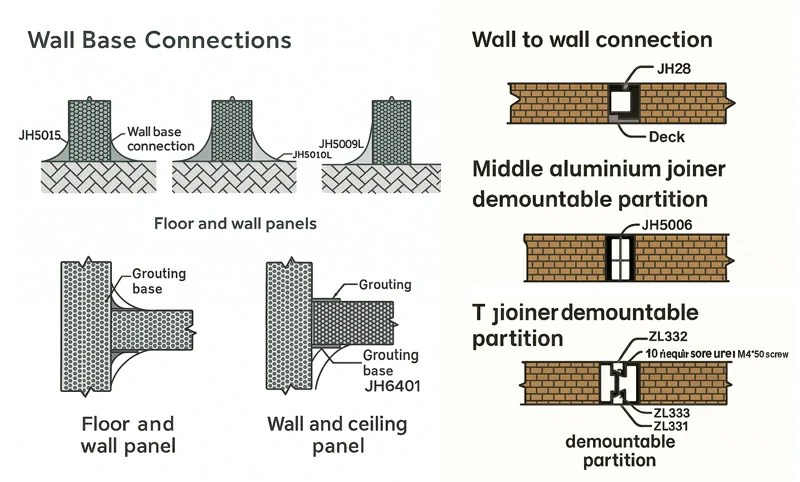

The wall-partition system consists of vertical posts/horizontal beams plus H/U trims, center H-Joiners, I-Joiners, floor/top guides and gaskets. The goal is to create flat, continuous, airtight surfaces at every node, supporting modular assembly and later replacement.

Contact us now

Components & Functions

- Floor-to-Panel Transition: Floor guides / cove skirting + inner radius or cove skirting; e.g., JH5015 (floor guide), KH6401 (inner radius), JH5010L/JH6009L (end caps).

- Wall-to-Wall (Flush): Center H-Joiner (e.g., JH5005 / JH28) for two-panel butt joints—flush appearance and easy disassembly.

- Demountable Partitions: I-Joiner (e.g., ZL331/ZL332), screw-fastened, suitable for equipment areas and future changeouts.

- Edge Trim & End Closure: U-trim/end posts for neat terminations at wall ends, openings, and turns.

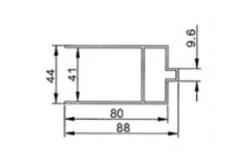

JH5015

KH6401

JH5010L

H-Joiner

I-Joiner

U-Trim

Selection & Installation Notes

- Confirm panel thickness / slot width / gasket series first, then choose the profile; order with Pre-cut/Pre-drilled to reduce onsite dust and labor.

- Align elevations and radii with the Coving System, floor guides, and doors to ensure smooth traffic and audit-ready appearance.

- Finishes: default Anodized; use Powder Coated in feature areas; evaluate ESD dissipative surfaces for electronics/semiconductor zones.

- Documentation: support Match Existing Dies, provide CAD/DXF and compatibility/slot charts for fast engineering hand-off.

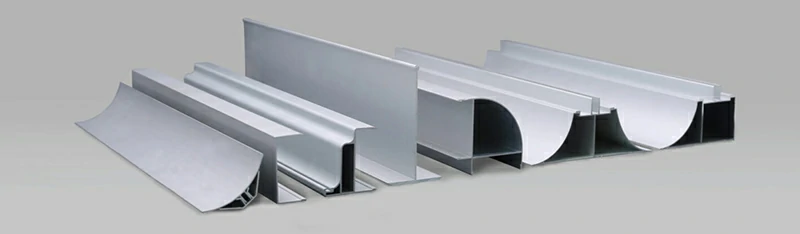

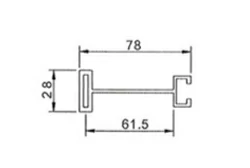

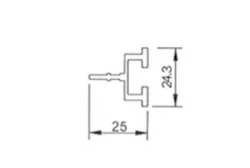

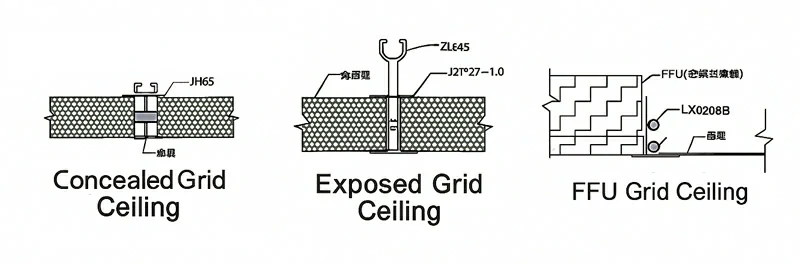

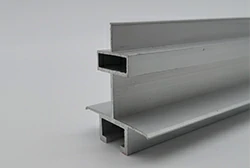

Ceiling Load-Bearing & Grid (Ceiling Grid)

Used to carry FFU/lighting/HEPA frames while keeping the ceiling flush and low-seam, with convenient access for maintenance. Three options are available:

Concealed Grid (Flush & Clean)

Exposed Grid (Cost-Effective)

Reinforced FFU Grid (High Load)

Core Components

- Main beams/carriers, secondary grid, pressure strips / snap-in strips, hangers/anti-seismic ties, access modules

- Works with wall panels/coving/edge trims to form a continuous airtight surface

- Unified elevation with doors and the Adjustable Floor Guide to avoid step joints

- Supports Pre-cut/Pre-drilled and pre-installed nuts to reduce onsite dust and labor

- Finishes: Anodized or Powder Coated; supports Match Existing Dies

Carrier / Center Beam

Pressure Strip / Snap-in Strip

FFU Beam

Selection Notes

- Modules & Loads: 600×600 / 1200×600 / 2×4 ft; calculate hang points by equipment weight and span.

- Sealing & Flushness: prefer Concealed Grid for high-grade zones; avoid steps and shadow seams at access hatches.

- Equipment Openings: reserve cut-outs and access for FFU/lighting/filter frames and maintenance routes.

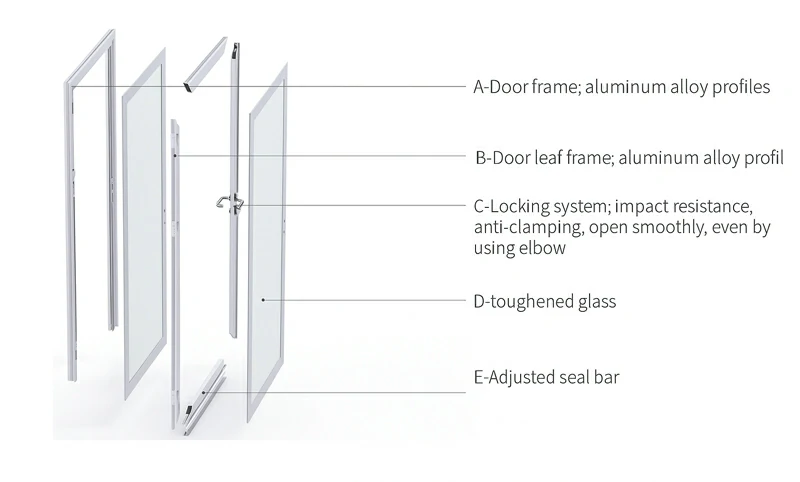

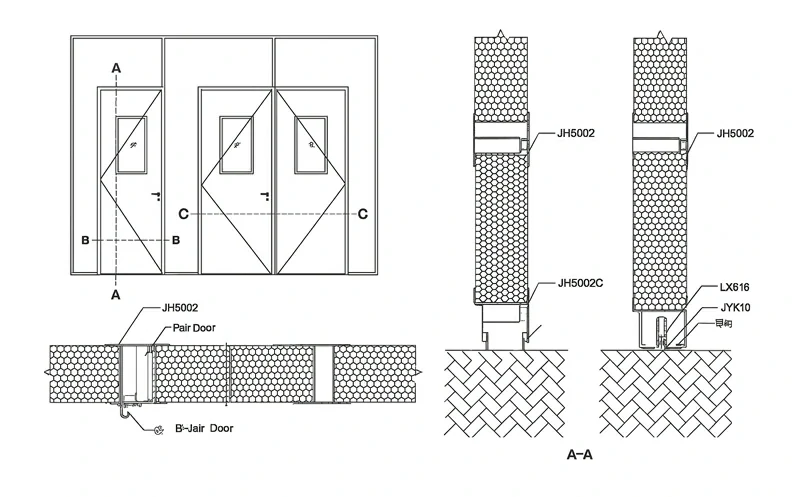

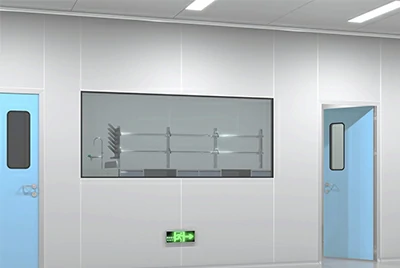

Door / Observation Window System

Designed for flush, low-seam installation of cleanroom doors and Observation Windows, balancing pressure sealing with high-frequency opening. Door frames, door-leaf frames, Pressure Strips/gaskets, and glass/panels work in concert. Supports Pre-cut/Pre-drilled and Match Existing Dies for efficient assembly and easy maintenance.

Contact us now

Core Components

- Door Frame / Door-Leaf Frame: 40 / 50 / 75 series profiles; door frame and leaf sit flush; compatible with glass or aluminium honeycomb/sandwich panels.

- Sealing System: Adjustable sealing strips + optional Bottom Seal (automatic drop); choose threshold / Adjustable Floor Guide to meet pressure and traffic needs.

- Observation Window Frame: Fixed, double-glazed, or sealed units; inner/outer Pressure Strips lock together to reduce condensation and dust traps.

- Edge & Transition: Align with wall H/U trims, Coving, and top/floor guides at a unified elevation to form a continuous airtight plane.

- Hardware Interfaces: Reserved seats for hinges, door closers, cylinder/linked locks; customer-specified glass/hardware can be adopted—we handle profile and fitting compatibility.

Selection Notes

- Clear opening size and swing direction (single/double, left/right); specify if a vision panel is required.

- Match panel thickness / slot width / gasket series; window clear opening and glass thickness (common 5–10 mm or insulated).

- Target pressure differential and cleanliness level to choose threshold / Bottom Seal方案.

- Finish & Color: Anodized or Powder Coated; evaluate ESD dissipative layer for electronics scenarios.

- Install & Maintenance: Pre-cut/Pre-drilled, pre-embedded corner connectors; keep nodes A-A / B-B / C-C aligned with wall/ceiling for convenient service.

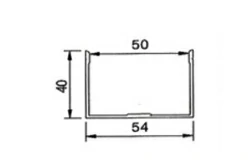

Floor Guides / Cove Skirting / Floor Edge System

Creates a flush, continuous, cleanable seal between wall panels and the floor (epoxy / PVC / tile, etc.), absorbing floor build-up and leveling tolerances; at doors, balances smooth passage with pressure sealing. Choose straight edge trims or Cove Skirting (e.g., R series) to meet hygiene grades and spatial constraints.

Contact us now

Functional Components

Adjustable Floor Guide

Compensates floor thickness and leveling deviations; facilitates later maintenance.

Water-Blocking Floor Guide

Drip/stop features reduce washback and seepage.

Top & Bottom Guide (Door Zone)

Works with Bottom Seal / threshold to balance pressure retention and trolley traffic.

Floor Channel (Utility Channel)

Edge/transition for equipment, cabling, or drainage locations.

Skirting Trim

Straight skirting gives a crisp look; Cove Skirting is hygiene-friendly and mop-friendly, continuous with wall Coving.

Adjustable Floor-Guide Corner Filler

Pairs with the Adjustable Floor Guide to cover gaps and form a continuous seal to straight or coved skirting.

Selection & Installation Notes

- Confirm floor type and thickness; match adjustment range and fixing method (chemical anchors / embedded parts).

- High-hygiene or wet zones: prefer Cove Skirting; dry or space-limited areas: straight edge trims are acceptable.

- Keep elevations and radii unified with walls / Coving / door zones to avoid steps and cleaning dead corners.

- Use gasket + structural adhesive dual sealing; add expansion joints where needed; coordinate color with floor/wall panels.

- Recommend Pre-cut/Pre-drilled with pre-embedded nuts to reduce onsite dust and labor; confirm samples before mass production.

Connection & Fastening Hardware

Used to quickly assemble, precisely locate, and create continuous seals across walls, Coving, ceilings, doors/windows, and floor guides. The full range fits 40 / 50 / 75 series modules, supports Pre-cut/Pre-drilled, offers Anodized / Powder Coated finishes, and can be supplied as complete fastener kits (common M6 / M8).

Contact us now

Functional Groups

- Corner Connector: Tee/cross/four-way pieces that reinforce critical turns, ensuring overall rigidity and flush continuity.

- Pressure Strip / Block: Clamps panels/glass to form an airtight face—directly impacts cleanliness and audit outcomes.

- Hinge & Latch: Core interfaces for door operation and pressure sealing—affecting access and safety.

- Hanger / Tie: Carries FFUs/lighting/grid members and controls sway—key to ceiling reliability and maintenance efficiency.

Corner Connector

Sleeve / Joiner Block

Corner Node

Clamp Block

Hinge

Turnbuckle / Tie

L Bracket / Support

Coving Segment

Coving Cap / Snap-on Cover

Kitting & Supply

- Complete System Coverage: Corners, wall/edge trims, ceilings, doors/windows, floor interfaces—uniform to 40 / 50 / 75 modules.

- Pre-Packed Sets: System-based kitting (incl. M6/M8 fasteners, gaskets, locating plates) for install-ready delivery.

- Fast-Build Friendly: Pre-cut/Pre-drilled and locating features reduce onsite dust and labor; assembly is stable.

- Docs & Customization: BOM + PDF drawings + install guides included; OEM and Match Existing Dies supported (optional EN 10204 3.1).

These modules cover corners, walls/edge trims, ceilings, doors, floor interfaces, and accessories. Leveraging the ready die library plus Pre-cut/Pre-drilled fast-build, with Anodized / Powder Coated finishes (optional ESD), they suit both new build and retrofit, consistent with ISO 14644-4 principles of minimal seams and cleanability. We can supply full kits matched to drawings, with BOM and install guides, supporting OEM / die-matching and sample confirmation.

Clean Room Aluminium Profile Gallery

Industry Solutions

Pharmaceutical & Medical Devices Solution

For high-frequency cleaning and strict audits, we provide a one-stop Clean Room Aluminium Profile solution built around coving & low-seam, flush & airtight nodes, and modular fast-build, covering ISO Class 5–8 areas while supporting quick retrofits and on-time acceptance.

Core Configuration

- Corners & Skirting: R25–R50 coving + Cove Skirting to eliminate 90° shadow joints; unified radius aids trolley traffic and cleaning.

- Doors/Windows & Airtightness: Flush door frames + Adjustable Floor Guide; door gap ≤2 mm. Flush Observation Window; anti-fog insulated glass optional.

- Ceiling & Loads: Concealed grid preferred; modules 600×600 / 1200×600 / 2×4 ft; reliable for HEPA/FFU/lighting, with reserved service access.

- Walls & Edge Trims: Pressure Strip + continuous gaskets create a continuous airtight face; supports Pre-cut/Pre-drilled for efficient assembly and easy maintenance.

- Materials & Cleaning: Default 6063 (optional 6061/6060); anodize 10–15 μm or powder coat 60–80 μm; tolerant to IPA/H₂O₂. ESD option 10⁶–10⁹ Ω.

Compliance & Delivery Support

Design/docs aligned with ISO 14644-4, EU GMP Annex 1, FDA cGMP; medical-device projects follow ISO 13485 documentation/traceability. Die-match / OEM, sample validation, BOM + install guides, and optional EN 10204 3.1 available.

Food / Beverage / Cosmetics Solution

With routine wet cleaning, chemical sanitation, and inspections, wall-to-floor turns must stay low-seam, easy to wash, and avoid water backflow. We prioritize large-radius coving + Cove Skirting, flush doors/windows with water-blocking floor guides, and continuous sealed trims to meet internal hygiene control and ISO Class 7–8 needs.

Key Points

- Corners & Skirting: Prefer R50–R75 coving + Cove Skirting to remove 90° shadow joints; withstand mopping/high-pressure rinsing without residue.

- Floor Edge & Drainage: Water-blocking floor guide + floor slope 1–2%; optional drip/stop features to reduce backflow/seepage.

- Doors/Windows & Airtightness: Flush frames; no/low threshold + Bottom Seal; door gap ≤2 mm for trolley traffic and pressure control.

- Materials & Finish: 6063; recommend powder coat 70–90 μm (or anodize 12–15 μm), resistant to alkaline/chlorinated/quaternary cleaners; fasteners 304/316 preferred.

- Walls & Trims: Pressure Strip + gaskets for continuous sealing; unified elevations; avoid steps and dirt traps at access openings.

Hospital / OR / ICU Solution

Focused on infection control and frequent disinfection—emphasizing coving & low seams, flush airtight nodes, smooth circulation, and privacy control. Suitable for ORs, ICUs, and laboratories with continuous sanitation and inspections.

Key Points

- Corners & Skirting: For wall-to-wall/wall-to-floor/door reveals, prefer R25–R50 coving + Cove Skirting; unify elevations to reduce cleaning dead corners.

- Airtight Doors & Access: Automatic sliding/swing airtight doors; door gap ≤2 mm. No/low threshold + Bottom Seal/Adjustable Floor Guide to ensure smooth stretchers/trolley flow.

- Observation Window & Privacy: Flush frames with double/insulated glazing; optional integral blinds for privacy during procedures.

- Ceiling & Service: Concealed grid; interfaces for laminar flow/filters and lighting, with maintenance routes (equipment by client, profiles by us).

- Finish & Cleaning: 6063; anodize 10–15 μm or powder coat 60–80 μm, resistant to alcohols/quats; corridors may use guards/bump rails.

- Pressure Coordination: Follow hospital positive/negative pressure zoning; use continuous sealing at doors and flush windows to reduce leakage and dirt traps.

Semiconductor / Electronics Solution (ESD | ISO Class 5–7)

The semiconductor sector demands both particle control and static protection. While maintaining airflow organization and maintenance efficiency, the system should offer dissipative surfaces, reliable grounding, dense FFU loading, and low-emission finishes—fit for ISO Class 5–7 production and test areas.

Key Points

- ESD & Grounding: Profiles with dissipative surfaces (10⁶–10⁹ Ω); provide ground take-off and test points at door frames/walls/ceiling, with equipotential bonding and conductive gaskets.

- Ceiling & Loads: Lay out 600×600 / 1200×600 / 2×4 ft modules for FFU/HEPA/lighting; use high-load grids/concealed grids with reserved service aisles; control deflection and sway.

- Walls & Sealing: Flush Pressure Strips + continuous gaskets form a continuous airtight plane; recommend R coving in critical zones; square corners are acceptable in general zones if kept flush and low-seam.

- Doors/Windows & Pressure: Door gap ≤ 2 mm with Adjustable Floor Guide / Bottom Seal; flush Observation Window to reduce turbulence and dust traps.

- Return-Air Interfaces (Optional): Aluminium frames and flush trims for slot/grille returns; optional quick-release face frames for cleaning. Air volume/equipment by HVAC; we supply flush-seal interfaces to wall/ceiling/floor nodes.

- Materials & Finish: Default 6063 (options 6061/6060); Anodized or low-VOC Powder Coated for low outgassing and easy cleaning; stainless-steel fasteners optional.

Research / Testing / Teaching Labs Solution

Focused on flexible reconfiguration, low-seam cleanability, and safety compliance. Typical cleanliness is ISO Class 7–8 (local critical zones to 5–6). Modular aluminium systems support rapid re-zoning, relocation, and maintenance while preserving glass visibility and equipment access.

Key Points

- Flexible Partitions: Modular walls + Adjustable Floor Guide allow quick room/bench re-layout; flush door reveals and Observation Windows; supports glass or aluminium honeycomb/sandwich panels.

- Corners & Trims: Square corners may be used in general zones if kept flush; wet/decon zones should prefer R coving + Cove Skirting to reduce shadow joints and residue.

- Doors & Access: No/low thresholds + Bottom Seal; door gap ≤ 2 mm; windows can be double/insulated with anti-fog options.

- Ceiling & Equipment Bays: Configure 600×600 / 1200×600 / 2×4 ft positions for lighting/filters; prefer concealed grids to ease service and expansion.

- Finish & Durability: 6063 aluminium; Anodized 10–15 μm or Powder Coated 60–80 μm, compatible with common cleaners; perform sample verification where special reagents contact is expected.

- Optional ESD: Dissipative surfaces 10⁶–10⁹ Ω with reserved grounding points for electronics/metrology/testing areas.

- Delivery Support: Die-match + Pre-cut/Pre-drilled, with BOM & install guides; samples and OEM available.

Based on each industry's compliance and cleaning priorities, we combine coving, doors/windows, ceilings, walls, and floor edges to deliver minimal-seam, flush-airtight, modular fast-build solutions within your schedule and budget—supplying die-match, pre-cut/pre-drilled, sample validation, and shipment with BOM + install guides. We support OEM and global delivery for your Clean Room Aluminium Profile projects.

Surface Finishes

We offer two mainstream appearance solutions plus optional ESD treatment for cleanroom use—aiming for low fingerprinting, cleanability, stable color, and long-term cost control.

Anodized

Matte metallic look, washable, fade-resistant, fewer fingerprints. Ideal for pharma/medical, ICU zones, and Observation Window frames. Film thickness and appearance controlled to ISO 7599 (typical 10–15 μm, thicker on request).

Powder Coated

Clean solid colors for zoning; moisture-tolerant and compatible with common detergents; low-gloss anti-glare available—suited to food/beverage/cosmetics and public corridors. Adhesion per ISO 2409 or ASTM D3359; gloss per ISO 2813. Typical film 60–80 μm (wet areas 70–90 μm by project spec; ΔE color control by project).

ESD (Optional)

For electronics/semiconductor or test zones, with dissipative surfaces and reserved grounding points. Surface resistance 10⁶–10⁹ Ω, tested to IEC 61340; test records can be provided with delivery, per site plan.

Quick Selection

- High-frequency disinfection / metallic look → choose Anodized.

- Color management / wet-zone friendly → choose Powder Coated.

- ESD control → add ESD on top of the chosen finish.

Delivery & Assurance

Sample parts / color chips for confirmation (appearance, touch, cleaner compatibility). RAL / custom colors and project ΔE control supported, with inspection and batch docs included.

Clean Room Aluminium Profiles Supplier

One-Stop System Supply

Organized around five systems—Coving/Skirting, Walls/Trims, Doors/Observation Windows, Ceiling Grid, and Floor Guides—we supply profiles + fittings as complete sets for install-ready delivery, supporting OEM/contract manufacturing and smooth collaboration with general contractors/M&E teams.

Factory-Direct, Total Cost Focus

In-house dies and processing, Match Existing Dies / build-to-print, unified coving radii and interfaces to reduce rework and downtime—balancing budget and schedule.

Fast-Build & Sampling

Pre-cut/Pre-drilled parts, embedded hardware, and sample validation; shipments include BOM + install guides to reduce onsite dust and labor and stabilize assembly.

Finishes & ESD Coverage

Anodized / Powder Coated (project ΔE control), optional ESD dissipative scheme with grounding points—ready for electronics/semiconductor/test areas.

Compliance & Documentation

Design/docs aligned with ISO 14644-4 and related requirements; optional batch and inspection files (e.g., EN 10204 3.1) for audits and records.

Global Delivery & Technical Support

Samples-first, drawing review, and onsite technical coordination available. Pack/label/traceability complete; sea/air/rail shipment supported worldwide.

FAQ

What is a Clean Room Aluminium Profile?

A system of aluminium extrusions and accessories for cleanroom walls, ceilings, door/window frames, and coving/skirting nodes—characterized by low seams, flush, non-porous, easy-to-clean surfaces, with modular fast installation and convenient maintenance.

How is it different from general industrial aluminium profiles?

Cleanroom profiles prioritize rounded corners and flush interfaces, continuous sealing with panels/gaskets, cleaner-resistant surfaces with controlled ΔE, and node designs consistent with ISO 14644-4—forming a complete system with cleanroom panels and hardware.

How do I choose a coving radius?

Commonly R25–R50. For pharma/food/hospital, prefer R50 for trolley traffic and audit-friendly cleaning. General zones can use square corners if kept flush and low-seam and matched to the cleaning method; keep a unified radius within the same area.

How do I choose the surface finish?

Choose Anodized for high-frequency disinfection and a metallic look. Choose Powder Coated for color zoning and wet-area stability. For electronics/semiconductor, add ESD (10⁶–10⁹ Ω) with grounding points; test records and samples are available.

How is airtightness and cleanliness ensured for doors/windows?

Use flush door frames/Observation Windows; door bottoms with Adjustable Floor Guide or Bottom Seal; door gap ≤ 2 mm. Windows can be double/insulated, locked by inner/outer Pressure Strips to reduce dust traps and condensation.

Can the ceiling carry FFU / HEPA / lighting?

Yes—high-load grids/concealed grids at 600×600 / 1200×600 / 2×4 ft modules with reserved service channels can carry FFUs, HEPA units, and lighting. FFU/filters/air volume are supplied by HVAC specialists; we supply profiles and flush trim interfaces.

Is it compatible with existing panels and profiles?

Yes—Match Existing Dies and build-to-print are supported. We align to panel thickness, slot width, gasket series, and opening clear sizes, and provide Pre-cut/Pre-drilled parts and embedded hardware to reduce onsite dust and labor.

What standards and documents are supported?

Dimensional tolerances are typically aligned with ASTM B221 / EN 755-2; anodizing can follow ISO 7599. Design/docs are aligned with ISO 14644-4, EU GMP Annex 1, FDA cGMP, and ISO 13485 where applicable. BOM, install guides, and batch files (e.g., EN 10204 3.1) can be provided.

Do you supply complete equipment (FFU, glass, locks, etc.)?

We focus on aluminium profiles & fittings and their flush trim/installation interfaces. FFUs/filters/dampers are supplied by specialist vendors. Glass and locks can follow client-specified brands; we ensure profile compatibility.

Lead Time, Samples, and MOQ?

Typical cadence is samples in around 2 weeks and mass production in 2–4 weeks, depending on the project. MOQ is friendly, and small trial batches are supported. Packages include labels/ink-jet codes for site management; sea/air/rail shipments are available.

What information is needed to place an order?

Please provide drawings/BOM, panel thickness and slot width, gasket series, clear opening sizes, cleanliness class, finish color (RAL), and quantity/batches. You can upload drawings for matching so we can configure the appropriate Clean Room Aluminium Profile system.