Busbar connectors are typically used in power systems in the form of connecting plates, flexible connecting strips, or laminated structures to achieve stable and reliable electrical connections between busbars. They are widely used in power distribution systems, energy storage systems, and various industrial electrical equipment. Their structural form, manufacturing precision, and material selection directly affect the conductivity and operational stability of the busbar connection.

Chalco offers a variety of connectors and structural components for busbar connections, primarily made of copper or aluminum, supporting selection and matching for different busbar specifications and connection methods. Common product forms include:

- Rigid busbar connector/connector plate, used for direct connection between busbars.

- Flexible busbar connectors and laminated connection structures are suitable for vibration compensation, thermal expansion, or space-constrained operating conditions.

- Fastening and auxiliary connection components used in conjunction with busbar connectors

The above-mentioned connectors can be processed and configured in terms of size, hole position and surface condition according to project requirements, so that customers can complete the busbar connection design in combination with their own system structure and installation method.

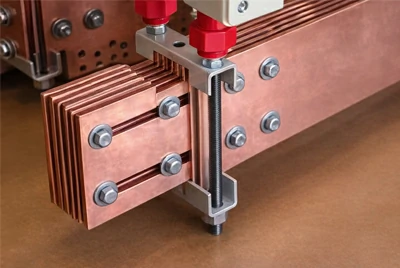

Rigid busbar connectors

Chalco supplies a variety of rigid busbar connectors and plates for direct conductive connections between busbars, widely used in distribution cabinets, complete sets of equipment, energy storage systems, and various stationary power systems.

These connectors are typically made of copper or aluminum and can be matched and configured according to the busbar size, current rating and installation conditions. They support different thicknesses, widths and hole types to meet the actual needs of engineering projects for connection stability and current carrying capacity.

Busbar Joint Plate

Bolt-On Busbar Connector Plate

Flat Copper / Aluminum Busbar Link

Chalco rigid busbar connectors support:

- Copper/Aluminum Material Selection

- Processing of connecting pieces with different thicknesses and widths

- Configure hole positions, hole spacing, and connection structures according to drawings or technical requirements.

- Surface finish is configured based on electrical performance and operating environment.

Rigid busbar connectors have a mature structure and strong adaptability. They are one of the most widely used and stable basic connectors in busbar connections, and are suitable for power systems that require installation reliability and long-term operational stability.

Flexible busbar connectors

Chalco offers a variety of flexible busbar connectors for flexible conductive connections between busbars. These connectors are suitable for power system scenarios involving vibration, thermal expansion, or installation displacement, and are widely used in energy storage systems, power electronic equipment, and various industrial electrical installations.

Flexible busbar connectors typically employ multi-layer copper foil or copper braided strip structures. Their flexible structure absorbs mechanical stress generated during operation, effectively reducing the impact of vibration and thermal cycling on the busbar connection points. These connectors can be matched and configured according to system layout, current rating, and connection method to meet the reliability and service life requirements of project-based applications.

Flexible Busbar

B raided Copper Busbar Connector

Laminated Flexible Busbar

Chalco flexible busbar connectors support:

- Multi-layer copper foil or copper braided strip structure

- Configurations with different lengths, widths and cross-sectional specifications

- The end connector structure and hole positions are customized according to the drawing

- Selection of connection processes such as end crimping, welding or brazing

Flexible busbar connectors have significant advantages in operating conditions requiring buffering displacement, vibration reduction, or compensation for thermal expansion, and are one of the commonly used and important connection methods in busbar systems.

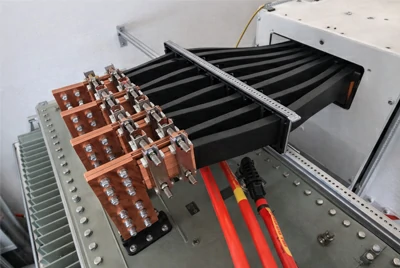

Laminated busbar connectors

Chalco offers a variety of laminated busbar connectors suitable for busbar connection applications with high requirements for space utilization, electrical performance and system integration. They are commonly found in energy storage systems, power electronic equipment and high power density power systems.

Laminated busbar connectors are typically composed of multiple layers of conductors and insulating materials, achieving stable current transmission and structural connection within a limited space. Through a well-designed laminated structure, these connectors can effectively reduce loop impedance and meet the system's comprehensive requirements for insulation and compact layout. Their structural configuration can be matched and configured according to the busbar interface, current rating, and system layout.

Rigid Laminated Busbar Connector

Flexible Laminated Busbar Connector

Multi-Layer Insulated Busbar Link

Chalco laminated busbar connectors support:

- Multilayer copper conductor structure and insulation layer combination

- Different number of layers, sizes and connection area structural designs

- Interface location, hole position, and connection method are customized according to the drawing

- Insulation materials and structural configurations adapted to system requirements

Laminated busbar connectors have significant advantages in applications with limited space or high power density, and are one of the important connection methods in busbar systems that balance structural integration and electrical performance.

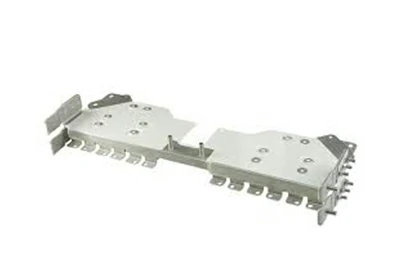

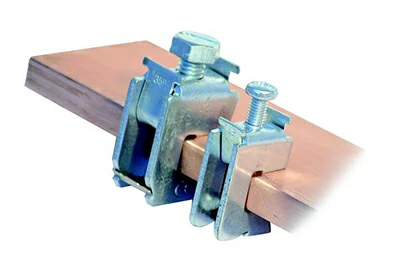

Connector Hardware & Matching Components

In busbar connection applications, fasteners and matching components are used to work with rigid, flexible, and laminated busbar connectors to achieve stable crimping, reliable conductivity, and structural fixation. Chalco can provide selection and supply support for matching components compatible with the connectors in busbar connection projects.

Conductive Washer

Busbar Bolts & Nuts

Spacers & Shims for Busbar Connections

Chalco supports the following connection and fastening solutions:

- Conductive pad configuration is supported to improve contact interface condition and reduce contact resistance.

- Selection and matching of fasteners to adapt to different busbar sizes and connection structures

- Spacing and adjustment shims are configured to meet the requirements for adjusting installation height, tolerances, or structural spacing.

The aforementioned supporting components are usually selected and used together with the busbar connectors. They can be matched and configured according to the specific connection structure, installation method and application environment to improve the overall stability and installation consistency of the busbar connection structure.

Busbar connectors are adaptable to various connection schemes and application areas.

Leveraging the diverse structural forms of rigid, flexible, and laminated busbar connectors, Chalco's busbar connectors and components are adaptable to various common busbar connection methods in engineering projects, meeting connection requirements under different busbar sizes, current ratings, vibration conditions, space constraints, and installation methods. Through appropriate matching of connector structure, dimensions, and supporting components, the requirements of different connection forms in terms of current carrying capacity, structural stability, and long-term operational reliability can be supported.

Given the above engineering conditions, busbar systems typically employ different connection methods in practical applications. Commonly adapted connection methods include:

Customer case studies in key application areas:

Distribution Cabinets & Electrical Assemblies

Busbar connectors are used to form stable direct busbar connections. Rigid connectors are commonly applied in fixed installations requiring high connection strength, current capacity, and long-term stability. Specifications can be matched to cabinet structure and busbar layout.

Energy Storage & Power Electronicst

Flexible and laminated busbar connectors are used to accommodate thermal expansion, vibration, and space constraints in connections between battery modules, PCS, and power units, improving reliability and supporting compact designs.

Industrial Electrical & Power Systems

Busbar connection solutions can be configured using rigid, flexible, or laminated connectors with matching hardware to meet durability, stability, and installation requirements. Clamp-type connectors may be used for rapid installation in upgrades or retrofits.

Technical Support & Project Collaboration

In busbar connection projects, the selection and configuration of connectors typically need to be confirmed in conjunction with busbar specifications, connection methods, and actual installation conditions. Chalco provides technical support and project coordination centered on connectors and components to address connection needs across various engineering scenarios, assisting customers in efficiently advancing busbar connection-related work.

Chalco offers the following technical and project support:

Connector selection support based on drawings or parameters: Assist in confirming the appropriate connector structure, specifications and matching component configuration according to busbar size, current rating and connection method requirements.

Connector machining and structural confirmation: Supports the machining confirmation of key dimensions such as hole positions, interface areas and end structures to ensure that the connectors match the customer's system structure.

Project-based supply and batch coordination: suitable for equipment manufacturing, system integration and engineering project applications, supporting the supply arrangement of connectors and components according to the project schedule.

Application communication and technical clarification support: During the project process, we can cooperate with customers to conduct technical communication on issues such as connector structure compatibility, installation conditions and usage environment.

Leveraging its mature experience in busbar deep processing and connector manufacturing, Chalco focuses on the adaptation and supply of busbar connectors and related components while maintaining stable quality and delivery time control. With clear product boundaries and stable processing capabilities, Chalco supports customers in efficiently completing busbar connection-related work in the system design and installation process.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote