Aluminum wall panels are a type of metal wall material that combines lightweight, durability, and decorative effects. They are widely used in interior walls, public areas, corridors, technical spaces, and as metal decorative surfaces for building exteriors. Chalco aluminum wall panels use high-quality aluminum alloy substrates and combine various surface treatments such as PVDF, powder coating, wood grain, stone grain , perforation, and laser engraving to provide architects and designers with a smooth, stable, and easy-to-process wall solution.

Whether used for clean, smooth interior walls or as metal cladding on building exteriors, aluminum wall panels offer a range of visual appeal and structural performance while maintaining excellent weather resistance.

Lightweight & Flat: Lightweight, strong, and very flat—ideal for large panels.

Applications: Suitable for walls, ceilings, and partitions.

Finishes & Colors: Multiple finishes and colors available.

Installation: Easy to install and maintain.

Customization: Customizable size and thickness.

Chalco Aluminum Wall Panel Application Scenarios

Exterior / Façade Aluminum Wall Panels & Cladding Systems

Chalco exterior aluminum wall panels use high-durability aluminum alloys with PVDF/FEVE coatings, suitable for curtain wall façades (curtain wall façades), rainscreen systems, entrance cladding, and exterior refurbishment of existing buildings. The panels offer excellent corrosion resistance, wind-load performance, and high flatness, making them ideal for façades in commercial buildings, transportation hubs, and residential projects.

Pre-fabrication options such as perforation, routing, edge folding, and stiffener reinforcement are available to support fast integration into various curtain wall and metal cladding systems.

Interior Aluminum Wall Panels / Interior Wall Lining

Chalco interior aluminum wall panels are lightweight, durable, smooth, and easy to clean, making them suitable for decorative wall surfaces in hotels, offices, corridors, and public areas. Multiple finishes are available, including anodized, brushed, wood grain, and stone grain, delivering a unified and modern appearance.

Custom processing such as cutting, beveling, and perforating is supported.

Modular Partition Wall Panels

Chalco aluminum panels can be used for modular partition wall systems, offering lightweight design, high strength, and easy maintenance. They are suitable for office partitions, medical facilities, clean rooms, and exhibition areas, allowing rapid assembly and compatibility with equipment and piping layouts.

Perforated mounting holes, pre-reserved installation grooves, and drawing-based customization are available.

Aluminum Metal Ceiling Systems

Chalco aluminum panels can be used for flat, linear, and perforated acoustic ceilings. They feature stable structure, no deformation, and can be seamlessly integrated with lighting, ventilation, and fire protection systems. Suitable for commercial, medical, transportation, and technology venues.

Reverse edge bending, perforation, and keel-adaptation processing are available.

Chalco Aluminum Wall Panel Product Types

Chalco aluminum alloy wall panels offer six functional panel structures to meet structural and application requirements: honeycomb panels, insulated panels, solid panels, corrugated panels, diamond-patterned panels, and sandwich panels. Each type balances lightweight, strength, thermal insulation, and decorative performance, making them widely applicable to building curtain walls, exterior wall systems, and industrial decoration projects.

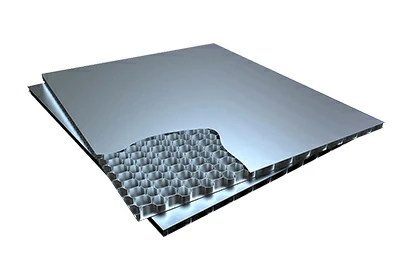

Honeycomb Aluminum Wall Panel

Structure: Double-layer aluminum panels with hexagonal honeycomb core.

Performance: High flatness, lightweight, strong bending resistance.

Applications: Airport lobbies, hotel lobbies, exhibition halls, office public areas.

Structure: Aluminum panels with mineral wool, MgO board, honeycomb, or corrugated core.

Performance: Strong rigidity, sound insulation, fire resistance.

Applications: Equipment rooms, factory interiors, technical spaces, partitions.

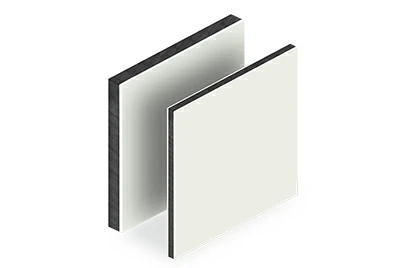

Solid Aluminum Wall Panel

Material: 3003/5052 aluminum alloy with CNC bending, spraying, anodizing, or wood grain.

Performance: High structural stability and strong weather resistance.

Applications: Commercial buildings, public areas, interior and exterior wall decoration.

Decorative Aluminum Wall Panel

Finishes: Wood grain, stone grain, brushed, mirror, embossed, perforated acoustic.

Performance: Decorative and functional, high visual appeal.

Applications: Brand image walls, kitchen backsplashes, corridors, commercial and residential interiors.

Aluminum Partition Wall Panel

Structure: Honeycomb, foam core, or hollow structure options.

Performance: Lightweight, strong, good acoustic control, modular installation.

Applications: Offices, conference rooms, hospitals, control rooms.

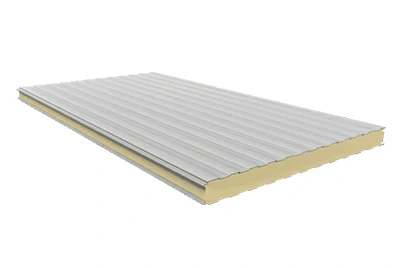

Insulated Aluminum Wall Panel

Structure: Double-layer aluminum panels with XPS/EPS/PU/foam core.

Performance: Excellent thermal insulation and impact resistance.

Applications: Garages, plants, warehouses, cold chain rooms, trailer walls, technical spaces.

Technical Data of Chalco Aluminum Wall Panel

| Project | Parameter range | Illustrate |

| Alloy | 3003 / 5052 / 6061 | Commonly used in decorative panels and functional wall panels |

| Thickness | 1.5–6.0 mm | Thinner sheets are used indoors; higher stiffness options are available for outdoor use. |

| Maximum Size | ≤1500×6000 mm | Large panels with high flatness, customizable. |

| Panel Structure | Solid/Honeycomb/Sandwich | To meet different strength and weight requirements |

| Surface finishing | PVDF / Anodizing / Powder Coating | Suitable for indoor and outdoor use |

| Flatness | ≤2.0 mm/m | Suitable for large wall surfaces |

| Weight | 2.5–7.5 kg/m² | Depends on structure and thickness |

| Acoustic performance | NRC 0.3–0.8 (perforation optional) | Suitable for indoor sound absorption systems |

| Fire rating | A2 / B1 (structural dependency) | Meet building fire protection requirements |

Chalco Aluminum Wall Panel Surface Finishes & Color Options

Chalco aluminum wall panels offer a variety of surface finishes and color combinations to suit project style, environmental conditions, and design requirements. Standard finishes include PVDF coated aluminum wall panels, anodized aluminum wall panels, brushed metallic finish, and powder coated aluminum wall panels. Each process undergoes rigorous weather resistance and adhesion testing to ensure durable appearance and color stability.

PVDF Fluorocarbon Coating

Uses a fluorinated resin coating with excellent UV resistance, corrosion resistance, and colorfastness, making it suitable for building exterior walls, outdoor cladding, and high-weather-resistance environments.

Anodizing Treatment

Electrochemical oxidation forms a dense protective film with a natural metallic luster, offering exceptional wear resistance and stable coloration, suitable for modern interior and exterior wall decoration.

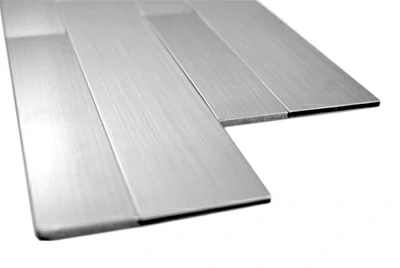

Brushed Metallic Surface

The refined metallic texture enhances visual depth and material quality, and is available in multiple metallic effects such as silver, black, gold, and titanium. It is commonly used in commercial spaces, office areas, and high-end interior wall surfaces.

Powder Coating Finish

An environmentally friendly, solvent-free process offering a wide range of matte, sand-texture, metallic, and wood-grain color options. It provides strong adhesion and high wear resistance, making it ideal for customized interior and exterior wall projects.

Chalco offers standard RAL colors, wood grain, stone grain, metallic gloss, and sand-texture finishes, and also supports custom color matching for project-specific requirements, meeting diverse design needs from commercial spaces to residential applications.

Chalco Aluminum Wall Panel System Solutions

Chalco not only provides high-quality aluminum wall panels, but also offers structural support designs for different installation methods, making construction easier and more standardized. Through pre-processing, modular design, and matching profiles, our wall panels are suitable for a variety of indoor and outdoor installation systems.

Adhesive Mounting

Application: Suitable for interior feature walls and commercial decoration.

Chalco provides: Back pretreatment, pre-cut dimensions, lightweight board surface, and adhesive recommendations.

Exposed Screw Fixing

Application: Used for functional walls in garages, workshops, trailers, etc.

Chalco provides: Pre-drilled holes, reinforcing ribs, wear-resistant surfaces, and color-matched screw caps.

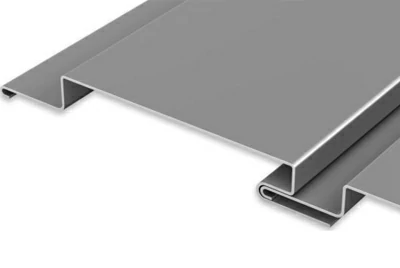

Concealed Clip (Z-clip / Hook-on)

Application: Suitable for areas requiring maintenance.

Chalco provides: Back-mounted structure, flatness control, modular numbering, quick assembly/disassembly.

Modular Partition System

Application: Offices, clean rooms, hospitals.

Chalco provides: Frame-compatible structure, honeycomb/foam core options, modular sizes, corner fittings.

Lightweight Sub-frame System

Application: Used for wall leveling, renovation, concealing pipes.

Chalco provides: Joist joint recommendations, fixing point matching, insulation/sound absorption compatible designs.

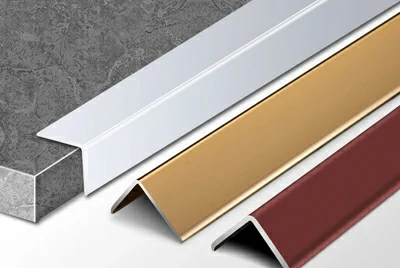

Edge Trimming & Corner Finishing

Application: Suitable for all wall panel systems.

Chalco provides: U/C/L edging, color-matched spraying, complete finishing solutions.

Chalco Aluminum Wall Panel Projects

Chalco aluminum wall panels (also known as aluminum metal wall panels or aluminum façade panels) are widely used in commercial facades, residential buildings, transportation hubs, and modern interior spaces due to their lightweight, high strength, weather resistance, and diverse appearances. The following examples demonstrate the comprehensive performance of aluminum wall panels in terms of structural stability, installation efficiency, and visual appeal across different scenarios.

Commercial Wall Panels: Used for feature walls in hotels, shopping malls, and showrooms, providing a high-quality metallic finish and scratch resistance.

Residential Exterior Walls: Used for the renovation of apartment and residential exterior walls; lightweight, corrosion-resistant, colorfast, and easy to maintain.

Office & Public Interior Walls: Suitable for public spaces such as offices, hospitals, and schools. The walls are smooth, easy to clean, and highly durable.

Industrial & Warehouse Walls: Used for the interior and exterior walls of workshops and warehouses, featuring impact resistance, corrosion resistance, and easy maintenance.

Modular partition systems (Partition Wall Systems): Lightweight partitions for office areas, clean rooms, and control rooms, with stable structure and easy installation.

Transportation Hub Interior Walls: Suitable for high-traffic public areas such as airports and train stations, featuring a clean appearance, high flame retardancy, and easy cleaning.

FAQ

Q1: What is the difference between decorative aluminum panels and aluminum wall panels?

A: Decorative aluminum panels are mainly used for interior walls, emphasizing texture and design effects; aluminum wall panels can be used for both interior and exterior walls, emphasizing weather resistance, corrosion resistance and structural stability, and are suitable for a wider range of applications.

Q2: Does Chalco aluminum wall panel support customization of size and surface treatment?

A: Yes. We offer custom sizes, thicknesses, folded edges, pre-drilled holes, and a variety of finishes including PVDF, powder coating, anodizing, wood grain, stone grain, and brushed metal.

Q3: Are aluminum wall panels environmentally friendly? Can they be recycled?

A: Yes. The Chalco Aluminum Wall Panel is made of 100% recyclable aluminum, is formaldehyde-free and odorless, and meets green building requirements.

Q4: How to choose the appropriate installation method?

A: Choose according to the purpose:

- Adhesive mounting: Suitable for interior feature walls and commercial spaces.

- Exposed screw fixing: Suitable for garages, workshops, and warehouses.

- Concealed clips (Z-clip / Hook-on): Suitable for public areas requiring maintenance.

- Partition system: used in offices, clean rooms, and control rooms.

- Lightweight subframe: Used for wall leveling or renovation.

If you have project drawings, we can provide structural compatibility advice and matching edge finishing solutions.

Q5: In which scenarios are aluminum wall panels suitable?

A: It can be used for various wall applications such as commercial spaces, residential exterior wall decoration, airports and public buildings, office interior walls, partition systems, garages and industrial plants.

Q6: How long can the surface coating of aluminum wall panels be used?

A: PVDF coatings can provide weather resistance for approximately 15–20 years; powder coating and anodizing can also maintain stable color and corrosion resistance over a long period, depending on the environment in which they are used.

If you are selecting the right aluminum wall panels for your project, Chalco can provide you with free selection advice and sample support. Please feel free to contact us for a quote.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote