Aluminum Magnet Wire is a lightweight, high-conductivity winding conductor used in motors, transformers, HVAC systems, and voice coils. Compared with copper, it greatly reduces weight and cost while ensuring stable insulation and long service life.

Chalco, leveraging its full-industry-chain manufacturing capabilities, offers magnet wire products that comply with NEMA MW 1000, IEC 60317, and IEC 60851 standards, and are certified by ISO 9001, CQM, SGS, and UL (E234565). Our solutions help customers achieve higher energy efficiency and long-term reliability.

Browse by Category

-

By Insulation Type

Enameled Wire

Paper-covered Wire

Fiberglass Wire

-

By Conductor Shape

Round

Rectangular/Flat

-

By Thermal Class

Class 120

Class 130/155

Class 180

Class 200/220

What Is Aluminum Magnet Wire?

Aluminum Magnet Wire is an insulated conductor used for winding electromagnetic coils. It plays a key role in energy conversion and signal transmission in devices such as motors, transformers, voice coils, and HVAC systems. Based on insulation type, aluminum magnet wire can be classified into three main categories:

-

Aluminum Enameled Wire

Aluminum Enameled Wire

This type is coated with insulation varnish such as polyester, polyurethane, or polyimide. It features a thin insulation layer, high mechanical strength, and is widely used in motors, transformers, and voice coil applications.

-

Aluminum Paper-covered Wire

Aluminum Paper-covered Wire

Wrapped with high-strength electrical papers such as NOMEX or DuPont paper, this type offers strong dielectric strength, making it ideal for oil-immersed transformers and high-voltage devices. It has excellent impregnation and heat resistance.

-

Fiberglass-covered Aluminum Wire

Fiberglass-covered Aluminum Wire

Reinforced with fiberglass wrapping and thermal treatment, it provides excellent heat resistance, radiation tolerance, and mechanical stress durability. Commonly used in heavy-duty motors and power generation equipment.

In the industry, enameled wire is just one subtype of magnet wire, while paper-covered and fiberglass-covered wires also fall within the same category.

It's also worth noting a broader term—Winding Wire—which refers to any conductor (insulated or bare) used for electromagnetic coil winding. If you're seeking more comprehensive conductor solutions, we recommend visiting our Winding Wire product page.

Chalco offers all types of magnet wire, including round and rectangular/flat conductors, covering Class 130 to Class 220 thermal grades. All products support customization and comply with international standards such as NEMA MW 1000 and IEC 60317, ensuring high reliability for various electromagnetic systems.

Round Wire vs Flat Wire: A Guide to Selecting Aluminum Magnet Wire

Chalco's Aluminum Magnet Wire is available in two main conductor shapes: round wire and flat wire, each offering unique advantages to meet various equipment designs and system requirements. Flat wire, with its superior space utilization, is increasingly adopted in high-efficiency motors and transformer systems.

Aluminum Round Magnet Wire

Diameter: 0.4 - 4.0 mm

Features: Flexible and easy to wind; suitable for automated production; cost-effective

Applications: General motors, small transformers, relays, voice coils, etc.

Aluminum Flat Magnet Wire

Dimensions: Width 2.0 - 25 mm, Thickness 0.8 - 6.0 mm

Features: High slot fill factor, excellent heat dissipation, low power loss

Applications: New energy vehicle motors, dry-type transformers, high-power inductors, and more

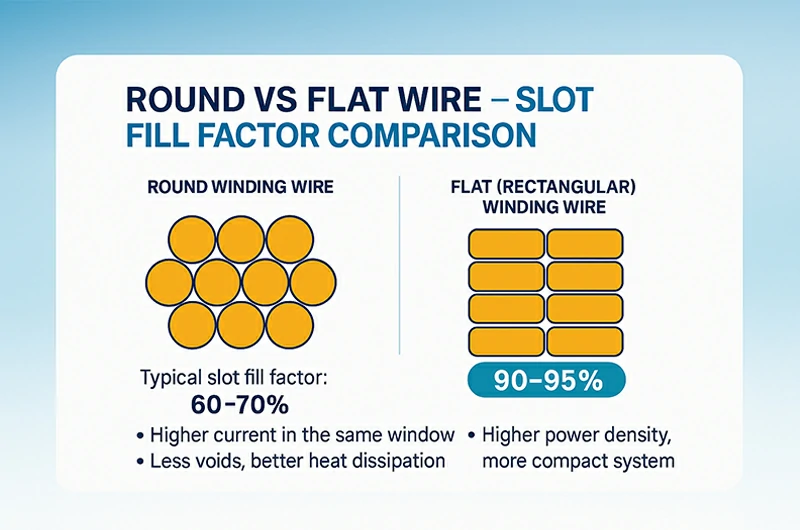

Flat Wire & Slot Fill Factor Advantages

Compared to conventional round wire, flat aluminum magnet wire achieves a much higher fill factor (conductor volume utilization), reaching up to 90–95%. This translates into:

- Higher current capacity within the same slot space

- Reduced winding voids and improved heat dissipation

- More compact system design with improved efficiency

Chalco's flat wire is manufactured using drawing + precision rolling technology, ensuring high dimensional accuracy and offering various edge radius customizations (R0.8 / R1.0 / R1.5, etc.). We support mold matching and custom tooling development to help customers optimize device performance.

Complete Guide to Insulation Classes for Aluminum Magnet Wire (Class 130–220)

The insulation layer of magnet wire not only determines its maximum operating temperature (Thermal Class), but also directly impacts the service life, insulation safety, and operational efficiency of equipment such as motors and transformers.

| Insulation Type | Thermal Class | Structural Features | Typical Applications |

| Polyester Enameled Wire | Class 130 | Low cost, good flexibility | Household motors, small transformers, fans |

| Polyesterimide Enameled Wire | Class 155 | Higher heat resistance, excellent mechanical/electrical properties | AC compressors, power tools, medium-sized motors |

| Polyester + Polyimide Composite Wire (PE+PAI) | Class 180 | Dual insulation, balanced heat resistance and flexibility | EV drive motors, inverters, high-speed motors |

| Acetal Enameled Wire | Class 200/220 | Resistant to high-frequency vibration and moisture | Precision motors, voice coils, relays |

How to Choose Aluminum Magnet Wire Based on Thermal Class?

The thermal class of magnet wire is critical to ensuring long-term equipment stability and performance. Chalco offers a complete range of aluminum enameled wires from Class 120 to Class 220, covering diverse industry needs—from general-purpose motors to advanced EV electronics.

- Class 120/130/155: Suitable for low-to-medium power motors, household appliances, fans, and power tools—ideal for moderate operating conditions

- Class 180/200/220: Designed for EV drive systems, high-speed motors, inverters, and high-frequency coils—ideal for high heat and high-stress environments

Understanding Different Insulation Systems

Chalco provides all major types of insulation materials and structures, including:

- Acetal Enameled Wire

- Polyester Enameled Wire

- Polyesterimide Enameled Wire

- Polyester + Polyimide Composite Wire

Not sure which insulation system fits your application?

Our engineering team is ready to assist with selection advice, sample testing, and technical support tailored to your design and reliability needs.

Application Fields: Typical Uses of Aluminum Magnet Wire

Chalco's aluminum magnet wire offers a lightweight design, excellent electrical conductivity, and cost advantages, making it an ideal solution for windings in motors, transformers, coils, home appliances, and electronic devices. Below are the main application sectors and recommended product configurations:

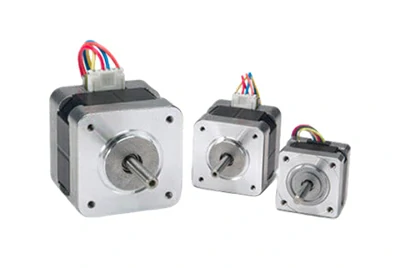

Motors & Power Tools

Electric motors and power tools operate under high-frequency starts, heavy loads, and elevated temperatures. These conditions demand winding wires with high thermal resistance, strong mechanical stress endurance, and reliable insulation performance. To ensure compact winding and efficient heat dissipation, aluminum rectangular (flat) wires or multi-layer insulated round wires are often preferred, typically rated between Class 155 to Class 200.

Recommended Product Configurations

| Thermal Class | Insulation Type | Conductor Material | Diameter / Width | Cross-Section Shape |

| Class 155 | Polyesterimide Enameled Wire | Copper-clad Aluminum / Aluminum | 0.8 – 2.0 mm | Round Wire |

| Class 180 | Polyester + Polyimide Composite Enameled Wire | Aluminum | 1.0 – 3.2 mm (width) | Flat / Rectangular Wire |

| Class 200 | Polyimide / Acetal Enameled Wire | Aluminum / Copper-clad Aluminum | 1.2 – 3.5 mm (width) | Flat / Rectangular Wire |

EV Drive Systems (Electric Vehicle Motors)

Electric vehicle drive motors operate under high voltage, thermal load, and compact structural constraints, placing extremely high demands on the magnet wire's thermal resistance, insulation level, mechanical strength, and slot fill factor. For this reason, rectangular aluminum magnet wire with Class 200/220 thermal rating has become the mainstream solution—ensuring high power density, improved cooling, and long service life.

Recommended Product Configurations

| Thermal Class | Insulation Type | Conductor Material | Width / Diameter | Cross-Section Shape |

| Class 200 | Polyimide Enameled Flat Wire | Aluminum | 1.5 – 4.0 mm | Rectangular / Flat Wire |

| Class 220 | Polyimide + PAI Composite Insulation System | Aluminum / Copper-clad Aluminum | 2.0 – 5.0 mm | Rectangular / Flat Wire |

AC Compressors & Fan Motors

Air conditioning systems operate under high temperature, humidity, and frequent start-stop cycles, especially in compressors and fan motors. This places demanding requirements on magnet wire for thermal resistance, insulation reliability, and moisture tolerance. Polyesterimide or dual-layer composite insulation systems are commonly used, often paired with copper-clad aluminum (CCA) conductors to balance conductivity and cost.

Recommended Product Configurations

| Thermal Class | Insulation Type | Conductor Material | Width / Diameter | Cross-Section Shape |

| Class 200 | Polyimide Enameled Flat Wire | Aluminum | 1.5 – 4.0 mm | Rectangular / Flat Wire |

| Class 220 | Polyimide + PAI Composite Insulation System | Aluminum / Copper-clad Aluminum | 2.0 – 5.0 mm | Rectangular / Flat Wire |

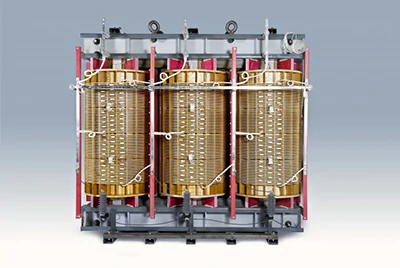

Transformers & Reactors

Magnet wires used in transformers and reactors must withstand continuous high temperatures, magnetic saturation, mechanical vibrations, and long-duty cycles, requiring excellent thermal stability and insulation performance. For large-scale equipment, flat or paper-covered wires rated Class 180–220 are preferred to extend insulation life and enhance structural reliability.

Recommended Product Configurations

| Thermal Class | Insulation Type | Conductor Material | Width / Diameter | Cross-Section Shape |

| Class 180 | Polyester + Polyimide Composite Enamel | Aluminum / Copper-clad Aluminum | 1.2 – 4.0 mm | Flat Wire |

| Class 200 | Acetal Enameled Wire / Polyimide Enameled Wire | Aluminum | 1.5 – 4.5 mm | Flat Wire |

| Class 220 | Paper-covered Wire / Dual Glass Fiber Composite Insulation | Aluminum / Copper | 2.0 – 5.0 mm | Flat or Trapezoidal Wire |

Coils & Communication Devices

Wireless communication modules, sensors, and miniature coils require extremely precise conductor dimensions, uniform insulation layers, and excellent electromagnetic performance. Ultra-fine diameter wires (≤0.5 mm) with high-frequency stable insulation systems are typically used to ensure signal integrity and EMI resistance. Common insulation types include polyester, acetal, and polyimide.

Recommended Product Configurations

| Thermal Class | Insulation Type | Conductor Material | Diameter | Cross-Section Shape |

| Class 130 | Polyester Enameled Wire | Aluminum / Copper-clad Aluminum | 0.1 – 0.5 mm | Round Wire |

| Class 200 | Acetal / Polyimide Enameled Wire | Aluminum | 0.2 – 0.6 mm | Round Wire |

Contact us for custom-designed magnet wire solutions tailored to your motor systems!

Integrated Manufacturing & Quality Assurance of Chalco Magnet Wires

At Chalco, we understand that magnet wire plays a dual role of conduction and insulation in motors, transformers, and coils, requiring exceptional dimensional accuracy, thermal endurance, and environmental resistance. Backed by our fully integrated in-house production lines and stringent process standards, we ensure stable and reliable product delivery.

Fully Integrated Manufacturing · End-to-End Process Control

From aluminum ingot casting → continuous rolling → wire drawing → annealing → enameling → baking → inspection → spooling, every step is completed within Chalco facilities, eliminating uncertainties and quality fluctuations from outsourcing.

- Multiple automated enameling lines supporting various insulation types including PEW, EIW, PI, and AIW.

- Precision annealing and coating processes ensure uniform enamel layer, with excellent dielectric strength and solvent resistance.

- Small-batch customization available; flexible specification switching; prototyping in as fast as 7 days.

Strict Quality Control · International Certifications

Chalco has established a comprehensive quality inspection system across the entire process, ensuring all magnet wires meet international standards in size, performance, and appearance.

- Testing includes dimensional tolerance, conductor resistance, enamel thickness, breakdown voltage, adhesion, thermal shock, solvent resistance, etc.

- Cleanroom filtration, online optical inspection, and manual sampling ensure surface cleanliness, avoiding scratches, bubbles, or contaminants.

- All spools are annealed and tension-wound to ensure smooth unwinding and reduce operational risk.

- Each spool is labeled with material, size, tolerance, batch number, and production date for traceability and digital archiving.

Chalco magnet wire products fully comply with IEC 60317, JIS C 3202, GB/T 6109, NEMA MW1000, and other international standards. Our facilities are certified to ISO 9001 and IATF 16949 (automotive), supporting applications in industry, power, and transportation.

Clean Packaging · Global Delivery

To protect the enamel coating from contamination or damage, Chalco uses clean winding and custom packaging solutions:

- Packaging includes: PE stretch film + shock-absorbing foam + reinforced cartons or plywood cases.

- Each unit features clearly marked labels for easy identification and storage.

- Global delivery options include international express or full-container sea freight. Upon request, we provide COA, COC, MSDS, RoHS and other compliance documentation for smooth customs clearance.

FAQ

1. How to choose the insulation class? Do you offer Class 200 or higher?

Yes. Chalco offers a full range of insulation classes including Class 130 (Polyester PEW), Class 155 (EIW), Class 180 (EIW/PAI), and Class 200 (Polyimide PI). We will recommend the most suitable system based on your operating temperature, cooling conditions, and equipment lifetime requirements.

2. What insulation types are available? Can I request custom combinations?

We supply various insulation systems including Polyester (PEW), Polyester-Imide (EIW), Polyimide (PI), and Acetal (AIW), in single or dual-layer structures. Custom coatings such as solvent-resistant, humidity-resistant, or corona-resistant are also available upon request.

3. Do you offer CCA (Copper-Clad Aluminum) or CCA (Aluminum-Clad Copper) conductors?

We primarily supply aluminum (EC grade) and copper-clad aluminum (CCA) conductors. CCA magnet wire offers a good balance between electrical conductivity and lightweight, ideal for transformers and motor windings where cost-performance optimization is critical.

4. Are Chalco magnet wires compliant with international standards? Do you provide test reports?

Yes. All products meet IEC 60317, GB/T 6109, NEMA MW1000, JIS C 3202, and other major standards. Upon delivery, we can provide full test reports, covering dimensions, enamel thickness, adhesion, breakdown voltage, thermal shock resistance, and more.

5. Is there a minimum order quantity (MOQ)? Can I get quick samples?

No MOQ for standard specifications. For customized specs, we support flexible low-volume orders, with minimum sampling from 10 kg. Thanks to our in-house wire production and enameling lines, sample delivery is possible within 7 working days.

6. What packaging and shipping options are available? Do you support global delivery?

We offer standard or custom spool packaging with anti-shock, dust-proof, and reinforced protection to prevent enamel damage during transport. We support courier, air freight, and sea freight, and can provide COC, MSDS, RoHS, and other export documents to meet global compliance.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote