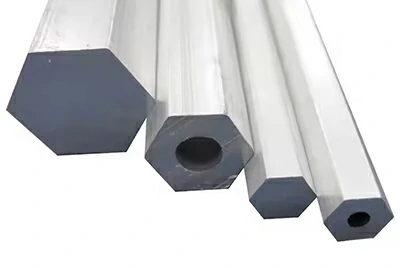

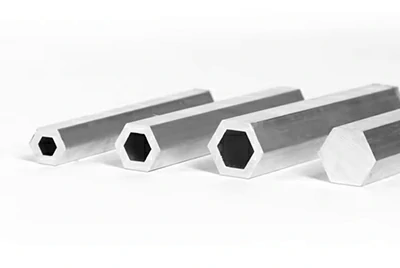

Aluminum hex tubes feature a distinctive hexagonal cross-section, offering superior bending resistance, rotational alignment, and space utilization compared to traditional round or square tubing. When combined with high-strength alloys like 6061-T6, they deliver a balance of lightweight structure, excellent strength, corrosion resistance, and flexible machinability. These tubes are widely used in applications with strict demands on strength and precision—such as automotive suspension systems, drone frameworks, industrial jigs, and decorative components.

Instant QuoteAs a professional aluminum hex tube manufacturer, Chalco offers one-stop services including standard and custom sizes, anodizing, precision cutting, and more—ensuring high-performance solutions for diverse structural applications.

Why Choose Aluminum Hex Tubing?

Aluminum hex tubing combines the material advantages of high-strength aluminum alloys with the structural benefits of a hexagonal profile. This makes it ideal for precision assembly and multi-directional stress applications—especially in systems that require strict tolerance for tapping, fastening, and structural stability.

- Hexagonal shape provides enhanced resistance to bending and torsion, outperforming round and square tubes of the same size.

- Compared to solid hex aluminum bars, the hollow structure significantly reduces weight for better load efficiency.

- Made from 6061/6063 aluminum alloys, offering a higher strength-to-weight ratio than many traditional materials.

- Excellent for tapping, CNC machining, and threaded assembly—ideal for steering rods, linkages, and adjustable joints.

- Compatible with TIG/MIG welding, delivering high-strength welds for complex structural assemblies.

- Multiple surface finishes available: anodizing (black/silver/gold), powder coating, and brushed finishes for both aesthetics and corrosion protection.

- 100% recyclable and compliant with RoHS/REACH environmental standards.

Specifications of Aluminum Hex Tube

Chalco specializes in manufacturing aluminum hex tubes in a variety of alloys, including 6061 and 6063, known for their strength, lightweight properties, and excellent machinability. These tubes are commonly used in steering systems, industrial frameworks, mechanical assemblies, and UAV structures. Custom non-standard sizes, fixed-length cutting, and deep processing options are available to meet both structural and dimensional precision needs.

Specification

| Metric | imperial | |

| Across Flats | 6mm - 150mm | 1/4" - 6" |

| Wall Thickness | 1.0mm - 12.0mm | 0.039" - 0.5" |

| Length | Cut to length, up to 6 meters | Up to 20 feet |

| Tolerance | Conventional tolerance ±0.2mm, precision grade up to ±0.05mm | |

| Standard | ASTM B221, AMS-QQ-A-200, EN 755 | |

| Surface Treatment | Anodizing (black/silver/gold), spraying, electrophoresis, brushing | |

| Further Processing | CNC, threading, tapping, grooving, drilling, chamfering, deburring, welding groove | |

Alloy

6061 Aluminum Hex Tube T6, T6511

6061 Aluminum Hex Tube T6, T6511General high-strength structural use, corrosion resistance, machinability

AMS 4113 AMS 4173 6063 Aluminum Hex Tube T5, T6

6063 Aluminum Hex Tube T5, T6Superior surface finish, suitable for architectural and decorative use

AMS 4156

Popular Sizes Available

| Detail | Alloy | Process | Processing services |

| 1/4" x 1/8" Aluminum Hex Tube | 6061 / 6063 | Extrusion | Polishing / Anodizing |

| 3/8" x 1/8" Aluminum Hex Tube | 6061 / 6063 | Extrusion | Polishing / Anodizing |

| 1/2" x 1/8" Aluminum Hex Tube | 6061 / 6063 | Extrusion | Polishing / Anodizing |

| 5/8" x 1/8" Aluminum Hex Tube | 6061 / 6063 | Extrusion | Threading / Black Oxide / Chamfering |

| 3/4" x 1/8" Aluminum Hex Tube | 6061 / 6063 | Extrusion | Threading / Black Oxide / Chamfering |

| 1" x 1/8" Aluminum Hex Tube | 6061 / 6063 | Extrusion | Polishing / Cutting / Anodizing |

| 1" x 1/4" Aluminum Hex Tube | 6061/ 6063 | Extrusion | Polishing / Cutting / Anodizing |

| 1-1/4" x 1/8" Aluminum Hex Tube | 6061 | Extrusion | Polishing / Cutting / Anodizing |

| 1-1/4" x 1/4" Aluminum Hex Tube | 6061 | Extrusion | Polishing / Cutting / Anodizing |

| 1-1/2" x 1/8" Aluminum Hex Tube | 6061 / 6063 | Extrusion | Cutting / Punching / CNC machining |

| 1-1/2" x 1/4" Aluminum Hex Tube | 6061 / 6063 | Extrusion | Cutting / Punching / CNC machining |

| 2" x 1/8" Aluminum Hex Tube | 6061 | Extrusion | Cutting / Punching / CNC machining |

| 2" x 1/4" Aluminum Hex Tube | 6061 | Extrusion | Cutting / Punching / CNC machining |

All popular aluminum hex tube sizes are supported by existing mold resources, with some specifications available in stock for immediate delivery. Chalco offers rapid prototyping, custom fabrication, and sample support to meet diverse project requirements.

For product selection advice, pricing, or technical consultation, click the contact button for a fast and professional response.

Instant QuoteProduct Categories of Aluminum Hex Tubes

To meet the diverse demands of different industries in terms of connection methods, load-bearing structure, and surface aesthetics, Chalco offers a wide range of aluminum hex tube products—from standard structural types to custom-engineered designs. All variants support custom length cutting and various deep processing options.

Special-Structure Aluminum Hex Tubes

For specific assembly or anti-rotation requirements, we offer two internal bore configurations that have been widely applied in steering connectors, modular structural frames, and mechanical joint systems:

Hex Tube with Round Bore

Featuring a hexagonal outer profile with a circular inner bore, this design combines structural rigidity with inner-hole compatibility. It supports thread tapping for easy integration with standard screws, ball joints, and steering systems.

Hex Tube with Hex Bore

Both inner and outer profiles are hexagonal, offering superior anti-rotation performance. Ideal for quick assembly, plug-in connections, and torsional alignment in modular systems.

Standard-Structure Aluminum Hex Tubes

Chalco provides a full range of standard aluminum hex tube types to suit applications from lightweight framing to high-load support:

- Extruded Aluminum Hex Tube

Manufactured using high-precision extrusion dies, ensuring consistent dimensions and uniform strength distribution. This is the most commonly used production method for aluminum hex tubes.

- Thin Wall Aluminum Hex Tube

Lightweight design with wall thickness typically ranging from 1.0mm to 2.0mm, suitable for display frames, lighting supports, and electronic housings where load-bearing is minimal.

- Thick Wall Aluminum Hex Tube

Reinforced wall structure (≥4.0mm) designed for high-stress environments, such as industrial equipment supports and hydraulic frames.

- Anodized Aluminum Hex Tube

Available in various anodized finishes including black, silver, and gold for enhanced corrosion resistance and aesthetic appeal. Widely used in architectural and custom product exteriors.

- Threaded Aluminum Hex Tube

The inner diameter is compatible with standard threading specifications, supporting right-hand/left-hand threading for precision assembly and adjustable connections.

- Custom Aluminum Hex Tube

Offers fully customized across-flat widths, wall thicknesses, and inner bore geometries to meet specialized needs in drone frames, racing tie rods, and medical device components.

Still unsure which structure or size to choose?

Contact us now for one-on-one engineering support, selection guidance, and sample prototyping.

Instant QuoteRelated products of aluminum hex tube

Typical Applications of Aluminum Hex Tubes

Due to their geometric stability, adjustable connection features, and lightweight yet high-strength material properties, aluminum hex tubes are widely used across a range of precision and engineering fields.

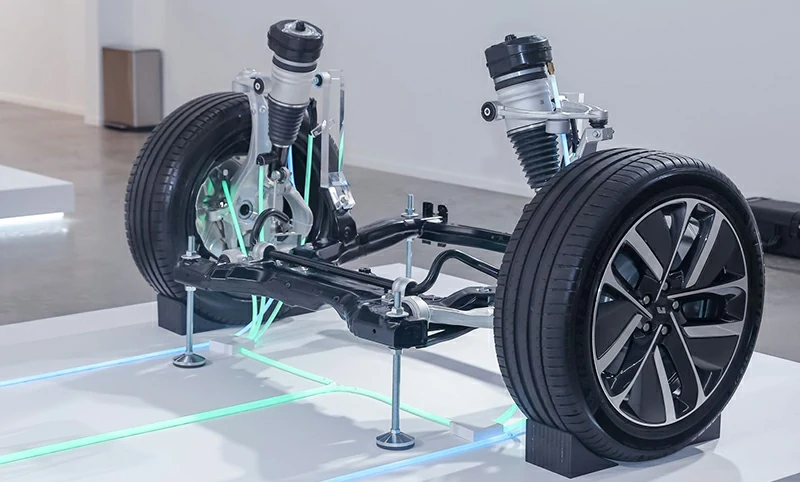

Suspension & Steering Systems (Automotive & Racing)

Aluminum hex tubes are commonly used in key suspension components such as tie rods, trailing arms, stabilizer links, and adjustable control arms in racing and performance vehicles. Their flat surfaces are ideal for tapping, and threaded ends allow for quick length adjustment to enhance handling and tuning efficiency.

Recommended alloy: 6061 aluminum hex tube for steering

Key advantages: Easy anti-rotation locking, adjustable length, better bending resistance than round tubes

Recommended processing: Black anodizing, double-end threading, slotted chamfering

Example sizes:

- 7/8" hex × .562" ID (fits approx. 5/8" thread)

- 1-1/8" hex × .687" ID (fits approx. 3/4" thread)

Drones & Lightweight Airframes

Aluminum hex tubes are ideal for structural parts such as multi-rotor drone arms, aerospace supports, and battery frames. Their excellent torsional rigidity and easy connectivity make them a superior alternative to round tubes.

Recommended alloys: 6061-T6, 7075-T6

Key advantages: Modular assembly compatibility, even load distribution across hexagonal faces

Common sizes: 1/2" × 1/8", 5/8" × 1/8", 3/4" × 1/8"

Optional processing: Anodizing, CNC precision cutting, groove machining

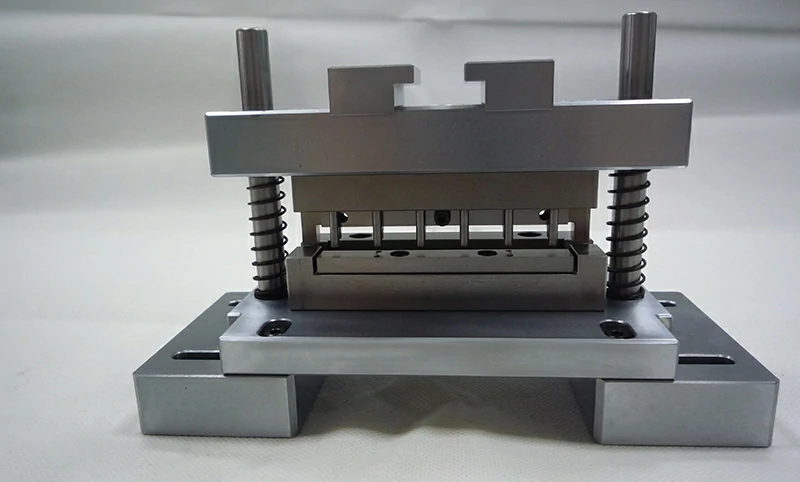

Fixtures & Automation Systems

In industrial fixtures, positioning systems, and automation structures, hex tubes serve as support rods or adjustment components. Their flat surfaces help prevent rotation, allowing for easy locking and alignment—making them irreplaceable in setups where round or square tubes fall short.

Recommended alloy: 6061-T6511

Key advantages: Easy to clamp and align, flat faces offer rigid fixation

Common sizes: 1" × 1/4", 1-1/4" × 1/8"

Optional processing: Precision cutting, CNC machining, thread tapping, surface coating

Architectural & Structural Framing

In curtain walls, decorative railings, and exhibition frames, aluminum hex tubes are favored for their aesthetic design and compatibility with anodized finishes. The six-sided profile distinguishes the structure from standard square tubing, delivering stronger visual impact.

Recommended alloys: 6063-T5, 6061-T6

Key advantages: High visual appeal, compatible with various coating treatments

Popular sizes: 1/2", 3/4", 1"

Optional surfaces: Black anodizing, electrophoresis, brushed polishing

Tools & Mechanical Components

Aluminum hex tubes are often used to manufacture adjustable wrenches, tool connector rods, fitness equipment pull rods, and other components that require a balance of strength and weight control.

Recommended alloys: 6061-T6, 7075-T6

Key advantages: High compression strength, excellent rigidity, easy to thread

Typical sizes: 1-1/2" × 1/4", 2" × 1/8"

Recommended processing: CNC milling, punching, thread tapping

Need help selecting the right product based on your industry application?

Contact the Chalco engineering team for technical support and a complete size handbook tailored to your needs.

Instant Quote

Chalco's Aluminum Hex Tube Processing Capabilities

As a professional aluminum hex tube supplier, Chalco offers a full range of post-processing services for aluminum hex tubes, covering both aesthetic enhancement and functional upgrades. These services are designed to meet multiple demands including structural strength, visual appeal, and assembly efficiency.

Surface Finishing Options

| Process Type | Features | Recommended applications |

| Anodizing | Corrosion resistance is enhanced, surface hardness is increased to HV400+, optional decorative colors such as black/silver/gold | Outdoor frames, drone arms, car modification parts |

| Powder Coating | UV resistance, strong wear resistance, available in a variety of colors (RAL standard) | Building profiles, guardrails, display stands |

| Electrophoresis | Uniform surface gloss, strong adhesion, suitable for high humidity or marine environment | Marine components, electrical housings |

| Brushed / Polished | Smooth and delicate surface, improving visual texture | Furniture frames, electronic equipment housings, exhibition decorations |

Machining Options

Chalco offers complete machining services, from sample prototyping to mass production, especially for engineering projects with strict precision and connection requirements:

- Precision Cutting: Tolerance ±0.2mm, suitable for batch short-length cuts

- Thread Tapping: Common sizes like 5/8"-18, 3/4"-16, ideal for suspension adjustment rods

- CNC Machining: Supports end milling, connector holes, slot designs

- Slotting / Chamfering: Designed for multi-face locking and threaded joints

- Punching / Drilling: For assembly holes and functional hole machining

- Weld Beveling: Prepared for structural welding with precise bevels

We offer custom fabrication, machining, and prototyping based on your technical drawings. OEM/ODM aluminum hex tubing services are available to enhance assembly efficiency and reduce downstream processing costs.

FAQ

Is aluminum hexagonal tubing suitable for precision applications such as steering and suspension systems?

Yes. Aluminum hexagonal tubes offer an excellent strength-to-weight ratio (e.g., 6061-T6 tensile strength ≥310 MPa). The hex profile ensures easy alignment and anti-rotation, especially suitable for threaded connections. Widely used in racing cars, off-road vehicles, and drone linkages.

What machining options are available for aluminum hex tubes? Can both ends be threaded?

Chalco supports a variety of machining processes, including cutting, thread tapping (e.g., 5/8"-18, 3/4"-16), CNC slotting, chamfering, and punching, all tailored to standard or custom part requirements. Double-end threading, fit tolerances, and custom slot structures can be produced based on technical drawings.

Are there standard sizes available? Do you offer non-standard customization?

We stock across-flat sizes ranging from 1/2" to 2", with custom length cutting up to 6 meters. Special wall thicknesses, large diameters, or specific inner dimensions can also be customized. Minimum order quantity is typically 500 kg.

What’s the difference between aluminum hex tubes and hex solid bars? Are their applications overlapping?

The structures and applications are distinct:

Hex solid bars are solid and used in high-load applications without hollow requirements.

Aluminum hex tubes are hollow, lighter in weight, and suitable for applications requiring weight reduction, wiring integration, or easy mounting.

What are the advantages of aluminum hex tubes over stainless steel tubes?

Aluminum has a lower density (2.7 g/cm³), approximately one-third the weight of stainless steel, and is easier to machine, cost-effective, and naturally corrosion-resistant. It is ideal for lightweight, multi-axis, and surface-treated applications.

While stainless steel is stronger, it is more expensive to process and difficult to weld.

Ae surface treatments available? Will they affect dimensional accuracy?

Chalco offers surface finishes like anodizing, powder coating, electrophoresis, and brushed polishing. Anodized coating is approx. 10–25μm thick, so it is recommended to allow clearance in the design for fitting tolerance. Surface treatment enhances corrosion resistance and appearance, suitable for outdoor and premium structural uses.

What's the price of aluminum hex tubing?

Pricing depends on dimensions, alloy type, temper, machining requirements, and surface finishing.

Feel free to submit your specifications for a quick quotation and lead time.

For detailed selection advice, technical drawing review, or a custom quote, feel free to contact the Chalco engineering team for fast and professional support.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote