In many aluminum component programs, the mainstream processes are still bar stock machining, die casting, and hot forging. As power density rises, dimensional tolerances tighten and cost pressure increases, these routes tend to show limitations in material utilization, dimensional consistency, and thermal performance.

For aluminum parts whose size and geometry are suitable, adopting an aluminum cold forging process can improve mechanical properties while significantly reducing material waste and machining time, and enhancing batch-to-batch consistency and fatigue life. For heat sinks and other thermal management components, combining high-conductivity aluminum with high fin-density structures allows higher cooling capacity within a more compact envelope.

Around Aluminum Cold Forging, most engineering projects tend to focus on three questions first:

- Is my part a good candidate for aluminum cold forging?

- In what situations is aluminum cold forging more advantageous than machining / hot forging / die casting?

- If we consider aluminum cold forging, what information do we need to prepare?

You can also explore by industry:

What Is Aluminum Cold Forging?

At room or near-room temperature, aluminum or aluminum alloy blanks are placed in a closed die and formed in one or more high-pressure blows on a mechanical / hydraulic press or multi-station cold header to reach a shape close to the final part. This family of near-net-shape forging processes is collectively referred to as aluminum cold forging.

From an engineering and sourcing perspective, aluminum cold forging has several typical features:

- Room-Temperature Forming: Forming at room or near-room temperature, without bulk heating, with minimal scale and lower overall energy consumption.

- Near-Net Shape: The blank volume is close to the part volume; most geometries are formed inside the die in one stroke or a few strokes, with only limited machining on critical faces and hole patterns.

- High Precision & Good Surface: Dimensions are controlled by the die, and cold work helps stabilize the shape, making the process suitable for batch parts that require tight tolerances and repeatability.

- Continuous Fiber Flow & High Material Utilization: During deformation, the metal flow lines follow the part geometry continuously, while chips are greatly reduced, laying the foundation for good mechanical and thermal performance.

Aluminum Cold Forging Specifications & Production Capability

| Item | Range of capabilities |

| Outer Diameter / Across Flats | Typical 10–150 mm; extreme approx. 6–180 mm (to be confirmed against die design / press tonnage) Blank OD tolerance: typically ±0.10–0.30 mm |

| Height / Length | Typical 5–120 mm; extreme approx. 3–150 mm Blank height tolerance: typically ±0.10–0.20 mm (depending on geometry) |

| Single Blank Weight | Typical 0.02–5.0 kg; extreme approx. 0.01–8.0 kg For parts above approx. 5 kg, hot forging / open-die forging is usually evaluated in parallel |

| Machining Tolerances | Typical fit diameters up to H7–H9; for guide shafts, etc., straightness / roundness + roughness Ra 0.8–1.6 μm can be reported on request |

| Alloy | 1xxx:1050 / 1070 / 1100 3xxx:3003 / 3A21 5xxx:5A02 / 5052 / 5754 6xxx:6061 / 6063 / 6082 7xxx:7075 |

| Condition | 1xxx / 3xxx / 5xxx: O, F, H112 and other soft tempers for easier cold forging 6xxx / 7xxx: forged in annealed or pre-treated temper, then heat treated (e.g. T6 / T651) as per design |

| Standard | ASTM B247/B247M (wrought aluminum and aluminum alloy forgings) EN 586 series, GB/T 12344 and other relevant forging standards Aerospace / special industries follow the AMS / EN / GB standards specified on the drawing |

Generally, aluminum cold forging is most economical for projects with a stable annual usage of ≥ 3,000–5,000 pcs / year / part number; small batches and prototypes can also be evaluated case by case.

Key Differences vs. Hot Forging / Machining / Die Casting

| Comparison Dimensions: | Hot Forging | Machining from Bar | Die Casting / Extrusion | Aluminum Cold Forging |

| Process Temperature & Energy Consumption | High-temperature forming; high energy use and oxide scale. | Room temperature cutting; moderate energy consumption, mainly from machine tools. | Melting or high-temperature extrusion; high energy consumption, sensitive to temperature control | Room-temperature forming with low energy use but demanding molds and lubrication. |

| Material Utilization & Unit Cost | Blank is near-net shape but has flash and machining loss; moderate yield. | Extensive material removal; maximum material waste, high cost per piece. | Near-net-shape forming + minimal machining; moderate to high material utilization | Near-net-shape forming with minimal chips and high material use, giving strong per-piece cost savings for medium to large batches. |

| Dimensional Accuracy & Batch Consistency | Medium precision, needs finish machining; consistent batches. | High precision, but entirely dependent on machining; good batch consistency but slow cycle time. | Complex shapes can be formed in one step; critical surfaces still require machining to ensure accuracy | Mold-formed for high-precision batch aluminum parts needing consistent surface quality. |

| Mechanical Properties & Reliability | Dense structure, good fiber flow; high strength, impact resistant. | Raw-material dependent, average rolled properties; best for small batches, simple parts, prototypes, iterative designs. | Die castings carry the risk of porosity/shrinkage; extruded materials exhibit significant anisotropy | Fiber continuity and work hardening boost fatigue strength over machined or cast parts. |

| Typical Applicable Parts/Scenarios | Suited to large load-bearing structures, flanges, rods, and other thick parts. | Room-temperature cutting; energy use mostly from machine tools. | Complex shells, thin-walled parts, long profiles, and exterior parts | Suited to medium/small aluminum structures, high-strength connectors, and heat sink blanks. |

- Hot forging is better suited to large-size, high-load parts with large deformation and heavy section.

- Machining from bar fits small batches, simple geometries and projects where the design changes frequently.

- Die casting / extrusion + machining is preferred for complex shapes, thin-wall housings and long profiles.

- Aluminum cold forging is most suitable for small to medium-size, highly repeatable parts with stable volumes.

Is My Part Suitable for Aluminum Cold Forging?

You can first use the three checks below to quickly screen your part:

- Size: The part is generally a small to medium-size component, not an ultra-large housing, extra-long beam or heavy flange.

- Volume: There is a stable, recurring annual demand (typically from several thousand pieces upwards).

- Performance: Beyond "just making the part", strength, fatigue life, dimensional consistency and material utilization matter.

If your part meets two or more of the above, it is usually worth seriously evaluating Aluminum Cold Forging as a candidate process.

Types of Aluminum Cold Forged Parts

Cold Forged Aluminum Heat Sinks

Size:30–120 mm Ø/width, 15–80 mm height

Alloys:1xxx / 3xxx, selected 6xxx

Features:high fin ratio, thin fins, solid aluminum, dense pore-free structure

Applications:LED drivers, power modules, automotive electronics, high-power cooling

Shafts, Splined & Stepped Parts

Size:Diameter 10–80 mm, length 20–200 mm

Alloys:5xxx / 6xxx / 7xxx

Features:multiple steps, splines and flange heads formed in one operation

Applications:drive shafts, splined shafts, flange shafts, pulley blanks

Bushings, Sleeves & Tubular Parts

Size:OD 10–120 mm, height/length 10–150 mm

Alloys:5xxx / 6xxx, selected 1xxx / 3xxx

Features:backward extrusion and piercing, high concentricity, uniform wall thickness

Applications:hydraulic and pneumatic housings, bushings, guide sleeves

Brackets & Flange-Type Components

Size:overall outline approx. 20–150 mm

Alloys:mainly 5xxx / 6xxx, optional 7xxx

Features:pre-formed holes, ribs and radii improve stiffness and fatigue life

Applications:brackets, clevises, blocks, rocker arms, structural connectors

Near-Net Forged Blanks for Machining

Size:small to medium parts with thick cross-sections

Alloys:6xxx / 7xxx

Features:pre-formed outlines and steps, reduced scrap and machining time

Applications:custom complex parts formerly machined from solid bar

Overall, aluminum cold forging is best suited to small and medium-sized aluminum parts with stable production volumes and clear requirements for mechanical properties and batch-to-batch consistency.

Conversely, very large or very long parts, extremely thin and complex shells, and one-off or very low annual volume projects are generally outside the typical process window of aluminum cold forging.

What Are the Advantages of Aluminum Cold Forging?

Compared with pure bar machining, conventional casting or some hot forging routes, Aluminum Cold Forging offers clear advantages in the following areas:

High Dimensional Accuracy and Consistency

Closed dies form the critical dimensions directly, delivering stable tolerances from batch to batch.

High Material Utilization and More Controllable Piece Cost

As a near-net-shape process, chip volume is very low, and material waste is significantly reduced.

Better Strength and Fatigue Life

With continuous fiber flow lines and appropriate cold work hardening, cold forged parts offer higher fatigue performance.

Good Surface Quality, Less Secondary Machining

The forged surface is smooth, dense and free from shrinkage defects.

Suited to Automated Mass Production, More Energy-Efficient and Environmentally Friendly

Room-temperature forming eliminates full-part heating, reducing energy consumption and emissions.

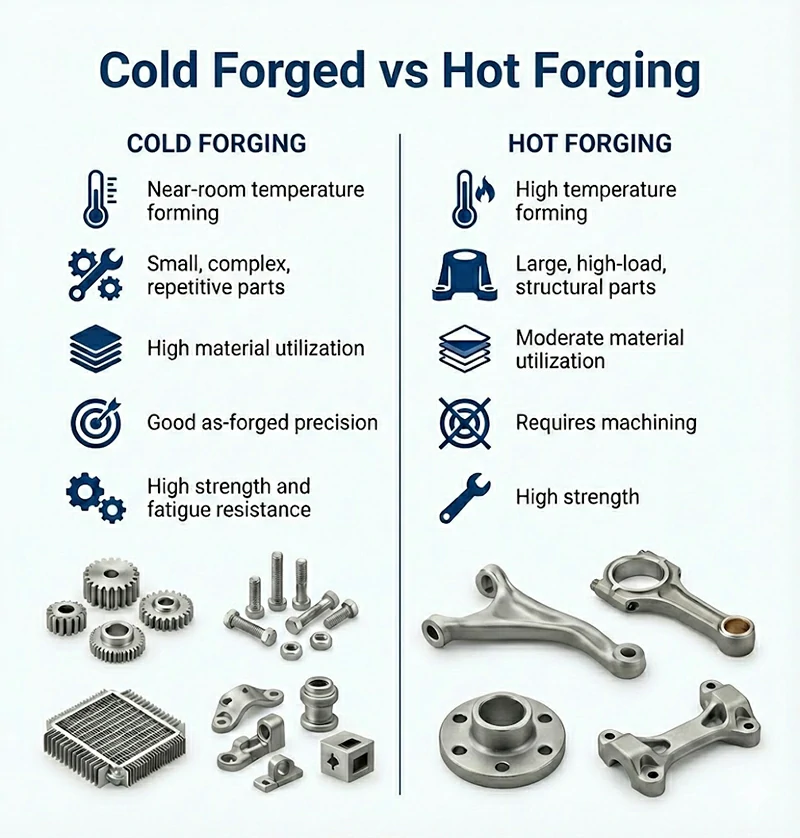

Cold Forged Aluminum vs Aluminum Hot Forging

| Project | Aluminum Hot Forging | Aluminum Cold Forging |

| Process temperature and energy consumption | Heating to high temperatures for forming; strong deformation capacity, high energy consumption, and oxide scale formation. | Forming at or near room temperature; no overall heating required, low energy consumption, and no oxide scale. |

| Size and shape range | Suitable for large load-bearing components with thick cross-sections, large deformation amounts, and relatively robust structures, such as connecting rods, flanges, and supports. | Suitable for small to medium-sized, compact, and repetitively shaped radiators, shafts, brackets, sleeves, etc. |

| Material utilization and unit cost | Has flash and machining allowance; moderate material utilization, cost influenced by both material quality and machining. | Near-net-shape forming, minimal chipping; high material utilization, lower unit cost for medium to large batches. |

| Dimensional accuracy and batch consistency | Precision mainly depends on subsequent machining; forging billet dimensions fluctuate significantly, suitable for parts with general tolerance requirements. | Critical dimensions are controlled by the mold; only minimal machining is required, resulting in good dimensional consistency for batch parts. |

| Mechanical properties and fatigue performance | Continuous fiber flow lines, dense structure, good strength and fatigue performance, suitable for high-load, large-section structural components. | Also features continuous streamlines and work hardening; strength and fatigue performance are generally superior for small to medium-sized parts. |

| Scenarios more suitable for priority evaluation | For large-size, thick-section, high-load parts with moderate annual usage, aluminothermic forging is usually the first consideration. | For small to medium-sized, repetitively shaped parts with stable annual usage and sensitivity to precision and cost, aluminum cold forging is the preferred option. |

Simply put, large, heavy, highly loaded parts tend to favor aluminum hot forging, while small to medium-sized aluminum parts with stable volumes and tight tolerance requirements are strong candidates for Aluminum Cold Forging.

For a more detailed comparison, you can refer to our dedicated Aluminum Hot Forging vs Aluminum Cold Forging page.

If you are not sure whether your part is better suited to hot forging or cold forging, just send us the drawing, estimated annual usage and a brief note of the current process.

Cold Forged Aluminum Industry Solutions

Cold Forged Aluminum Heat Sinks Solutions

For high power density, space-constrained, long-duty applications such as LED lighting, power modules, onboard OBC / DC-DC and drive motor controllers, cold forged aluminum heat sinks deliver higher thermal performance and more stable consistency within a limited envelope.

Alloys & Size Capability Window

| Item | Capability Range |

| Alloy and Condition | High thermal conductivity: 1050 / 1070 / 1100 / 3003 (O, F, H112); |

| Typical Outer Diameter / Width | Overall performance: 6061 / 6063 / 6082 (can be T5 / T6 / T651 after cold forging) |

| Typical Height | 30–120 mm (special structures can be evaluated up to approximately 150 mm) |

| Fin Capacity | 15–80 mm (including base + fins) |

| Single Blank Weight | Typical fin thickness ≥ 0.7 mm; fin height/pitch ratio up to approximately 20–25:1, for high-density fin arrays |

Surface finishing includes sandblasting and anodizing; critical mounting surfaces and locating holes can be CNC machined to ensure assembly accuracy.

Surface Finishing & Secondary Machining

Surface finishing: Sandblasting + natural silver anodizing or black anodizing as standard; custom dark grey / dark blue engineering colors available on request.

Critical machining surfaces: The base surface, mounting surfaces and locating holes of the heat sink can be CNC-machined to ensure low contact thermal resistance and assembly accuracy.

Other options: Tapped holes, counterbores and locating grooves can be pre-formed to reduce secondary operations at the customer's side.

Key Comparison Points vs. Other Heat Dissipation Solutions

Versus extruded heat sinks: Cold forging offers advantages in high fin ratios, complex 3D fin geometries and internal density, making it suitable for small to medium-size, high-power modules.

Versus bonded / soldered fin heat sinks: Cold forged heat sinks are a one-piece aluminum structure with no adhesive or weld interfaces, resulting in lower interface thermal resistance and better long-term reliability.

Versus die-cast heat sinks: Cold forging produces a dense structure with low porosity risk; mechanical and fatigue performance are better suited to high-reliability applications.

Typical Application Scenarios

- LED lighting / displays: Street lights, high-mast lights, tunnel lights, outdoor displays and other high-power, outdoor applications.

- Industrial and IT power supplies: Industrial inverters, UPS, server power supplies, motor drives, etc., where cabinet space is limited.

- Automotive and new energy: OBC / DC-DC converters, inverters, motor controllers and similar components requiring long-term stability under vibration and thermal cycling.

- Telecom and industrial control: Base station equipment, industrial controllers, servo drives and other systems that demand consistent appearance and batch-to-batch dimensional stability.

RFQs should include power load, available space and annual usage so feasibility and alloy selection can be evaluated efficiently.

Automotive Aluminum Cold Forged Structural Parts Solutions

For small to medium-sized aluminum structural parts used in passenger cars and light commercial vehicles, aluminum cold forging supports lightweight design while meeting strength, fatigue life and batch consistency requirements.

| Project | Capability Range |

| Alloy and Condition | 5xxx: 5083 / 5454, etc., O / H112, used for load-bearing and corrosion-resistant structural components; 6xxx: 6061 / 6082, etc., can be made into T6 / T651 after cold forging; 7xxx: 7075, used for local high-strength connecting parts. |

| External Dimensions | Small to medium-sized structural components such as brackets, trunnions, and flanges with outline dimensions of approximately 20–150 mm. |

| Shaft Dimensions | Rotating components such as shafts, splined shafts, and flanged shafts with diameters of approximately 10–80 mm and lengths of approximately 30–250 mm. |

| Single Blank Weight | The weight range of approximately 0.05–5.0 kg offers the best economic efficiency and is more suitable for medium to large-volume production of automotive/commercial vehicles. |

- Chassis and suspension brackets

- Steering and driveline rotating parts

- Brake and axle accessories

- Frame and body accessories

Surface Finishing & Secondary Machining

Secondary machining: CNC turning, milling, drilling, tapping, knurling, etc., for precision machining of functional surfaces such as fit surfaces, sealing surfaces, hole patterns and splines.

Surface finishing: Blasting, anodizing (natural, black or grey engineering colors), powder coating or electrophoretic coating, selected according to the assembly's corrosion protection and appearance requirements.

Typical Application Scenarios

- Chassis & suspension brackets: Stabilizer bar brackets, small knuckles, connecting blocks and other small to medium-sized load-bearing / mounting components.

- Steering & driveline rotating parts: Spline shafts, flange shafts and aluminum shafts with steps and threaded sections, where concentricity and fatigue life are critical.

- Brake and axle accessories: Lightweight caliper brackets, sensor brackets and other auxiliary parts falling within the cold forging size range.

- Frame / body accessories: Aluminum brackets, lifting lugs and mounting blocks on frames or tanks, with repeatable geometries and stable batch demand.

Mechanical Equipment & Hydraulic / Pneumatic Systems Solutions

For pump housings, valve bodies, manifolds, end covers and sleeves, aluminum cold forging reduces weight and improves corrosion resistance while meeting pressure and fatigue requirements.

| Item | Capacity Range |

| Alloy and Condition | 1xxx / 3xxx / 5xxx: Soft state (O, F, H112, etc.), suitable for corrosion protection and forming; 6xxx / 7xxx: Annealed cold forging, T6 / T651 heat treatment available upon request; |

| Dimensions (Outer Diameter/Length/Width) | 30–150 mm (round or square housing/valve block) |

| Height/Length | 10–120 mm (small to medium-sized parts such as pump housings, valve bodies, end caps, and sleeves) |

| Typical Wall Thickness | 2.5–10 mm (can be thickened or thinned according to pressure and flow channel design) |

| Hole Diameter and Hole Arrangement | Through holes/stepped holes/threaded holes approximately 4–40 mm, allowing for the arrangement of multiple oil/air ports and mounting hole groups |

| Single Blank Weight | Approximately 0.05–4.0 kg, covering most aluminum pump housings, valve bodies, and porous block projects |

Surface Finishing & Secondary Machining Options

CNC turning / milling / drilling / tapping to finish sealing surfaces, locating surfaces and threaded holes, ensuring assembly accuracy and sealing performance.

Anodizing (clear or colored) and hard anodizing to improve corrosion and wear resistance, suitable for water- and oil-based media.

Fine deburring, shot blasting and cleaning / drying to control internal residue and cleanliness, reducing the risk of system contamination.

Typical Application Scenarios

- Hydraulic pump housings / gear pump end covers / electronic control pump housings: achieve lightweight housings and stable dimensions while meeting working pressure and burst pressure requirements.

- Valve bodies / manifolds: multi-port blocks with the main contour and most port locations formed in one step, reducing solid-block machining chips and cycle time.

- Cylinder end caps / pistons / sleeve bushings: cold forging pre-forms external shapes and internal bores to improve concentricity and fatigue life, and to facilitate subsequent precision machining.

- Pneumatic valve island housings / connectors: use corrosion-resistant aluminum alloys and suitable surface treatments to reduce weight while enhancing appearance and environmental durability.

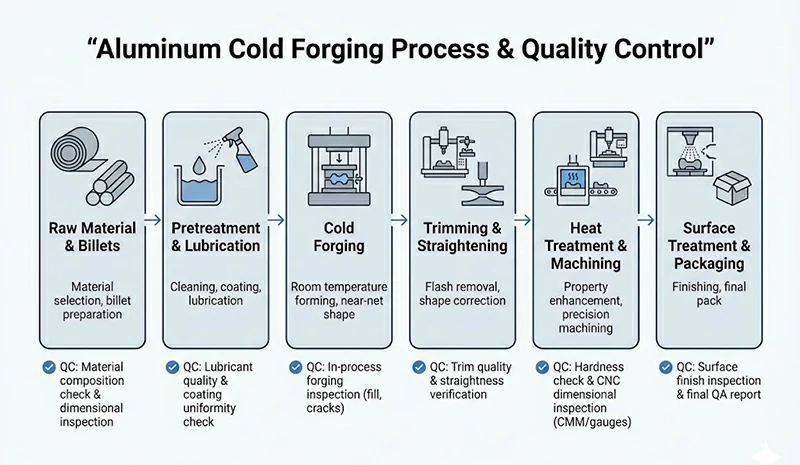

Aluminum Cold Forging Process & Quality Control

For projects considering Aluminum Cold Forging, a stable process and traceable quality system are key criteria when selecting a supplier. Below is the typical workflow and main control points Chalco applies to cold forged aluminum parts.

Aluminum Cold Forging Process Overview

The overall process usually includes: raw material & billets → pre-treatment & lubrication → cold forging → trimming & straightening → heat treatment & machining → surface finishing & packaging.

Raw Material & Billet Preparation

Select the specified alloy grade and size according to the drawing (such as 1050, 3003, 6061, 7075, etc.), verify the EN 10204 3.1 mill test certificates, and cut billets by batch number.

Billet Pre-Treatment & Lubrication

Carry out annealing or softening according to the alloy and required deformation, combined with phosphating–soaping or dedicated aluminum cold forging lubricants to reduce forming load and improve metal flow.

Cold Forging / Cold Heading

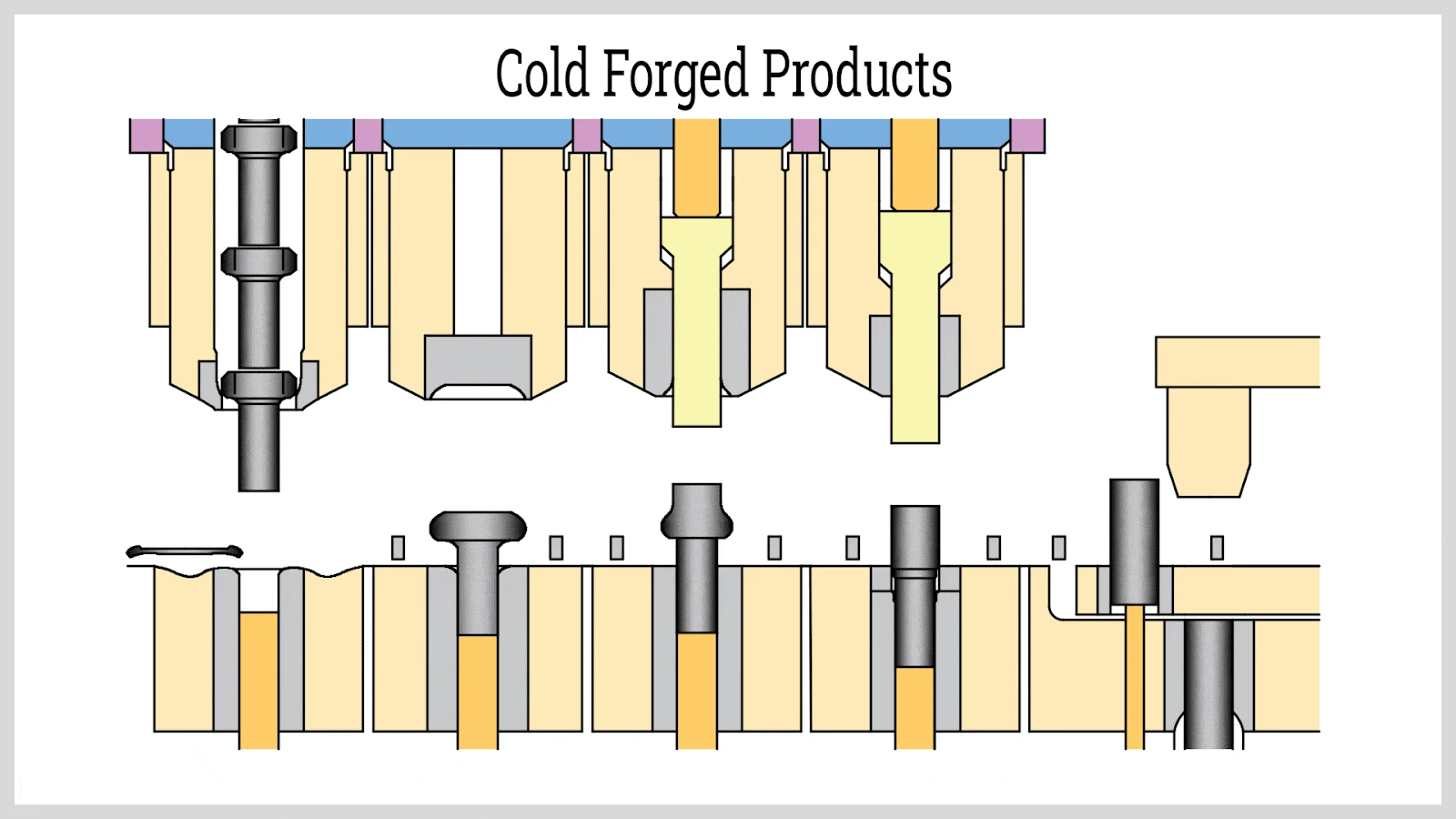

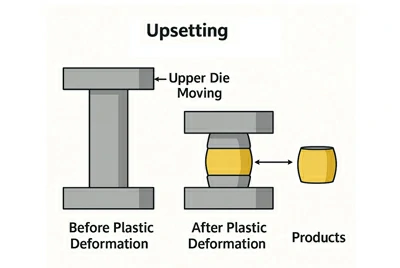

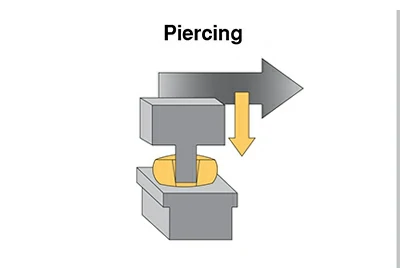

On mechanical / hydraulic presses or multi-station cold headers, use operations such as upsetting / heading, forward extrusion, backward extrusion, piercing and local coining in one or multiple stages to deform the billet into a near-net-shape aluminum cold forged part.

Trimming, Deburring & Straightening

Punch off flash and excess material, remove burrs and chamfer edges as required, and straighten shafts, brackets and other parts to secure reliable datums for subsequent machining and assembly.

Heat Treatment & CNC Machining

Perform solution treatment and ageing (such as T6 / T651) on 6xxx / 7xxx alloys as required, then use CNC turning, milling, drilling and tapping to finish critical mating surfaces and hole patterns to the specified tolerances and surface roughness.

Surface Finishing & Final Packaging

Select suitable surface treatments such as anodizing, shot blasting or coating according to the service environment, and use protective, corrosion-resistant packaging to control appearance and dimensional risks during transportation and storage.

Quality Control & Testing for Aluminum Cold Forging

Chalco applies multi-level control over raw materials, processes and finished parts to provide traceable quality assurance for aluminum cold forged parts.

- Raw Material & Batch Traceability: For each heat, batch and alloy grade we keep full identification, verify chemical composition and temper, and issue EN 10204 3.1 mill certificates in line with ASTM / EN / GB standards.

- Dimensional & Geometric Inspection: We use CMMs, dedicated gauges and plug gauges for first-piece, in-process and final inspection, focusing on fit diameters, concentricity, flatness and run-out; dimensional inspection reports and PPAP / ISIR documentation are available on request.

- Mechanical Properties & Heat Treatment Verification: For batches requiring heat treatment we perform hardness and, where necessary, tensile tests to the relevant ASTM / ISO standards, confirming strength levels and recording results against each heat-treatment batch and part batch.

- Special Testing & Quality Documentation: For pressure-retaining, thermal-management or safety-critical parts we can add NDT (UT / PT), leak / pressure testing, and thermal resistance or cooling-performance verification, with the corresponding test reports.

With this process and quality-control system, Chalco provides Aluminum Cold Forging solutions with stable batch-to-batch consistency and complete quality documentation for automotive, power electronics and industrial machinery applications.

Why Choose Chalco as Your Aluminum Cold Forging Supplier?

Integrated Cold Forging + Heat Treatment + Machining

With single-station cold forging presses, multi-station cold heading machines, heat-treatment furnaces for 6xxx / 7xxx alloys (solution + aging), CNC turning & milling centers, and in-house anodizing, blasting and coating lines, Chalco can deliver aluminum cold forged parts from forged blanks to fully machined and finished components on a single, controlled process chain.

Comprehensive Inspection & Validation Capabilities

Using CMMs, dedicated gauges, hardness testing and, where required, tensile testing, we control both dimensions and mechanical properties. Depending on part criticality, we can add NDT (UT / PT), leak / pressure tests and thermal or life-related performance tests, so key Aluminum Cold Forging parts are backed by data and full traceability.

Quality Systems & Standards Aligned With Overseas Projects

Chalco is certified to ISO 9001 / AS9100 and can produce to ASTM B247/B247M, EN 586, GB/T 12344 and related forging standards, providing EN 10204 3.1 material certificates, dimensional and test reports, and – where required – PPAP / ISIR documentation to support audits in automotive, power electronics and other industries.

Engineering-Driven Front-End Support

Based on your drawings, alloy grade, annual volume and current process, we help compare machining / hot forging / die casting versus Aluminum Cold Forging in terms of suitability and cost structure. Through sample trials and small pilot runs, we gradually lock in the cold forging process and tooling方案, reducing the risk when switching manufacturing routes.

What Information Do I Need to Prepare for Aluminum Cold Forging?

To help us quickly determine whether your part is suitable for Aluminum Cold Forging and to provide an initial quotation range, you only need to prepare the three groups of key information below:

1) Drawings and Technical Requirements (Required)

- 2D drawings (PDF / image) + 3D models (if available)

- Alloy grade and temper, or target strength / hardness range

- Critical dimensions and tolerances, GD&T requirements (such as concentricity, flatness, runout, etc.)

- A brief description of the operating conditions: whether it is a pressure-bearing / fatigue-critical / thermal-management critical part

2) Volume and Cost Information

- Estimated annual usage (EAU) and approximate quantity per batch

- Rough project timeline: prototype / pilot run timing and SOP / mass-production timing

- If possible, a target cost range, so we can help balance one-time tooling investment and piece price when proposing the forging

3) Project Stage and Supporting Needs

- Current stage: new design / replacing machining / optimizing an existing process

- Whether you would like us to provide DFM suggestions (radii, ribs, hole positions, wall thickness, etc. for manufacturability optimization)

- Required scope of supply: cold forged blanks only, or cold forging + machining + heat treatment / surface treatment + material and inspection reports (such as 3.1 certificates, dimensional reports, PPAP documentation, etc.)

Once you send us the above three sets of information together with your drawings, we will first come back with three key points: whether the part is suitable for Aluminum Cold Forging, the recommended process route, and a rough range for tooling investment and unit cost, helping you and your team make the next-step decision.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote