Aluminum ceiling panel systems combine aluminum alloy panels with suspended support structures to provide durable, lightweight ceiling solutions for indoor and outdoor applications.

Chalco supports these systems with project-oriented aluminum ceiling panel solutions, offering flexible panel types, structures, and surface finishes to meet architectural and commercial requirements.

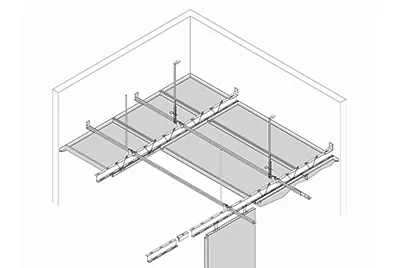

Components of a Typical Aluminum Ceiling System

Metal Ceiling Panels: Various structural forms including strip/linear, slat/baffle, drop ceiling, plank/panel, and perforated sound-absorbing panels, to suit different spaces and design needs.

Optional Acoustic & Structural Core Options : Lightweight sandwich structures such as honeycomb, 3D core, corrugated aluminum core, and aluminum foam sandwich panel significantly improve the sound absorption performance, structural strength, and flatness of the ceiling system. These are commonly used in high-level projects such as airports, transportation hubs, and large public spaces.

Suspended Ceiling Framework : T-shaped exposed frames, clip-in concealed frames, lay-in recessed ceilings, baffle vertical hanging systems, and hook-on structures suitable for large or heavy-duty panels .

Chalco aluminum ceiling panels: main product types

Aluminum ceiling panels come in various forms depending on their panel structure, installation method, and visual effect, to meet the diverse architectural needs of offices, hospitals, airports, subway stations, shopping malls, and outdoor spaces. Common types are as follows:

Strip / Linear Aluminum Ceiling

The linear panel structure creates a strong sense of visual extension, making it suitable for offices, subway passages, and commercial spaces.

The lines are neat and clean.

Quick installation.

Strong sense of modernity.

Slat / Baffle Aluminum Ceiling

Composed of vertical panels or U-shaped baffles, it delivers an open, decorative look with strong sound absorption.

Strong sense of layering.

Suitable for airports and shopping malls.

Excellent sound absorption.

Drop Ceiling Panels

T-shaped exposed or clip-in concealed systems provide easy maintenance and a flat, clean appearance, making them widely used in commercial spaces.

Standardized dimensions (e.g., 600×600)

Easy to disassemble and assemble.

Easy to maintain.

Plank / Panel Aluminum Ceiling

The wide aluminum panel design creates a strong sense of unity and is suitable for corridors, office areas, and semi-outdoor sunshade passageways.

Large sizes are also available.

Visually simple.

Compatible with multiple installation systems.

Cell / Open Grid Aluminum Ceiling

The grid or honeycomb-like perforated structure is lightweight and transparent, allowing for flexible placement of lighting fixtures and equipment.

It also provides good ventilation.

Highly decorative.

Suitable for subways and large public areas.

Perforated aluminum ceiling panels

Perforated sound-absorbing aluminum ceilings achieve excellent acoustic absorption by creating round, square, or custom-shaped holes in solid aluminum panels and pairing them with black sound-absorbing backing. They are the most commonly used metal sound-absorbing ceiling systems in commercial buildings and public spaces.

- Excellent sound absorption: The perforated structure effectively reduces echoes and noise.

- Various hole types are available for customization: round holes, square holes, elongated holes, and patterned holes are available.

- Lightweight and flat: Solid aluminum sheet is stable and does not deform, and is easy to maintain.

- Compatible with multiple installation systems: adaptable to T-type surface rack, clip-in and lay-in systems.

- Wide range of applications: suitable for airports, hospitals, subway stations, offices and conference rooms.

The hole shape, size, and backing sound absorption level can be customized according to project requirements to meet different acoustic and decorative needs.

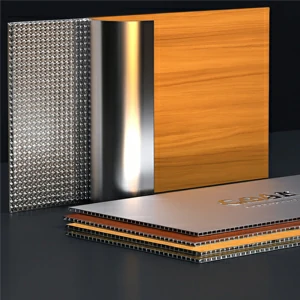

Sandwich & Structural Core Ceiling Panels

Sandwich aluminum ceilings use lightweight structures such as aluminum honeycomb, 3D aluminum core, corrugated aluminum core, or foamed aluminum as core materials, which are combined with aluminum panels. They have extremely high flatness, rigidity, and sound absorption performance, and are widely used in engineering projects with higher requirements for dimensional stability and acoustic performance, such as airport halls, transportation hubs, exhibition centers, and large public spaces.

-

Aluminum Honeycomb Ceiling Panel

With its exceptional flatness and rigidity, it is suitable for large-sized, high-end engineering ceilings that do not sag.

-

3D-Core Panel

It combines lightweight and high strength, and its structural stability is superior to that of traditional solid panels.

-

Corrugated Aluminum Core Ceiling

With strong bending resistance and lighter weight, it is an economical structural solution for wide-width suspended ceilings.

-

Aluminum Foam Ceiling Panel

The natural sound-absorbing structure achieves excellent acoustic performance and a lightweight ceiling.

Features

- Extremely high flatness: The honeycomb and corrugated core keep the large board from deforming over a long period of time.

- Lightweight and high-strength: The sandwich structure is lightweight yet rigid, and can replace thick plates.

- Excellent acoustic performance: The 3D core and aluminum foam have natural sound absorption capabilities.

- Supports large-format customization: allows for larger sizes and complex shapes.

- Highly compatible with various systems including hook-on, clip-in, and baffle.

The sandwich panel can be made into flat, perforated or shaped panels according to project requirements, and offers a variety of decorative effects such as powder coating, wood grain, metal brushing, and anodizing, making it an ideal solution for high-end building ceiling systems.

Outdoor & Porch Aluminum Ceiling Panels

Aluminum ceilings, with their excellent corrosion resistance, weather resistance, and stable structure, are ideal for outdoor environments such as patios, porches, canopies, soffits, and under-deck spaces. Compared to PVC, wood, or plaster, aluminum does not absorb water, deform, or mold outdoors, and maintains its flatness and color stability over a long period, making it the most reliable choice for outdoor ceiling systems.

- High weather resistance: The sprayed surface is resistant to UV, moisture and salt spray, and will not fade.

- Lightweight and easy to install: Suitable for weight-sensitive areas such as under eaves and walkways.

- Long-term non-deformation: It remains flat and stable even in outdoor environments.

- Diverse structures: Supports various appearances such as strips, slats, grilles, and perforations.

- Easy to conceal wiring: can be integrated with lighting, cabling and drainage systems.

Chalco outdoor ceilings are suitable for various applications including: residential porch and patio, commercial building soffitts, traffic corridors, hotel entrance canopies, and under-deck shading systems.

Chalco Aluminum Alloy Ceiling Panel Technical Specifications

Material and alloy : Aluminum alloy, with options for 3003, 5052, 5754, 6061, etc., providing higher corrosion resistance and strength levels.

Board thickness : standard 0.5–1.2 mm; sandwich structure can reach 3–25 mm (honeycomb, 3D core, corrugated core, aluminum foam).

Standard sizes: 300×300 / 300×600 / 600×600 / 600×1200 mm; custom sizes and large panel ceilings are supported.

Flatness : ≤ 0.5 mm/m (solid board); sandwich structure can achieve even higher flatness.

Core material structure : honeycomb core, 3D stereoscopic core, corrugated aluminum core, spherical/beaded core, foamed aluminum sandwich.

Installation systems : T-type exposed rack, clip-in, lay-in, baffle, hook-on heavy-duty system.

Fire rating : A2-s1,d0 (according to EN 13501-1); the metal body is non-combustible.

Weather resistance : Outdoor-grade powder coating is available, which is resistant to UV rays, corrosion, and humidity changes.

Acoustic performance : Perforated + backing/sandwich structure can achieve NRC 0.60–0.85.

Surface Finishes & Colors :

Powder Coating

Bright White / Off-White

Light Gray / Dark Gray / Graphite Gray

Black, Metallic Silver, Outdoor Weather-Resistant Coating

Contact us now

Special Finishes

Microporous Texture

Brushed Metallic Texture

Custom RAL / Project Color Chart

Contact us now

Chalco Aluminum Ceiling Mounting System

Chalco offers complete aluminum ceiling system solutions for various architectural scenarios, including panel processing, structural design assistance, detailed node support, and pre-installation preparation (such as opening holes, chamfering, reinforcement treatment, sound-absorbing backing configuration, etc. ).

We provide matching keel types, system compatibility suggestions, and construction reference schemes based on project requirements to ensure seamless integration of panels with the site structure, achieving optimal flatness, durability, and installation efficiency. In actual projects, Chalco products can be flexibly matched with various ceiling systems such as Clip-in, Lay-in, Baffle, and Pipe-Baffle, providing construction companies with high-quality, easy-to-implement metal ceiling material support.

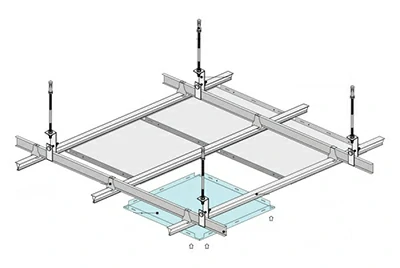

Clip-in Ceiling System

The panel is fixed to the keel by hidden clips, with no visible gaps on the surface, resulting in high flatness and a clean appearance.

Suitable for: well-furnished spaces such as offices, hotels, shopping malls, and conference rooms.

Clip-in tile options: Offers multiple sizes, hole types, and finishes compatible with standard clip-in joists.

Edge & joint styles: Provides narrow, wide, straight, or chamfered edges for different visual effects.

Project-ready fabrication: Supports pre-drilling, grooving, and joist-matching preparation.

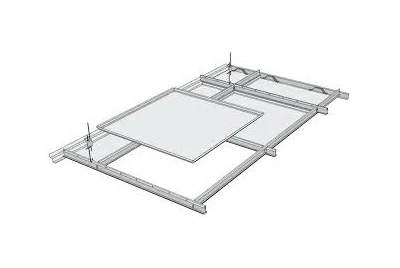

Embedded System (Lay-in Ceiling System)

The panel is directly embedded in the T-shaped keel or flat keel, making installation and maintenance convenient, and it can support standardized specifications (such as 600×600, 300×300).

Suitable for: hospitals, schools, public buildings, and large spaces.

Lay-in panel options: Supports 600×600 / 300×300 sizes in flat, perforated, or light acoustic forms.

Grid compatibility: Fits standard T-grid frames for easy installation and maintenance.

Project-ready fabrication: Provides pre-cutting, backing treatment, and coordinated opening preparation.

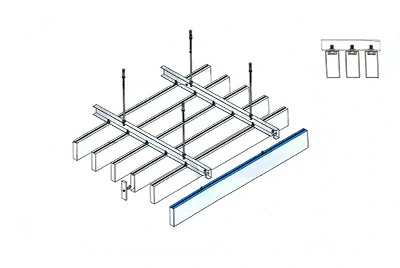

Baffle & Pipe - Baffle Ceiling System

Composed of vertical aluminum strips, U-shaped hanging panels, and O-shaped or square tubes, it forms an open ceiling structure with a strong sense of transparency, and is a commonly used system in airports, subway stations, and shopping mall atriums.

Suitable for: transportation hubs, commercial atriums, corridors, and spaces with extra-large ceilings.

Profile options: Supports U-Baffle, round tubes, square tubes, and linear profiles.

Open-space aesthetics: Provides a transparent look for airports, atriums, and corridors.

Custom fabrication: Customizable length, spacing, curvature, and surface treatment.

Hook-on / Heavy-Duty Ceiling System

Suitable for large-size, heavy-duty, or sandwich panel ceilings (honeycomb, 3D core, corrugated core, etc.). Panels are fixed by hooks or load-bearing structures, offering high flatness and suitable for outdoor or large venues.

Applications include: airport halls, exhibition centers, train station waiting rooms, and outdoor walkways.

Large-format compatibility: Supports large, thick, or sandwich panels with stable, anti-sag performance.

Secure installation: Uses hook-on or load-bearing frames for high-strength, wind-resistant setups.

Project-ready support: Provides detailing, pre-drilling, edge treatment, and keel matching guidance.

Chalco Aluminum Ceiling Panel Cooperation Case

Chalco aluminum ceilings have been widely used in numerous engineering projects, providing reliable ceiling solutions for different types of architectural spaces thanks to their stable quality, customizable structures, and diverse finishes.

- Commercial Buildings: Office buildings, commercial complexes, exhibition centers, and other spaces utilize strip, exposed frame, and panel aluminum ceilings, resulting in a clean and streamlined overall appearance and easy maintenance.

- Transportation hubs: Airports, high-speed rail stations, and subway stations use grilles, hanging panels, and perforated sound-absorbing ceilings to meet the ventilation, acoustic, and visual needs of large spaces.

- Healthcare & Education: Easy-to-clean, moisture-proof, and corrosion-resistant aluminum ceilings are used in areas such as hospitals, laboratories, and schools, supporting rapid maintenance of the lay-in system.

- Public and Cultural Venues: Conference centers, theaters, and stadiums often use perforated or sandwich-structured ceilings to achieve better acoustic performance and flatness.

- Outdoor Porch & Walkways: Outdoor aluminum ceilings with weather-resistant powder coating enhance corrosion resistance and are suitable for commercial entrances, walkways, and courtyard areas.

FAQ

Q1: What environments are aluminum ceilings suitable for?

Aluminum ceilings are lightweight, moisture-proof, and corrosion-resistant, making them suitable for offices, hospitals, airports, subway stations, commercial spaces, and semi-outdoor environments such as porches, terraces, and corridors. Different panel types and installation systems can match a variety of architectural scenarios.

Q2: Can aluminum ceilings be used outdoors?

Yes. Aluminum itself has strong weather resistance, and with powder coating and anti-corrosion treatment, it can be used for a long time in outdoor areas such as porch, patio, and under-deck without rusting or deforming.

Q3: How effective is the sound absorption of perforated aluminum ceiling panels?

The perforated panels, combined with their perforated design and backing structure, effectively absorb mid-to-high frequency noise, making them suitable for airports, schools, conference rooms, and public spaces. For even higher levels of sound absorption, honeycomb, 3D core, or aluminum foam structures can be selected.

Q4: What are some common installation systems for aluminum ceiling panels?

Common systems include clip-in, lay-in, T-grid systems, and U-shaped/O-shaped/square tube hanging systems. Chalco can provide project design, matching processing, and system selection advice.

Q5: What is the standard thickness of aluminum ceiling panels?

The standard thickness is 0.5–1.2 mm; for large panels or sandwich structures, the overall thickness can be customized according to project requirements.

Q6: What surface treatments can be done on aluminum ceilings?

A variety of options are available, including powder coating, anodizing, wood grain transfer, brushed metal, special textures, and perforated finishes, to suit different architectural styles.

Q7: Does Chalco support customized sizes and shapes?

Yes. Panel size, opening style, edge structure, thickness, and color can all be customized according to project drawings, suitable for standard modular ceilings and large panel systems.

Q8: What is the difference between sandwich structure aluminum ceilings and ordinary ceilings?

Sandwich structures (honeycomb, 3D core, corrugated core, foam aluminum) have higher flatness, strength and sound absorption performance, making them suitable for large public spaces and high-end buildings, and requiring higher structural stability.

Q9: Are aluminum ceilings easy to maintain?

Yes. The surface is stain-resistant and corrosion-resistant, and will not get damp or moldy. It only requires daily wiping to keep it clean, making it suitable for high-frequency use areas.

Q10: Can you provide samples or project proposals?

Yes. Chalco can provide physical samples, structural design suggestions, bills of materials (BOM), and processing support services to help clients quickly advance project design and selection.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote