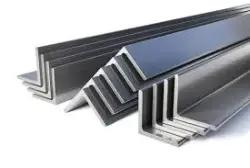

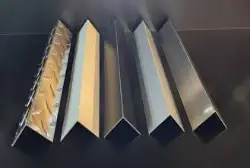

Aluminum angle bar is a versatile structural profile widely used in construction, industrial fabrication, and architectural applications. As a professional aluminum angle bar supplier, Chalco provides aluminum angle bars in 7075, 6061, 6063, 2024 and other alloys, available in equal and unequal leg sizes. Lightweight, corrosion-resistant and easy to process, our aluminum angle bars support cutting, drilling, bending and custom length services to meet diverse project requirements.

Aluminum Angle Bar Specifications

- Available alloys: 6061, 6063, 2024, 7075, 5052, 5083, 6060 aluminum angle bars

- Standards: ASTM B308, ASTM B221, AMS-QQ-A-200/8, AMS-QQ-A-200/9

- Processing services: cut-to-length, drilling, CNC machining, milling, bending, rolling

- Surface finish options: anodizing, powder coating, polishing, brushing, grinding

- Anodizing colors: black, matte black, bronze, and custom colors

Click to view Selection Guide for aluminum angle applications.

Common Aluminum Angle Bar Alloys

ASTM B308; AMS-QQ-A-200/8

A high-strength extruded aluminum angle bar offering an excellent balance of strength, corrosion resistance, and machinability. Commonly selected for load-bearing frames, brackets, supports, and general structural components.

ASTM B221; AMS-QQ-A-200/9

Known for its excellent surface finish and corrosion resistance. Suitable for applications where appearance quality and dimensional consistency are important, such as architectural and light structural uses.

-

2024 Aluminum Angle Bar

High strength and excellent fatigue resistance, commonly used for aerospace and high-load mechanical structures. Surface treatment is recommended due to limited corrosion resistance.

-

Ultra-high strength aluminum angle bar for demanding structural applications, widely used in aerospace and military-related components. Anodizing is commonly applied to enhance corrosion performance.

-

5052 Aluminum Angle Bar

Excellent corrosion resistance and good formability, making it suitable for marine, chemical, and outdoor environments where durability is critical.

-

5083 Aluminum Angle Bar

High strength combined with outstanding corrosion resistance, widely used in marine engineering, transportation, and harsh environmental applications.

Chalco Aluminum Angle Bar Sizes & Stock Availability

To support different project requirements, Chalco supplies aluminum angle bars in a wide range of structural forms and size options. Whether for load-bearing frames or architectural detailing, our aluminum angles are available in both standard and customized configurations, covering common equal-leg and unequal-leg designs used across industrial and construction applications.

Common aluminum angle bar sizes supplied for structural and architectural use include 1×1, 1-1/2×1-1/2, and 2×2 inch aluminum angles, as well as metric sizes such as 25×25 mm, 40×40 mm, and 50×50 mm. Selected standard aluminum angle bar sizes are supported by regular production programs and flexible stock availability, allowing fast delivery depending on order timing.

-

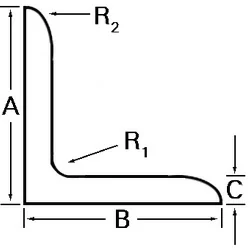

Structural Aluminum Angle Bar

Structural aluminum angle bars, typically supplied in 6061-T6, provide high strength, corrosion resistance, and good machinability for frames, brackets, and load-bearing structures.

-

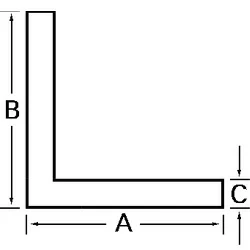

Architectural Aluminum Angle Bar

Architectural aluminum angle bars, typically made from 6063 alloy, offer high surface quality and dimensional consistency for decorative trims, frames, and interior or exterior architectural details.

| Reference size for Structural Angle |

|

|||

| Leg (A) | Leg (B) | Thickness (C) | Radius (R1) | Radius (R2) |

| 1 | 1 | 1/8 | .125 | .094 |

| 1 | 1 | 3/16 | .125 | .094 |

| 1 | 1 | 1/4 | .125 | .094 |

| 1 1/4 | 1 1/4 | 1/8 | .188 | .125 |

| 1 1/4 | 1 1/4 | 3/16 | .188 | .125 |

| 1 1/4 | 1 1/4 | 1/4 | .188 | .125 |

| 1 1/2 | 1 1/2 | 1/8 | .188 | .125 |

| 1 1/2 | 1 1/2 | 3/16 | .188 | .125 |

| 1 1/2 | 1 1/2 | 1/4 | .188 | .125 |

| 2 | 1 1/2 | 3/16 | .188 | .125 |

| 2 | 1 1/2 | 1/4 | .188 | .125 |

| 2 | 2 | 1/8 | .250 | .125 |

| 2 | 2 | 3/16 | .250 | .125 |

| 2 | 2 | 1/4 | .250 | .250 |

| 2 | 2 | 3/8 | .250 | .125 |

| 2 1/2 | 2 | 1/4 | .250 | .125 |

| 2 1/2 | 2 1/2 | 3/16 | .250 | .125 |

| 2 1/2 | 2 1/2 | 1/4 | .250 | .125 |

| 2 1/2 | 2 1/2 | 3/8 | .250 | .125 |

| 3 | 1 1/2 | 3/16 | .250 | .188 |

| 3 | 2 | 3/16 | .250 | .188 |

| 3 | 2 | 1/4 | .312 | .188 |

| 3 | 2 | 5/16 | .312 | .313 |

| 3 | 2 | 3/8 | .312 | .250 |

| 3 | 3 | 3/16 | .312 | .250 |

| 3 | 3 | 1/4 | .312 | .250 |

| 3 | 3 | 3/8 | .312 | .250 |

| 3 | 3 | 1/2 | .312 | .250 |

| 3 1/2 | 3 1/2 | 1/4 | .375 | .250 |

| 3 1/2 | 3 1/2 | 3/8 | .375 | .250 |

| 4 | 2 | 1/4 | .375 | .250 |

| 4 | 3 | 1/4 | .375 | .250 |

| 4 | 2 1/2 | 1/4 | .375 | .250 |

| 4 | 3 | 3/8 | .375 | .250 |

| 4 | 4 | 1/4 | .375 | .250 |

| 4 | 4 | 3/8 | .375 | .250 |

| 4 | 4 | 1/2 | .375 | .250 |

| 5 | 3 | 1/4 | .250 | .250 |

| 5 | 3 | 3/8 | .375 | .312 |

| 5 | 5 | 3/8 | .500 | .375 |

| 5 | 3 | 1/2 | .375 | .312 |

| 6 | 4 | 3/8 | .500 | .375 |

| 6 | 4 | 1/2 | .500 | .375 |

| 6 | 6 | 3/8 | .500 | .375 |

| 6 | 6 | 1/2 | .500 | .375 |

| 6 | 6 | 3/4 | .750 | .375 |

| 8 | 8 | 1/2 | .500 | .375 |

| Reference size for Sharp Corner Architectural Angle |

|

|

| Leg (A) | Leg (B) | Thickness (C) |

| 1/2 | 1/2 | 1/8 |

| 1/2 | 1/2 | 1/8 |

| 3/4 | 3/4 | 1/8 |

| 1 | 3/4 | 1/8 |

| 1 | 1 | 1/8 |

| 1 1/4 | 1 1/4 | 1/8 |

| 1 1/2 | 1 | 1/8 |

| 1 1/2 | 1 1/2 | 1/16 |

| 1 1/2 | 1 1/2 | 1/8 |

| 1 1/2 | 1 1/2 | 3/16 |

| 2 | 1 | 1/8 |

| 2 | 1 1/2 | 1/8 |

| 2 | 2 | 1/8 |

| 2 | 2 | 3/16 |

| 2 | 2 | 1/4 |

| 3 | 1 | 1/8 |

| 3 | 3 | 1/4 |

-

Aluminum Equal Angle Bar

Aluminum Equal Angle Bar

Aluminum equal angle bars are among the most commonly supplied profiles for frames and brackets. Chalco offers standard aluminum equal angles across multiple size ranges to support both light and heavy structural needs. Typical aluminum equal angle sizes include 1×1 inch, 1-1/2×1-1/2 inch, 2×2 inch, and metric profiles such as 25×25 mm, 30×30 mm, and 50×50 mm.

Click to check aluminum equal bar sizes: 5–30 mm | 30–60 mm | 60–200 mm

-

Aluminum Unequal Angle Bar

Aluminum Unequal Angle Bar

Aluminum unequal angle bars are available in standard and custom unequal-leg sizes, including 2×1 in, 3×2 in, and metric options such as 40×25 mm or 50×30 mm, for asymmetric structural requirements.

Click to check aluminum unequal bar sizes: ≤ 40 mm | 40–80 mm | ≥ 80 mm

In addition to stocked aluminum angle bar sizes, Chalco supports rapid extrusion for customized profiles through an established aluminum angle die system. With a wide range of existing extrusion dies and flexible tooling development capability, we help shorten lead times for both standard and project-specific aluminum angles. To learn more about available extrusion dies and profile customization options, please refer to our aluminum angle die solutions, or contact Chalco for stock availability and technical support tailored to your project.

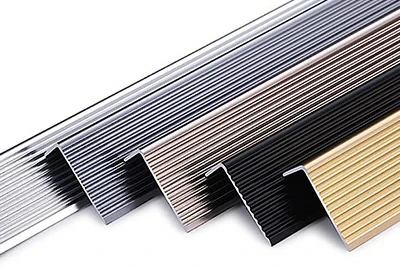

Aluminum Angle Surface Finishes & Ready-to-Use Options

To meet different project environments and appearance requirements, Chalco supplies aluminum angle bars with a range of ready-to-use surface finishes.

These surface treatments improve corrosion resistance, durability, and visual consistency, allowing aluminum angle bars to be installed directly in structural, architectural, and decorative applications without additional processing.

Mill Finish Aluminum Angle Bar

Clear Anodized Aluminum Angle

Black Anodized Aluminum Angle Bar

Powder Coated Aluminum Angle

Brushed Finish Aluminum Angle

Fabrication-Ready Aluminum Angle

Processed Aluminum Angle Options

In addition to standard aluminum angle bar stock, Chalco provides a full range of processed aluminum angle solutions to support faster installation and project-specific requirements. Based on extruded aluminum angle bars, our value-added processing services cover slotting, drilling, bending, and perforation—allowing customers to receive ready-to-use aluminum angles instead of raw stock.

-

Slotted aluminum angle

Slotted aluminum angles are made from standard angle bar stock with customizable slot size and spacing, ideal for adjustable frames, mounting systems, racks, and modular assemblies.

-

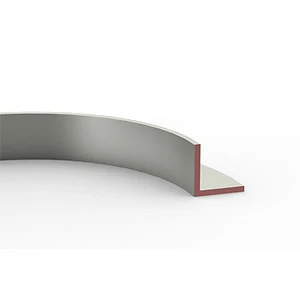

Curved aluminum angle

Curved aluminum angles are formed by precision bending of standard angle bars, ensuring consistent curvature and dimensional accuracy for architectural and custom structural applications.

-

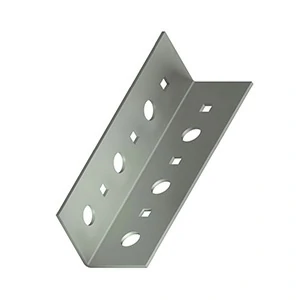

Pre drilled aluminum angle

Pre-drilled aluminum angles feature custom hole positions and diameters, reducing on-site fabrication time for building, machinery, and prefabricated structural applications.

-

Perforated aluminum angle

Perforated aluminum angles are made from standard angle bar stock with customizable hole patterns for ventilation, drainage, weight reduction, or architectural design.

Aluminum Angle Manufacturing & Fabrication Capabilities

Chalco supports aluminum angle bar supply through integrated extrusion, fabrication, and finishing capabilities, serving both stock programs and project-based requirements.

Core Manufacturing: Extruded Aluminum Angle Bar

Aluminum angle bars are primarily produced by hot extrusion, allowing precise control of leg dimensions, wall thickness, and corner geometry. Chalco manufactures extruded aluminum angle bars in both equal-leg and unequal-leg designs, supporting common structural and architectural applications.

Typical production programs are built around common structural and architectural alloys. In addition to stocked profiles, dedicated extrusion dies are used to support special leg dimensions and project-specific angle sections.

Fabrication Based on Standard Angle Bar Stock

All fabrication services are performed on standard extruded aluminum angle bar stock, ensuring material consistency, stable supply, and controlled lead times across batches.

- Cut-to-length processing based on stock aluminum angle bars

- Pre-drilled and slotted aluminum angles for fast installation

- Bending and rolling for curved or non-90° angle requirements

- CNC machining for precise connection and assembly features

Surface Finishing for Aluminum Angle

Surface finishing is applied to both stock and fabricated aluminum angle bars to meet durability and appearance requirements across different service environments.

- Anodized aluminum angle for corrosion resistance and clean appearance

- Powder coated aluminum angle for color consistency and outdoor durability

- Brushed aluminum angle for architectural and decorative applications

- Polished aluminum angle for visible and finish-critical uses

Extended Extrusion Profiles

In addition to aluminum angle bars, Chalco also supplies extruded aluminum profiles including T profiles, U channels, Z bars, and I beam profiles, produced on the same extrusion lines for structural and architectural use.

Aluminum Angle Applications & Project Use

Chalco aluminum angle bars are supplied for a wide range of structural and architectural projects, including building construction, industrial framing, interior finishing, and renewable energy systems. Based on extruded aluminum angle bar stock, our solutions support equal-leg and unequal-leg configurations across multiple alloys, sizes, and finishing options.

Construction & Architectural Framing Aluminum Angle

Common Alloys: 6063, 6061 aluminum angle bars

Typical Forms: Equal-leg and unequal-leg aluminum angles

Applications: window and door frames, curtain wall supports, edge protection profiles, light structural framing

Decorative Aluminum Angle Trim

Surface Options: anodized, brushed, powder coated aluminum angle

Typical Sizes: small and thin aluminum angle bar sections

Applications: wall corners, tile edge trims, stair nosings, interior decorative detailing

Industrial Frame & Equipment Support Aluminum Angle

Common Alloys: 6061, 7075 aluminum angle bars

Processing: cut-to-length, pre-drilled, CNC machining

Applications: machine frames, equipment racks, brackets, load-bearing support structures

Solar & Wind Energy Structure Aluminum Angle

Aluminum angle bars are commonly used in solar mounting systems and wind energy support frames, where corrosion resistance, lightweight construction, and dimensional consistency are required for long-term outdoor service.

Aluminum Angle Application Gallery

Frequently Asked Questions About Chalco Aluminum Angle Bars

1. Are aluminum angle bars mainly produced by extrusion?

Yes. Most aluminum angle bars are produced by extrusion, which allows precise control of leg dimensions, wall thickness, and corner geometry. Chalco supplies extruded aluminum angle bars in both equal-leg and unequal-leg configurations for structural and architectural applications.

2. What aluminum alloys and customization options are available for aluminum angle bars?

Common alloys include 6061 aluminum angle bars for structural and load-bearing use and 6063 aluminum angle bars for architectural applications. For higher strength requirements, 2024 and 7075 aluminum angles are also available. In addition to standard sizes, Chalco supports custom aluminum angle production through dedicated extrusion dies for special leg dimensions, wall thicknesses, and project-specific profiles.

3. Do you supply aluminum angle bars from stock?

Chalco supports fast supply of commonly requested aluminum angle bar sizes through flexible stock availability and standard extrusion programs. Both equal-leg and unequal-leg aluminum angles can be supplied with short lead times depending on specifications and order timing.

4. What size ranges are available for aluminum angle bars?

Chalco supplies aluminum angle bars in common inch sizes such as 1×1, 1-1/2×1-1/2, and 2×2 inches, as well as metric sizes including 25×25 mm, 40×40 mm, and 50×50 mm. Both equal-leg and unequal-leg aluminum angles are available, with custom sizes supported through extrusion dies based on project requirements.

5. Can aluminum angle bars be cut or machined before delivery?

Yes. Based on standard aluminum angle bar stock, Chalco provides cut-to-length, pre-drilled, slotted, bending, and CNC machining services to support fabrication-ready delivery.

6. What surface finishes are available for aluminum angles?

Available finishes include mill finish aluminum angle bars, clear anodized aluminum angles, black anodized aluminum angles, powder coated aluminum angles, and brushed finish aluminum angle trims, depending on functional and aesthetic requirements.

7. How can I select the right aluminum angle bar for my project?

If you are selecting aluminum angle bars for structural, architectural, or industrial applications, our technical team can assist with alloy selection, size confirmation, processing options, and delivery planning. Contact Chalco for stock availability, customization support, and a quotation tailored to your project.

For aluminum angle bar projects involving structural design, fabrication, or customized profiles, Chalco's technical team can assist with alloy selection, size verification, processing feasibility, and supply planning. Contact us to discuss your application and receive engineering support with a project-based quotation.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote