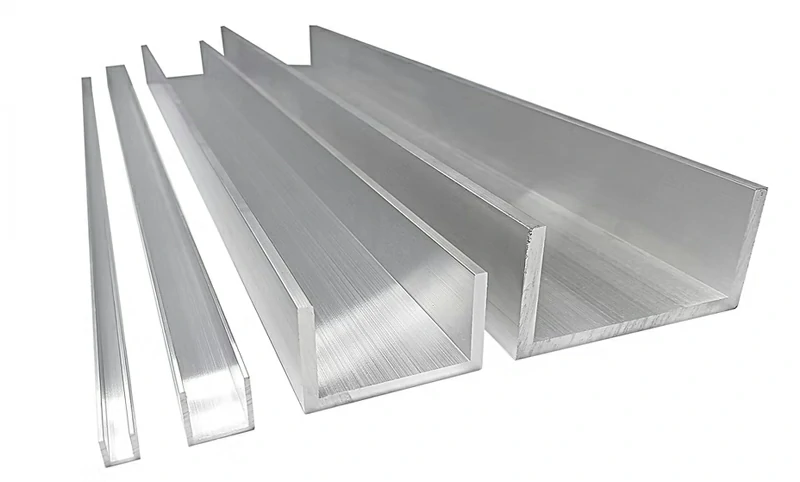

With our advanced know-how and broad product range, we supply U Type Tube without extra customization fees—shortening lead times by 1–2 weeks and reducing total cost.

We focus on the production, stocking, and supply of U Type Tube. No additional customization charges mean lower costs and 1–2 weeks faster delivery. We can tailor sizes to your requirements, and we support both small trial orders and large-volume industrial procurement.

Our U Type Tube offers high strength to withstand significant pressure and impact, excellent machinability for easy cutting, bending, and joining, and outstanding corrosion resistance for long-term performance in harsh environments. For surface finish, we offer smooth and matte options to meet different application and aesthetic needs.

Aluminium U Type Tube — Specifications

ASTM B221 (extruded aluminum products)

EN 755-2 (mechanical properties), EN 755-9 (dimensional tolerances)

EN 12020-2 (precision extrusions; apply when tighter tolerances are specified)

Tolerances on leg height/width, base width, wall thickness, straightness, and twist are controlled per the selected standard and size class.

Internal corners are supplied with the natural as-extruded fillet radius by default. If sharp inner corners are required, please mark them clearly on the drawing.

EN 10204 3.1 Mill Test Certificate available on request. Products comply with RoHS and REACH.

Straightness ≤ 1.0 mm/m; twist ≤ 1°/m (final limits depend on profile size and alloy/temper).

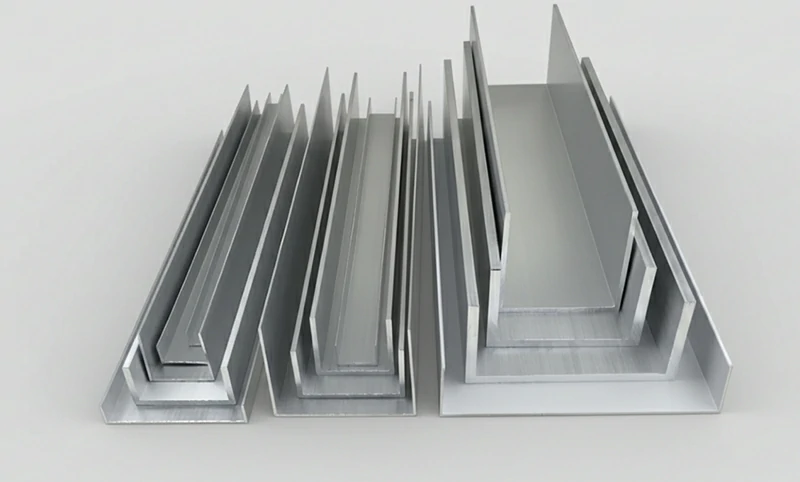

Related Products for Aluminium U Type Tube

| Title | Summary |

| 6063 Aluminum U Channel | Extruded profile with 90° inner/outer corners, flat surface, and good corrosion resistance; ideal for decorative and architectural applications. |

| Aluminum U Channel | An aluminum "U”-shaped channel produced by extrusion; covers configuration |

| Channel Types Overview (U / C / Hat / Z) | Structural support use cases, alloy selection guidance and differences (e.g., 5456, 6082, 6060, 6005; high-load recommendations). |

| Aerospace-Grade 2219 Aluminum Tube | High-strength, weldable tubing to AMS 4066/4068 and ASTM B241; for critical piping/structures requiring strength at elevated or low temperatures (incl. cryogenic media). |

Aluminium U Type Tube – standard die list

Below are die sizes for Aluminium U Type Tube available for direct ordering. Please select a size and include alloy, temper, surface finish, and quantity with your RFQ.

All sizes use existing dies—no new tooling cost—delivering lower unit cost and shorter lead times (no tooling stage required).

| Model | A × B × T (mm) or T1/T2 | R1 / R2 (mm) | Weight (kg/m) | Standard Lengths |

| X-9000 | 7.2 × 12 × 0.9 | — | 0.075 | 3m / 6m |

| C8×8-1.0 | 8 × 8 × 1.0 | — | 0.06 | 3m / 6m |

| C10×10-1.5 | 10 × 10 × 1.5 | — | 0.11 | 3m / 6m |

| C12×12-1.0 | 12 × 12 × 1.0 | — | 0.092 | 3m / 6m |

| C12×20-1.6 | 12 × 20 × 1.6 | — | 0.212 | 3m / 6m |

| X-9002A | 12.7 × 12.7 × 0.9 | — | 0.089 | 3m / 6m |

| C13×20-1.25 | 13 × 20 × 1.25 | — | 0.171 | 3m / 6m |

| C14×16×2.0 | 14 × 16 × 2.0 | — | 0.228 | 3m / 6m |

| C14×33-2.0 | 14 × 33 × 2.0 | — | 0.412 | 3m / 6m |

| C15×15×2.0 | 15 × 15 × 2.0 | — | 0.222 | 3m / 6m |

| X-9001-09 | 9.5 × 9.5 × 0.9 | — | 0.065 | 3m / 6m |

| X-9004-10 | 19.05 × 19.05 × 1.0 | — | 0.152 | 3m / 6m |

| S-9004-22 | 19.05 × 19.05 × 2.2 | — | 0.313 | 3m / 6m |

| C20×20×2.0 | 20 × 20 × 2.0 | — | 0.304 | 3m / 6m |

| C20×30-2.0 | 20 × 30 × 2.0 | — | 0.412 | 3m / 6m |

| C21.4×24.5-2.0 | 21.4 × 24.5 × 2.0 | — | 0.36 | 3m / 6m |

| C22×15-1.5 | 22 × 15 × 1.5 | — | 0.198 | 3m / 6m |

| C23×23-1.5 | 23 × 23 × 1.5 | — | 0.268 | 3m / 6m |

| C25×25×2.0 | 25 × 25 × 2.0 | — | 0.385 | 3m / 6m |

| C30×30-2.0 | 30 × 30 × 2.0 | — | 0.466 | 3m / 6m |

| C38×38-3.0 | 38 × 38 × 3.0 | — | 0.878 | 3m / 6m |

| C39×60×39R-4.0 | A = 60 / B = 39 / T = 4.0 (differential wall) | R1 = 3 / R2 = 0 | 1.42 | 3m / 6m |

| C50×25-3.2 | 50 × 25 × 3.2 | — | 0.812 | 3m / 6m |

| C50×50-3.0 | 50 × 50 × 3.0 | — | 1.171 | 3m / 6m |

| C50×50-5.0 | 50 × 50 × 5.0 | — | 1.897 | 3m / 6m |

| Y-OR0013 | A = 17 / B = 20 / T1 = 1 / T2 = 1 | R2 = 0.8 | 0.148 | 3m / 6m |

| HM26766 | A = 32 / B = 8 / T = 2.7 | R1 = 1 / R2 = 2.5 | 0.305 | 3m / 6m |

| C76.2×38.1R-6.35 | A = 76.2 / B = 38.1 / T = 6.35 | R1 = 4.78 / R2 = 7.92 | 2.206 | 3m / 6m |

Need T1/T2/R1/R2 callouts or a wide-web type? We also support variable-thickness + fillet-radius designs (e.g., Y-OR0013, C39×60×39R-4.0). Send your drawing for verification.

Aluminium U Type Tube — Processing, Forming & Joining

Bending (U Channel)

Bend along the extrusion direction for better stability; use multi-pass gradual bends to reduce ripples.

Protect visible surfaces with soft pads / V-block guards to prevent clamp marks.

Typical angular tolerance ±1°; tighter limits available upon agreement.

Appearance parts: For the most uniform look, anodize/powder-coat after bending. If finishing first, accept the risk of whitening/halo in the bend zone.

Welding (MIG/TIG; ER4043 / ER5356)

Process: MIG/TIG (AC). Shielding gas: Argon (trace helium optional to increase heat input).

Filler selection: ER4043 flows well with lower cracking risk (anodized color appears slightly darker); ER5356 offers higher strength and closer color match to base metal—preferred for marine / higher-strength service.

Prep: Degrease → remove oxide (dedicated stainless-steel brush) → dry → weld → grind/dress.

Acceptance: Appearance grade, dimensions, leak integrity; dye-penetrant and/or pressure/helium leak tests as required.

Slotting / Punching

Slot end radius: R ≥ 0.5 × slot width to avoid stress concentration at sharp ends.

Edge & pitch rules (guideline): Edge distance ≥ 2 × T; hole-to-hole pitch ≥ 3 × T (or per drawing).

Process choice: Small batches/high precision → CNC milling; large volume → progressive stamping.

Deburring: Manual or tumbling; no burrs on show faces. Thoroughly clean before anodizing/powder coating.

Machining

Allowances: Saw-cut with +1.5–3 mm stock, then finish machine; machine mating and visible faces last.

Tooling: Sharp carbide, positive rake; ample coolant (aluminum-grade cutting fluid).

Finish consistency: For minimal color variation, finish machine then anodize/coat.

Aluminum U Type Tube Surface Finishes

Anodizing

Typical thickness: 8–12 μm (indoor), 15–25 μm (outdoor), 25–50 μm (hard anodizing).

Colors: natural, black, champagne, bronze, gold (matte or gloss).

Film grows inward + outward; for critical fits, allow ~0.5 × film thickness as clearance.

Sharp edges coat thinner—recommend edge radius R ≥ 0.2–0.5 mm.

Sealing (hot water or nickel salt). Verify thickness / color variation / sealing quality per project spec.

Powder Coating

Typical film 60–120 μm; any RAL color, gloss, or texture. Excellent coverage and weathering—ideal outdoors.

Sharp edges and hanger points need masking notes on drawings; chamfer/round edges for better coverage.

Acceptance focuses on film thickness, adhesion, impact resistance, and salt-spray performance.

Electrophoretic Coating (E-coat)

Thin, very uniform film; clear, tea, coffee, bronze tones with strong metallic look.

For higher corrosion resistance and refined appearance, combine with anodizing (anodize first, then clear e-coat).

Brushed / Polished

Common grits #180 / #240, up to #8 mirror.

Recommend "brush first, then anodize” to lock in grain and improve wear resistance.

Specify grain direction on show faces; apply PE protective film through production & logistics.

Mill Finish

As-extruded surface—suitable for subsequent machining or secondary finishing.

Minor extrusion lines/scratches may be present; for decorative show faces, prefer anodizing or powder coating for a stable appearance.

Aluminium U Type Tube Applications

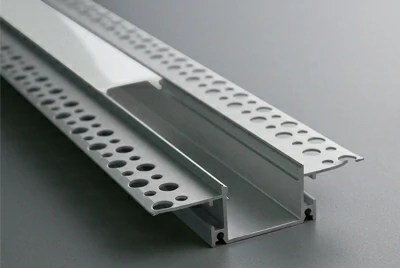

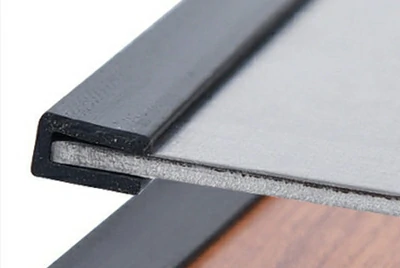

Architectural Edge Trim / Door & Window Beads

Used for edge finishing and seam covering on curtain walls, doors/windows, and wall panels, with emphasis on uniform appearance and straight, clean edges. Choose décor-friendly alloys and finishes (e.g., anodizing or powder coating). Typical assembly uses self-tapping screws, rivets, or structural adhesive. At ordering, specify visible-face orientation and color consistency requirements.

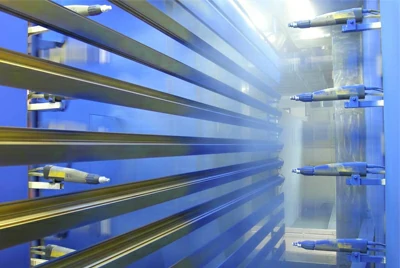

LED Channels / Luminaire Housings

Provide light guiding, heat dissipation, and shielding while keeping weight low and appearance clean. Use rounded internal transitions to ease LED-strip installation. Exterior finishes are commonly black anodizing or sandblast + anodizing. Specify cover clip details, fit features, and tolerances on drawings. Apply protective film throughout transport.

Display & Furniture Frames

For racks, showcases, partitions, and furniture frames—balancing stiffness and aesthetics. Prioritize brushed + anodized finishes for visible décor; choose higher-strength alloys for load-bearing sections. Common joining: bending, corner brackets, or modular profile assembly. Hole spacing and edge distances per drawing.

Equipment Guards / Edge Protection / Cabinets

For machine enclosures and edge protection where impact resistance, scratch resistance, and cleanability matter. Pair with durable finishes such as powder coating or hard anodizing. Control edge distances, shapes, and positional tolerances for holes/slots per drawings, and remove burrs and sharp edges on show faces.

Storage Racking / Logistics Bumper Strips

Used as rack edge guards, conveyor lane stoppers, and pallet borders—prioritizing stiffness and wear resistance. Select alloys with a good strength-toughness balance; ensure straightness and consistency on long lengths. Consider wear-resistant textured powder coatings. Assembly typically with screws or rivets; add local reinforcement around hole zones.

Vehicle Interiors / Conversions (RV / Van / Truck)

Applied as interior edge trim, track covers, and guards, focusing on lightweight and corrosion resistance. Bending radius and process depend on alloy and temper. For visible parts, prefer black anodizing or a highly consistent coating system; control color variation and scratch risk on show faces.

HVAC / MEP Service-Line Capping

Covers edges of ducts, piping, and cable trays; requires weatherability and easy maintenance. Outdoors, use weather-resistant anodizing or powder coating. Clearly define mating relations at clip/hinge features on drawings. For transport, use end caps and pallet restraints to prevent deformation.

Offshore / Chemical Equipment Shrouds

For long-term exposure to salt spray or process media, choose corrosion-resistant alloys or apply heavy-duty protective coating systems on structural alloys. Use stainless fasteners with proper galvanic isolation. Documentation can include material certificates and environmental compliance declarations to support bidding and acceptance.

Quality & Packaging

Process Control Multi-zone, PID-controlled artificial aging with temperature uniformity ±2 °C; 100% stretch-straightening.

Consistency Same-batch, same-tank anodizing for color uniformity; graded control of show/non-show faces; full batch traceability end-to-end.

Inspection 100% dimensional and visual checks; mechanical properties sampled as required. Third-party inspection available (e.g., SGS / BV).

Packaging PE protective film → anti-scratch interleaves → shrink wrap/Kraft paper → end protectors → fumigated pallets/crates. Container reinforcement schemes available on request.

Why Choose Our Aluminium U Type Tube?

Order directly from our large die library no new-die fees.so you skip tooling, cut unit cost, and move into production faster. Use our downloadable PDF die list and online weight calculator to size profiles, verify theoretical weight, and plan container loading efficiently.

We provide one-stop, in-house manufacturing: extrusion, bending, punching/slotting, welding, CNC machining, and finishing (anodizing or powder coating). Quality is centralized with full traceability (barcode lots), and we supply EN 10204 3.1 MTC plus RoHS/REACH documents.

Supply is flexible choose cut-to-length or standard mill lengths, with export-grade packaging, end caps, and global shipping. Imperial and metric options keep appearance and dimensions consistent across batches.

Contact us for alloy/finish recommendations and to check live inventory and lead times.

FAQ

Q: What's the difference between a U channel and a C channel?

A: U channels typically have two legs of equal height. C channels are more common in structural parts, with geometry oriented for load-bearing and usually thicker walls.

Q: Can I specify different thicknesses for legs and web?

A: Yes. Use T1/T2 to define differential wall, and indicate R1/R2 for inside/outside corner radii.

Q: How is weight calculated?

A: By cross-sectional area × density (≈ 2.70 g/cm³) as a theoretical value. Normal production tolerances apply to batch weight.

Q: How tight can length tolerance be?

A: Typical cut tolerance is ±1.0–2.0 mm; CNC cut-to-length can be tightened further.

Q: Which alloy is most stable for a black finish?

A: 6063-T5/T6 offers the most stable anodized color—recommended for decorative applications.

Q: Are welding and bonding compatible?

A: 6xxx/5xxx series support standard MIG/TIG welding. Structural bonding is possible with industrial adhesives (surface cleaning/roughening or anodize pretreatment required). We'll propose a welding plan and filler wire (e.g., ER4043/ER5356) based on your alloy and finish.