Aerospace cellular structures are widely used in aircraft interiors, floors, secondary structures, and high-temperature components for their lightweight, high strength, and dimensional stability. Performance depends on core material, face sheets, and the composite process, requiring different material systems—such as aluminum, aramid paper, stainless steel, and titanium—matched to specific structural and thermal demands.

Chalco supplies multiple cellular core and panel systems and configures application-oriented, high-performance solutions based on project requirements.

Honeycomb core material system

Aluminum honeycomb core

Aramid paper honeycomb core

Stainless steel honeycomb core

Titanium honeycomb core

Panel materials and composite methods

Metal panels:aluminum alloy; stainless steel, titanium, etc.

Composite material panels:FRP ; CFRP

Composite methods:film lamination ; epoxy adhesive lamination ; polyurethane lamination

Aviation Application Parts and Recommended Structure

Cabin interior

Aircraft floor panels

Secondary load-bearing structure

Engine and high-temperature components

Chalco Aerospace Honeycomb Core Materials

The performance of aerospace cellular structures is primarily defined by the core material. Chalco supplies aluminum, aramid paper, stainless steel, and titanium cellular cores for interiors, flooring, secondary structures, and high-temperature applications. These core systems deliver high performance, consistency, and environmental resistance, while supporting large formats, ultra-low densities, and demanding operating conditions, with both standardized and project-specific configurations available.

- "Three Highs": High precision in mechanical properties (compressive strength ±4%), high consistency, and high weather resistance;

- "Three Extremes": Extremely large size (reduced splicing), extremely light density (lightest as low as 7 kg/m3), and extreme environment (resistant to high temperature and salt spray).

- "One positive": positive design, Ganxingda honeycomb can be further customized, and the specifications of the air pores, honeycomb specifications, corrosion resistance and mechanical properties can be customized.

-

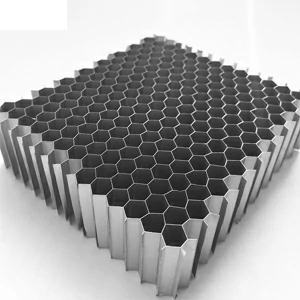

Aerospace Aluminum Honeycomb Core

Aerospace Aluminum Honeycomb Core

Aluminum honeycomb cores are formed by expanding 3003, 5052, and 5056 series aluminum foil, combining lightweight and high specific strength, making them the most widely used metal honeycomb material in aerospace manufacturing.

-

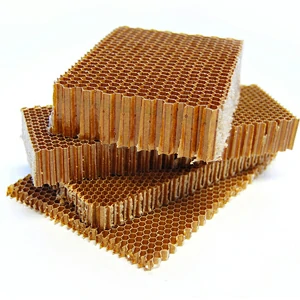

Aerospace Aramid Paper Honeycomb Core

Aerospace Aramid Paper Honeycomb Core

It is made by impregnating meta-aramid paper with phenolic resin and expanding it into shape. It is extremely lightweight and has flame-retardant, electrical insulation and radar transparency properties, making it the mainstream honeycomb core material for aircraft cabin interiors.

-

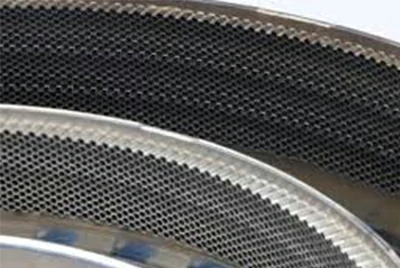

Aerospace Stainless Steel Honeycomb Core

Aerospace Stainless Steel Honeycomb Core

Processed with high-temperature resistant stainless steel foil such as 304 and 321, it is suitable for high-strength aerospace structures that need to withstand thermal cycling, corrosion or impact.

-

Aerospace Titanium Honeycomb Core

Aerospace Titanium Honeycomb Core

Made of titanium alloys such as Ti-6Al-4V, it combines lightweight, high specific strength and excellent high temperature resistance, making it suitable for critical structures or high-end aerospace components.

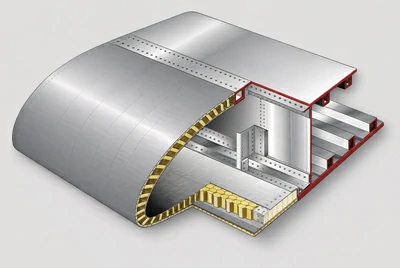

Chalco Aerospace Cellular Panel Materials and Composite Methods

The structural performance of honeycomb sandwich panels depends not only on the core material but also heavily on the selected panel material and its composite method. Different panel systems have different focuses in terms of strength, stiffness, temperature resistance, flame retardancy, and aesthetics. Chalco offers a variety of aerospace-grade metal and composite panels and matches them with adhesive films, epoxy, or polyurethane composite processes according to different applications to form stable and reliable honeycomb sandwich structures.

-

Aerospace Aluminum Alloy Facings

Aerospace Aluminum Alloy Facings

Widely used in aerospace honeycomb sandwich panels for their lightweight strength and ease of fabrication.

Popular stock grades: Alclad 2024-T3 / T42, Alclad 7075-T6, 5052-H32, 5056-H39, 6061-T6 / T651.

-

Aerospace Titanium Alloy Facings

Aerospace Titanium Alloy Facings

Used in high-temperature, highly corrosive, and demanding structural areas, such as engine nacelles and critical structural components.

Popular grades in stock: Ti-6Al-4V (Grade 5), Ti-6Al-2Sn-4Zr-6Mo.

Composite method: Film Adhesive Bonding.

-

Aerospace Stainless Steel Facings

Aerospace Stainless Steel Facings

Offer high-temperature stability and corrosion resistance, suitable for fire-resistant structures and high-temperature components around engines.

Popular grades in stock: 304, 321.

Composite method: Film Adhesive Bonding.

-

Aerospace composite materials and interior panel systems

Aerospace composite materials and interior panel systems

Hot-selling products: Fiberglass panels (FRP), carbon fiber panels (CFRP), and fire-resistant laminated decorative panels.

Composite methods: primarily epoxy resin lamination and polyurethane lamination.

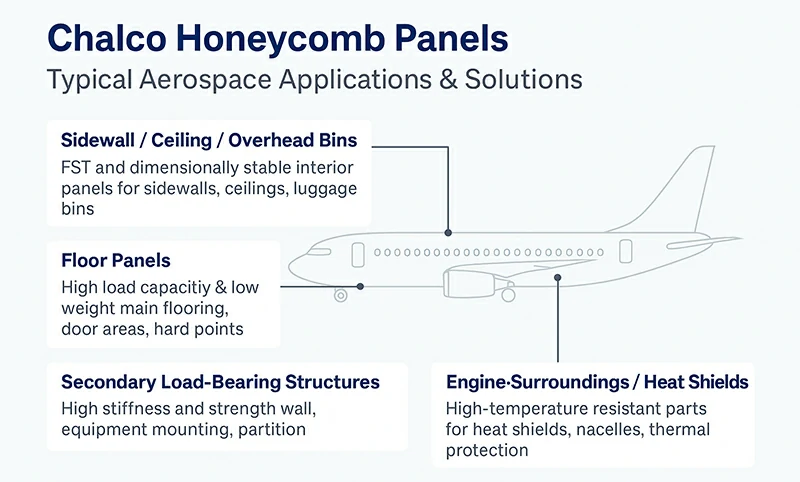

Chalco Aerospace Cellular Panel Typical Applications and Project Solutions

Leveraging its experience supplying multiple aerospace projects, Chalco has developed a comprehensive system of cellular structure solutions to meet the diverse performance requirements of cabins, floors, load-bearing structures, and high-temperature components. We offer a variety of material and structural combinations to help customers quickly select components and complete engineering applications.

| Recommended product structure | |

|

Cabin interior Side walls/roof panels: FRP panels + aramid paper honeycomb core (FST interior-specific) Luggage rack and lightweight structure: CFRP panel + aramid paper honeycomb core (high rigidity/lightweight) Local reinforcement or equipment installation points: High-density aramid paper honeycomb core |

Aircraft floor panels Main floor: 2024-T3 aluminum panel + aluminum honeycomb core (common aerospace load-bearing structure) Lightweight flooring: CFRP panel + aramid paper honeycomb core (for business/lightweight models) Door area reinforcement/hard spot filling: high-density aluminum honeycomb core |

|

Secondary load-bearing structure Bulkhead load-bearing plate: 2024-T3 aluminum panel + aluminum honeycomb core Equipment mounting plate: CFRP panel + aluminum honeycomb core (weight reduction + rigidity) High-strength partition panel: Stainless steel panel (304/321) + stainless steel honeycomb core |

Engine and high-temperature components High-temperature insulation panel: Titanium alloy panel (Ti-6Al-4V) + titanium honeycomb core Heat protection/high-temperature corrosion areas: Stainless steel panel (321) + stainless steel honeycomb core High-temperature load-bearing components: Aluminum panel (3003 or 6061) + brazed aluminum honeycomb core |

Chalco Aviation Air Cell Quality System and Certification

Chalco leverages its comprehensive quality management system and testing capabilities to provide reliable consistency and traceability assurance for aerospace cellular structures.

- ISO 9001–controlled manufacturing, compatible with AS9100 aerospace requirements

- Full process traceability, from raw materials to final inspection

- Stable batch consistency, ensuring uniform strength and dimensional accuracy

- Aerospace NDT & dimensional control, including ultrasonic testing, flatness, and thickness control

- FST-compliant interior solutions, meeting FAR 25.853 flame, smoke, and toxicity requirements

- Structural performance testing support, covering delamination, compression, high-temperature, and thermal-humidity validation

Chalco's Aerospace Cellular Manufacturing and Processing Capabilities

Chalco offers end-to-end aerospace honeycomb solutions, covering core manufacturing, composite bonding, brazing, welding, and precision panel processing for interior, structural, and high-temperature applications.

Multi-process honeycomb core manufacturing: adhesive-bonded honeycomb, brazed aluminum honeycomb, laser-welded stainless steel honeycomb, high-density honeycomb core

Multi-material composite capability: honeycomb sandwich composite of aluminum panels, FRP/CFRP, titanium, and stainless steel

Supports multiple lamination methods: film lamination, epoxy lamination, PU lamination, brazing lamination, etc., to adapt to different structural requirements.

Large-size solid plate processing: Supports cutting, chamfering, CNC machining, irregular shaping, and processing of embedded parts areas.

Supports both whole panels and honeycomb cores: bare core materials or composite finished panels can be provided .

Covering multiple application needs: aerospace structural components such as interior trim, flooring, load-bearing structures, and high-temperature protection.

Chalco Aerial Cellular Technical Specifications

| Honeycomb Core Material Parameter Range Table | ||||

| Parameter categories | Aluminum honeycomb core | Aramid paper honeycomb core | Stainless steel honeycomb core | Titanium honeycomb core |

| Typical density range (kg/m³) | 20–150 | 29–144 | 80–300 | 48–192 |

| Cell Size | 1/8", 3/16", 1/4" | 1/8", 3/16", 1/4" | 1/8", 3/16" | 1/8", 3/16" |

| Available thickness (Core Thickness) | 3–80 mm (customizable) | 3–50 mm | 3–50 mm | 3–50 mm |

| Service Temperature | ≤ 180°C | ≤ 180°C | ≥ 600°C | ≥ 500°C |

| Flame retardant properties (FST) | It needs to be determined with the panel system. | Compliant with FST standards | Related to structural system | Related to structural system |

| Corrosion resistance | medium | good | excellent | excellent |

| Features | Lightweight, cost-effective, and with a wide range of strengths | FST interior-specific, with excellent stability | High temperature/corrosion resistant | High strength/high temperature resistance |

| High-density performance range of aluminum honeycomb core | ||

| Performance items | Standard requirements | Available range |

| Room temperature stratification intensity | ≥ 0.22 kN (above 131 kg/m³) | 0.22–1.32 kN |

| Delamination strength after heat and moisture (boiling water for 2 hours) | ≥ 0.04 kN | 0.04–1.23 kN |

| High-temperature delamination strength (150–175°C) | ≥ 0.12 kN | 0.12–0.69 kN |

| High-temperature intensity decay (175–250°C) | Conventional aluminum honeycomb cells experience a degradation of 25–55%. | PPT data decays by 30–55%. |

| Mechanical consistency | No clear standard | Compressive strength accuracy ±4% |

| Sandwich panel composite parameter range | |

| Overall thickness (Panel Thickness) | 5–50 mm |

| Available panel materials | 2024/3003/5052/6061 aluminum alloy; 304/321 stainless steel; Ti-6Al-4V titanium alloy; FRP; CFRP; FST interior trim panels |

| Composite method | Film lamination / Epoxy lamination / PU lamination / Metal brazing |

| Machinability | CNC machining, chamfering, cutting, embedded part processing, irregular shape composite, large-size whole plate composite |

Frequently Asked Questions (FAQ)

What sizes of honeycomb core materials are available?

Standard thicknesses range from 3 to 80 mm, and can be customized to project requirements; cell sizes support 1/8", 3/16", and 1/4"; large-size panels can be provided as whole pieces or cut into sections.

Can you provide full panel + finishing services?

Yes. Chalco offers integrated delivery capabilities from honeycomb cores and composite sandwich panels to CNC finishing, chamfering, grooving, and embedded part processing.

Can you provide interior materials that meet FST requirements?

Yes. FRP, CFRP, and interior trim panels can all be provided in accordance with FAR 25.853 requirements.

Can technical parameters be kept confidential on a project-by-project basis?

Yes. Chalco supports signing confidentiality agreements (NDAs) and provides customized parameters or non-public data based on client projects.

What are the standard lead time and minimum order quantity (MOQ)?

Cellular cores typically take 2–4 weeks; composite panels take 3–6 weeks depending on processing complexity. MOQ can be flexibly adjusted according to the type of structural component, and sample productio

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote