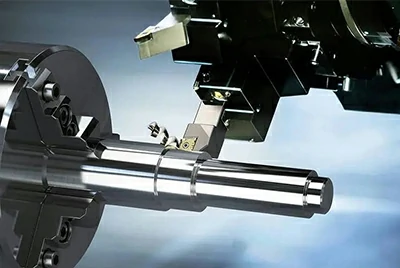

Designed for Swiss-type/guide-bushing production, the 7075 precision ground rod features a default OD of −0.02 mm (custom ±0.02 mm), straightness ≤0.2 mm/m, and roundness ≤0.005 mm. The double-end chamfer ensures smooth automatic feeding without jamming, and cutting remains stable with low chatter at 8,000 rpm. We control the coarse-grain ring to <0.5 mm to reduce anodizing "white spots/snowflakes” for a more uniform finish. The T651 stress-relieved version resists post-machining distortion and is well-suited for precision components.

Why choose our 7075 precision ground rods?

Double-end chamfer and a default negative OD tolerance of −0.02 mm with optional ±0.02 mm customization enable smooth entry into guide bushings and feeders, reducing jams and downtime.

Straightness controlled to ≤0.2 mm/m and roundness to ≤0.005 mm, resulting in lower runout at high speed, finer tool marks, more stable batch dimensions, and higher yield.

Stable cutting at 8,000 rpm supports long unattended cycles in automation.

Coarse-grain ring controlled to <0.5 mm reduces anodizing defects such as white spots and snowflakes, improving surface uniformity and first-pass yield.

T651 is produced from T6 with stress-relief stretching, lowering residual stress so parts resist distortion after machining and suit precision components.

Standards and certifications

- GB/T 3190-2020 chemistry

- GB/T 3191-2019 mechanical properties and inspection for extruded bar

- EN 573-3 chemistry

- EN 755-2 mechanical properties for extruded rod and bar

- EN 754-2 mechanical properties for cold-drawn rod and bar

- AMS per drawing or contract, e.g., AMS 4122/4123/4124 for cold-finished bar and AMS 4154 for extrusions

Specifications and precision

Default tolerance −0.02 mm, optional ±0.02 mm

Straightness ≤0.2 mm/m

Roundness ≤0.005 mm

Available tempers T6 and T651

Double-end chamfer for smooth automatic feeding

Recommended spindle speed up to 8,000 rpm for stable operation

Centerless-ground surface with high guide-bushing conformity

Custom cut-to-length and small-lot sampling available with low MOQ

Stock sizes

| Product | Alloy | Temper | Diameter (mm) | Length (mm) |

| Grinding rod | 7075 | T6 | 4 | 2500 |

| Grinding rod | 7075 | T6 | 5 | 2500 |

| Grinding rod | 7075 | T6 | 6 | 2500 |

| Grinding rod | 7075 | T6 | 7 | 2500 |

| Grinding rod | 7075 | T6 | 9 | 2500 |

| Grinding rod | 7075 | T6 | 10 | 2500 |

| Grinding rod | 7075 | T6 | 11 | 2500 |

| Grinding rod | 7075 | T6 | 12 | 2500 |

| Grinding rod | 7075 | T6 | 13 | 2500 |

| Grinding rod | 7075 | T6 | 13.5 | 2500 |

| Grinding rod | 7075 | T6 | 13.8 | 2500 |

| Grinding rod | 7075 | T6 | 14 | 2500 |

| Grinding rod | 7075 | T6 | 15 | 2500 |

| Grinding rod | 7075 | T6 | 16 | 2500 |

| Grinding rod | 7075 | T6 | 16 | 2500 |

| Grinding rod | 7075 | T6 | 16.8 | 2500 |

| Grinding rod | 7075 | T6 | 17 | 2500 |

| Grinding rod | 7075 | T6 | 18 | 2500 |

| Grinding rod | 7075 | T6 | 19 | 2500 |

| Grinding rod | 7075 | T6 | 19.1 | 2500 |

| Grinding rod | 7075 | T6 | 20 | 2500 |

| Grinding rod | 7075 | T6 | 22 | 2500 |

| Grinding rod | 7075 | T6 | 23 | 2500 |

| Grinding rod | 7075 | T6 | 24 | 2500 |

View the detailed stock size list here.

Chemical composition (GB/T 3190-2020)

| Element | Content (%) |

| Si | ≤0.40 |

| Fe | ≤0.50 |

| Cu | 1.2–2.0 |

| Mn | ≤0.30 |

| Mg | 2.1–2.9 |

| Cr | 0.18–0.28 |

| Zn | 5.1–6.1 |

| Ti | ≤0.20 |

| Zr | — |

| Others (single/total) | ≤0.05 / ≤0.15 |

| Al | remainder |

Mechanical properties (GB/T 3191-2019)

| Temper | Tensile strength Rm | 0.2% yield strength Rp0.2 | Elongation A (%) | Brinell hardness HB |

| T6 | ≥540 | ≥480 | ≥7 | ≥150 |

Applications

Aerospace uses 7075-T651 for wing spars, ribs, fuselage frames, and mounting brackets. High specific strength reduces weight, and straightness ≤0.2 mm/m with roundness ≤0.005 mm improves assembly accuracy and fatigue reliability.

Automotive and motorsport use 7075 for suspension bushings, connector blocks, and locating axles. Double-end chamfer plus a default −0.02 mm OD feeds smoothly through guide bushings, and machine-ready turning shortens trial cuts and setup.

Semiconductor and electronics use 7075-T651 for gripper pins, support posts, and guide blocks. Stress relief lowers size drift after multiple re-clamps, and a <0.5 mm coarse-grain ring improves anodized appearance consistency.

Precision jigs and automation fixtures choose 7075 for guide shafts, locating pillars, and spacers. Centerless-ground OD and low runout reduce wear and chatter, keeping surfaces and dimensions stable at 8,000 rpm.

Machine building uses 7075 for bushings, sliders, links, and guides. Negative OD and double-end chamfer reduce jamming and downtime, improving batch yield.

Machining process

Use double-end chamfer and a default OD of −0.02 mm (optional ±0.02 mm). Long bars feed smoothly through guide bushings and loaders, and jamming risk drops.

Based on centerless grinding, straightness is held to ≤0.2 mm/m and roundness to ≤0.005 mm. Slender parts remain stable at 8,000 rpm with fine tool marks.

T651 stress relief lowers residual stress. Precision parts resist warpage and size drift after roughing, finishing, and multiple re-clamps.

Use aluminum-geometry carbide or PCD with high rake and polished chip grooves. Sharp edges reduce built-up edge and promote short chips.

Choose MQL or 6–10% water-soluble coolant for adequate cooling and lubrication. Use EP oil for tapping and reaming to improve thread integrity and hole finish.

Align guide-bushing concentricity and preload, and support slender work with a follower rest or tailstock. Long automated cycles maintain low runout and consistent surfaces.

Complete deburring and chamfering in the same setup. Fewer re-clamps improve dimensional consistency and yield.

Provide a "turned-to-machine” supply option. The OD is pre-turned to your machine-ready size to shorten trial cuts and setup time and raise first-pass yield.

Control the coarse-grain ring to <0.5 mm and keep a consistent pre-anodizing rhythm. White spots and snowflake patterns are reduced and color variation is smaller.

Combine in-line diameter gauging with sampling to verify OD, straightness, and roundness. EN 10204 3.1 material and dimensional reports are available for traceability.

FAQ

Q1: What is the difference between T6 and T651

A :T651 is T6 followed by stress-relief stretching. Dimensions stay more stable after machining, making it easier to hit hole spacing, flatness, and coaxiality on precision parts.

Q2 :Why use a −0.02 mm negative OD

A :The negative OD mates more smoothly with guide bushings and auto feeders, preventing jams. For assemblies that reference a master or guiding bore, fit stability improves.

Q3 :Is 8,000 rpm mandatory

A: No. 8,000 rpm is our stable reference for this precision level. Higher speeds depend on machine rigidity and tooling and should be validated in trials.

Q4 :Will anodizing show color variation

A :We control the coarse-grain ring to <0.5 mm and keep pretreatment steps consistent to lower color-shift risk. If you need natural, black, or DLC, specify at ordering.

Q5 :What is the main advantage of 7075 versus 6061 or 7005

A: Higher strength and a higher yield-to-tensile ratio suit demanding structural and lightweight parts. Welding and high-temperature strength are lower than 5xxx/6xxx, so select by application.

Q6: Can you provide EN 10204 3.1

A:Yes. 3.1 material and dimensional reports are available by default or on request.