7050 aluminum angle is a high-strength, heat-treatable aluminum alloy profile primarily used in aerospace and other structural applications that demand exceptional strength, corrosion resistance, and toughness. Made from 7050 aluminum alloy—well known for its outstanding mechanical properties and excellent resistance to stress corrosion cracking—it is ideally suited for load-bearing framework structures.

Compared to general-purpose aluminum alloys, 7050 aluminum angle offers a higher strength-to-weight ratio, making it particularly suitable for high-performance structures operating in harsh environments. In critical applications, 7050 is often used as an upgraded alternative to 7075 aluminum due to its superior corrosion resistance and improved toughness in thick sections.

Instant QuoteIntroduction to 7050 aluminum angle

| Alloy Grade | 7050 |

| Product Form | Equal and unequal aluminum angles (Extruded Aluminum Angle) |

| Tempers | T73511, T76511, T736511 |

| Standards | ASTM B221, AMS 4341, AMS 4340, AMS 4342 |

| Length Range | Standard: 3000 mm – 6000 mm (customizable upon request) |

| Wall Thickness Range | 1.5 mm – 10 mm (subject to specific die availability) |

| Tolerance Standard | ±1/16 inch or processed according to customer drawings |

| Surface Finishes | Anodizing (clear/black), coating, electrophoresis, etc. |

| Available Colors | Natural silver, black, champagne, gray, etc. |

| Processing Services | Cutting, drilling, welding, stamping, CNC machining, and more |

| Application Fields | Aircraft structures, military frames, automotive frameworks, marine brackets, machinery frames |

| Performance Advantages | High strength, excellent toughness, fatigue resistance, outstanding stress corrosion resistance |

Common types of 7075 aluminum angle

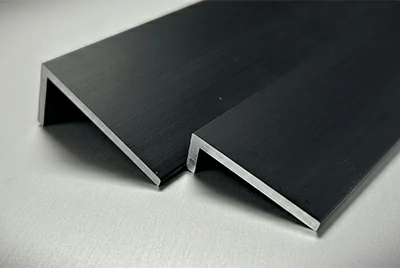

7050 equal aluminum angle

The equal 7050 aluminum angle is the most common standard profile, featuring two sides of equal length and a standard 90-degree angle. It is suitable for most symmetrical connections and structural reinforcement applications. With balanced load-bearing and easy installation, it is widely used in aerospace structural frames, brackets, and reinforcement components.

7050 unequal aluminum angle

The unequal 7050 aluminum angle is ideal for space-constrained or specialized connection structures. One leg is longer than the other, offering a larger support surface or greater installation flexibility. It is commonly used in irregular frame connections and structural reinforcement where customized structural adaptation is required.

7050 inside radius aluminum angle

This type of aluminum angle features a rounded inside corner instead of a sharp angle, which helps reduce stress concentration and improve fatigue resistance. It is especially suitable for structural components with high fatigue life requirements, such as those used in aerospace, rail transit, and precision equipment.

7050 outside radius aluminum angle

The outside radius aluminum angle features rounded outer corners, offering a more refined and visually appealing appearance. It is often used in visible components or structures that require enhanced edge safety. Typical applications include equipment enclosures, frame protection, and display structures.

7050 heavy-duty aluminum angle

This type of aluminum angle is designed for heavy-load structures, featuring thicker walls, higher strength, and enhanced stability. It is suitable for high-strength applications such as aerospace ground equipment, military armor frames, and construction machinery structures.

7050 custom aluminum angle

Custom aluminum angles made from 7050 alloy can be tailored according to customer drawings or specific requirements, including non-standard angles (such as 45°, 60°, 135°, etc.), leg lengths, and wall thicknesses. They are ideal for specialized industrial equipment, structural engineering, and precision assembly components.

The above are the common types of 7050 aluminum angles offered by Chalco, covering a wide range of standard structural forms to meet the high-strength application needs of aerospace, defense, machinery, transportation, and more.

If you can't find a suitable aluminum angle specification for your project among our existing products, we also provide customization services. We can manufacture 7050 aluminum angles in non-standard dimensions, special angles, or custom wall thicknesses according to your drawings or specific requirements. Feel free to contact us anytime for a quote or technical support!

Instant QuoteFeatures of 7050 aluminum angle

Excellent stress corrosion resistance

Compared to 7075, 7050 demonstrates significantly better resistance to stress corrosion cracking, especially in thick sections. This makes it ideal for structural components exposed to moisture, corrosive environments, or long-term loading, offering extended service life.

Superior toughness and fatigue resistance

While maintaining high strength, 7050 also provides excellent toughness and fatigue resistance. It performs reliably in environments with frequent vibrations or alternating loads, making it widely used in aerospace connectors and load-bearing supports under dynamic conditions.

Optimized for thick sections

Tempers like 7050-T7451 and T7651 are particularly suitable for large, thick-section profiles. They offer consistent mechanical properties throughout and resist performance degradation, outperforming 7075 in large-scale structural applications.

Good machinability

Despite its high strength, 7050 aluminum angle maintains good machinability after heat treatment, making it suitable for CNC machining and the assembly of complex structures.

Aerospace-grade approval

7050 aluminum is widely used by major aircraft manufacturers such as Boeing and Airbus. It is a certified material for aerospace structures, offering globally recognized quality and compliance with industry standards.

Stock sizes of 7050 aluminum angle

| Product | dimension A x B x T(inch) | Specification |

| 7050 t73511/t76511 aluminum angle | 1/2" x 1/2" x 1/16" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1/2" x 1/2" x 1/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 3/4" x 3/4" x 1/16" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1" x 1" x 1/16" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1" x 1" x 1/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1" x 1" x 3/16" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1" x 1" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1" x 1-1/2" x 1/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1-1/4" x 1-1/4" x 1/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1-1/4" x 1-1/4" x 3/16" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1-1/4" x 1-1/4" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1-1/2" x 1" x 1/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1-1/2" x 1" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1-1/2" x 1-1/2" x 1/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1-1/2" x 1-1/2" x 3/16" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1-1/2" x 1-1/2" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1-3/4" x 1-3/4" x 1/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 1-3/4" x 1-3/4" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2" x 1-1/2" x 1/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2" x 1-1/2" x 3/16" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2" x 1-1/2" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2" x 2" x 1/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2" x 2" x 3/16" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2" x 2" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2" x 2" x 3/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2-1/2" x 1-1/2" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2-1/2" x 2" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2-1/2" x 2-1/2" x 1/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2-1/2" x 2-1/2" x 3/16" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2-1/2" x 2-1/2" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 2-1/2" x 2-1/2" x 3/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 3" x 2" x 3/16" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 3" x 2" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 3" x 2" x 3/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 3" x 3" x 3/16" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 3" x 3" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 3" x 3" x 3/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 3" x 3" x 1/2" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 3-1/2" x 3-1/2" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 3-1/2" x 3-1/2" x 3/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 3-1/2" x 3-1/2" x 1/2" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 4" x 3" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 4" x 3" x 3/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 4" x 3" x 1/2" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 4" x 4" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 4" x 4" x 3/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 4" x 4" x 1/2" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 5" x 3" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 5" x 3" x 3/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 5" x 3" x 1/2" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 5" x 5" x 1/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 5" x 5" x 3/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 5" x 5" x 1/2" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 6" x 3" x 3/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 6" x 4" x 3/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 6" x 4" x 1/2" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 6" x 6" x 3/8" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 6" x 6" x 1/2" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 6" x 6" x 3/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 8" x 6" x 3/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 8" x 8" x 1/2" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 8" x 8" x 3/4" | AMS4341, AMS4340 |

| 7050 t73511/t76511 aluminum angle | 8" x 8" x 1" | AMS4341, AMS4340 |

If the above sizes do not meet your requirements, please contact us for customization.

Instant Quote7050 aluminum angle vs 7075 aluminum angle

In the field of high-strength aluminum angles, both 7050 and 7075 aluminum angles are highly popular choices, widely used in aerospace, defense, automotive, and high-performance structural components. Although both belong to the 7xxx series aluminum alloys and offer high strength and excellent mechanical properties, they differ significantly in key areas such as corrosion resistance, performance in thick sections, and fatigue life.

| Comparison Item | 7050 Aluminum Angle | 7075 Aluminum Angle |

| Alloy Series | 7xxx series (Al-Zn-Mg-Cu) | 7xxx series (Al-Zn-Mg-Cu) |

| Key Features | High strength, excellent stress corrosion resistance, optimized for thick sections | Ultra-high strength, widely used, suitable for thin or medium sections |

| Tensile Strength | Slightly lower than 7075 but still suitable for high-load applications | Very high tensile strength (up to 572 MPa in T6 temper) |

| Corrosion Resistance | Better, especially in T7451/T7651 tempers | Weaker, usually requires anodizing or coating |

| Fatigue Performance | Superior, ideal for dynamic or vibration-prone structures | Slightly lower, less ideal for high-cycle fatigue loads |

| Section Thickness | Excellent for thick extrusions with stable performance | Best suited for medium to thin sections |

| Machinability | Good, suitable for CNC machining and structural components | Excellent, easy to machine and form |

| Common Tempers | T7451, T7651 (optimized for corrosion resistance) | T6, T651, T73 (optimized for strength) |

| Typical Applications | Aircraft fittings, landing gear, heavy-duty frames, military structures | Aircraft fuselage, molds, bicycle parts, high-strength components |

How to choose?

When deciding between 7050 and 7075 aluminum angles, consider the specific requirements of your application:

- Choose 7050 aluminum angle if your project involves high stress loads, thick-section structures, or corrosive environments. It offers better stress corrosion resistance and superior fatigue performance, making it ideal for aerospace, military, and long-term structural applications.

- Choose 7075 aluminum angle if maximum strength and weight reduction are your top priorities, especially in thin-section or machined components. It is a cost-effective choice for high-performance parts where corrosion resistance is not the primary concern.

Performance of 7050 aluminum angle

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| T73511 | 500 | 440 | 12 |

| T76511 | 552 | 490 | 11 |

| T7451 | 524 | 469 | 11 |

Related products of 7050 aluminum angle

Why choose Chalco as your 7050 aluminum angle supplier?

7050 aluminum angle free samples

Chalco offers free samples of standard-size 7050-T7451/T7651 aluminum angles for qualified partners. These samples support structural validation, mechanical testing, and trial assembly, helping you accelerate project design verification and early-stage production. Contact us now to request your free sample.

Reliable stock availability

We maintain a stable inventory of 7050 aluminum angles in various tempers and dimensions, especially for aerospace, defense, rail transit, and engineering equipment projects. We support bulk exports and fast delivery to meet tight deadlines and strict quality demands.

Focused on high-strength alloys with superior performance

7050 aluminum angle offers an exceptional strength-to-weight ratio, excellent stress corrosion resistance, and outstanding fatigue performance. As a typical aerospace-grade structural material, it is widely used in critical load-bearing applications. Chalco specializes in the development and production of 7xxx series alloys, ensuring international performance standards are met.

Multiple specifications and precision machining support

We offer 7050 aluminum angles in tempers such as T73511 and T76511, including equal leg, unequal leg, square corner, and radius corner types. Custom dimensions based on drawings are available. Machining services such as CNC cutting, drilling, chamfering, welding, and stamping are also provided to support complex structural assembly needs.

Advanced manufacturing ensures dimensional consistency

Using aerospace-grade extrusion equipment and a full-process digital inspection system, Chalco ensures precise control of angles, wall thickness, and geometric tolerances. This guarantees high dimensional consistency and structural reliability for high-standard assemblies in aerospace, high-speed rail, and advanced equipment manufacturing.

Diverse surface treatment options to improve corrosion resistance and appearance

To meet the needs of harsh environments, Chalco offers various surface treatments for 7050 aluminum angles, including anodizing, electrophoretic coating, sandblasting, and spraying. These treatments enhance both corrosion resistance and visual appeal, making the product suitable for marine, humid, and industrial environments.

Strict quality control and full certification support

Each batch of 7050 aluminum angles is delivered with a complete quality inspection report, including data on mechanical properties, chemical composition, and dimensional tolerances. Production complies with aerospace-grade quality systems and supports export to the U.S., Europe, and other high-standard markets.

Compliant with international standards for hassle-free export

Chalco provides 7050 aluminum angles in compliance with the following standards, ideal for international project bidding and customs clearance:

- AMS 4341, AMS 4340, ASTM B221, AMS 4342, EN 755

- Equivalent grades: AA7050 / EN AW-7050 / UNS A97050

7050 aluminum angle FAQs

What industries is 7050 aluminum angle used in?

7050 aluminum angle is widely used in aerospace, military structures, rail transit, engineering machinery, and precision equipment frames. Its high strength-to-weight ratio, excellent stress corrosion resistance, and long fatigue life make it a premium alternative to 7075, especially in high-load, thick-section, and high-demand structural applications.

How should 7050 aluminum angle be cut and machined?

Use rigid equipment such as carbide-tipped saw blades, CNC band saws, or machining centers. Due to its hardness, cutting tools must be sharp and the material should be securely clamped. Coolant is recommended to reduce heat. Bending should be carefully controlled to prevent cracking or springback.

Do you offer cutting and CNC machining services?

Yes. Chalco provides a range of machining services for 7050 aluminum angles, including precision cutting, drilling, tapping, chamfering, CNC milling, and end processing. Custom fabrication is available based on customer drawings to support aerospace and precision mechanical assemblies.

What factors affect the price of 7050 aluminum angle?

Pricing is influenced by:

- Raw material cost (aluminum ingot + alloying elements)

- Temper (e.g., T7451, T7651)

- Profile dimensions (leg length, wall thickness, length)

- Surface treatment (anodizing, electrophoresis, coating)

- Additional processing or customization (mold setup, CNC precision machining)

How is the weight of 7050 aluminum angle calculated?

Use the following steps:

- Density of 7050 aluminum ≈ 2.83 g/cm³

- Cross-sectional area A = (a × t) + (b × t) – t²

- Volume = A × length

- Weight = volume × density (convert to kg or lbs as needed for design or logistics)

Can 7050 aluminum angle be welded?

Welding is not recommended. Due to its high zinc and copper content, 7050 aluminum has poor weldability and is prone to hot cracking. If welding is necessary, special filler wires and techniques should be used, followed by heat treatment or structural reinforcement.

Can 7050 aluminum angles be customized?

Absolutely. Chalco offers custom fabrication of 7050 aluminum angles in equal leg, unequal leg, rounded corner, and non-90° configurations. Customizable parameters include length, angle, wall thickness, and hole positions to meet aerospace, defense, and precision industrial needs.

Is 7050 aluminum angle reliable for outdoor use?

7050 offers good corrosion resistance, especially in the T7451 temper, and outperforms 7075 in harsh conditions. For long-term outdoor use in marine, humid, or acidic environments, additional surface treatments such as anodizing or coating are recommended to enhance durability.

Can 7050 aluminum angle be anodized?

Yes. 7050 aluminum can undergo anodizing, electrophoretic coating, or hard coating processes. Although its anodized brightness is lower than 6xxx series alloys, it significantly improves surface hardness, corrosion resistance, and appearance, making it suitable for both structural and visible components.

How is 7050 aluminum angle packaged?

Chalco provides professional packaging solutions to ensure surface protection, dimensional accuracy, and corrosion resistance during shipping and storage:

- Each piece is individually wrapped in scratch-resistant film

- Bundles are packed in PE or dust-free bags

- Exterior packaging uses waterproof plywood or steel-strapped wooden crates

- Custom palletization is available for container loading