6951 aluminum brazing clad sheet is a specialized brazing material manufactured by rolling 6951 aluminum alloy as the core, clad on both sides with aluminum–silicon brazing alloy and corrosion-resistant transition alloy.

Compared with general structural aluminum plates such as 3003 and 6061, 6951 offers a more suitable composition and property profile for brazed heat exchanger service conditions. It exhibits good microstructural stability and strength retention near brazing temperatures, while also providing formability and corrosion resistance.

The high-grade 6951 five-layer aluminum brazing clad sheets supplied by Chalco are mainly used for heat exchanger plates, fins, and cooling plates in aerospace applications, automotive systems, and HVAC systems.

Chalco 6951 five-layer brazing clad sheet supply dimensions

Chalco can provide the following typical supply dimensions for 4104 / 3003 / 6951 / 3003 / 4104 five-layer brazing clad sheets (coil & plate):

| Project | Specification Range |

| Thickness | 0.40 – 6.35 mm (thin-gauge advantage range: 0.30 – 0.80 mm, including 0.36 mm coil capability) |

| Width | Coil: 500 – 1600 mm; Cut-to-length sheets: 500 – 1500 mm (optional conventional widths: 600 / 800 / 1000 / 1219 / 1500 mm) |

| Length | Cut-to-length sheets: 500 – 6000 mm (maximum plate length from Chalco: 6000 mm) |

| Supply Form | Coil; cut-to-length sheet/plate |

| Coil Core | 305 / 405 / 505 mm (paper core or aluminum core, selectable to match customer equipment) |

| Dimensional Tolerance | Sheet tolerance in accordance with ANSI H35.2 or EN 485-4; for coils with thickness 0.125–0.185 inch and width 6–12 inch, width tolerance: ±1/32 inch |

| Cladding Thickness Ratio | Click to view details |

| Mechanical Properties | Click to view mechanical properties |

| Bending & Forming Capability | Capable of 180° bending without cracking; click to view specific parameters |

Specifications for 6951 five-layer brazing clad sheet

Chalco high-grade 6951 five-layer aluminum brazing clad sheets are produced under a controlled quality system and manufactured and tested in accordance with internationally recognized industry standards. If customer drawings or technical specifications conflict with industry standards, customer technical requirements shall take precedence; if no specific requirements are provided, the following standards will apply by default:

| Standard / Specification | Category |

| AMS 2355 | Quality assurance and sampling |

| EN ISO 6892-1 | Mechanical property testing |

| ANSI H35.2 | Dimensions and tolerances |

| EN 485-4 | Dimensions and tolerances |

| EN 573-3 | Chemical composition |

| EN 10204 3.1 / 3.2 | Material certification documents |

| ASTM B660 | Packaging specifications |

| ASTM E380 | Units of measurement |

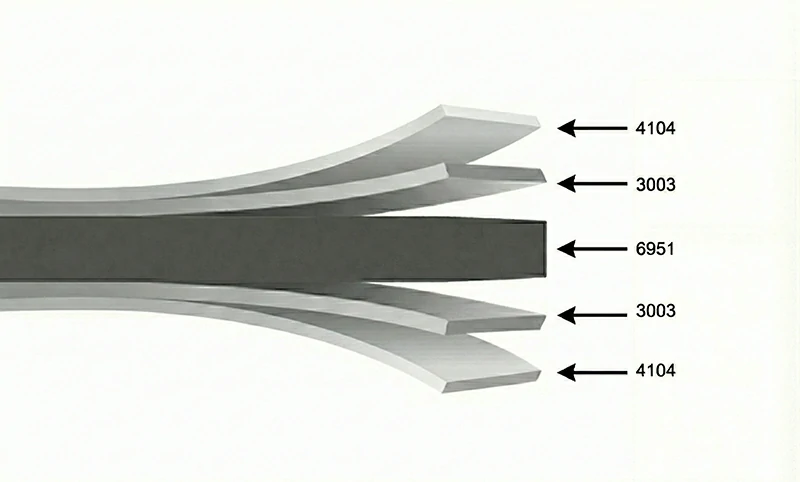

Structural composition of the five-layer brazing clad sheet

Chalco adopts an aerospace- and automotive-grade five-layer 6951 aluminum brazing clad structure (5-layer clad), where functional layering is engineered to maximize welding reliability, corrosion life, and load-bearing performance simultaneously, rather than compromising for a single property.

Typical five-layer structure

-

Core layer

Alloy: 6951

High-strength, high-thermal-conductivity core material that maintains microstructural stability at brazing temperatures, used in critical load-bearing and heat-exchange applications.

-

Surface brazing layer

Alloy: 4104

High-silicon brazing layer that preferentially melts to form the weld seam, offering stable wettability and flowability to support brazing of complex channels and multi-layer structures.

-

Transition layer

Alloy: 3003

Prevents excessive diffusion of Si into the core, delays corrosion, and maintains post-braze strength and structural stability.

Why the five-layer structure is more recommended?

A three-layer structure can meet basic brazing requirements, whereas the Chalco five-layer structure is further enhanced for service life and structural reliability under demanding operating conditions:

| Technical Index | Three-layer Sheet | Chalco Five-layer Sheet |

| Brazing Consistency | Medium | High (more controllable diffusion behavior) |

| Corrosion Life | Medium–High | High (sacrificial layer protects the core in advance) |

| Post-braze Strength Retention | Average | Excellent |

| Applicable Environment | Standard heat exchangers | High refrigerant corrosion / high salt spray / high thermal fatigue / long service life platforms |

| Overall Cost-effectiveness | Lowest cost | Lowest cost per service life |

Corrosion and service life advantages of the five-layer structure

- 3003 transition layers act as a "buffer / sacrificial” layer, slowing the diffusion of Si into the core and reducing the advance of the corrosion front;

- In high salt-spray and high refrigerant corrosion environments, the multi-layer structure allows the outer brazing and transition layers to be consumed first, delaying failure of the 6951 core;

- Suitable for heat exchangers operating on long-service platforms and under severe thermal cycling conditions.

Cladding thickness ratio of the five-layer 6951 brazing clad sheet

| Alloy | Layer Position | Standard Cladding Ratio Range (%) |

| AA3003 | Inner layer on one side adjacent to the core | 8 – 12 |

| AA3003 | Inner layer on the other side adjacent to the core | 8 – 12 |

| AA4104 | Outer surface layer on one side (one of the filler layers) | 12 – 18 |

| AA4104 | Outer surface layer on the other side (one of the filler layers) | 12 – 18 |

Typical application fields

6951 five-layer aluminum brazing clad sheet is a specialized material developed for high-reliability heat exchangers and thermal management systems. Compared with general brazing sheets using 3003, 6061, and similar alloys as the core, it maintains microstructural stability, post-braze strength retention, and corrosion life near brazing temperatures, making it highly suitable as the core load-bearing layer and plate material for high-performance heat exchangers.

Aerospace heat exchangers

Engine oil coolers, fuel coolers, and environmental control system (ECS) heat exchanger cores, designed for high temperature, high pressure, strong vibration, and long-service platforms.

Automotive and commercial vehicle heat exchange systems

Engine radiators, intercoolers, engine oil coolers, and transmission oil coolers, suitable for high refrigerant pressure and frequent thermal cycling conditions.

HVAC and industrial cooling equipment

Building HVAC heat exchangers, chillers, industrial oil coolers, and compressor coolers, meeting long-term continuous operation and low leakage requirements.

Other industrial heat exchange scenarios

Oil coolers and water coolers for construction machinery, marine equipment, and power generation equipment, used in heat exchange systems operating under high salt spray, high corrosion, or high load environments.

Other types of 6951 clad brazing sheets

In addition to supplying high-grade five-layer brazing clad sheets with 6951 aluminum as the core, Chalco can also provide other types of brazing clad sheets using 6951 as the core material to meet differentiated requirements for cost, service life, and operating conditions across different heat exchanger platforms.

-

4104 + 6951 + 4104

High-strength brazing clad sheet with 6951 as the core and 4104 cladding on both sides, suitable for medium-pressure heat exchangers in automotive and HVAC applications.

-

6951 core, 4104 clad, double-sided cladding

Used for plate structures requiring brazed joints on both sides, suitable for conditions where both the upper and lower surfaces of plates in stacked heat exchanger cores need to be sealed and connected simultaneously.

-

6951 core + 4343 clad, single-sided cladding

Compliant with AMS4255 specification, used for structures where brazing is required on one side while avoiding filler metal on the other, such as heat exchanger components with one-sided contact surfaces for fins or tubes.

-

6951 core, 4343 clad, double-sided cladding

Compliant with AMS4256 specification, used in heat exchanger cores where both sides of the plate are brazed simultaneously to fins and tubes, such as multi-channel plates for oil coolers, radiators, and condensers.

-

6951 core, 4045 clad, single-sided cladding

Compliant with AMS4465 specification, used for single-sided brazing structures requiring higher filler metal flowability, such as brazed plates with larger local gaps or complex cavity geometry on one side.

-

6951 core, 4045 clad, double-sided cladding

Compliant with AMS4460 specification, used for high-strength, high-reliability multi-surface brazed heat exchanger cores, suitable for critical components such as oil coolers and fuel coolers operating under high pressure and severe thermal cycling conditions.

If the above types still cannot meet your design or operating requirements, we can also customize other types of brazing clad sheets according to drawings and target working conditions, including specialized structures with different cores, cladding alloys, cladding layer counts, and cladding ratios.

Comparison of different core materials: 6951 vs 3003 vs 6061

| Alloy | 3003 | 6061 | 6951 |

| Positioning | General heat exchanger core material | High-strength alloy for structural and machined parts | Specialized brazing core material for heat exchangers |

| Brazing Compatibility | Suitable for conventional brazing | Narrow brazing window, difficult to control | Suitable for CAB / VB |

| Post-braze Strength | Medium | Significant decrease | High |

| Formability | Good | Average | Good |

| Corrosion Resistance | Medium | Excellent (but not targeted for heat exchanger corrosion conditions) | High (when paired with the five-layer structure) |

| Recommended Applications | Standard automotive / HVAC heat exchangers | Load-bearing structures, machined parts | High-pressure / high-corrosion / long-service heat exchangers and cold plates |

Brazing process compatibility and process window

Applicable brazing processes

Chalco 6951 five-layer aluminum brazing clad sheet is well compatible with mainstream Controlled Atmosphere Brazing (CAB) and Vacuum Brazing (VB) processes:

CAB furnace lines: Suitable for mass production of automotive and HVAC heat exchangers. The 6951 core maintains microstructural stability under typical furnace temperature profiles, and the double-sided 4104 brazing layers ensure reliable wetting and filling.

VB furnace lines: Suitable for heat exchangers requiring higher cleanliness and weld quality, such as oil coolers and cold plates. The five-layer structure helps control residues and long-term corrosion risks.

Typical process window

Key parameters can be referenced within the following ranges and further optimized based on the specific furnace type and component design:

- Preheating zone temperature: approx. 450–560 °C

- Peak brazing temperature: approx. 580–610 °C

- Soaking time and heating rate: set according to plate thickness, furnace load, and structural complexity to ensure complete melting of the brazing layers while controlling core sagging and collapse.

Surface quality

Chalco 6951 five-layer aluminum brazing clad sheets are factory-controlled to ensure flat, clean surfaces free from indentations, folds, severe scratches, and corrosion marks that may affect brazing quality; any allowable minor appearance defects must not impact subsequent forming, assembly, or weld continuity.

The strip must maintain good shape in both longitudinal and transverse directions, avoiding noticeable waviness, warping, or twisting. Flatness and dimensional tolerances may follow ANSI H35.2 / EN 485-4 or mutual agreement; for thin gauges such as 0.30–0.80 mm, curl and shape stability are strictly controlled to facilitate subsequent processing and fixturing.

Sheet edges must be free from heavy burrs and split edges, and coil ends must remain neat. Corner and edge protection can be added when required to improve consistency during transportation and delivery.

Family of complementary aluminum brazing materials

Around the 6951 five-layer aluminum brazing clad sheet, Chalco can also supply complementary aluminum fin stock, tubing, and other brazing clad sheet products. Optional ranges include:

- Fin stock: 3003 / 3102 aluminum fin strip;

- Tubing: 3003 / 6063 / 6061 round tubes, flat tubes, and other heat exchanger tubes;

- Other brazing clad sheets: three-layer or multi-layer clad sheets using 3xxx series as the core with 4104 / 4045 / 4343 aluminum–silicon brazing cladding.

Through a unified alloy system and clad design, customers can conveniently achieve material matching and process optimization for plates, fins, tubes, and end plates within the same platform.

Typical combinations and selection recommendations

For heat exchanger platforms using 6951 as the core, a common combination is:

6951 five-layer plate + 3xxx series fins/tubing

For cost-sensitive platforms with relatively moderate operating conditions, three-layer brazing sheets with 3xxx as the core can be selected and produced within the same or a similar brazing process window.

Chalco can recommend alloy and structural combinations for plates, fins, and tubes based on refrigerant type, system pressure, target service life, plate thickness, and structural design, helping customers strike the right balance among cost, service life, and reliability.

Supply and services

Supply form and MOQ

Chalco 6951 five-layer aluminum brazing clad sheets can be supplied as coils and cut-to-length sheets, covering conventional thickness and width ranges.

The specific MOQ varies with thickness, width, structure type (five-layer / three-layer), and whether the dimensions fall within standard specifications, and will be confirmed in the contract or technical agreement.

For new projects or validation stages, smaller trial batches can be negotiated under conditions that meet process requirements, helping reduce initial introduction costs.

Lead time and sampling support

Standard specifications can be delivered according to regular production schedules; special thickness/width or customized cladding ratios require additional time for supporting process validation and production planning.

Chalco can provide trial coils/sheets to support brazing process debugging, joint evaluation, leakage and durability verification, and jointly confirm mass production specifications and technical conditions based on trial results.

Packaging

Packaging can follow ASTM B660 and other relevant specifications, with moisture-proof and damage-prevention solutions selected according to sea, land, or air transportation; edge and end protection is applied to both coils and sheets before shipment to facilitate handling and storage.

FAQ

When is the 6951 five-layer structure more suitable?

It is ideal for high pressure, high refrigerant corrosion, severe thermal cycling, or long-service platforms. Compared with 3003 three-layer material, the 6951 five-layer structure offers advantages in post-brazing strength, anti-sag performance, and corrosion life; if operating conditions are moderate and cost is the priority, the three-layer structure remains an option.

Is the 6951 five-layer the only option?

No. In addition to the five-layer structure, 6951 three-layer brazing clad sheets are also available, along with multiple structures using 3xxx as the core clad with 4104 / 4045 / 4343 and other aluminum–silicon brazing alloys. Selection can be based on operating severity, cost target, and platform compatibility.

Can it be used with existing CAB / vacuum brazing furnace lines?

Yes. The 6951 five-layer structure is compatible with both CAB and VB processes, with a typical peak temperature of approximately 580–610 °C. Final mass-production parameters must be adjusted according to furnace type and component structure, and Chalco can assist verification with trial coils / trial sheets.

Is a complete heat exchanger material solution supported?

Yes. Supporting materials such as fin stock, tubing, and other brazing clad sheets can be supplied. A common combination is "6951 five-layer plate + 3xxx series fin / tubing.” Material pairing recommendations can be provided based on refrigerant type, pressure, and service life objectives.

How are MOQ and lead time arranged?

MOQ and lead time depend on size specifications and structure type and are confirmed by contract or technical agreement. Small-batch prototyping and sampling are supported for process validation in new projects or material upgrades..

Technical parameters of 6951 five-layer brazing clad sheet

Mechanical properties

| Property | Yield strength Rp0.2 (MPa) | Tensile strength Rm (MPa) | Elongation A50 (%) |

| Minimum (Min.) | 110 | 120 | 2 |

| Maximum (Max.) | — | 170 | — |

Chemical composition

| Elements / Alloy | AA6951 (%) | AA3003 (%) | AA4104 (%) |

| Si | 0.20–0.50 | ≤0.60 | 9.0–10.5 |

| Fe | ≤0.80 | ≤0.70 | ≤0.80 |

| Cu | 0.15–0.40 | 0.05–0.20 | ≤0.25 |

| Mn | ≤0.10 | 1.0–1.5 | ≤0.10 |

| Mg | 0.40–0.80 | ≤0.05 | 1.0–2.0 |

| Cr | ≤0.05 | ≤0.05 | ≤0.05 |

| Zn | ≤0.20 | ≤0.10 | 0.02–0.20 |

| Bi | ≤0.05 | ≤0.05 | ≤0.20 |

| Zr | ≤0.05 | ≤0.05 | ≤0.05 |

| Ti | ≤0.05 | ≤0.05 | ≤0.05 |

| Ni | ≤0.05 | ≤0.05 | ≤0.05 |

| Al | Remainder | Remainder | Remainder |

| Other(each) | 0.05 | 0.05 | 0.05 |

| Other(total) | 0.15 | 0.15 | 0.15 |

Pre-braze bending performance and formability

To meet the complex forming requirements of bending, flanging, corrugating, and box bending for aerospace and core heat exchanger components before brazing, Chalco 6951 five-layer brazing clad sheet provides excellent room-temperature bending ductility in the as-supplied condition.

| Nominal Thickness | Bend Factor | Minimum Bend Radius | Conclusion |

| ≤ 0.019 in (≤ 0.48 mm) | 1 | Rmin = 1t | Passes 180° bend without cracking |

| > 0.019 – 0.050 in (0.48–1.27 mm) | 2 | Rmin = 2t | Passes 180° bend without cracking |

| > 0.050 – 0.113 in (1.27–2.87 mm) | 3 | Rmin = 3t | Passes 180° bend without cracking |

| > 0.113 in (> 2.87 mm) | Subject to mutual agreement | As agreed | Determined per design requirements |

Under the above conditions, Chalco 6951 five-layer brazing clad sheet in the as-supplied condition can meet the requirement of 180° bending without cracking, making it suitable for pre-braze forming of heat exchanger plates, side members, and bent manifold plates.

Request a quote

Chalco supplies 6951 five-layer aluminum brazing sheet in coil and cut-to-length sheet for high-performance heat exchangers and cooling systems. With stable quality, controlled clad ratios and custom dimensions, we support your automotive, HVAC and aerospace projects.

Share your drawings or specifications and our team will provide material recommendations and a tailored quotation within 24 hours.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote