Why choose 6101 precision-ground rod?

Under the T6 temper, 6101 ground rod maintains strength while meeting ≥59.5 IACS conductivity, making it suitable for electrical connectors and high-voltage terminals.

Optimized for Swiss-type (sliding-head) guide-bushing turning: tight control of straightness and roundness, double-chamfered ends, and a −0.02 mm negative diameter tolerance together ensure smooth automatic feeding; long bars remain stable at 8,000 rpm.

The coarse-grain ring <0.5 mm effectively avoids white/snowflake blemishes, improving consistency for subsequent anodizing or appearance finishes.

Combined optimization of the 6101 ground rod and machining process improves chip breaking, forming short chips more easily, reducing bird-nesting and downtime, and extending tool life and part yield.

Specifications & precision

Dimensions & geometric tolerances

Diameter tolerance: default −0.02 mm (custom ±0.02 mm available)

Straightness: ≤0.2 mm/m

Roundness: ≤0.005 mm

Ends: double-chamfered; smooth automatic feeding without jamming

Speed validation: no visible vibration/tool marks at 8,000 rpm spindle speed

Supply temper: T6 standard; stress-relieved tempers (e.g., T651 / T6511) available to reduce machining distortion

Surface & coarse-grain control

Coarse-grain ring: <0.5 mm, delivering uniform anodized appearance and fewer blemishes

Supply length: standard 3 m / 6 m; cut-to-length and single-piece packaging supported

Chemical composition — GB/T 3190-2020

| Element | Content |

| Si | 0.30–0.70 |

| Fe | ≤0.50 |

| Cu | ≤0.10 |

| Mn | ≤0.03 |

| Mg | 0.35–0.80 |

| Cr | ≤0.03 |

| Zn | ≤0.10 |

| Ti | ≤0.10 |

| Others (single/total) | ≤0.05 / ≤0.15 |

| Al | remainder |

Mechanical properties — GB/T 3191-2019

| Specimen temper | Rm (MPa) | Rp0.2 (MPa) | A (%) | HB |

| T6 | ≥200 | ≥170 | ≥10 | ≥70 |

Machining process

Machining highlights

Precision-ground OD with a −0.02 mm (optional ±0.02 mm) tolerance; straightness ≤0.2 mm/m, roundness ≤0.005.

Double-chamfered ends for Swiss-type / guide-bushing machines; smooth feeding, fewer jams, reduced bushing wear.

Stable long-bar cutting at 8,000 rpm, with fine tool marks and low vibration.

"Turned-to-size” pre-processing: OD can be pre-turned to your machine’s usable size before shipment to shorten trial cuts and setup.

Coarse-grain ring <0.5 mm for more consistent anodizing, fewer white/snowflake blemishes.

Improved chip-breaking behavior for shorter chips, less bird-nesting and downtime, longer tool life, and higher part yield.

Optional T651 stress-relieved temper for more stable dimensions during secondary machining.

Tooling & process

Carbide/PCD tools with large positive rake, polished chip grooves, and aluminum-specific chipbreakers.

Coolant: water-soluble 6–10% or MQL; use EP cutting oil for tapping/rolling.

Verify guide-bushing concentricity and preload; use follow rest/tailstock for slender parts.

Finishing turns with small depth of cut/feed; milling with polished 3-flute aluminum cutters, high surface speed, and small radial engagement.

Quality & yield

Pre-machining sampling of OD/straightness/roundness; keep a consistent negative OD tolerance within a lot.

Complete deburr and chamfer in the same setup to reduce re-clamping error.

First-article 100% inspection plus patrol checks for key dimensions (OD, threads, coaxiality, etc.).

For anodized parts, choose lots with coarse-grain ring <0.5 mm and keep pretreatment cycles consistent.

Common issues & remedies

Long chips / bird-nesting: increase feed, use Al-specific chipbreaker, optimize coolant delivery.

Chatter / fine ripples: shorten overhang, re-check bushing concentricity/preload, verify clamping and straightness.

Dimensional drift: use T651 temper; add a cooling dwell between rough and finish cuts.

Anodizing blemishes / color variation: select lots with smaller coarse-grain ring; standardize pretreatment/dye; improve surface finish.

Delivery & collaboration

Cut-to-length, pre-turned OD, double-chamfered ends, and individual protective packaging.

Provide EN 10204 3.1 plus chem/mech/dimension/appearance reports (optional IACS and coarse-grain evaluations).

Send drawings; 48-hour manufacturability review and cost-down suggestions.

Applications

New energy vehicles (EV)

High-voltage connector terminals, bus terminals, and grounding posts are turned from 6101 ground rod to balance conductivity and assembly strength. The OD negative tolerance, straightness, and roundness stabilize fit and contact resistance; double-chamfered ends support smooth guide-bushing feed; T651 reduces machining distortion; coarse-grain ring <0.5 mm improves anodized appearance consistency.

DC fast chargers

High-voltage connector terminals and plug-in core parts must resist outdoor corrosion and minimize contact temperature rise. Long bars remain stable at 8,000 rpm with better surface quality and repeatability; improved chip-breaking cuts downtime and entanglement.

Standards & equivalents

- American Aluminum Association (AA): 6101

- UNS: A96101

- ISO: R209 E-AlMgSi

- China: GB 6101

- France: NF A-GS/L

- UK: BS 6101A(91E)

- Germany: DIN EN AW6010/5/3/2037

- Japan: JIS A6101 (ABC×2)

Supply capabilities

Available tempers: mainly T6; stress control via stretch stress-relief (e.g., T6511), or balance conductivity/strength with T61/T63/T64 as required.

Cutting & tolerance: cut-to-length with a −0.02 mm default negative OD strategy; provide straightness/roundness inspection data.

Certificates & testing: EN 10204 3.1 MTC, chemical & mechanical reports; optional IACS conductivity and appearance/coarse-grain evaluations.

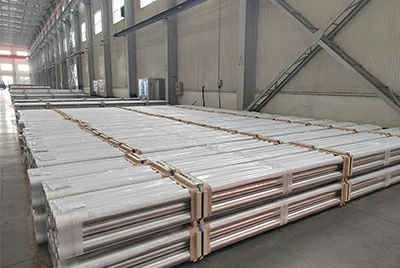

Packaging: foam wrap + moisture barrier + corner/bump protection + fumigated wooden crate for ocean/air freight.

FAQ

Q: What’s the value of ground rod vs. standard extruded rod?

A: Tighter dimensions and geometry; with double-chamfered ends and a negative OD strategy, feeding is smoother, vibration is lower, and yield is higher.

Q: Can you supply ±0.02 mm symmetric tolerance?

A: Yes. Default is −0.02 mm for bushing/assembly friendliness; ±0.02 mm is available on request.

Q: How to reduce machining deformation?

A: Choose stress-relieved (T651) supply and include straightness/residual-stress checks in incoming inspection; pre-turn OD and consider thermal aging when needed.

Q: Can you supply OD ready for my guide bushing?

A: Yes. We can pre-turn OD to your machine’s usable size while keeping the −0.02 mm strategy for smooth clamping.

Q: How do you ensure stability at 8,000 rpm?

A: By controlling straightness and roundness with double-chamfered ends, plus uniform microstructure and stress relief for high-speed stability.

Q: How to control anodizing color variation?

A: Keep the coarse-grain ring <0.5 mm, and standardize pretreatment/dye cycles for consistent appearance.

Q: Is stress-relieved temper available?

A: Yes, T651 is available for distortion-sensitive precision machining.

Request a quote

Chalco Aluminum stocks 6101 precision-ground rod year-round with custom machining and fast delivery. Send drawings or size requirements for same-day pricing and technical support.

Contact us: sale@chalcoaluminum.com