Why choose 6082 aluminum grinding rods?

6082 aluminum grinding rods offer high geometric precision with diameter tolerance ≤ -0.02 mm, straightness ≤ 0.2 mm/m, and roundness ≤ 0.005, ensuring high-accuracy machining. The double-ended chamfer design reduces guide bush wear and enables smooth automatic feeding without jamming.

T651 stress-relieved temper keeps machined parts stable and resistant to deformation. The coarse grain ring is controlled to <0.5 mm, preventing white spots and streaks after anodizing and ensuring consistent appearance. Improved machinability reduces chip-breaking problems, increases yield, and extends tool life.

Stock sizes

| Product | Alloy | Temper | Diameter (mm) | Length (mm) |

| Grinding rod | 6082 | T6 | 10.2 | 3000 |

| Grinding rod | 6082 | T6 | 10 | 3000 |

| Grinding rod | 6082 | T6 | 11 | 3000 |

| Grinding rod | 6082 | T6 | 12 | 2500 |

| Grinding rod | 6082 | T6 | 13 | 2500 |

| Grinding rod | 6082 | T6 | 13 | 2950 |

| Grinding rod | 6082 | T6 | 14.2 | 3000 |

| Grinding rod | 6082 | T6 | 15.2 | 3000 |

| Grinding rod | 6082 | T6 | 15 | 2500 |

| Grinding rod | 6082 | T6 | 15 | 2800 |

| Grinding rod | 6082 | T6 | 15 | 3000 |

| Grinding rod | 6082 | T6 | 16 | 3000 |

| Grinding rod | 6082 | T6 | 19 | 2500 |

Click here to view full stock sizes

Dimensions and tolerances

Diameter tolerance: ≤ -0.02 mm (customizable to H7/H8/H9)

Straightness: ≤ 0.2 mm/m

Roundness: ≤ 0.005

Chamfer: double-ended chamfer, suitable for automatic feeding

Surface roughness: Ra 0.3–0.8 μm (optional)

Supply length: 3 m / 6 m, supports cut-to-length

Chemical composition (GB/T 3190-2020)

| Element | Content (%) |

| Si | 0.7–1.3 |

| Fe | ≤0.5 |

| Cu | ≤1.0 |

| Mn | 0.4–1.0 |

| Mg | 0.6–1.2 |

| Cr | ≤0.25 |

| Zn | ≤0.2 |

| Ti | ≤0.10 |

| Zr | — |

| Others | Single ≤0.05; total ≤0.15 |

| Al | Balance |

Mechanical properties (GB/T 3191-2019)

| Diameter range | Temper | Tensile strength Rm (MPa) | Yield strength Rp0.2 (MPa) | Elongation A (%) | Hardness (HB) |

| ≤20 mm | T6 | ≥295 | ≥250 | ≥8 | ≥95 |

| >20 mm | T6 | ≥310 | ≥260 | ≥8 | ≥95 |

Processing technology

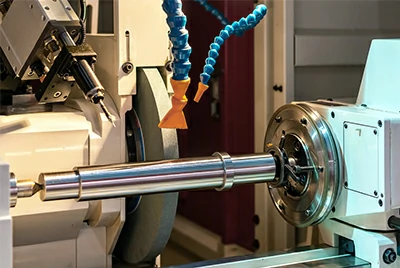

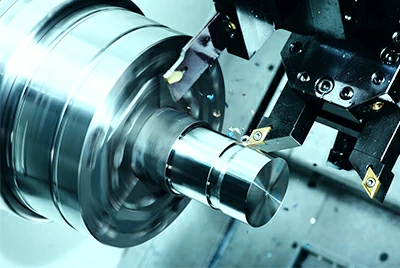

High-precision Swiss-type/guide bushing turning

Diameter tolerance up to ±0.02 mm, straightness ≤0.2 mm/m, and roundness ≤0.005 mm ensure stable performance even at 8,000 rpm on high-speed spindles, reducing vibration and tool marks.

Double-ended chamfering and automatic feeding

The double-ended chamfer design allows bars to enter guide bushings and feeding systems more smoothly, preventing jamming and improving automation efficiency.

"Turning stock” solution

Bars can be pre-turned at the factory to match customer equipment dimensions, taking into account guide bushing limits and clamping length. This reduces trial cuts and shortens setup time.

Chip breaking and tool life

Uniform grain structure combined with sharp positive-rake tools and chip breakers effectively minimizes long chips, prevents tool entanglement, extends tool life, and improves finished part yield.

Anodizing consistency

Coarse grain ring is controlled to below 0.5 mm, reducing white spots and streaks, ensuring more consistent anodized surface color and appearance.

Stress-relieved condition

T651 temper undergoes stress-relieving stretch treatment, preventing deformation after machining, especially suitable for long shafts and thin-walled parts with high dimensional stability requirements.

Application fields

Aerospace industry

6082 aluminum grinding rods are used for aircraft structural parts, connectors, and precision components, offering lightweight properties with medium strength. T651 stress relief ensures stability after machining and improves assembly reliability.

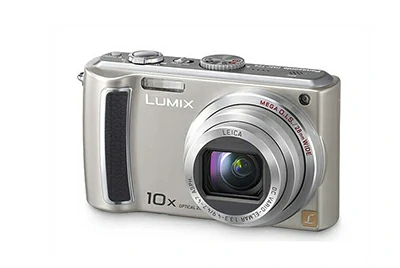

Optics and precision instruments

In components such as camera lenses and couplers, the ±0.02 mm tolerance and excellent machinability of 6082 grinding rods ensure dimensional accuracy. Controlled coarse grain ring below 0.5 mm reduces anodizing color variations and enhances appearance consistency.

Marine and offshore equipment

In ship parts and hardware manufacturing, 6082 provides good corrosion resistance. Double-ended chamfering and high straightness enable smoother automatic feeding, improving processing efficiency.

Electronics and electrical industry

6082 aluminum grinding rods are widely used in electronic parts, connectors, and electrical components. High dimensional consistency and excellent weldability ensure precise assembly and conductivity, suitable for mass production.

Automotive and braking systems

Components such as hinges, rod ends, and brake pistons benefit from the medium strength and good machinability of 6082 aluminum grinding rods. Improved chip-breaking reduces tool entanglement and significantly increases finished product yield.

Hydraulic and valve industry

Hydraulic pistons, valves, and valve bodies are often made from 6082 grinding rods. The material combines strength and toughness to withstand frequent opening and closing impacts, while T651 stress relief ensures long-term dimensional stability.

Decorative and general hardware

In decorative and general hardware applications, 6082 aluminum grinding rods offer good formability and anodizing consistency, resulting in smooth surfaces without blemishes, meeting high aesthetic requirements.

Specifications and certifications

Standards: GB/T 3190-2020 (chemical composition), GB/T 3191-2019 (mechanical properties)

Certificates: EN 10204 3.1 mill test certificate available on delivery

Inspection reports: optional UT ultrasonic testing, pressure/gas tightness testing, dimensional inspection

Quality management: ISO 9001, AS9100, IATF 16949 certified

Available tempers and delivery

Tempers: T4 / T6 / T651

Packaging: pearl cotton + moisture-proof film + fumigated wooden cases, suitable for sea or air freight

Delivery: low MOQ, sample support, 48-hour sample dispatch available

Common information

T6 and T651 differ in that T651 is stretched to relieve internal stress after T6 treatment, making it more stable during machining and better suited for long slender shafts and thin-walled parts.

Compared with ordinary cold-drawn bars, grinding rods have higher diameter consistency, roundness, and surface finish; double-ended chamfering reduces feeding jams, lowering downtime and scrap rates.

EN 10204 3.1 certificates and dimensional/straightness/roundness reports are available, along with optional UT, pressure, or leak tests.

Pricing depends on temper (T6/T651), diameter and length, tolerance grade, quantity, machining and inspection requirements, and delivery terms (FOB/DDP).

Small MOQ and samples are supported; customized turning stock can be supplied, with bars pre-turned to customer-required outer diameters and lengths before shipment.

For chip control and tool life, sharp positive-rake aluminum inserts are recommended, with chip breakers and sufficient coolant to reduce built-up edge and long chip formation.

Contact us

Chalco Aluminum maintains regular stock of 6082 aluminum grinding rods, supporting customized processing and fast delivery. Send us your drawings or dimensional requirements to receive same-day quotations and technical support.

Contact us now: sale@chalcoaluminum.com