Core Product Introduction: 6061 T62 Forged Plate

Compatible with 4000T forging presses, with finished plate sizes ranging from 100–4000 mm × 100–1600 mm and a single-piece weight up to 5 t.

Compatible with 8000T forging presses, with finished plate sizes ranging from 100–4000 mm × 100–2000 mm and a single-piece weight up to 8 t.

6061 forged plate offers high strength, corrosion resistance, and excellent machinability. With stress relief and controlled microstructure, it maintains flatness and dimensional stability even after large window milling or vacuum baking, while significantly reducing anodizing color variation.

It is particularly suitable for semiconductor vacuum chambers, probe station bases, precision jigs, and wafer handling platforms, ensuring both dimensional accuracy and long-term reliability in demanding applications.

Specifications and Quality Systems

Compliant with international standards such as ASTM B209, AMS4027, and ASME SB209 for chemical composition and mechanical properties.

Certified to IATF 16949 Automotive Quality Management System, AS9100D:2015 Aerospace Quality Management System, ISO 22163 Railway Industry Quality Management System, and ISO 9001 Quality Management System.

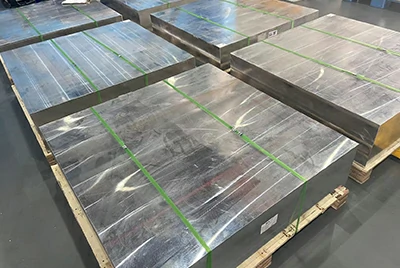

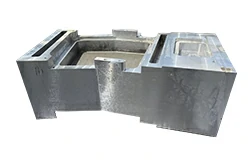

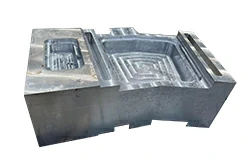

Delivered Product Showcase

Large-Size Forged Plate

3525 × 1585 × 252 mm

3525 × 1585 × 252 mm

1910 × 1172 × 485 mm

1720 × 1210 × 270 mm

1710 × 1635 × 340 mm

1375 × 996 × 470 mm

1175 × 1050 × 235 mm

1175*1050*235mm

1136*1012*330mm

Medium-Thickness Forged Plate

860*605*265mm

720*480*220mm

745*735*190mm

860*605*265mm

720*480*220mm

745*735*190mm

Small and Medium-Size Forged Plate

545*520*410mm

420×420×340mm

580*410*190mm

545*520*410mm

420×420×340mm

580*410*190mm

Chemical Composition

Comparison of 6061 Standard vs. 6061 Semiconductor

| Element | 6061 Standard Composition (%) | 6061 Semiconductor Composition (%) |

| Si | 0.4-0.8 | 0.5-0.7 |

| Fe | ≤ 0.7 | ≤ 0.2 |

| Cu | 0.15-0.40 | 0.2-0.3 |

| Mn | ≤ 0.15 | ≤ 0.05 |

| Mg | 0.8-1.2 | 0.8-1.2 |

| Cr | 0.04-0.35 | 0.04-0.06 |

| Zn | ≤ 0.25 | ≤ 0.05 |

| Ti | ≤ 0.15 | ≤ 0.05 |

| Other | ≤ 0.15 | ≤ 0.05 |

| Al | Reminder | Reminder |

6061 Standard Alloy: Meets the strength and processing requirements for general structural parts, aerospace, and transportation applications.

6061 Semiconductor-Grade Alloy: Features narrower composition ranges and lower impurity levels. Designed to improve flatness, anodizing consistency, and vacuum tightness, making it suitable for wafer chambers, precision jigs, vacuum components, and other semiconductor/electronic applications.

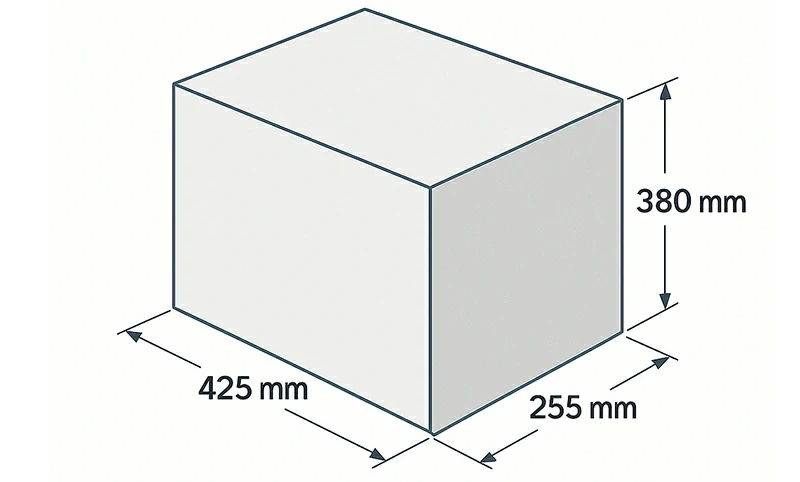

Physical Properties

Length direction: 425 mm

Width direction: 255 mm

Thickness direction: 380 mm

Physical properties (according to GB/T 16865)

| Physical properties (according to GB/T 16865) | ||||

| Sampling Direction (Edge) | Tensile Strength Rm / MPa | Yield Strength Rp0.2 / MPa | Elongation % | |

| Longitudinal (L): Minimum | 260 | 240 | 7 | |

| Actual Value | 327 | 296 | 13.3 | |

| Long Transverse (LT): Minimum | 255 | 235 | 5 | |

| Actual Value | 320 | 290 | 12 | |

| Short Transverse (ST): Minimum | 220 | 240 | 3 | |

| Actual Value | 315 | 283 | 11.3 | |

Strict control of trace elements affecting anodizing performance ensures that 6061 alloy can be mass-produced without color variation, while providing excellent breakdown voltage resistance and corrosion resistance.

Comparison of 6061-T652 vs. 6061-T651 Conditions

| Item | 6061-T651 | 6061-T652 |

| Heat treatment path | Solution treatment → Tensile stress relief → Artificial aging | Solution treatment → Compressive stress relief → Artificial aging |

| Stress relief method | Residual stress released through tensile stretching | Residual stress released through compression |

| Residual stress control | Effective for small to medium plates, but large thick plates may still show instability | More effective for large thick and oversized plates, ensuring better flatness stability |

| Typical applications | General structural parts, load-bearing components, conventional machining parts | Semiconductor thick plates, large panels, vacuum chambers, fixtures and base plates requiring high flatness |

| Anodizing performance | Good uniformity, but thick plates may deform slightly due to residual stress | Controlled microstructure + compressive stress relief, ensuring higher consistency in anodized appearance of thick plates |

| Common standards | ASTM B209 / AMS4027, etc. | ASTM B209 / AMS4027, etc. (some customer drawings specifically require T652) |

| Supply | Widely applied, commonly available | Preferred in semiconductor/aerospace and other high-demand fields; suppliers must have large-tonnage forging and precision heat treatment capabilities |

Application Fields

Aerospace

Aircraft structural parts, engine rings, fuselage frames, and vacuum chambers, meeting requirements for lightweight, high strength, and reliability.

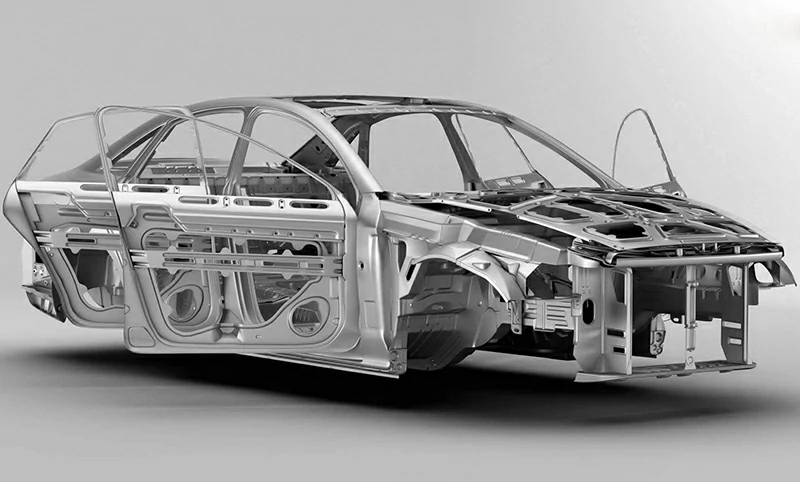

Automotive Industry

Used in chassis parts, suspension systems, engine components, and EV battery housings, combining fatigue resistance, impact strength, and machining precision to support lightweighting and energy efficiency.

Rail Transit

Key structural and load-bearing components for high-speed trains and subways, offering toughness, fatigue resistance, and long service life, compliant with ISO 22163.

Semiconductor Equipment

Widely used in vacuum chambers, probe station bases, precision jigs, and wafer platforms. Stress-relieved materials ensure dimensional stability and vacuum reliability.

Electronics & Communication

Applied in 5G base stations, 3C electronics, and advanced heat dissipation components, with excellent thermal conductivity and dimensional accuracy for high-performance electronics.

Processing Technology and Production Capacity

Casting

A sound casting structure is the foundation of high-performance forgings. The company operates five 35T casting lines, three of which are equipped with Hydro degassing systems and low-pressure casting machines. All lines are equipped with tubular filtration systems to ensure clean and stable melt quality.

Supporting this are two advanced homogenization lines, each with six 35T homogenizing furnaces and four cooling furnaces, enabling automated logistics and production management. In addition, the company has five Suzhou Boneng static furnaces with a monthly capacity of 18,000 tons, and twelve Foshan Hangxing homogenizing furnaces with a monthly capacity of 16,000 tons.

With this complete and advanced casting and homogenization capability, the company stably produces high-quality aluminum alloy materials, widely used in semiconductor equipment, 5G communications, 3C electronics, and automotive components.

Forging

Forging technology and equipment configuration are the core to producing high-quality forgings. Our forging workshop is equipped with four servo multi-station presses (2500T–8000T), integrated with automatic temperature-controlled furnaces (±8 ℃ accuracy) and rail-operated manipulators, enabling fully automated production from heating to forming.

In terms of capacity and equipment, we operate two Hefei 40MN forging presses (monthly capacity 600 tons), one Tianjin Tianduan 25MN quick forging press (monthly capacity 200 tons), and one Tianjin Tianduan 80MN forging press (monthly capacity 800 tons). This configuration provides a complete capability range, covering small and medium forgings (around 100 kg) up to large products (up to 8 tons).

Backed by extensive experience in 2XXX–7XXX series alloy development and certified quality systems (IATF 16949 Automotive QMS, AS9100D:2015 Aerospace QMS), we are able to stably supply semiconductor forged plates, rings, and various complex shapes, meeting the stringent requirements of high-end industries.

Sawing

The sawing workshop is equipped with three vertical CNC band saws (processing range 0–4 m × height 1.4 m) and one horizontal band saw, achieving cutting accuracy of 3–5 mm in compliance with national standards.

Vertical band saws are particularly suitable for efficient pre-processing of slabs and forgings, reducing raw material loss by approximately 18%. The equipment adopts variable frequency drive technology, achieving 23% energy savings compared with traditional methods, and further reduces overall costs by 8% through process optimization.

In addition, the company is equipped with large-scale Lianshida vertical saws, including two units dedicated to slabs (monthly capacity 450 tons) and one unit dedicated to forgings (monthly capacity 360 tons).

Machining

The machining workshop is equipped with four horizontal lathes (CW6193B, CW61160B) and two vertical CK5240 series turning centers, enabling precision machining of forgings in multiple specifications. All equipment is integrated with UT ultrasonic flaw detection systems, strictly following GB/T 6519 standards, to achieve 100% inspection and rejection of Class A internal defects (≤Φ1.2 mm equivalent). While ensuring quality, the machining cycle is reduced by 32% compared with conventional processes.

Currently, the company operates four Anyang/Shenyang Machine Tool 6193/1610 lathes (monthly capacity 450 tons), one Dalian Baofeng 2 m vertical lathe (monthly capacity 240 tons), and one Dalian Baofeng 4 m vertical lathe (monthly capacity 300 tons). Certified to ISO 22163 Railway Quality Management System and ISO 9001 Quality Management System, we provide customers with high-precision, reliable, and fully traceable machining services.

Heat Treatment

The heat treatment workshop is equipped with two intelligent quenching furnaces (3.4T–9.6T) and one direct-injection 7T aging furnace, all supplied by Anzhong Machinery. The equipment adopts a six-zone PID precise temperature control system to achieve a uniform field of ±3 ℃, and is fitted with real-time temperature monitoring modules that allow full-process heat treatment curve tracking and data traceability.

The setup includes one 9.6T quenching furnace (monthly capacity 900 tons), one 3.4T quenching furnace (monthly capacity 360 tons), and one 7T aging furnace (monthly capacity 250 tons), providing comprehensive heat treatment capabilities.

Fully integrated with the forging production line, the process cycle is reduced from the conventional 48 hours to just 26 hours, significantly improving efficiency while ensuring aerospace-grade forging performance and on-time delivery.

3.4T Quenching Furnace

7T Aging Furnace

9.6T Quenching Furnace

Product Inspection

Chemical Composition Testing

Chemical composition is strictly controlled in accordance with internal standards stricter than customer requirements. Composition analysis is performed using a German SPECTRO spectrometer and a U.S. Thermo 3460 spectrometer, with four tests per furnace to ensure greater accuracy.

Spectrometer

Chemical composition analysis

Mechanical property testing

Macro & micro examination, internal structure, dimensional and surface quality

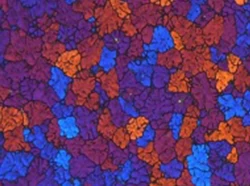

Samples from each furnace are subjected to macro- and microstructure inspection to ensure billets are free from inclusions, coarse grains, slag, overheating, or bright grain defects, strictly guaranteeing internal quality.

For forged bars and billets requiring high internal soundness, 100% ultrasonic testing is performed for every furnace. Surface quality is also inspected at 100% for each furnace, and dimensions and straightness are randomly checked on 5 pieces per furnace.

Macro examination

Micro examination

Artightness testing equipment

Packaging and Delivery

6061-T652 semiconductor forged plates are packed with multiple layers of protection, including anti-static bags, moisture-proof film, pearl cotton, corner protectors, and fumigated wooden crates, ensuring safe long-distance transportation.

Each package is clearly labeled with furnace number, batch number, and inspection grade for easy verification upon receipt. Flexible delivery terms are available, including FOB, CIF, and DDP, with third-party inspection supported. For R&D or small-batch requirements, we provide rapid sampling and small-lot delivery, with the fastest lead time of just 7–10 days to shorten project cycles.

Frequently Asked Questions

Q: What is the difference between 6061-T652 and 6061-T651?

A: T651 releases residual stress through tensile stretching, while T652 uses compression. T652 is better suited for thick and large plates, ensuring more stable flatness.

Q: Can you supply in compliance with ASTM B209 and ASTM B594?

A: Yes. We can supply according to ASTM B209 and perform ultrasonic testing per ASTM B594 or GB/T 6519, with EN 10204 3.1 material certificates provided.

Q: How can anodizing streaks be avoided?

A: By controlling alloy composition and microstructure, optimizing heat treatment processes, and verifying with anodizing samples, streaks and color variations can be significantly reduced.

Q: What is the maximum supply size?

A: Up to 4000 × 2000 mm, with a single-piece weight of up to 8 tons.