Why choose 6061 aluminum grinding rods?

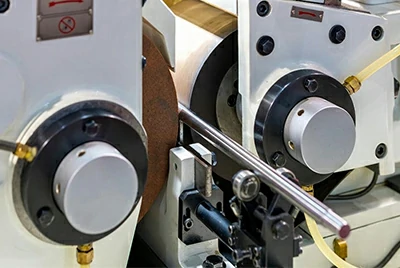

Designed for Swiss-type CNC lathes

The rods are centerless-ground with a diameter tolerance of ±0.02 mm, straightness ≤0.2 mm/m, and roundness ≤0.005 mm. Both ends are double-chamfered to ensure smooth automatic feeding without jamming. For equipment limitations, we can also pre-turn the outer diameter to match the guide bushing size, allowing the rods to be loaded directly for machining.

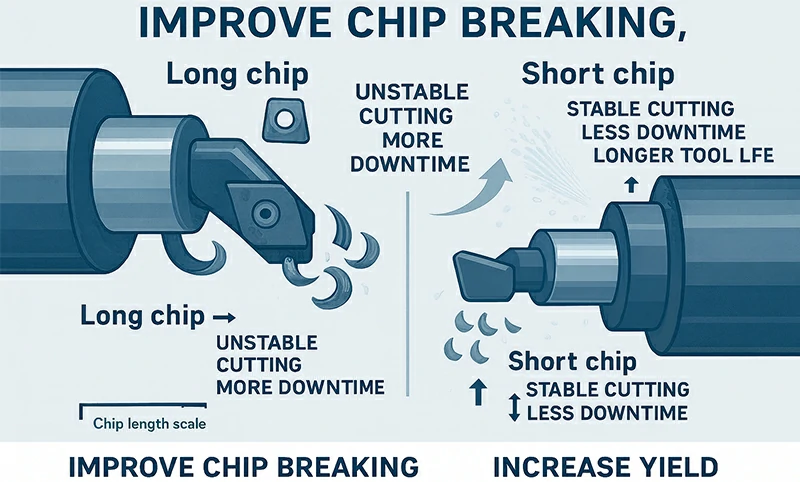

Improved chip breaking, higher yield

Optimized microstructure makes cutting easier to form short chips, preventing long chip entanglement. This reduces downtime, minimizes tool wear, and improves first-pass yield.

Better anodizing consistency

The coarse grain ring is strictly controlled to less than 0.5 mm, effectively avoiding white spots, streaks, and snowflake patterns, ensuring uniform color and consistent surface quality after anodizing.

Stock sizes

| Product | Alloy | Temper | Diameter (mm) | Length (mm) |

| Grinding rod | 6061 | T6 | 21.5 | 2500 |

| Grinding rod | 6061 | T6 | 31 | 2500 |

| Grinding rod | 6061 | T6 | 32 | 2500 |

| Grinding rod | 6061 | T6 | 22 | 2650 |

| Grinding rod | 6061 | T6 | 5 | 2300 |

| Grinding rod | 6061 | T6 | 5 | 2500 |

| Grinding rod | 6061 | T6 | 7 | 2500 |

| Grinding rod | 6061 | T6 | 18 | 2500 |

| Grinding rod | 6061 | T6 | 10.8 | 1850 |

| Grinding rod | 6061 | T6 | 10.8 | 1920 |

| Grinding rod | 6061 | T6 | 10.88 | 1850 |

| Grinding rod | 6061 | T6 | 10.88 | 1920 |

| Grinding rod | 6061 | T6 | 10.88 | 2500 |

| Grinding rod | 6061 | T6 | 10.9 | 3000 |

Click here to view full stock size list

Chemical composition (GB/T 3190-2020)

| Element | Content (%) |

| Si | 0.40–0.80 |

| Fe | ≤0.70 |

| Cu | 0.15–0.40 |

| Mn | ≤0.15 |

| Mg | 0.80–1.20 |

| Cr | 0.04–0.35 |

| Zn | ≤0.25 |

| Ti | ≤0.15 |

| Others | Single ≤0.05, Total ≤0.15 |

| Al | Balance |

Mechanical properties (GB/T 3191-2019)

| Property | Value |

| Temper | T6 |

| Tensile strength Rm (MPa) | ≥260 |

| Yield strength Rp0.2 (MPa) | ≥240 |

| Elongation A (%) | ≥8 |

| Hardness (HB) | ≥95 |

Machining process

Use sharp positive-rake carbide tools with chip breaker designs to form short chips quickly during cutting, avoiding long chip entanglement and improving surface finish.

Apply suitable cutting fluids to reduce built-up edge and cutting heat, extending tool life and lowering tool replacement frequency.

For Swiss-type CNC lathes, choose our pre-turned outer diameter grinding rods to match guide bushings, eliminating extra adjustments and reducing setup time.

Maintain consistent surface finish before anodizing to effectively minimize color variations and streaks, ensuring uniform appearance.

During tapping and reaming, ensure proper cooling and cleaning for better thread integrity and hole wall accuracy, reducing rework.

Perform deburring and chamfering in the same clamping to minimize secondary setup errors and maintain dimensional stability.

At high spindle speeds (up to 8000 rpm), strict control of straightness and roundness effectively suppresses vibration and tool marks, improving machine utilization.

Application fields

Aerospace and transportation industry

6061 aluminum grinding rods are used for fuselage structures, support brackets, and lightweight connectors. Medium strength and excellent machinability ensure structural integrity while reducing weight. Anodized surfaces remain uniform, extending service life and enhancing safety.

Automation and precision machinery industry

Guide shafts, locating pins, and coupling sleeves are made with 6061 grinding rods. Tolerance of ±0.02 mm and straightness ≤0.2 mm/m guarantee stability even at high-speed turning, enabling smooth automatic feeding, improved efficiency, and higher yield.

Communications and electronic equipment industry

Mounting brackets, heat dissipation connectors, and housing frames use 6061 rods. Excellent thermal conductivity and weldability ensure efficient heat transfer and structural reliability, meeting lightweight and high-reliability requirements while reducing thermal failure risks.

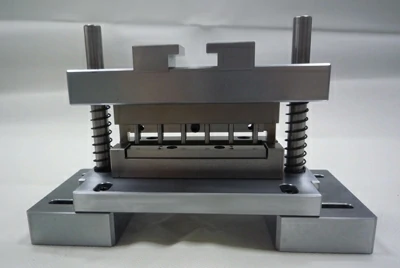

Mold and fixture industry

Jig posts, locating blocks, and clamping components are produced with 6061 rods. Stress-relieved T651 temper maintains dimensional stability after heavy machining, reducing deformation and rework, improving fixture durability, assembly accuracy, and production stability.

Energy and industrial equipment industry

Support shafts, sealing components, and bearing blocks adopt 6061 rods. Good corrosion resistance and medium strength guarantee long-term reliability in complex working conditions, with optional non-destructive testing (NDT) reducing downtime and maintenance risks.

Specifications and standards

Dimensional tolerances

Diameter tolerance: ±0.02 mm

Straightness: ≤0.2 mm/m

Roundness: ≤0.005 mm

Ends: double-chamfered for smooth automatic feeding

Optional: pre-turned OD to match guide bushings

Surface: centerless-ground for ready-to-machine finish

Supply conditions

T4 / T6 / T651 (stress-relieved), ensuring stability during machining and suitable for carbide tooling in precision parts.

Standards

ASTM B221

AMS-QQ-A-200/8

GB/T 3191

Production and quality assurance

Grinding and straightening

Multiple-pass centerless grinding combined with controlled straightening ensures straightness ≤0.2 mm/m. Even at 8000 rpm high-speed turning, rods run stably with no vibration.

Stress relief and microstructure control

T651 stress-relieving effectively reduces residual stress, preventing distortion after machining. The coarse-grain ring is strictly limited to ≤0.5 mm, ensuring consistent anodizing appearance.

Inspection and reports

Each batch undergoes dimensional checks for diameter, roundness, and straightness. Spectrochemical analysis, thread gauging, and optional NDT can be provided. EN 10204 3.1 material certificates and dimensional inspection records are available upon request.

Packaging, MOQ, and delivery

Rods are protected with pearl cotton, moisture-proof film, shock-absorbing pads, and fumigated wooden crates, suitable for sea or air transport.

Small MOQ is supported, with samples ready within 48 hours. Regular orders ship within 3–7 days.

Frequently Asked Questions (FAQ)

Q1: What is the difference between T6 and T651?

A: Both have similar strength, but T651 adds a stress-relieving stretch process on top of T6, reducing deformation after heavy machining. It is ideal for precision components.

Q2: Can you provide rods with double chamfering?

A: Yes. All our grinding rods are double-chamfered, and we can also pre-turn the outer diameter to match guide bushings.

Q3: Do you follow Chinese or international standards?

A: Chemical composition follows GB/T 3190-2020, and mechanical properties follow GB/T 3191-2019. We also supply to ASTM B221 and AMS standards.

Q4: Will anodizing cause white spots?

A: With coarse-grain rings strictly controlled under 0.5 mm, risks of white spots and streaks are greatly reduced. With proper anodizing process control, surface appearance remains stable.