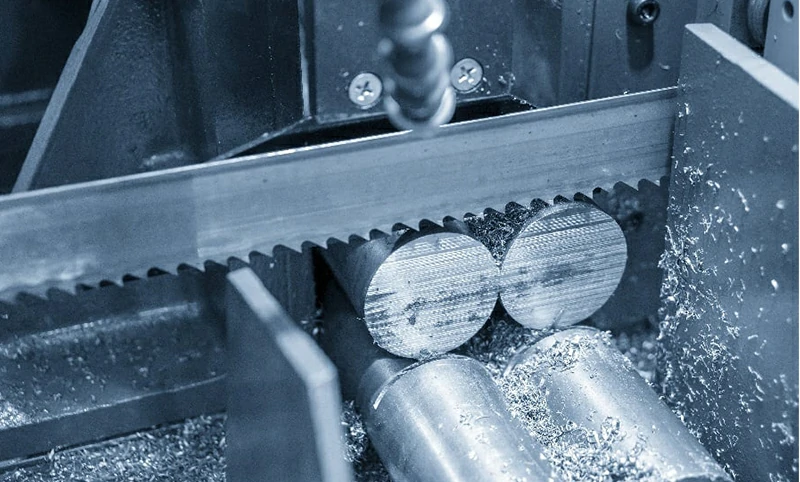

Why choose 5083 precision ground aluminum rod?

5083 aluminum grinding rod performs exceptionally in seawater and chloride environments, offering natural corrosion resistance and long-term service stability.

It has excellent weldability and belongs to the non-heat-treatable strengthening system, making post-weld strength and dimensional stability easier to control.

Parameters are optimized for high-speed guide bushing machining, with stable straightness and roundness, and double-end chamfering ensures smooth automatic feeding and consistent production rhythm.

The coarse grain ring is controlled to <0.5 mm, effectively reducing white spots and snowflake defects, ensuring a more uniform anodized appearance.

Full traceability is guaranteed, with each batch supplied with EN 10204 3.1 material and dimensional inspection records, reducing communication and acceptance costs from the source.

Chemical composition (Standard: GB/T 3190-2020)

| Element | Range (%) |

| Si | ≤0.4 |

| Fe | ≤0.4 |

| Cu | ≤0.1 |

| Mn | ≤0.1 |

| Mg | 4.0–4.9 |

| Cr | 0.05–0.25 |

| Zn | ≤0.25 |

| Ti | ≤0.15 |

| Zr | — |

| Other (single) | ≤0.05 |

| Other (total) | ≤0.15 |

| Al | Balance |

Longitudinal mechanical properties & delivery condition (GB/T 3191-2019)

| Condition | Tensile strength Rm (MPa) | Yield strength Rp0.2 (MPa) | Elongation A (%) | Hardness (HB) |

| H112 | ≥270 | ≥125 | ≥12 | 70 |

Dimensions & tolerances (grinding condition)

Diameter tolerance: ≤ −0.02 mm (can be aligned to H7 fit if required). This level of precision ensures 5083 precision ground aluminum bar runs stable in CNC guide bushings and high-speed turning.

Straightness: ≤ 0.2 mm/m (stable up to 8000 rpm machining).

Roundness: 0.005 mm.

Surface: Ra controlled for stable feeding and surface finishing.

Ends: Double-end chamfering ensures smooth automatic feeding and protects guide bushings and tool tips.

Optional customization: coaxiality/cylindricity, length tolerance & end squareness, surface grade (polished/rolled/film-coated), NDT (UT/eddy current), barcoding and individual sleeve packaging, etc.

Machining performance

The microstructure is uniform and stable, ensuring short chip formation during cutting and reducing the risk of continuous chips and tool entanglement.

Sharp positive rake tools combined with optimized chip breakers improve machining efficiency and maintain a smooth surface finish.

Carbide tools with proper cutting fluid effectively control built-up edge and cutting heat, extending tool life and reducing downtime for tool changes.

During tapping and reaming, sufficient cooling and cleaning ensure complete threads and accurate hole walls; deburring and chamfering can be completed in the same setup to minimize secondary clamping errors.

The coarse grain ring is controlled to less than 0.5 mm, avoiding white spots and snowflake defects, resulting in reduced color variation and a more uniform anodized appearance.

The outer diameter can be pre-turned to customer-specific equipment sizes before delivery, balancing guide bushing limitations and reducing trial machining time, thereby shortening production preparation cycles.

Straightness ≤0.2 mm/m and roundness 0.005 mm ensure stability at 8000 rpm high-speed turning, maintaining machining accuracy and increasing part yield.

Automatic feeding relies on double-end chamfering, ensuring smooth bar feeding without jamming, stable production rhythm, and reduced machine downtime.

Typical applications

Shipbuilding & offshore engineering

5083 aluminum grinding rods are used for guide shafts, locating pins, valves, and outfitting connectors. Their seawater corrosion resistance and excellent weldability ensure long service life and stable post-weld strength in marine and offshore equipment, enhancing structural reliability and safety.

Refrigeration & cryogenic equipment

Fluid distribution blocks, spindle cores, and heat exchanger connectors adopt 5083 aluminum rods. The alloy retains high toughness at low temperatures, avoiding brittle fracture and ensuring airtightness and sealing performance, making it suitable for refrigeration and cryogenic pressure vessels.

Automotive & tooling fixtures

Fixture posts, locating pillars, and lightweight connecting shafts are manufactured from 5083 aluminum round bars. Precision remains stable after machining, improving assembly accuracy. With medium strength and lightweight advantages, tooling fixtures are more durable, reduce weight, stabilize takt time, and minimize yield loss caused by fixture deformation.

Drilling & industrial equipment

Guide pins, coupling sleeves, and sealing seats use 5083 aluminum rods. With high straightness and roundness accuracy, plus optional non-destructive testing, they ensure reliability and safety under high-load conditions, reducing downtime and maintenance costs.

Armor & protective structures

Connecting nodes and support pins adopt 5083 aluminum bars. Batch-to-batch consistency and traceability ensure stable performance in protective and load-bearing applications, avoiding risks caused by inconsistent properties across different production lots.

Quality & compliance

Each batch is supplied with an EN 10204 3.1 material certificate covering spectrochemical and mechanical data, with full batch traceability. Dimensional reports cover diameter, straightness, roundness, and chamfering, with inspection records archived.

Microstructure and appearance are controlled with coarse grain rings less than 0.5 mm, inspected under standardized lighting conditions.

Measurements are performed at 20 °C; roundness is evaluated using a roundness tester by total variation, straightness is checked using V-blocks with dial indicators or laser measurement, and surface roughness reports include sampling length and filter settings.

Delivery, packaging & ordering tips

We support small-batch trial production with samples before mass orders. Standard inquiries receive formal quotations and lead time proposals within 48 hours.

Default packaging includes pearl cotton, moisture-proof film, anti-collision pads, and fumigation wooden cases. For long-distance sea freight, desiccants and oil seals can be added on request, with barcoding and individual sleeves available.

To avoid inconsistencies during inspection and acceptance, please specify in your drawing or contract: target fit (e.g., h7/h6), surface roughness Ra, UT requirement, barcoding or individual sleeves, as well as length tolerance and end squareness. For H34 or H36 delivery, please also confirm target strength/elongation ranges and sampling frequency.

Frequently asked questions (FAQ)

Q: Do you support H112, H34, and H36 conditions?

A: Yes. H112 follows GB/T 3191-2019. H34/H36 are strain-hardened tempers, supplied according to your target strength/elongation requirements, with test reports provided for each batch.

Q: What factors affect the price?

A: Alloy and condition, diameter and length, grinding tolerance and surface grade, inspection requirements (e.g., UT), packaging, and delivery terms.

Q: Can you provide samples and small MOQ?

A: Yes, samples and small trial batches are available for process validation and takt time matching.

Q: How is weight calculated?

A: By volume × theoretical density or by actual measured weight. Send us your dimensions and we can provide a PDF sheet with theoretical and measured weight comparison.

Q: What if I require T651 stress-relieved stability?

A: 5083 is non-heat-treatable and does not have a T651 temper. If stress-relief stability is essential, we recommend 6061/6082 precision ground bars as alternatives, which we can supply in parallel for comparison.

Quick inquiry (CTA)

Send us your required diameter, length, quantity, target tolerance/surface grade, NDT requirement, and delivery address. We will provide a quotation, lead time, and packaging solution within 48 hours.

Email: sale@chalcoaluminum.com

WhatsApp: +86 17344894490