Why Choose 5052 Aluminum Grinding Rods?

5052 aluminum grinding rods offer lighter structural weight and excellent corrosion resistance. The material remains stable in salt spray, humid heat, and various chemical environments, making it ideal for fuel tanks, lubrication and fuel pipelines, and liquid containers. Its good formability and weldability also simplify secondary processing and assembly.

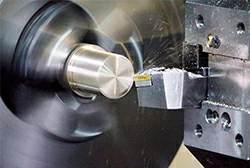

Precision grinding ensures that diameter, straightness, and roundness all meet machining-grade accuracy. The rods operate smoothly at spindle speeds up to 8,000 rpm, reducing vibration and tool marks.

During turning, the material provides improved chip breaking, which helps minimize chip clogging and entanglement issues while enhancing production yield. With the coarse grain ring controlled to within 0.5 mm, defects such as white spots and snowflake patterns are avoided, ensuring consistent quality for appearance parts and anodized components.

Tolerances and Geometrical Accuracy

Diameter tolerance: ±0.02 mm

Straightness: ≤0.2 mm/m

Roundness: ≤0.005

Coarse grain ring: ≤0.5 mm, effectively avoiding white spots and snowflake defects

Double-end chamfering: smooth feeding without jamming

Chemical Composition (GB/T 3190-2020)

| Element | Content (%) |

| Si | ≤0.25 |

| Fe | ≤0.40 |

| Cu | ≤0.10 |

| Mn | ≤0.10 |

| Mg | 2.2–2.8 |

| Cr | 0.15–0.35 |

| Zn | ≤0.10 |

| Ti | – |

| Others | Single ≤0.05, total ≤0.15 |

| Al | Balance |

Mechanical Properties (GB/T 3191-2019)

| Property | H112 |

| Tensile strength Rm (MPa) | ≥170 |

| Yield strength Rp0.2 (MPa) | ≥70 |

| Elongation A (%) | ≥15 |

| Hardness (HB) | ≥47 |

5052 vs 3003 vs 6061 Grinding Rods

| Comparison Item | 5052 Grinding Rod | 3003 Grinding Rod | 6061 Grinding Rod |

| Strength & Stability | Medium, can be improved by cold working | Low to medium | Medium to high, can be improved by heat treatment |

| Formability & Welding | Excellent formability and weldability | Excellent formability | Good weldability |

| Machinability | Average, can be improved with process optimization | Average | Better |

| Corrosion Resistance & Appearance | Excellent, suitable for anodized appearance parts | Good | Good |

Machining Performance

CNC Guide Sleeve Turning

With diameter tolerance ±0.02 mm, straightness ≤0.2 mm/m, and roundness ≤0.005, the rods ensure stable performance at high spindle speeds (8,000 rpm), reducing vibration and tool marks. This guarantees dimensional consistency and high yield.

Automatic Feeding and Chamfering

The double-end chamfering design allows the rods to enter guide sleeves and feeding systems more smoothly, avoiding jamming. This minimizes downtime and increases automation efficiency.

Chip Breaking and Tool Life

With the coarse grain ring controlled to ≤0.5 mm, chip breaking is improved and continuous chips are avoided. This extends tool life, reduces scrap, and lowers overall machining cost.

Welding and Forming

High plasticity and excellent weldability ensure the rods perform well during deep drawing, bending, and welding without cracking. This makes them suitable for containers, pipelines, and welded structures with long-term reliability.

Surface Treatment Compatibility

The rods can be polished or anodized, presenting uniform color without grain-related streaks. This ensures both functional and aesthetic quality, ideal for medical, electronic, and decorative applications.

Application Fields

Fuel Tanks and Pipelines

5052 aluminum grinding rods are widely used in automotive, motorcycle, and marine fuel tanks as well as gasoline and lubrication pipelines. They deliver outstanding corrosion resistance against fuels and lubricants, and welded joints remain dense and leak-free.

Liquid Containers

Used in beverage storage equipment, chemical solution tanks, and marine coolant boxes, 5052 aluminum provides high ductility and resistance to acids and alkalis. This extends container lifespan while maintaining a clean and easy-to-treat surface, reducing extra anti-corrosion processes and production costs.

Deep-Drawn and Thin-Walled Parts

5052 is suitable for instrument housings, lighting covers, and small aerospace structural parts. It resists cracking during deep drawing, while its surface quality supports polishing and anodizing, ensuring both structural strength and an attractive finish.

Welded Structures

In light-load supports, equipment frames, and enclosures, 5052 offers excellent weldability and crack resistance. This results in high-strength welds and fewer defects, enhancing long-term structural reliability.

Appearance and Decorative Parts

5052 surfaces can be polished or anodized with uniform color and no coarse-grain-related defects. It is widely used for electronic panels, medical device housings, and decorative profiles, where both lightweight design and premium appearance are required.

Production and Quality Control

Raw material spectrographic analysis to ensure composition accuracy

Centerless grinding for precise diameter, roundness, and straightness

Double-end chamfering to ensure smooth feeding

Coarse grain ring control ≤0.5 mm

100% inspection before delivery, with test reports provided

Protective packaging: pearl cotton + moisture-proof film + wooden cases/paper tubes

Each rod labeled for traceability

Certifications and Standards

Chemical Composition Standard: GB/T 3190-2020 (equivalent to EN AW-5052 / UNS A95052)

Mechanical Properties Standard: GB/T 3191-2019

Dimensional and Tolerance Standard: ISO 2768-mK or as per customer drawings

Quality Management Certification: ISO 9001, AS9100, IATF 16949

Material Certificates: EN 10204 3.1 report supplied with shipment, optional third-party inspection (SGS, TÜV)

Compliance Declarations: RoHS, REACH, MSDS available upon request

Frequently Asked Questions (FAQ)

Q:Can free samples be provided?

A:Yes, samples of common diameters are available for trial machining.

Q:Is 5052 aluminum grinding rod suitable for anodizing?

A:Yes. With coarse grain ring controlled ≤0.5 mm, anodized surfaces maintain uniform color, ideal for electronic housings and medical devices.

Q:How to choose between 5052 and 6061 aluminum rods?

A:Choose 6061 if strength and machinability are prioritized. Choose 5052 if corrosion resistance, weldability, and formability are required.

Q:Which alloy is commonly used for automotive fuel tanks?

A:5052 aluminum grinding rods are widely applied due to their fuel corrosion resistance, reliable weldability, and high ductility.

Q:What kind of material certificates can be provided?

A:EN 10204 3.1 certificates are provided with each shipment, with optional third-party inspection reports (SGS, TüV).

Contact Us

For 5052 aluminum grinding rod samples or instant quotations, please send your required dimensions, temper, length, and chamfering specifications to sale@chalcoaluminum.com

Our team will respond within 2 hours with solutions and lead times.