4047 O Aluminum Brazing Sheet Product Introduction

4047 O aluminum brazing sheet is a high-silicon aluminum alloy with a stable silicon content of 11–13% and a melting point of around 581 °C. The material exhibits excellent flowability and wettability during brazing, producing dense and reliable weld seams without porosity or cracks.

In the O temper, it combines strength with ductility, featuring a uniform fine microstructure, smooth surface, and strictly controlled dimensional tolerances.

Compliant with GB/T standards and supplied with EN 10204 3.1 certification, it ensures stable brazing performance and high dimensional accuracy. Thanks to these properties, it is widely used in aerospace heat exchangers, fuel systems, and engine components.

Specifications & Certifications

Specifications: Thickness 0.42 mm, width 9.51 mm, with strictly controlled tolerances

Standards: GB/T 3190-2008, GB/T 228.1-2021, GB/T 7999-2015, GB/T 3246.1-2024

Quality: Manufactured under ISO 9001 / AS9100 aerospace quality management systems

Certification: EN 10204 3.1 Mill Test Certificate, with all inspection results qualified

Additional Testing: Optional UT ultrasonic inspection and microstructure analysis; RoHS / REACH compliant upon request

Chemical Composition

According to GB/T 7999-2015 spectroscopic analysis, the chemical composition of 4047 O aluminum sheet is as follows:

| Element | Standard Range (wt.%) | Measured Value (wt.%) | Result |

| Si | 11.0-13.0 | 11.57 | Qualified |

| Fe | ≤0.80 | 0.11 | Qualified |

| Cu | ≤0.30 | 0.008 | Qualified |

| Mn | ≤0.15 | 0.01 | Qualified |

| Mg | ≤0.10 | 0.01 | Qualified |

| Zn | ≤0.20 | 0.003 | Qualified |

| Ti | - | 0.001 | Qualified |

| Others (single) | ≤0.05 | - | Qualified |

| Others (total) | ≤0.15 | - | Qualified |

| Al | Balance | REM | Qualified |

The high silicon content provides excellent brazing flowability and resistance to hot cracking, making 4047 O aluminum sheet an ideal choice for aerospace brazed structural components.

Mechanical Properties

According to GB/T 228.1-2021 room temperature tensile testing, the performance data of 4047 O aluminum sheet are as follows:

| Item | Standard Requirement | Measured Result | Conclusion |

| Tensile Strength Rm (MPa) | 90-135 | 133-135 | Qualified |

| Yield Strength Rp0.2 (MPa) | 35-85 | 72-75 | Qualified |

| Elongation A50 (%) | ≥20 | 34-38 | Qualified |

4047 O aluminum brazing sheet not only maintains relatively high strength but also offers excellent elongation, meeting the forming and reliability requirements of aerospace components.

Product Testing

Microstructure

According to GB/T 3246.1-2024 metallographic inspection, the microstructure of 4047 O aluminum brazing sheet shows a uniform distribution of silicon particles with an average size of about 2.6 μm, without coarse silicon crystals or abnormal segregation. The silicon particles are finely dispersed and stably distributed within the matrix, a feature that is critical for brazing performance.

- Uniform distribution: prevents local overheating or uneven melt pools during brazing, ensuring smooth flow.

- Fine particles: improve the density and uniformity of brazed joints, enhancing reliability.

- No coarse particles: reduce the risk of crack initiation, extending service life in high-temperature and corrosive environments.

This stable microstructure guarantees uniform welds and dense joints, ensuring consistency and reliability of brazed connections in aerospace applications and providing high safety assurance.

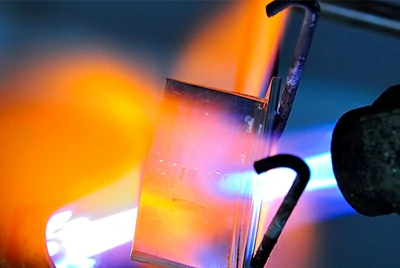

Melting Point and Brazing Performance

The melting point range of 4047 O aluminum brazing sheet is 577–585 °C, with a measured value of 581 °C. This narrow and stable range gives excellent process control and reduces the risk of defects caused by temperature fluctuations.

In practical brazing applications, the alloy exhibits outstanding flowability and wettability. The molten metal spreads rapidly and evenly fills joint gaps, forming continuous, smooth, and dense welds. Testing confirmed that the welds were free from porosity, inclusions, and lack of fusion.

In aerospace applications, 4047 O aluminum brazing sheet demonstrates high reliability: it ensures long-term sealing in fuel systems, enhances heat transfer efficiency in heat exchangers, and provides durability for engine components under high temperature and vibration. These characteristics make it a key material in advanced manufacturing, supporting both lightweight design and long service life.

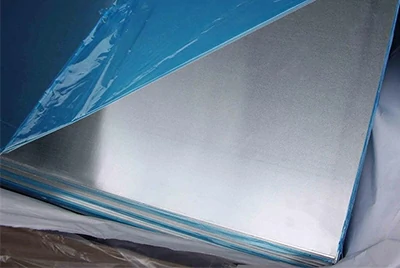

Surface Quality and Dimensional Accuracy

The surface of 4047 O aluminum brazing sheet is bright silver, smooth, and free from oil stains, cracks, or delaminations, ensuring stable appearance quality.

For dimensional accuracy, the thickness tolerance is controlled within ±0.035 mm, with a measured value of 0.425 mm; the width tolerance is ±0.15 mm, with a measured value of 9.51 mm. Both conform to standard requirements.

Strict tolerance control and excellent surface quality allow this material to meet the precision assembly and stable brazing demands of aerospace structures, ensuring long-term consistency and reliability of components in service.

4047 vs 4045 vs 4343 – Composition and Application Comparison

| Alloy Grade | Si Content (wt.%) | Melting Point (°C) | Brazing Flowability | Typical Applications | Key Features |

| 4047 O | 11–13 | ~581 | Excellent, strong wettability, dense welds | Aerospace fuel systems, heat exchangers, engine components | High silicon content, outstanding weld reliability and durability |

| 4045 | ~10 | Slightly higher than 581 | Good, but slightly inferior to 4047 | Automotive radiators, cooling systems | Cost-effective, suitable for mass automotive production |

| 4343 | ~7 | Higher | Moderate, weaker flowability | Industrial heat exchangers, general brazing components | Low cost, suitable for applications with lower brazing requirements |

Compared with 4045 and 4343, 4047 O aluminum brazing sheet is more suitable for aerospace and other high-reliability applications, offering superior weld density and longer service life.

Application Fields

Aerospace Industry

4047 O aluminum brazing sheet is most typically used in the aerospace sector, including fuel tanks, engine cooling systems, heat exchanger plates, and various structural brazed components. With its stable melting point and excellent wettability, it ensures long-term sealing of fuel systems, improves heat transfer efficiency, and guarantees the durability and reliability of engine parts under high-temperature and vibration conditions.

Automotive Industry

In automotive manufacturing, this material is mainly applied in radiators, cooling systems, and lightweight exhaust components. Compared with conventional alloys, the high silicon content of 4047 O aluminum sheet produces denser weld joints, helping reduce vehicle weight, enhance thermal management performance, and extend the service life of cooling and exhaust systems.

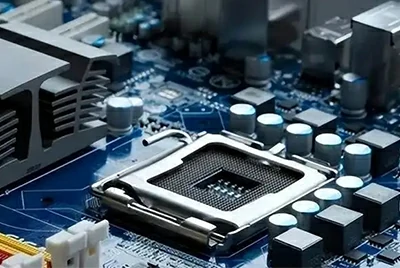

Electronics and Energy Industry

In the electronics and energy sector, it is commonly used for power electronic heat sinks and high-temperature thermal conduction components. The uniform microstructure and stable weld quality allow it to maintain efficient heat dissipation in high-power devices, preventing performance degradation caused by heat accumulation and ensuring the safe and stable operation of energy equipment.

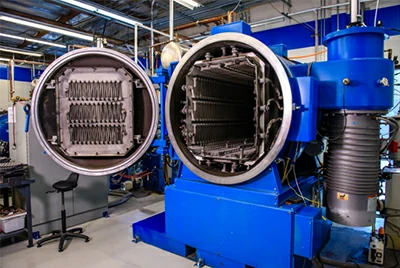

Industrial Equipment Industry

For industrial equipment, 4047 O aluminum brazing sheet is widely used in vacuum-brazed parts and high-temperature heat exchangers. Its narrow and stable melting range ensures weld seam density and consistency, allowing the material to maintain high strength and corrosion resistance over long service periods in harsh operating environments.

Processing Technology

4047 O aluminum brazing sheet in O temper has good plasticity and formability, suitable for common processing methods. It exhibits excellent cold-working properties and can be stamped, bent, or deep drawn to meet complex component requirements.

The high silicon content provides excellent weldability, especially for vacuum brazing and protective atmosphere brazing, resulting in dense and reliable joints. During machining, the uniform distribution of silicon particles reduces tool wear and delivers a smooth surface finish, minimizing the need for post-polishing.

In aerospace applications, the alloy can also be anodized, electrophoretically coated, or treated with other protective finishes to enhance corrosion resistance and surface appearance

Packaging and Delivery

4047 O aluminum brazing sheet can be supplied as full sheets, cut-to-size, or in small batches according to customer requirements. Packaging includes protective plastic film against moisture and scratches.

with wooden cases or pallets for safe long-distance transportation and export. Standard dimensions are available in stock for fast delivery, while customized sizes can be produced on order with controllable lead times.

Frequently Asked Questions (FAQ)

Q1: What is the difference between 4047 O aluminum brazing sheet and regular aluminum sheet?

A: 4047 O is a high-silicon alloy with a stable melting range of 577–585 °C, excellent brazing flowability and wettability, producing dense and reliable welds. Regular aluminum sheets cannot achieve the same welding and heat resistance performance.

Q2: Why is it widely used in aerospace?

A: It combines strength and ductility with a uniform microstructure and stable weld quality, capable of long-term service under high temperature, vibration, and fuel environments, meeting aerospace demands for lightweight and reliability.

Q3: Can this sheet undergo surface treatment?

A: Yes. 4047 O can be anodized, electrophoretically coated, or finished with other protective coatings to improve corrosion resistance and appearance.

Q4: Is quality certification available?

A: Every batch is tested according to GB/T standards and supplied with an EN 10204 3.1 certificate. Additional documentation such as RoHS/REACH compliance can also be provided.

Q5: How is its corrosion resistance?

A: The high silicon content ensures excellent corrosion resistance in fuel, lubricants, and aerospace service environments, making it suitable for long-term use.

Q6: What is the service life of this material?

A: With proper welding and application, 4047 O aluminum brazing sheet produces dense and stable joints, effectively resisting fatigue cracking and extending component lifespan.

Q7: Do you support customized specifications and fast delivery?

A: Yes. Different thicknesses, widths, and cut-to-size options are available. We keep standard stock for immediate delivery and provide customized production on request.