2024 Centerless Ground Aluminum Rod Overview

2024 centerless ground aluminum rod (Al-Cu, high strength) meets GB/T 3190-2020 and GB/T 3191-2019 standards, commonly supplied in T3, T4, and T351 tempers. Precision centerless grinding ensures ±0.02 mm diameter tolerance, ≤0.2 mm/m straightness, and ≤0.005 mm roundness—ideal for CNC machining and high-precision assembly.

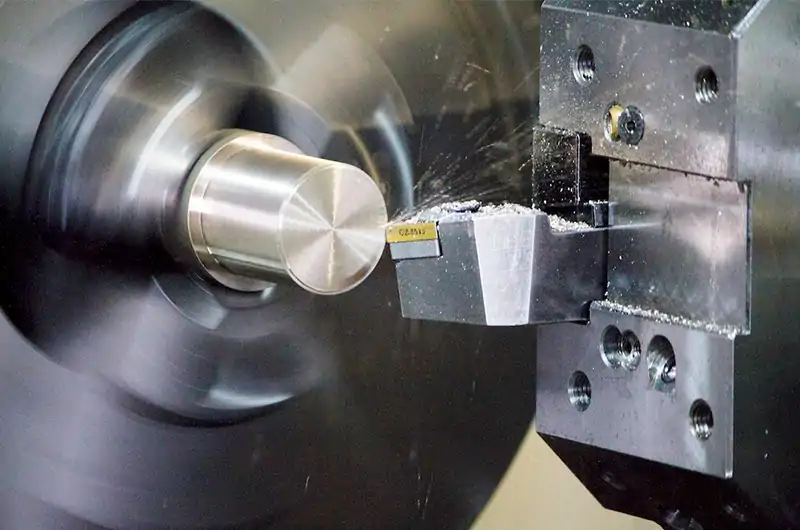

T3 temper provides tensile strength ≥450 MPa, delivering high-load stability. It is lighter than equivalent-strength steel, reducing weight and cost. Excellent machinability for turning, milling, and drilling, with smooth surface finish and extended tool life—suitable for aerospace, precision equipment, and automotive components.

stock sizes

| Product type | Alloy temper | Diameter (mm) | Length (mm) |

| Centerless Ground Aluminum Rod | 2024-T3 | 10.8 | 2500 |

| Centerless Ground Aluminum Rod | 2024-T3 | 11 | 2500 |

| Centerless Ground Aluminum Rod | 2024-T3 | 12 | 2500 |

| Centerless Ground Aluminum Rod | 2024-T3 | 12.3 | 2500 |

| Centerless Ground Aluminum Rod | 2024-T3 | 13 | 2500 |

| Centerless Ground Aluminum Rodk | 2024-T3 | 14 | 2500 |

| Centerless Ground Aluminum Rod | 2024-T3 | 14.7 | 2500 |

| Centerless Ground Aluminum Rod | 2024-T3 | 15 | 2500 |

| Centerless Ground Aluminum Rod | 2024-T3 | 9 | 2500 |

| Centerless Ground Aluminum Rod | 2024-T4 | 17 | 2500 |

| Centerless Ground Aluminum Rod | 2024-T4 | 35 | 2500 |

| Centerless Ground Aluminum Rod | 2024-T4 | 6 | 2900 |

Chemical composition (GB/T 3190-2020)

| Element | Content (%) |

| Si | ≤ 0.50 |

| Fe | ≤ 0.50 |

| Cu | 3.8–4.9 |

| Mn | 0.3–0.9 |

| Mg | 1.2–1.8 |

| Cr | ≤ 0.10 |

| Zn | ≤ 0.25 |

| Ti | ≤ 0.15 |

| Zr | — |

| Others | Each ≤ 0.05, total ≤ 0.15 |

| Al | Balance |

Mechanical properties (GB/T 3191-2019)

| Temper | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) | Brinell hardness (HB) |

| T3 | ≥ 450 | ≥ 310 | ≥ 8 | ≥ 120 |

Precision parameters & sizes for 2024 ground aluminum rod

Precision centerless grinding with high geometric accuracy: diameter tolerance ±0.02 mm, straightness ≤ 0.2 mm/m, roundness ≤ 0.005 mm.

Standard stock and non-standard custom sizes available to support high-precision assembly and mass production.

Stable dimensional accuracy suitable for sliding-head (guide-bushing) CNC lathes and other ultra-precision processes.

High straightness ensures no noticeable vibration at ≥ 8,000 rpm, ideal for high-speed cutting.

Double-end chamfer for smooth, jam-free automatic bar feeding.

Turned bar head process optimizes the OD to fit different machines and fixtures.

Coarse-grain ring ≤ 0.5 mm, effectively avoiding white spots/snowflake banding.

Refined alloy microstructure reduces stringy chips and improves yield.

Stress-relieved T651 condition minimizes machining distortion and suits carbide tooling for high-precision parts.

Application fields of 2024 ground aluminum rod

2024 Ground Aluminum Rod combine high strength, excellent dimensional stability, and good machinability, and are widely used across multiple industries.

Aerospace

Used for wing ribs, skin fastener interfaces, rivets, and other load-bearing structural parts. These components face vibration and complex loads during flight; 2024 rods deliver the required fatigue strength and dimensional accuracy while keeping weight low to improve fuel efficiency and flight performance.

Automotive manufacturing

Applied to drive shafts, suspension components, and chassis members in high-performance cars and racing vehicles. Lightweight properties cut vehicle mass, improve acceleration response and handling stability, and withstand impacts and dynamic loads at high speed.

Precision machinery

Used for high-precision guide posts, mold accessories, and precision shafts that demand tight dimensional tolerances and superior surface finish. The typical accuracy (±0.02 mm tolerance, ≤ 0.005 mm roundness) and good cutting behavior ensure assembly consistency and stable operation.

Sporting goods

Adopted for high-end bicycle frames, mountaineering gear, and ski equipment where both light weight and high strength are required, balancing performance and durability in competitive and outdoor environments.

Machining & surface finishing for 2024 ground aluminum rod

Machining performance

2024 rods suit turning, milling, drilling, and tapping, from prototypes to mass production.

They run stably on CNC machining centers, automated lines, and sliding-head lathes, maintaining dimensional consistency and throughput.

Chips break evenly, reducing long-chip wrapping, lowering tool wear, and extending tool life.

High straightness and tight OD tolerance support stable high-speed machining with no obvious chatter even at 8,000 rpm and above.

Use HSS or carbide tools with appropriate coolant to achieve surface finish and dimensional stability in series production.

Common surface finishing methods

Anodizing forms a uniform, dense oxide film that markedly improves corrosion resistance, especially for marine, outdoor, or humid environments; multiple colors are available to combine function and appearance.

Electroplating adds a metal coating to increase hardness and wear resistance while improving electrical contact where needed.

Painting/powder coating adds an extra protective layer for weathering and chemical resistance; colors and textures can be customized for differentiation and branding.

Purchasing & quality assurance for 2024 ground aluminum rod

Each batch is produced and tested to international standards.

GB/T 3190-2020 / GB/T 3191-2019 define chemistry, mechanical properties, and manufacturing accuracy for China.

ASTM B211 covers aluminum and aluminum-alloy bars and rods for international markets.

AMS 4120 / AMS 4045 support aerospace-grade requirements for structural applications.

Packaging uses pearl-cotton interlayers + moisture-barrier film + fumigated wooden crates to prevent oxidation, deformation, or scratching during transport and to meet sea/air freight requirements. Both sample orders and large-volume purchases are delivered on schedule with full technical support.

Frequently asked questions (FAQ)

Q: Can 2024 ground aluminum rod replace 6061?

A: Where higher structural strength is required, 2024 can replace 6061—especially for parts under high static or cyclic loads. Since 2024 has lower corrosion resistance than 6061, it is not recommended for prolonged exposure to seawater or aggressive environments unless paired with anodizing or protective coatings.

Q: What is the difference between T3 and T351?

A: T3 is solution heat treated, cold worked, and naturally aged to balance strength and elongation. T351 adds stress relief to reduce deformation risk during precision machining, which is well-suited for parts requiring high dimensional stability.

Q: Can you supply custom sizes and samples?

A: Yes. We can cut to any required diameter and length and provide small-lot samples for performance testing, machining trials, or appearance approval. Typical lead times are 3–5 days for stock and agreed schedules for custom production.

Q: Which machining processes are suitable for 2024 ground aluminum rods?

A: Turning, milling, drilling, and tapping are all suitable. The alloy cuts cleanly with uniform chip breakage, which supports longer tool life and better surface quality. For mass production, carbide tooling with coolant is recommended for optimal efficiency and precision.

Q: How do you ensure the quality of 2024 ground aluminum rods?

A: All outgoing products comply with GB/T, ASTM, and AMS standards. Dimensions are 100% checked, with diameter tolerance controlled within ±0.02 mm. Packaging with pearl-cotton, moisture film, and fumigated crates prevents moisture ingress, oxidation, and scratching during shipment.