2024 aluminum angle is a high-strength aluminum alloy profile and one of the strongest among heat-treatable aluminum alloys. Known for its excellent fatigue resistance and high tensile strength, 2024 aluminum is widely used in aerospace, military, and high-stress structural applications.

2024 aluminum angle is commonly supplied in T3 or T3511 temper, offering a tensile strength of up to 470 MPa—significantly higher than that of 6061 aluminum alloy. Compared to 6061 aluminum angle, 2024 provides superior mechanical properties, especially in load-bearing, impact resistance, and fatigue strength, making it more suitable for critical structural components under dynamic loads..

Therefore, if you need an aluminum angle designed for high strength and precision structural applications, 2024 aluminum angle is undoubtedly the more professional and reliable choice.

Instant Quote2024 aluminum angle product overview

| Alloy | 2024 |

| Equivalent Names | 2024, AA2024, A92024, EN AW-2024, AlCu4Mg1, 3.1355 |

| Hot Temper | T3, T351, T3511 |

| Specifications | ASTM B221, AMS-QQ-A-200/3, AMS 4152, AMS 4164, EN 573, EN 755 |

| Thickness | 1/16”, 1/8”, 1/4”, 3/8”, 1/2” and more |

| Leg Height | 1/2” – 6”, customizable |

| Length | 1–6 meters or customized as needed |

| Tolerance | Standard length tolerance: ±1/4”, Custom cut tolerance: ±1/16” |

| Manufacturing Process | Extruded |

| Surface Treatment | Optional anodizing, powder coating, sandblasting, polishing, etc. |

| Fabrication Services | Cutting, drilling, bending, welding, milling, CNC machining |

Common types of 2024 aluminum angle

Chalco offers a wide range of 2024 aluminum angle types to meet your diverse needs. If required, please click to send an inquiry via email.

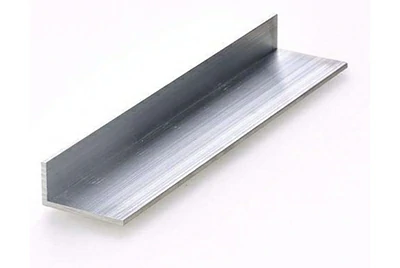

Instant Quote2024 equal leg aluminum angle

Both legs are of equal length, providing symmetrical structure, high strength, and excellent load-bearing capacity. Ideal for use in aerospace brackets, frames, and load-bearing sections of standardized structures.

2024 Unequal leg aluminum angle

Designed with legs of different lengths, making it suitable for installations with space constraints or uneven force distribution. Widely applied in customized brackets, reinforcements, and industrial equipment structures.

2024 right aluminum angle

High strength and excellent fatigue resistance, suitable for high-stress areas requiring precise joint alignment. The 90° sharp angle design facilitates secure fastening and accurate assembly.

2024 round corner aluminum angle

Designed with rounded corners to reduce stress concentration and improve crack resistance and safety. Commonly used in aerospace frames and mechanical connection points.

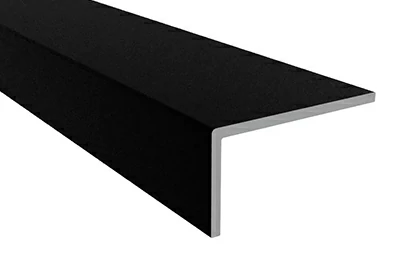

Anodized 2024 aluminum angle

The surface is anodized to improve corrosion and wear resistance, making it suitable for high-strength components used in harsh environments.

Polished 2024 aluminum angle

Smooth and bright surface finish with unchanged structural strength, combining aesthetics and functionality. Commonly used in high-end equipment, display frames, or instrument enclosures.

Color-coated 2024 aluminum angle

Features a vibrant surface coating with excellent corrosion and UV resistance, ideal for exposed frames, aircraft interiors, or specialized signage where both function and appearance matter.

Slotted 2024 aluminum angle

Integrated with pre-set mounting slots for quick assembly and adjustable connections. Offers stable structure, ideal for modular aerospace equipment and on-site rapid installation.

Hot-selling sizes of AA2024 aluminum angle

Chalco can supply standard sizes of 2024 aluminum angle as well as custom dimensions upon request. If you have any requirements, please feel free to contact us.

Instant Quote

Ordering Information:

- Free samples available: We offer free samples for testing before you place an order. Chalco is fully confident in the quality of its products.

- Multiple mold sizes: A wide range of existing mold sizes helps you save on tooling costs.

- No minimum order quantity: All stock products are available for retail sales with no MOQ. Orders can be cleared and shipped within one week after confirmation.

- Direct factory supply: As a primary manufacturer, Chalco offers integrated large-scale production. Our 2024 aluminum angle pricing is approximately 10% lower than the market price for the same quality.

- Trusted brand with strict quality control: We ensure product quality through rigorous inspection processes, giving you peace of mind with every order.

- Discounts for bulk and repeat orders: Enjoy competitive pricing and additional discounts for large-volume and repeat purchases.

If you don't find a suitable size from the list below, please feel free to contact us — we'll help you find the right solution.

2024 aluminum angle dimensions chart

| Product | dimension A x B x T(inch) | Specification |

| 2024 t3/t3511 aluminum angle | 1/2" x 1/2" x 1/16" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1/2" x 1/2" x 1/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 3/4" x 3/4" x 1/16" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1" x 1" x 1/16" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1" x 1" x 1/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1" x 1" x 3/16" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1" x 1" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1" x 1-1/2" x 1/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1-1/4" x 1-1/4" x 1/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1-1/4" x 1-1/4" x 3/16" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1-1/4" x 1-1/4" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1-1/2" x 1" x 1/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1-1/2" x 1" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1-1/2" x 1-1/2" x 1/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1-1/2" x 1-1/2" x 3/16" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1-1/2" x 1-1/2" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1-3/4" x 1-3/4" x 1/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 1-3/4" x 1-3/4" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2" x 1-1/2" x 1/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2" x 1-1/2" x 3/16" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2" x 1-1/2" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2" x 2" x 1/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2" x 2" x 3/16" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2" x 2" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2" x 2" x 3/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2-1/2" x 1-1/2" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2-1/2" x 2" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2-1/2" x 2-1/2" x 1/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2-1/2" x 2-1/2" x 3/16" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2-1/2" x 2-1/2" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 2-1/2" x 2-1/2" x 3/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 3" x 2" x 3/16" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 3" x 2" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 3" x 2" x 3/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 3" x 3" x 3/16" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 3" x 3" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 3" x 3" x 3/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 3" x 3" x 1/2" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 3-1/2" x 3-1/2" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 3-1/2" x 3-1/2" x 3/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 3-1/2" x 3-1/2" x 1/2" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 4" x 3" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 4" x 3" x 3/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 4" x 3" x 1/2" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 4" x 4" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 4" x 4" x 3/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 4" x 4" x 1/2" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 5" x 3" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 5" x 3" x 3/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 5" x 3" x 1/2" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 5" x 5" x 1/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 5" x 5" x 3/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 5" x 5" x 1/2" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 6" x 3" x 3/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 6" x 4" x 3/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 6" x 4" x 1/2" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 6" x 6" x 3/8" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 6" x 6" x 1/2" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 6" x 6" x 3/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 8" x 6" x 3/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 8" x 8" x 1/2" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 8" x 8" x 3/4" | AMS-QQ-A-200/3 |

| 2024 t3/t3511 aluminum angle | 8" x 8" x 1" | AMS-QQ-A-200/3 |

Features of 2024 aluminum angle

High strength and lightweight structure: 2024 is an Al-Cu-Mg series high-strength aluminum alloy with excellent tensile strength and strength-to-weight ratio. In T3/T351 temper, its tensile strength can reach up to 470 MPa, making it ideal for high-stress structural applications.

Excellent fatigue resistance: 2024 aluminum alloy offers outstanding fatigue performance, making it suitable for structures subjected to cyclic loads, such as aircraft wings and fuselage frames.

Good machinability: The alloy has good formability in the annealed condition and is well-suited for cutting, drilling, milling, and other machining operations. It is ideal for manufacturing precision components.

Limited weldability: Due to its high copper content, 2024 has poor weldability and is prone to hot cracking. Welding is generally not recommended unless special techniques are used.

Lower corrosion resistance: 2024 aluminum has relatively poor corrosion resistance because of its copper content. It is often treated with Alclad cladding or anodizing to enhance surface durability.

Heat-treatable for improved performance: 2024 aluminum can be strengthened through heat treatment, such as T3 or T3511 temper, making it suitable for applications requiring enhanced mechanical properties.

Ideal for high-strength structural use: Thanks to its superior strength and fatigue resistance, 2024 aluminum angle is widely used in aerospace, defense, mold-making, and other high-strength structural fields.

Applications of 2024 aluminum angle

Aerospace

Widely used in key components such as aircraft fuselage, wing structures, and landing gear due to its high strength and excellent fatigue resistance.

Contact us now

Automotive manufacturing

Used in high-performance vehicles to produce chassis, suspension systems, and engine components, helping reduce weight and improve fuel efficiency.

Contact us nowMilitary equipment

Used in the construction of military aircraft structures, armored vehicles, and missile components to meet high strength and fatigue resistance requirements.

Contact us now

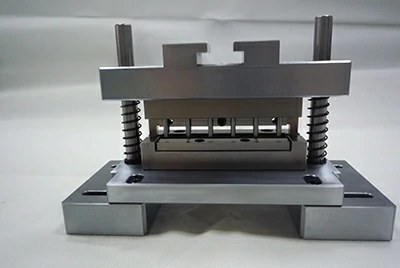

Industrial machinery

Applied in the manufacturing of heavy-load mechanical structures, molds, and fixtures due to its excellent machinability and high strength characteristics.

Contact us nowRail transit

Used in subway and high-speed train carriages to manufacture lightweight structural components, enhancing energy efficiency and overall performance.

Contact us now

Architectural engineering

Used as a substitute for steel in building structures, especially in applications where weight reduction is critical.

Contact us nowDifferences between 2024 aluminum angle and 6061 aluminum angle

| Property | 2024 Aluminum Angle | 6061 Aluminum Angle |

| Alloy Series | Al-Cu-Mg (Aluminum-Copper) | Al-Mg-Si (Aluminum-Magnesium-Silicon) |

| Common Tempers | T3, T351 | T6, T651 |

| Tensile Strength | ≈ 470 MPa (T3) | ≈ 290 MPa (T6) |

| Yield Strength | ≈ 325 MPa (T3) | ≈ 240 MPa (T6) |

| Ductility | Moderate | Good |

| Fatigue Resistance | High | Moderate |

| Corrosion Resistance | Poor (requires cladding or anodizing) | Excellent (stable Mg₂Si phase) |

| Weldability | Poor (prone to cracking) | Good (easy to weld) |

| Machinability | Excellent | Good |

| Heat Treatment Response | Strong | Strong |

| Strength-to-Weight Ratio | Superior | Moderate to good |

| Typical Applications | Aerospace, military, high-stress structures | Construction, brackets, general structural use |

| Cost | Slightly higher | More economical |

Recommendation:

Choose 2024 aluminum angle when your application demands maximum strength and fatigue resistance, especially in aerospace or critical structural components.

Choose 6061 aluminum angle when you need good corrosion resistance, weldability, and lower cost, ideal for general fabrication and outdoor structures.

Related products of 2024 aluminum angle

Why choose Chalco as your 2024 aluminum angle supplier?

Free 2024 aluminum angle samples

Chalco offers free samples of 2024-T3/T351 aluminum angle in standard sizes for qualified customers. These samples support structural validation, performance testing, and trial assembly—helping you quickly complete early-stage project verification. Click here to request a free sample

Instant QuoteReliable inventory with aerospace-grade delivery speed

We maintain stock of various tempers and dimensions of 2024 aluminum angle, tailored for high-demand applications in aerospace, defense, and tooling. Bulk export orders are supported with fast delivery to meet urgent project timelines.

High-performance aluminum, engineered for strength

2024 is a high-strength aluminum alloy, and Chalco specializes in aerospace-grade production. Every batch of aluminum angle offers excellent tensile strength and fatigue resistance, suitable for demanding load-bearing scenarios.

Precision machining and custom specifications

Available in T3, T351, and T3511 tempers, our 2024 aluminum angles come in equal, unequal, sharp, and round corner types. We support custom services including cutting, drilling, chamfering, and CNC machining for precise structural assembly.

Advanced production ensures dimensional consistency

Using aerospace-grade extrusion equipment and full-process digital inspection systems, we guarantee accurate angles, tight tolerances, and consistent quality—perfect for high-standard assemblies and premium applications.

Versatile surface treatments for durability and appearance

While raw 2024 aluminum has limited corrosion resistance, Chalco provides professional treatments such as anodizing, Alclad cladding, and powder coating to significantly enhance durability and aesthetic appeal for diverse application environments.

Strict quality inspection and factory certification

Each batch includes a complete mill test report with mechanical properties, dimensional tolerances, and chemical composition. Our quality assurance process meets aerospace material standards and ensures compliance with global export requirements.

International standards compliance, export-ready

Chalco supplies 2024 aluminum angles in full compliance with AMS-QQ-A-200/3, AMS 4152/4164, ASTM B221, and EN 755. Supported international equivalents include AA2024, EN AW-2024, and UNS A92024, ensuring smooth customs clearance, tender participation, and use in multinational projects.

FAQs of A92024 aluminum angle

What industries are 2024 aluminum angles used in?

2024 aluminum angles are widely used in aerospace, military equipment, mold manufacturing, mechanical frameworks, and high-strength connection structures. Their excellent strength and fatigue resistance make them ideal for applications requiring high load capacity and precision.

How to properly cut and process 2024 aluminum angles?

It is recommended to use carbide-tipped saw blades, CNC band saws, or precision CNC machines for cutting. Ensure the material is firmly clamped to prevent vibration. Due to the high hardness of 2024, bending requires precise angle control to avoid cracking or spring-back.

Do you provide cutting and CNC processing services?

Yes. Chalco offers a range of processing services for 2024 aluminum angles, including cutting, drilling, chamfering, CNC milling, and tapping. Custom fabrication based on drawings is supported to meet the needs of high-precision parts and aerospace structural components.

What factors affect the price of 2024 aluminum angles?

Pricing is influenced by raw material market fluctuations, alloy temper (e.g., T3, T351), dimensions, processing requirements, and whether Alclad cladding or anodizing is applied. High-precision or customized parts may also involve tooling and labor costs.

How to calculate the weight of 2024 aluminum angles?

Calculation steps:

- Use the density of 2024 aluminum (approx. 2.78 g/cm³)

- Cross-sectional area A = (a × t) + (b × t) – t²

- Volume = A × length

- Weight = Volume × density (convertible to kg or lbs)

This helps with engineering design and shipping cost estimation.

Can 2024 aluminum angles be welded?

Welding is generally not recommended. Due to its high copper content, 2024 aluminum is prone to hot cracking. If welding is necessary, special filler materials and techniques are required, along with post-weld heat treatment or structural reinforcement.

Can 2024 aluminum angles be customized?

Yes. Chalco offers a wide range of customization options, including equal/unequal leg angles, special corner angles, fixed-length cutting, hole drilling, Alclad cladding, and anodizing. These services are well-suited for military, aerospace, and other high-strength applications.

Are 2024 aluminum angles suitable for outdoor use?

Uncoated 2024 aluminum has relatively poor corrosion resistance and is not recommended for long-term exposure to moisture or acidic environments. Its durability can be significantly improved through Alclad cladding or anodizing, making it suitable for critical exposed parts.

Can 2024 aluminum angles be anodized?

Yes. While the anodized finish may be less glossy than 6061 or 6063, it significantly enhances surface hardness and corrosion resistance. Anodized 2024 angles are commonly used in aerospace components, instrument frames, and structural connectors that require both durability and aesthetics.

How is 2024 aluminum angle packaged?

To ensure surface integrity and dimensional stability during transportation, Chalco offers various professional packaging solutions tailored for export shipping and customer storage needs.

| Single-piece PE film wrap | Each aluminum angle is individually wrapped with protective PE film to prevent surface scratches; ideal for orders with high surface quality requirements. |

| Bundled multi-piece pack | Multiple angles are neatly bundled with foam spacers or kraft paper to avoid friction and impact; suitable for bulk shipments. |

| Carton/tube packaging | Small-size or cut-to-length products can be packed in reinforced cartons or paper tubes for easy manual handling and domestic delivery. |

| Wooden crate/pallet for export | Export orders are packed in fumigated or non-fumigated wooden crates or pallets, with bubble wrap and stretch film for sea/air freight protection. |

| Custom labeling & anti-counterfeit marks | Labels with alloy grade, temper, and dimensions are provided; custom barcodes, anti-counterfeit codes, and branding are available on request. |