Product Overview

2017 (2017/2017A, Al-Cu-Mg-Si series) is a high-strength aluminum alloy with excellent machinability. It is widely used for automatic lathes, threaded parts, and structural components. After centerless grinding, the bar has a smooth surface and stable accuracy, making it suitable for CNC mass production.

Stock Sizes

| Product Type | Alloy / Temper | Diameter (mm) | Length (mm) |

| Ground Bar | 2017-T4 | 13.5 | 2500 |

| Ground Bar | 2017-T4 | 13 | 2500 |

Chemical Composition (%), GB/T 3190-2020

| Element | Range |

| Si | 0.2 – 0.8 |

| Fe | ≤ 0.7 |

| Cu | 3.5 – 4.5 |

| Mn | 0.4 – 1.0 |

| Mg | 0.4 – 0.8 |

| Cr | ≤ 0.10 |

| Zn | ≤ 0.10 |

| Ti | ≤ 0.15 |

| Zr | Trace |

| Al | Balance |

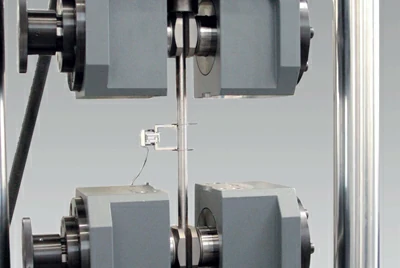

Mechanical Properties (GB/T 3191-2019)

| Item | Value |

| Temper | T4 / T451 |

| Tensile Strength ≥ | 345 MPa |

| Yield Strength ≥ | 215 MPa |

| Elongation ≥ | 12% |

Available Sizes and Tolerances

| Item | Range / Notes |

| Temper | T4, T451 in stock; T651 available on request |

| Diameter | Ø6 – Ø100 mm |

| Length | 1 – 3 m; custom cut lengths available |

| Tolerance | ±0.02 mm |

| Straightness | ≤ 0.2 mm/m |

| Roundness | ≤ 0.005 mm |

| Documentation | Inspection report, material certificate (EN 10204 3.1) |

Comparison with Other Alloys

| Item | 2017/2017A | 2024 | 2011 | 6061 |

| Strength | High | Higher | Medium | Medium |

| Machinability | Good | Medium | Excellent | Medium |

| Corrosion Res | Medium to Low | Low to Medium | Low | Good |

| Weldability | Limited | Poor | Poor | Good |

| Common Forms | Ground bar / Turned bar | Plate / Forging | Free-machining bar | General purpose bar |

Processing Performance and Advantages

2017 aluminum precision ground bar offers excellent machining accuracy and stability. Tolerance is ±0.02 mm, straightness ≤0.2 mm/m, and roundness ≤0.005 mm. Even at 8000 rpm, it runs smoothly without vibration.

Double-end chamfering ensures smooth automatic feeding. Coarse grain rings are limited to ≤0.5 mm, preventing defects such as white spots or snowflake marks.

The high copper content provides strong chip-breaking ability. Short chips are formed during cutting and threading, preventing tool jamming. This makes 2017 ideal for mass production of threaded holes, bolts, and fasteners.

Carbide or coated HSS tools are recommended. Sharp positive rake designs improve chip flow, ensure thread forming, and extend tool life.

In T451 temper, stress relief minimizes deformation. Multiple light cuts and small finishing passes achieve consistent dimensions and smooth surfaces.

Although its corrosion resistance is lower than 6xxx alloys, 2017 adapts well to anodizing, chemical conversion, or coatings. These treatments improve durability and enhance appearance.

Applications

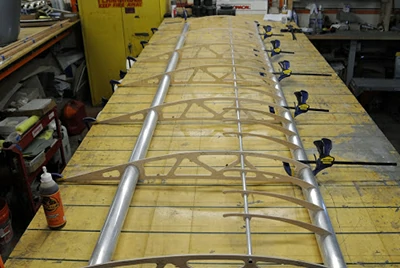

Aerospace

2017 aluminum ground bar is used in aircraft wing spars, fuselage frames, door frames, and ribs. Its high strength and threading performance ensure dimensional consistency. Compared with 6xxx alloys, 2017 breaks chips more easily, improving threading efficiency.

Marine and transportation

It is applied in ship frameworks, hull fasteners, and rail connectors. Stronger than most 5xxx and 6xxx alloys, 2017 maintains stability in long parts under high-speed use. With anodizing or coatings, it performs well in humid or marine environments.

General machinery

2017 ground bar suits gear shafts, guide rods, bushings, and automation components. High straightness keeps accuracy stable during long-term high-speed operation, reducing deformation and extending equipment life.

Fasteners and threaded parts

It is widely used for screws, bolts, nuts, and inserts. Excellent machinability and chip-breaking improve production efficiency. The chamfer design ensures smooth feeding, reduces tool wear, and increases pass rates.

Certification and Standards

The company is certified to ISO 9001, AS9100, and IATF 16949. Each batch is supplied with EN 10204 3.1 certificates and complies with GB/T 3190-2020 and GB/T 3191-2019. ASTM, EN AW, and AMS standards are available upon request.

Quality Assurance and Delivery

2017 aluminum ground bar can be anodized, chemically treated, or coated for protection. When used with stainless steel or copper, isolation is required to avoid galvanic corrosion.

Each batch includes inspection reports, with coarse grain rings ≤0.5 mm for structural consistency. All products are traceable, and samples are available for trial machining.

Packaging uses pearl cotton, moisture-proof film, and rust-proof paper with end caps, secured in wooden cases or steel-banded crates. Standard sizes ship same or next day, while custom cut, chamfered, or polished bars are delivered in 2–3 working days.

FAQ

Q: Is there a difference between 2017 and 2017A?

A: They are interchangeable. EN AW-2017A is the European designation, with slight compositional differences but similar performance.

Q: Why choose precision ground bar instead of regular stock?

A: Ground bar offers higher accuracy and stability in automatic feeding and high-speed machining.

Q: Can 2017 aluminum be welded?

A: Fusion welding is not recommended. Resistance welding is preferred.

Q: Is 2017 aluminum suitable for anodizing?

A: Yes, but process control is essential to avoid color variation.

Q: Can h9/h8 tolerances be provided?

A: Yes, custom tolerances such as h9 or h8 are available based on customer drawings.

Q: Are samples available?

A: Yes, sample bars can be provided for trial cutting and assembly testing.