What is 2011 Centerless-Ground Aluminum Rod?

A 2011 ground aluminum rod is a free-machining aluminum alloy bar. Its chemistry includes Cu 5.0–6.0% to increase strength and hardness, Pb or Bi 0.2–0.6% to form chip-breaking phases for easy chip evacuation, and Zr 0.2–0.6% to refine grains and improve surface quality. Typical supply forms are bar, tube, and wire, suitable for making screws, hydraulic fittings, electronic structural parts, and other machined components that require excellent machinability.

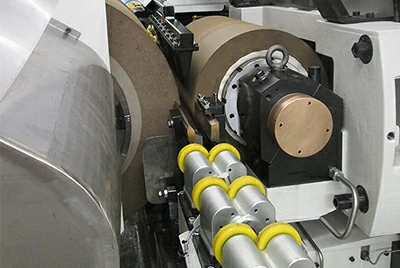

Dimensional Accuracy & Process Stability

Machining accuracy: up to 0.02 mm supports Swiss-type sliding-head (guide-bushing) mode.

Straightness: < 0.2 mm/m no noticeable vibration at spindle speeds ≥ 8,000 rpm.

Roundness: ≤ 0.005 mm verified by multi-point measurement along the full length to ensure concentricity of rotating parts.

Surface roughness: Ra ≤ 0.2 µm mirror-smooth finish reduces downstream polishing cost.

Double-end chamfer: ensures smooth, jam-free automatic bar feeding.

Turned bar head: pre-turned OD/step so the bar fits the machine's chuck/collet limitations.

Coarse-grain ring: ≤ 0.5 mm controls grain size to avoid white spots/snowflake banding.

Improved chip control: optimized metallography reduces stringy chips and increases yield.

Tempers & Typical Uses

T3: solution heat treated, cold worked, naturally aged; suitable for high-speed free-machining.

T6: solution heat treated and artificially aged; for higher-strength load-bearing parts.

T651: solution heat treated, stress-relieved by stretching, then artificially aged; helps prevent distortion during machining and provides very high dimensional stability.

Chemical Composition

| Element | Range (wt.%) |

| Si | 0.4 |

| Fe | 0.7 |

| Cu | 5.0–6.0 |

| Mn | — |

| Mg | — |

| Cr | — |

| Zn | 0.3 |

| Ti | — |

| Zr | 0.2–0.6 |

| Pb | 0.2–0.6 |

| Bi | — |

| Others (each/total) | — |

| Al | Balance |

Key Performance Indicators

| Temper | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) | Brinell hardness (HB) | Machinability |

| 2011 T3 (common after grinding) | ≥ 320 | ≥ 270 | ≥ 10 | ≥ 90 | ★★★★★ |

| 2011 T6 | ≥ 380 | ≥ 270 | ≥ 8.5 | ≥ 110 | ★★★★☆ |

| 2011 T8 | ≥ 410 | ≥ 310 | ≥ 9.8 | ≥ 100 | ★★★★☆ |

Density 2.82 g/cm³ · Thermal conductivity 151 W/m·K · Resistivity 0.038 µΩ·m · Solidus 535 °C.

At high speeds (> 6,000 rpm), using a positive-rake milling cutter with mist cooling can produce mirror-like chips and further reduce bar surface roughness.

2011 vs 6061 / 6262 Free-Machining Aluminum Comparison

| Metric | 2011 (T3) | 6061 (T6) | 6262 (T9) |

| Tensile strength (MPa) | 320 | 310 | 390 |

| Machinability rating | 100% (baseline) | 50% | 90% |

| Pb/Bi free-machining elements | Yes | No | Yes |

| Corrosion resistance | Medium | Good | Good |

| Anodic decorative appearance | Medium | Good | Good |

Typical Applications

Application components

Fastener manufacturing: covers screws, bolts and nuts and is ideal for CNC high speed free machining and single pass forming.

Hydraulic and pneumatic components: include fittings, valve bodies and distributors and offer high strength with excellent dimensional stability.

Precision mechanical parts: include jigs and fixtures, locator pins and sliders and can meet tight coaxiality and position tolerances.

Electronic structural parts: include heat posts and brackets and combine high thermal conductivity with low weight for mass production.

Defense and special equipment: covers cartridge type parts and other precision components that require high speed machining.

Product Forms

Bars: available as centerless ground, bright drawn and turned versions.

Tubes: supplied in round and profiled shapes for precision assemblies.

Wire: suitable for cold heading and automatic lathes.

Processing Capability & Secondary Surfaces

Centerless grinding achieves Ra ≤ 0.8 µm and ultra finishing reaches Ra ≤ 0.4 µm.

CNC high speed cutting runs at 6,000 to 10,000 rpm with feed 0.05 to 0.25 mm/rev and depth of cut 0.5 to 3 mm and the parameters should be optimized for the machine and tooling.

Surface treatments include anodizing, micro hard chrome and electroless nickel and they improve corrosion resistance in harsh environments.

Custom lengths range from 0.5 m to 3,000 mm and chamfering, knurling and threading can be completed in the same setup.

Available Sizes & Quality Control

The diameter range is Ø 6 to 150 mm and standard fits follow h9 or h10 in the ISO tolerance system.

The standard length is 3 m and cut to length per drawing is available.

The quality system follows ISO 9001 and ISO 14001 and the material meets ASTM B211 and EN 755 Part 2.

Documentation includes MTC (mill test certificate) and COC (certificate of conformity) with each batch and optional SGS or ICP OES chemistry reports plus RoHS and REACH statements.

Purchasing Advantages at a Glance

| We provide | You get |

| Grinding-grade tolerances and mirror-level finish | No secondary grinding; cut immediately after clamping |

| ASTM / EN / ISO certification | Seamless global supply-chain qualification |

| Anodizing / nickel plating / micro hard chrome | Better corrosion resistance and longer part life |

| 48-hour sample shipping to North America and Europe | Shorter validation cycles and faster ramp-up |

| One-to-one engineer advice on material and toolpaths | Higher machine efficiency and lower tool wear |

FAQ

Q: Which tempers are available for 2011 ground aluminum rods?

A: Stock tempers include T3 (free-machining baseline), T6, and T8; other tempers can be produced to order.

Q: How much faster is machining versus brass?

A: On the same machine, finished parts per unit time typically increase by 15–20%, while part weight drops by about 60%.

Q: How do you address the moderate corrosion resistance of 2011?

A: We can pre-apply anodizing or nickel plating. Salt-spray life can increase by ≥ 200 h (per test report).

Q: What are the MOQ and lead time?

A: Stock diameters have MOQ 25 kg; non-standard cut lengths MOQ 50 kg. Stock ships in 3–5 days; custom orders in 10–14 days.

Q: Can you provide cutting parameter recommendations?

A: Yes. We include recommended spindle speeds, feeds, tool grades, and cooling strategies with your quotation.

Request Free Samples & Quote

Click the button below or email sale@chalcoaluminum.com with size, quantity, and destination. A professional engineer will reply within 24 hours with pricing and machining advice.