Why Choose 1070 Precision-Ground Aluminum Rod?

High Purity & Trace-Element Advantages

Ultra-high Al content: ≥ 99.7% with very low alloying additions for optimum electrical conductivity and corrosion resistance.

Trace-element optimization: Si ≤ 0.20%, Fe ≤ 0.25%, Cu ≤ 0.04%—slightly improves cutting strength and grain uniformity.

Uniform appearance: fine surface after grinding; even luster after anodizing for decorative parts.

Superior Conductivity & Corrosion Resistance

High electrical conductivity: 61% IACS, significantly reducing contact resistance at busbars and terminals.

High thermal conductivity: ≈ 237 W/m·K, faster heat dissipation enhances electronics reliability.

Corrosion resistance: the native oxide film resists chloride attack, suitable for marine and outdoor use.

Lightweight & Cost Advantages

Low density: 2.70 g/cm³, ≥48% lighter than copper to reduce equipment weight.

Cost efficiency: no heat treatment required; low and stable material cost.

Eco-friendly recycling: pure aluminum is easy to recycle, lowering waste and environmental costs.

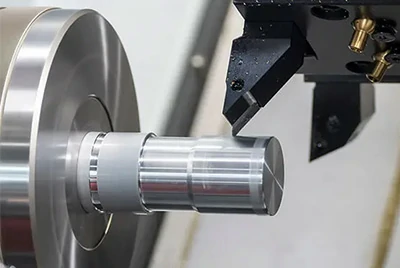

Precision & Surface Roughness

Diameter tolerance: ±0.05 mm (for centerless-ground finished sizes Ø 3–300 mm).

Machining accuracy: centerless grinding + Swiss-type CNC achieves 0.02 mm, compatible with guide-bushing mode.

Straightness: < 0.2 mm/m—no noticeable vibration at ≥ 8,000 rpm.

Double-end chamfer: smooth, jam-free automatic bar feeding.

Turned bar head: pre-turned front step fits various CNC collets/fixtures, overcoming chuck-depth limits.

Coarse-grain ring: ≤ 0.5 mm; controlled grain size avoids white/snowflake banding.

Improved turning performance: optimized microstructure promotes chip breaking, reduces built-up edge, and increases yield.

Stress relief (T651): stress-relieved for zero-deformation machining, suitable for hard-alloy tooling and precision assemblies.

Surface roughness: Ra ≤ 0.4 µm; mirror polishing up to Ra ≤ 0.2 µm.

Alloy Comparison: 1070 vs 1050 and 1060

| Metric | 1050 | 1060 | 1070 |

| Al purity (%) | 99.5 | 99.6 | 99.7 |

| Conductivity (% IACS) | 61 | 62 | 61 |

| Market price | ★☆☆ | ★★☆ | ★★★ |

| Typical applications | sheet stamping, foil | low-voltage busbars, conductors | high-end conductive parts, mirror-polished parts |

Chemical Composition

| Element | Mass fraction (%) |

| Al | ≥ 99.70 |

| Si | ≤ 0.20 |

| Fe | ≤ 0.25 |

| Cu | ≤ 0.04 |

| Mn | ≤ 0.03 |

| Mg | ≤ 0.03 |

| Zn | ≤ 0.04 |

| Ti | ≤ 0.03 |

| V | ≤ 0.05 |

| Others | ≤ 0.03 |

Typical Mechanical & Physical Properties

| Property | H112 temper | Note |

| Tensile strength σᵦ (MPa) | ≥ 60 | low-alloy, non-heat-treatable |

| Yield strength σ₀.₂ (MPa) | ≥ 23 | — |

| Elongation A (%) | ≥ 25 | — |

| Electrical conductivity (% IACS) | 61 | slightly increases with higher purity |

| Density (g/cm³) | 2.7 | — |

Performance Advantages

Ultra-high conductivity: ≈ 61% IACS, ideal for low-voltage busbars and transformer windings.

Excellent corrosion resistance: the dense native alumina film remains stable in humid and chemical environments.

Easy polishing & precision grinding: O/H112 temper offers good ductility; mirror finish up to Ra ≤ 0.4 µm.

Good weldability: suitable for MIG, TIG, brazing, and explosive welding.

Quality System

- Quality management: ISO 9001:2015, IATF 16949

- Environmental & chemical compliance: ISO 14001, RoHS, REACH

- Pressure Equipment Directive: PED 2014/68/EU

Tolerance & Straightness

| Item | Standard value | Note |

| Diameter tolerance | ±0.05 mm | for centerless-ground finished sizes Ø 3–300 mm |

| Straightness | 0.3 mm/m | verified after centerless grinding |

| Supply temper | O, H112 | default H112; O temper on request |

Machining Capability

CNC Turning (O/H112 temper)

| Tool material | Cutting speed (m/min) | Feed f (mm/rev) | Depth ap (mm) | Note |

| TiN-coated carbide | 350–450 | 0.05–0.25 | 0.5–3 | general roughing/finishing |

| PCD | 800–1 200 | 0.05–0.15 | 0.2–1 | mirror turning, Ra ≤ 0.4 µm |

| CBN | 250–350 | 0.03–0.10 | 0.2–0.8 | light cuts on hard H18 |

Centerless Grinding

| Parameter | Recommended range | Purpose |

| Wheel surface speed (Vs) | 30–60 m/s | keep grinding zone < 150 °C to prevent Al pickup |

| Regulating wheel speed (Vw) | 0.2–1.5 m/s | control circumferential feed, improve roundness |

| Cross-feed per stroke | 0.01–0.05 mm | reduce feed in finish pass to reach Ra ≤ 0.4 µm |

| Material removal per pass | 0.05–0.15 mm | rough then finish to avoid thermal distortion |

| Coolant | water-based synthetic + 3% sulfurized EP additive | cooling, anti-built-up edge, longer wheel life |

Process tip: Use a #1200 alumina wheel with elastic dressing for the final polish to consistently achieve Ra ≈ 0.2 µm "ultra-mirror”.

Main Applications

1070 aluminum has low hardness and excellent formability, making it especially suitable for low-voltage and slow-charging scenarios.

Low-voltage power busbars

Use case: busbars in residential, commercial, and industrial distribution panels.

Key advantages: 61% IACS conductivity ensures stable supply for 230 V/400 V systems; easy stamping and welding for fast, large-scale production.

EV charging-gun conductive terminals

Use case: terminals in AC chargers and EV charging-gun heads.

Key advantages: excellent conductivity and corrosion resistance for long outdoor life; H112 temper offers moderate hardness, TIG/MIG weld joints without cracking.

Charging equipment busbars and terminals

Use case: internal busbars and connector tabs inside charging piles.

Key advantages: high ductility supports fine blanking or punching of complex shapes; low resistance reduces contact losses, improving charging efficiency and thermal stability.

FAQ

Q: What polishing grades are available for 1070 ground rods?

A: Standard mirror ≤ Ra 0.4 µm; custom ultra-mirror ≤ Ra 0.2 µm.

Q: What is the minimum order quantity (MOQ)?

A: 50 kg for regular sizes; special dimensions ≥ 100 kg.

Q: Can you provide third-party test reports?

A: Yes. SGS/CTI reports for chemistry, mechanical properties, and conductivity can be supplied with shipment.

Q: Can 1070 aluminum ground rods be dissimilar-welded to copper busbars?

A: Yes—explosive welding or FSW can form Al–Cu clad busbars with resistance increase < 5%.

Q: How do you ensure dimensional stability and straightness?

A: Through centerless precision grinding combined with Swiss-type CNC machining; straightness up to 0.3 mm/m for stable high-speed machining (≥ 8,000 rpm).

Q: What size tolerances can you supply?

A: Standard ground tolerance h11; for close-fit parts we can achieve h9 or even h8.

You're welcome to contact Chalco

Ready to upgrade your conductive components?

Send email to sale@chalcoaluminum.com to receive pricing, stock availability, and sample arrangements within 30 minutes.